The Arcturus brand currently offers 5 replicas from the AR-15 family. The reviewed AR15 PDW is a very compact replica and the shortest one in the series.

The set includes:

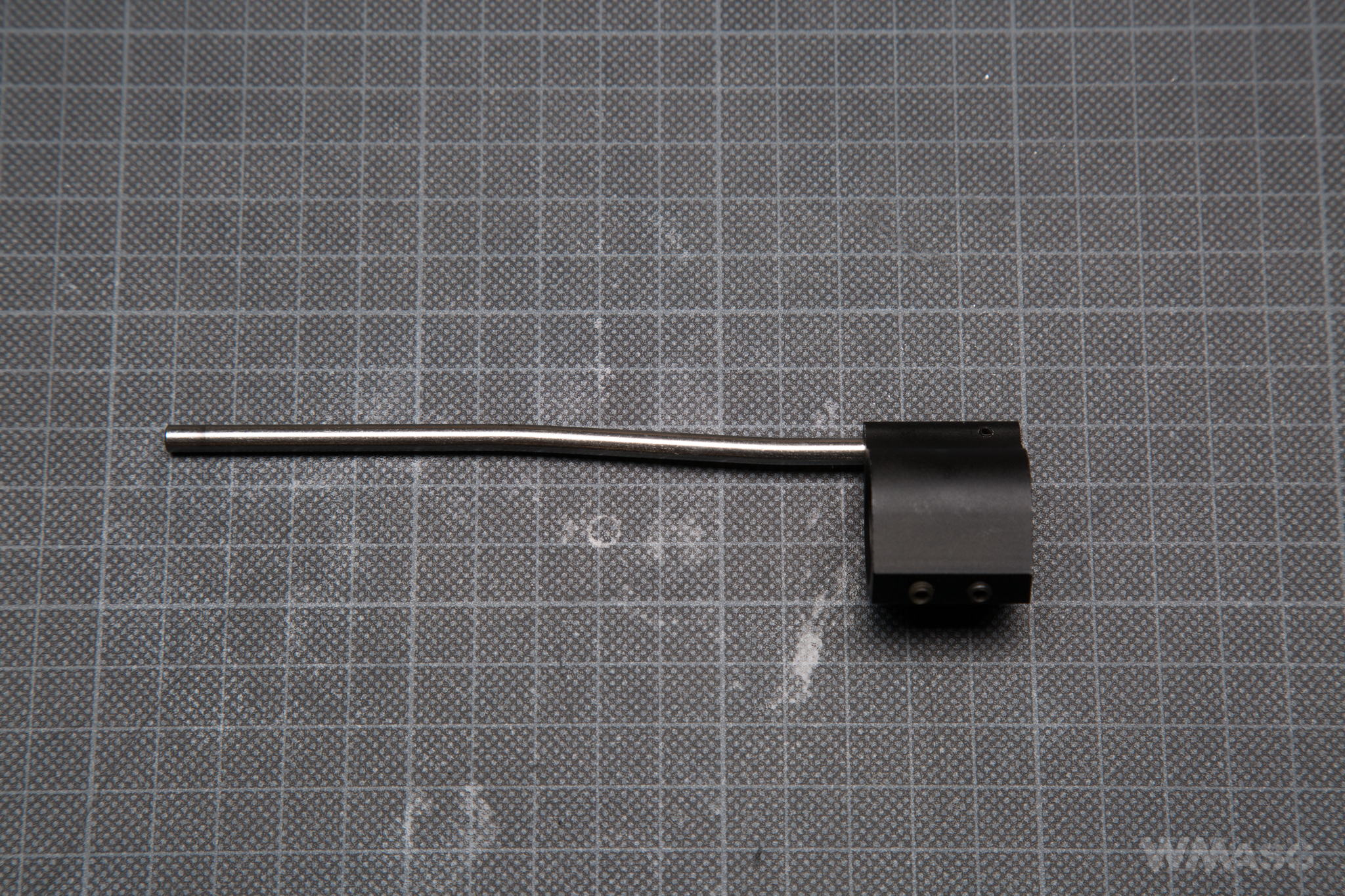

- folding Picatinny rail sights;

- an allen key for mounting the sights;

- a hi-cap magazine holding 300 BBs wound with a pull cable;

- a variable capacity real/mid-cap magazine holding from 30 to 120 BBs;

- additional parts for the pistol grip;

- a manual in English;

- a confirmation of conducting a primary checkup and muzzle velocity measurements;

- a plastic cleaning rod.

Technical data:

- weight without magazine: 2.6 kg,

- length: 550/680 mm,

- length of the inner barrel: 200 mm,

- diameter of the inner barrel: 6,02 mm,

- muzzle velocity: 360 fps.

Just after opening the corrugated cardboard box, everything looks good. The individual parts of the set are placed in sockets cut out in the foam, which protects them from damage. The replica itself makes a very good impression. It is uniformly matte black. It is almost entirely made of metal. Most of the parts are made of aluminum alloy, a few are made of steel. Those are the butt stock guide, the forward assist button, the magazine latch, the dust cover, both pins connecting the upper and lower receiver and front grip mounting screws.

The upper and lower receiver are standard for the AR-15 family, without any modern improvements. On the right side is the forward assist, the deflector, the ejector port and the duct cover, the magazine latch button and the fire selector switch cap. On the left side there is the a functional bolt-catch and the safety lever, which is the only deviation from the "old school" design. It is screwed from the outside with a hexagon socket screw. On the side note: the disassembly of the lever is necessary while stripping the replica. The cocking handle is also standard, without any novelties. It has a one-sided latch.

The replica does not have any licensed markings. The left side is completely empty, on the right side, just above the trigger there is the Arcturus company name and a serial number.

The aforementioned functional bolt-catch works as in many other replicas - after pulling the cocking handle the duct cover opens and the dummy bolt stays in the rear position to facilitate Hop-Up adjustment. Pressing the bolt-catch releases the dummy bolt.

It is worth noting that the bolt returns to the front position very dynamically. With above average speed and power. This is accompanied by quite a loud, metallic sound.

The front grip

The carbine is equipped with an aluminum front grip which is 20 cm long, made to work with the M-Lok system. The bed has a roughly octagonal cross-section; the M-Lok sockets are placed on seven of its sides. The eight, top side has a standard Picatinny rail.

The front grip is attached using three patented screws, each of which doubles as a QD socket for attaching a sling. If screwed too loosely the front grip has a tendency to wobble vertically a bit - the screws in the tested unit had to be tightened very firmly. Unfortunately, the replica does not come with an appropriate wrench to do this. I used adjustable pliers. After tightening the screws the wobbling disappeared.

Another side note: the picture below shows that the Picatinny rails of the front grip and the upper receiver are not leveled. The difference in height is almost 1 mm.

After dismantling the front grip, we reveal a very carefully made external barrel with a dummy gas system.

The barrel is mounted very firmly, there is no slack.

The end of the barrel has a flash hider resembling the KX3 made by Noveske. It is secured with a grub screw. Instead of a compression spring, a rubber o-ring is used.

The sights

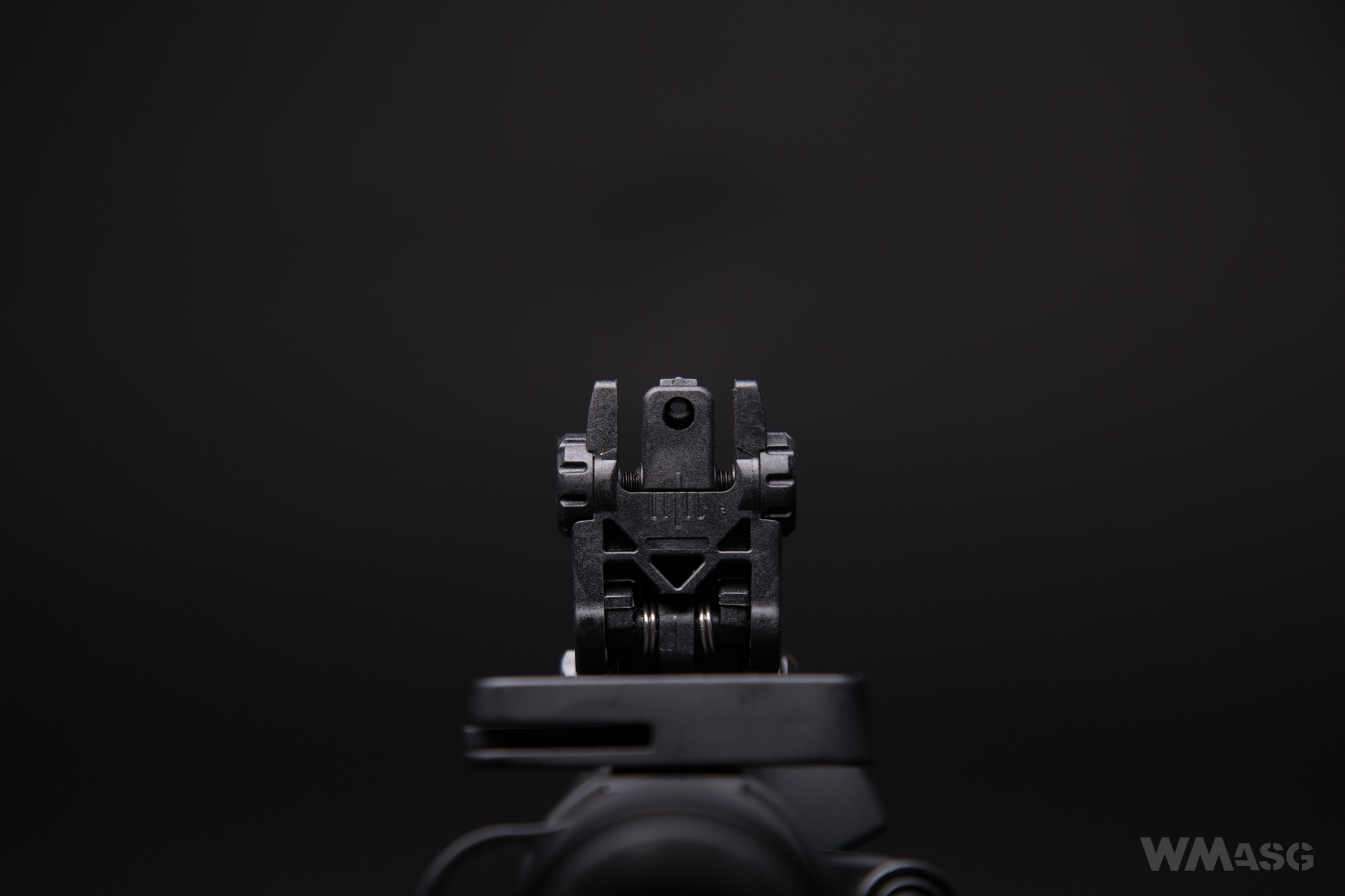

The carbine comes with detachable polymer sights very similar to MBUS sights made by Magpul. The sights are mounted on a Picatinny rail using the included hex wrench. The front sight has vertical adjustment for which a standard key is needed. Unfortunately, it is not included with the replica. The rear sight is adjustable horizontally with a knob. It has two typical aperture settings.

Both sights flip-up after pressing a button. While up they are not a prime example of stability, but they fulfill their function. Because they are made as a low profile type, they can also be used without unfolding.

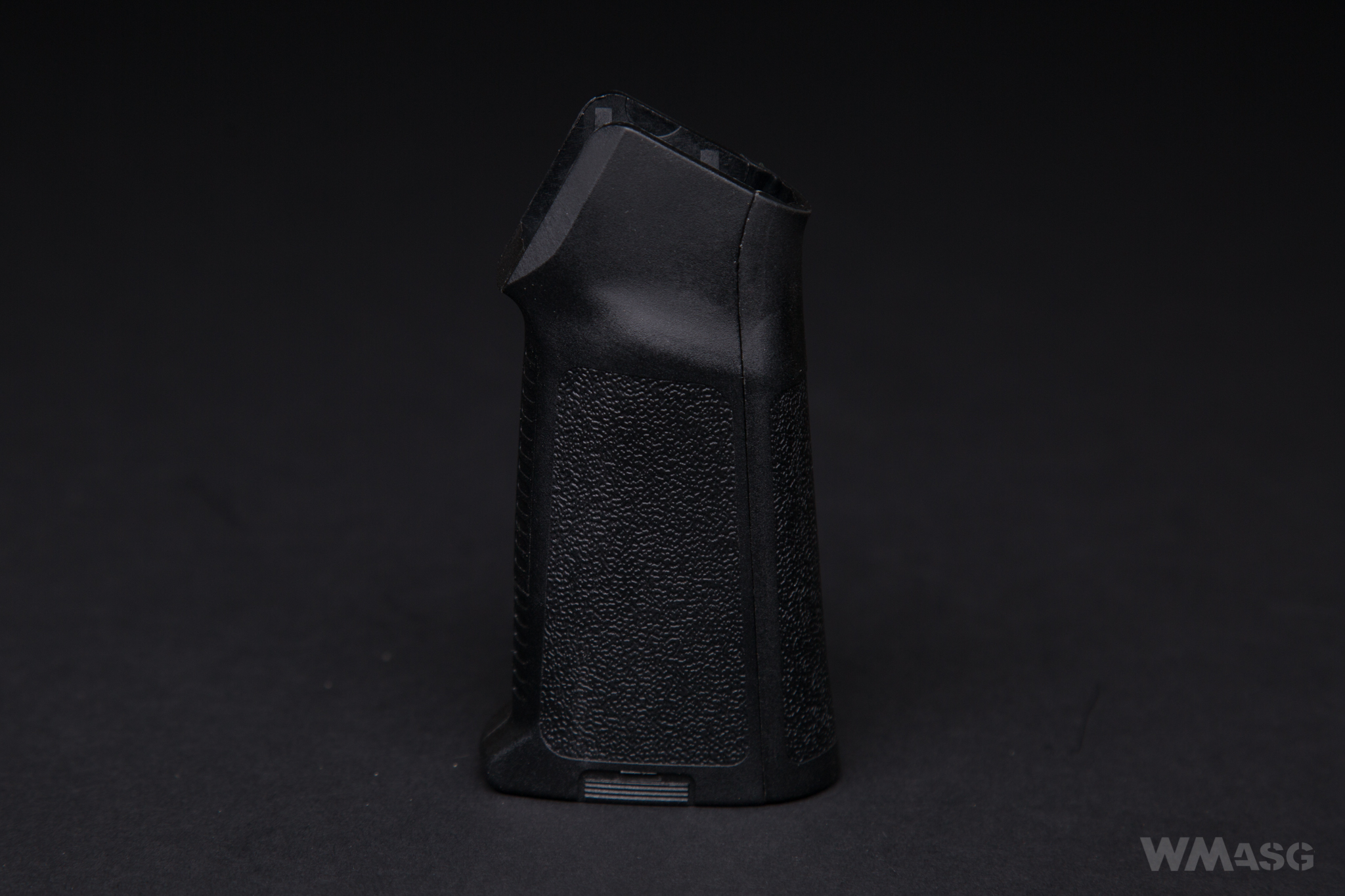

The pistol grip

The replica has a modular pistol grip design that allows you to adjust its shape and size to individual preferences. We have a smaller and bigger ridge to choose from, the latter with a part overlapping the lower receiver, and two front sections: a smooth one and one that has a nub separating the fingers. The dorsal parts can be replaced at any time - they are inserted with a safety latch. Replacing the front part requires taking off the grip from the replica, because this part is moved up. After replacing the parts, there is a slight slack on the dorsal part.

The grip has threaded brass bushings for the screws that secure that bottom cover. The cover itself is made of metal and has numerous ventilation slots for better motor cooling. The motor is adjusted using a flat screwdriver. A spacer is not used.

The buttstock

The six-position buttstock is made predominantly of aluminum alloy. The buttstock plate is slow made from aluminum. The only steel parts are the guide poles.

On the right side of the buttstock mount there is a loop for attaching a sling. On the bottom you will find a large comfortable button for adjusting the length of the buttstock.

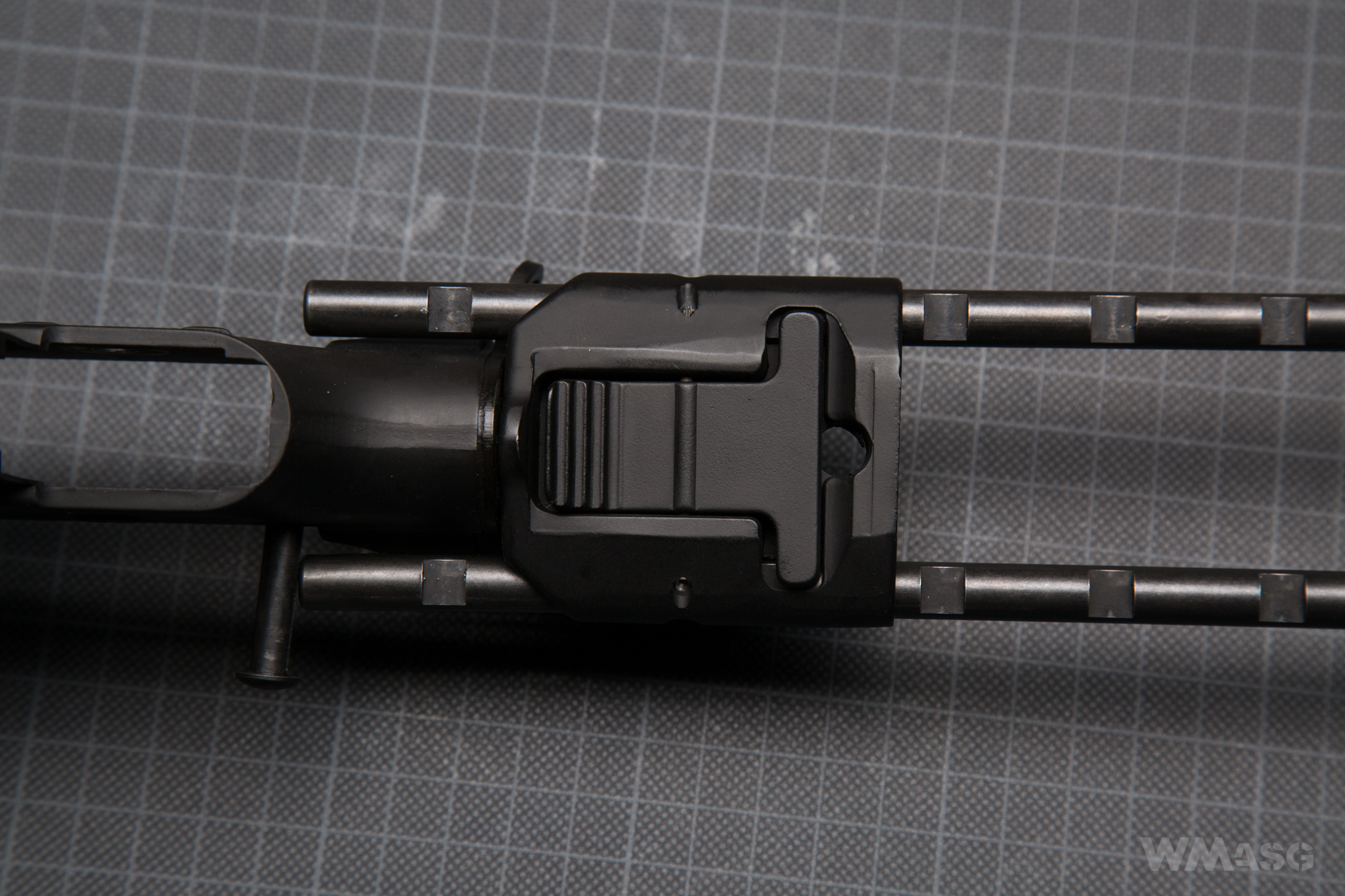

The space for the battery is provided inside the stock guide. Unfortunately, it is rather small. It is only 11 cm long and the inner diameter of the guide is only 3 cm. The battery and plug will have to fit inside this space. Inside the guide, at is bottom, is a flathead screw which stabilizes the spring guide. Under it is the access to the spring guide, as a part of the "quick spring change system". Unfortunately, in my opinion, the exchanging the spring is only possible in workshop conditions, as it is required quite a long screwdriver.

And one more thing concerning the buttstock. In the reviewed unit, the buttstock has a slight slack around the guide axis. This could be easily fix if the corresponding wrench has been included with the replica. You need a castle nut wrench with four lugs with an outer diameter of 30 mm and a length (with possible extension) of not less than 35-40 mm.

Magazines

The replica comes with 2 magazines: a hi-cap holding 300 BBs and a mid-cap holding 120 BBs which has a function of limiting the capacity to 30 BBs. The magazines are stylized on Magpul PMAG design and are made entirely of polymer.

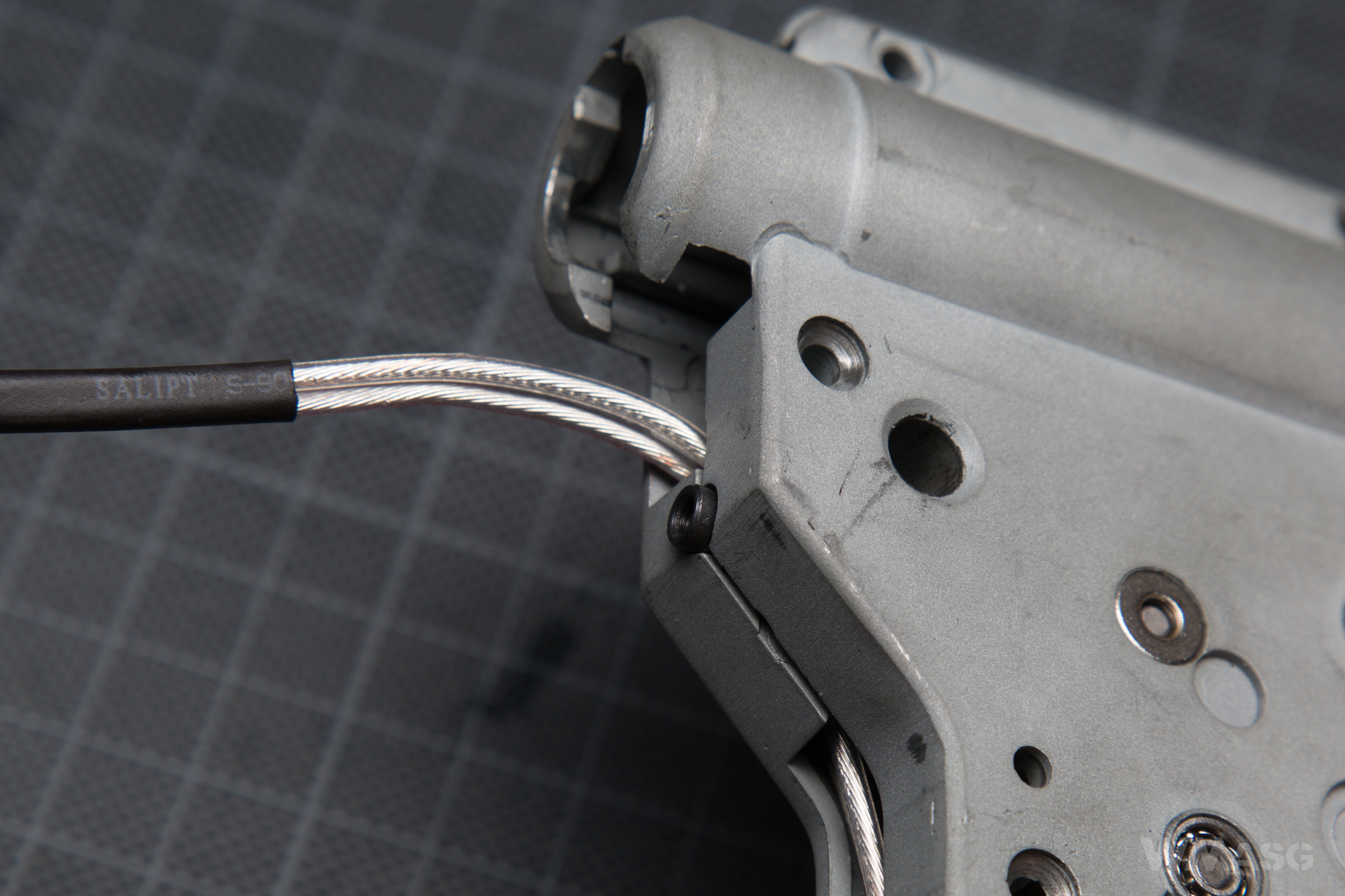

The Hi-cap is wound using a with a pull cable. To access is one must move the bottom plate to the side. The plate is protected from being lost by the rails it moves on. The cable is made of steel, which should extend the life of the magazine.

The mid-cap looks almost identical. To change the capacity, the bottom plate must be completely removed and the magazine internals pulled out.

The photo below shows the position of the slider changing the capacity of the magazine. After changing its position it, in theory, mechanically locks a part of the magazine spring, shortening its working length to approximately 30 BBs. In the tested unit its working were not consistent. That is, the lock could be set, but when loading the magazine with a BB speed loader, after filling the magazine with about 30 BBs, there was only minimal resistance, and the blockade itself shifted enough that it was possible to continue loading. However, I have no certainty whether this is a design flaw or a failure of a heavily battered unit. In the mid-cap mode the magazine worked perfectly.

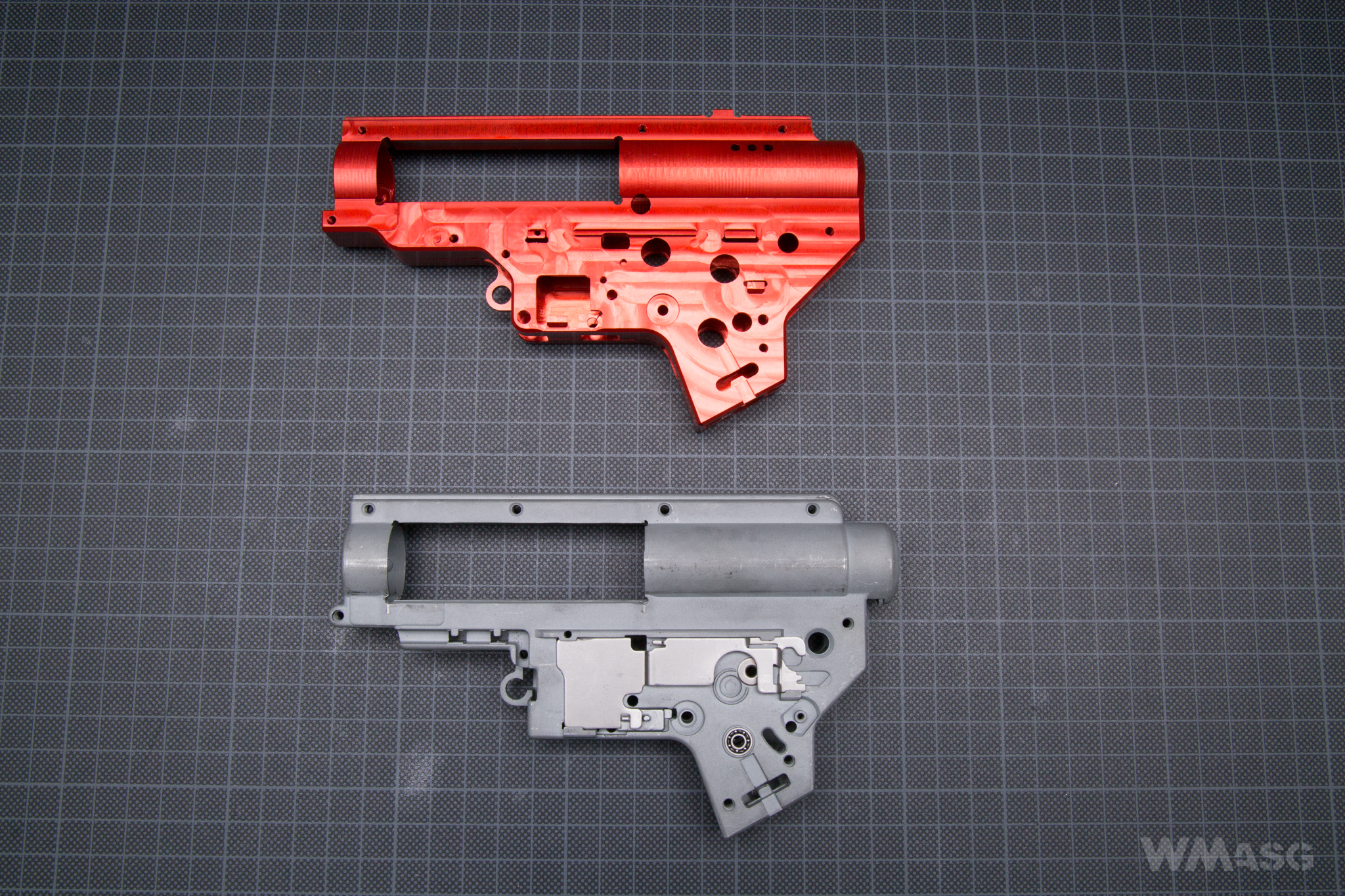

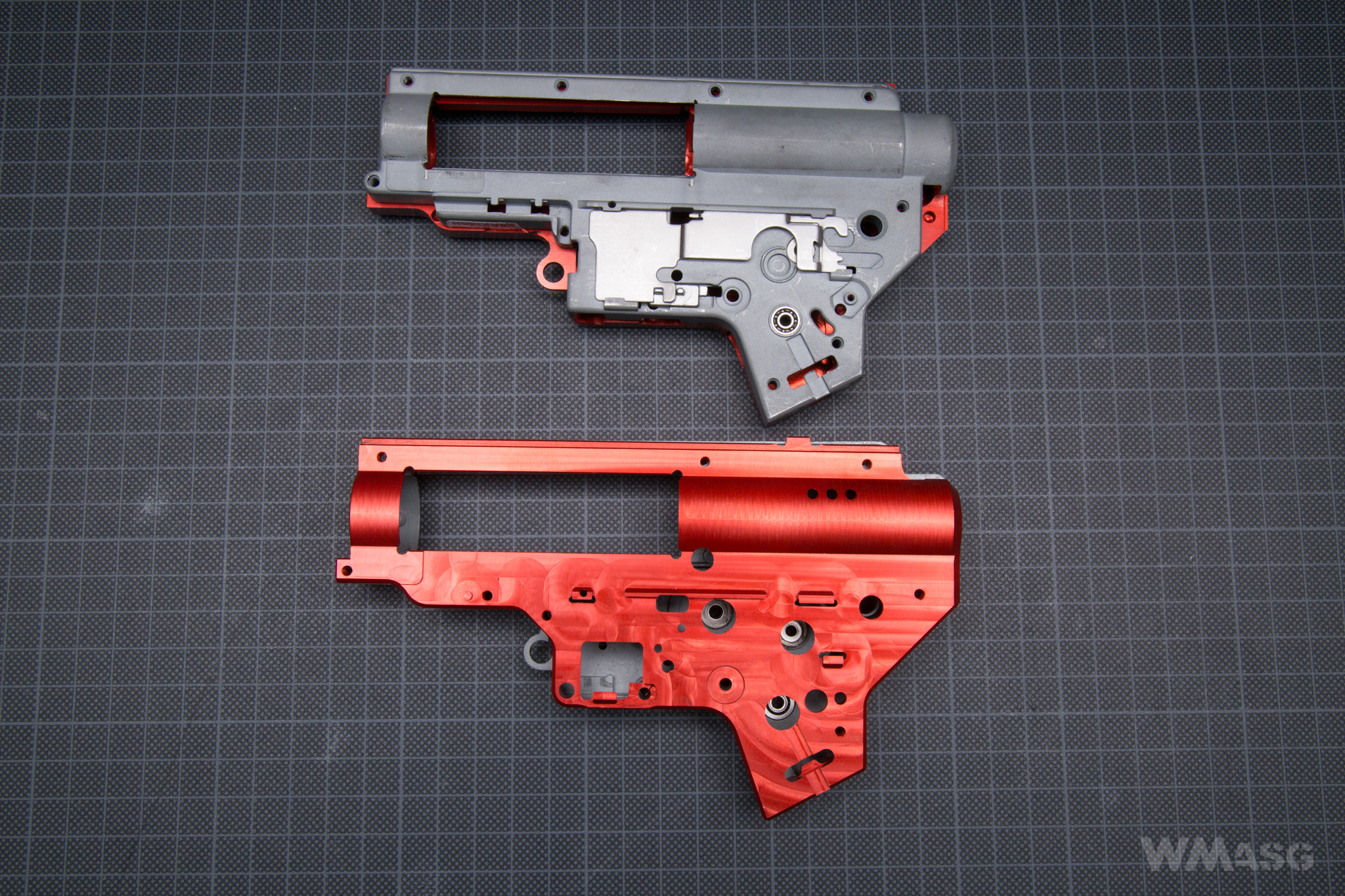

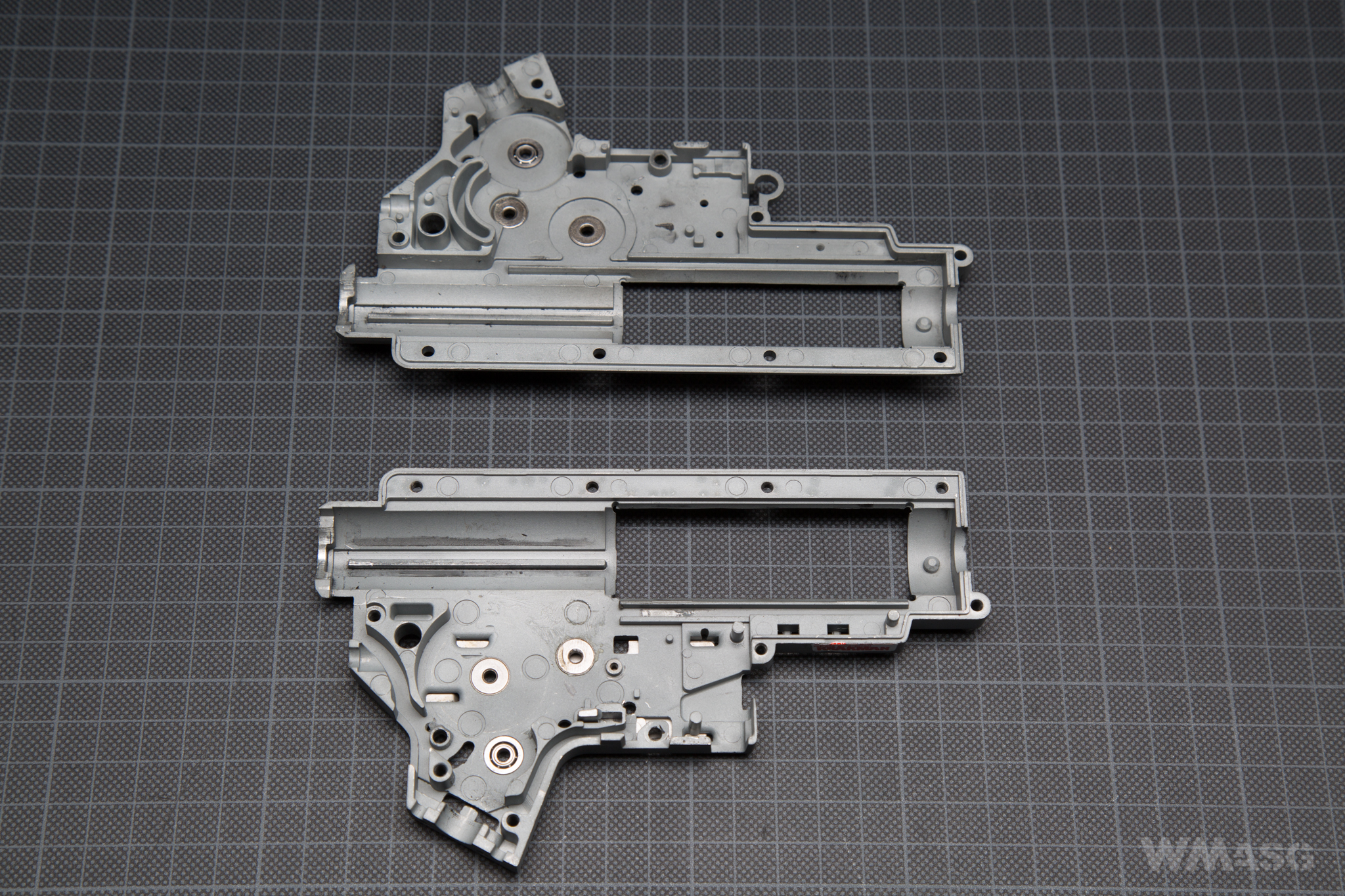

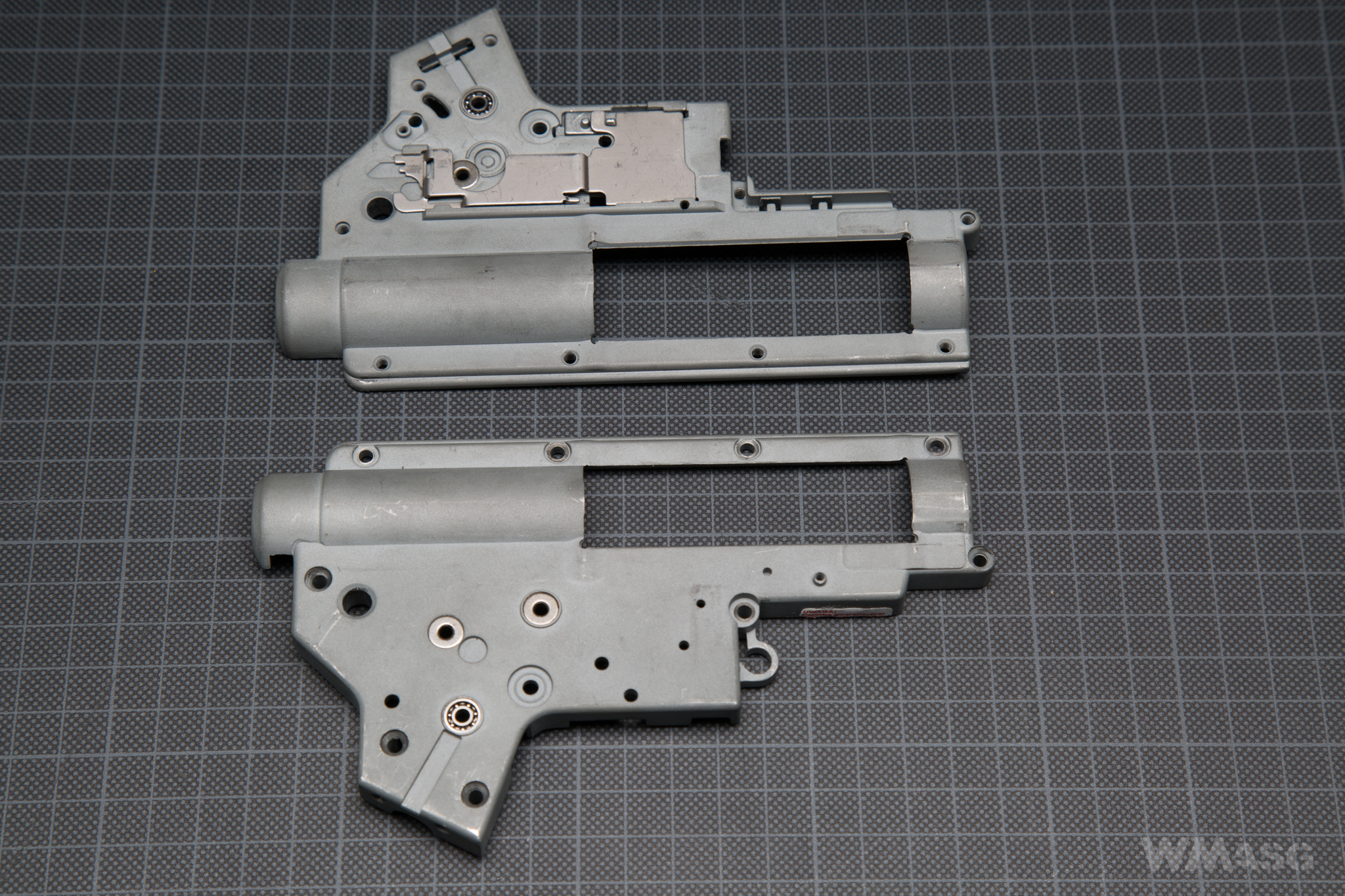

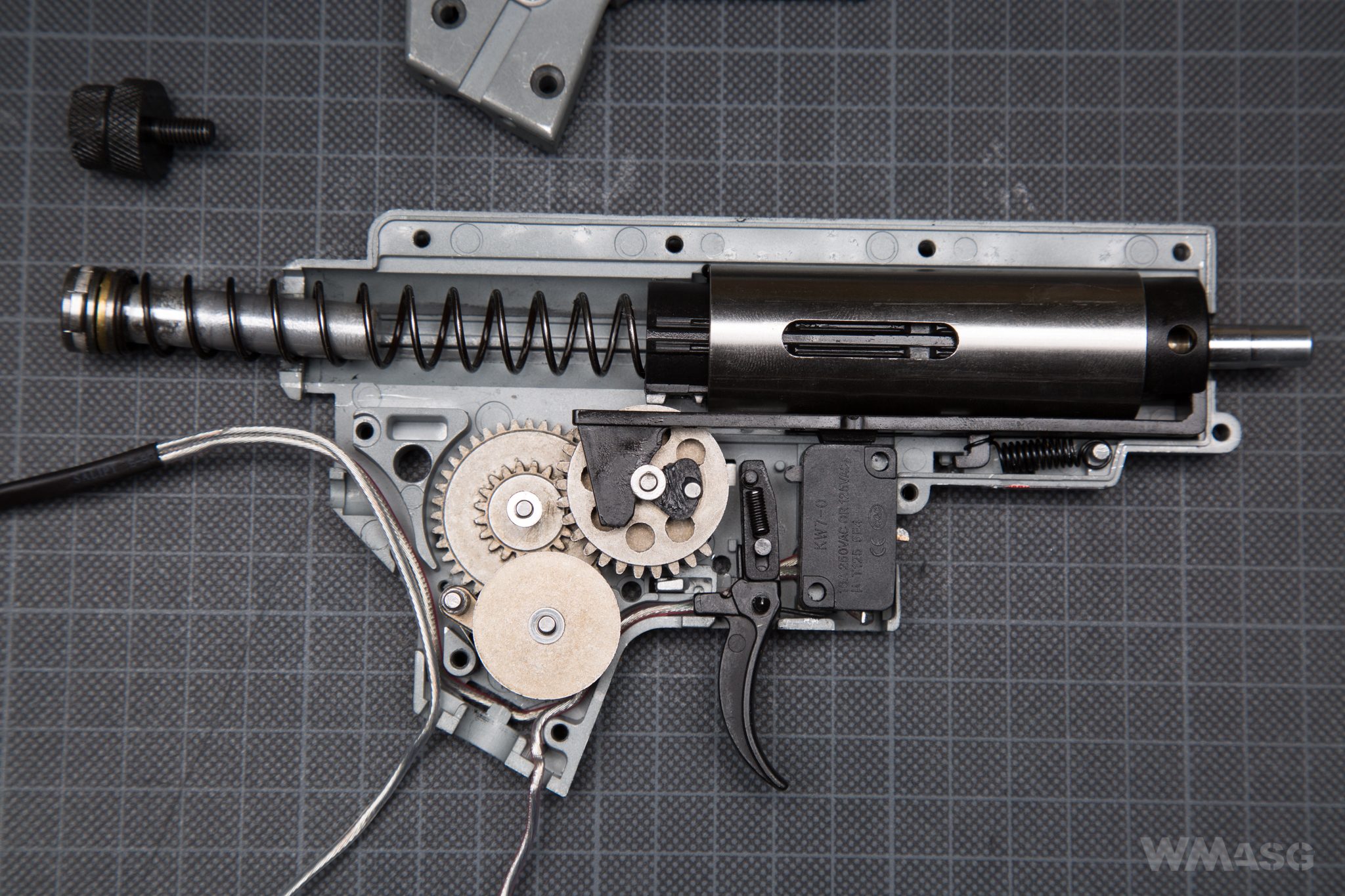

The gearbox

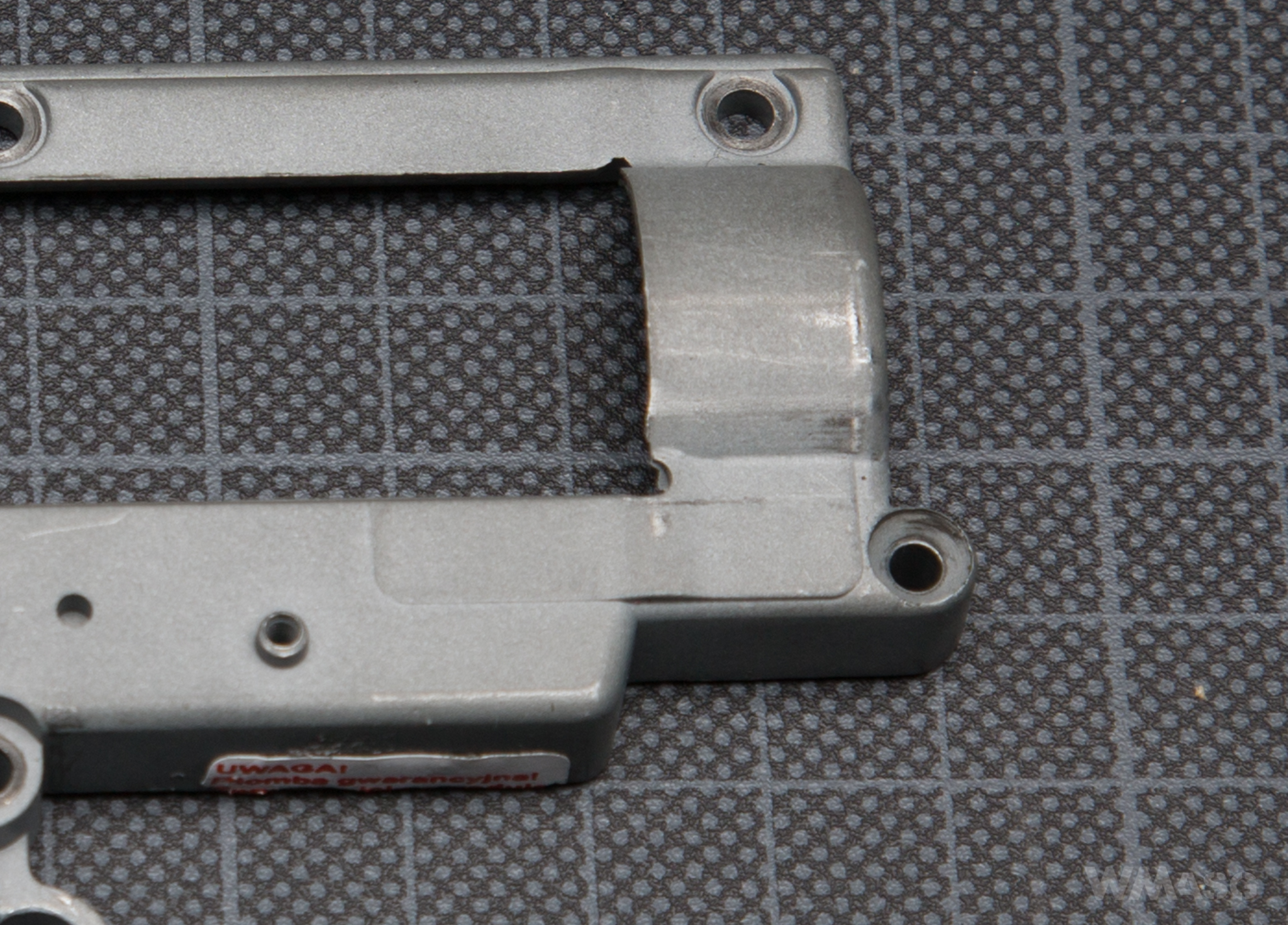

The gearbox is a heavily modified V2 with a quick spring change system. At first glance, you can see the difference between the Arcturus' frame and the standard one which, without significant modifications, cannot be mounted in the body of the replica.

The gearbox looks great. It does not resemble frames used in budget replicas in the slightest. It is heavy, precisely made and has a good finish.

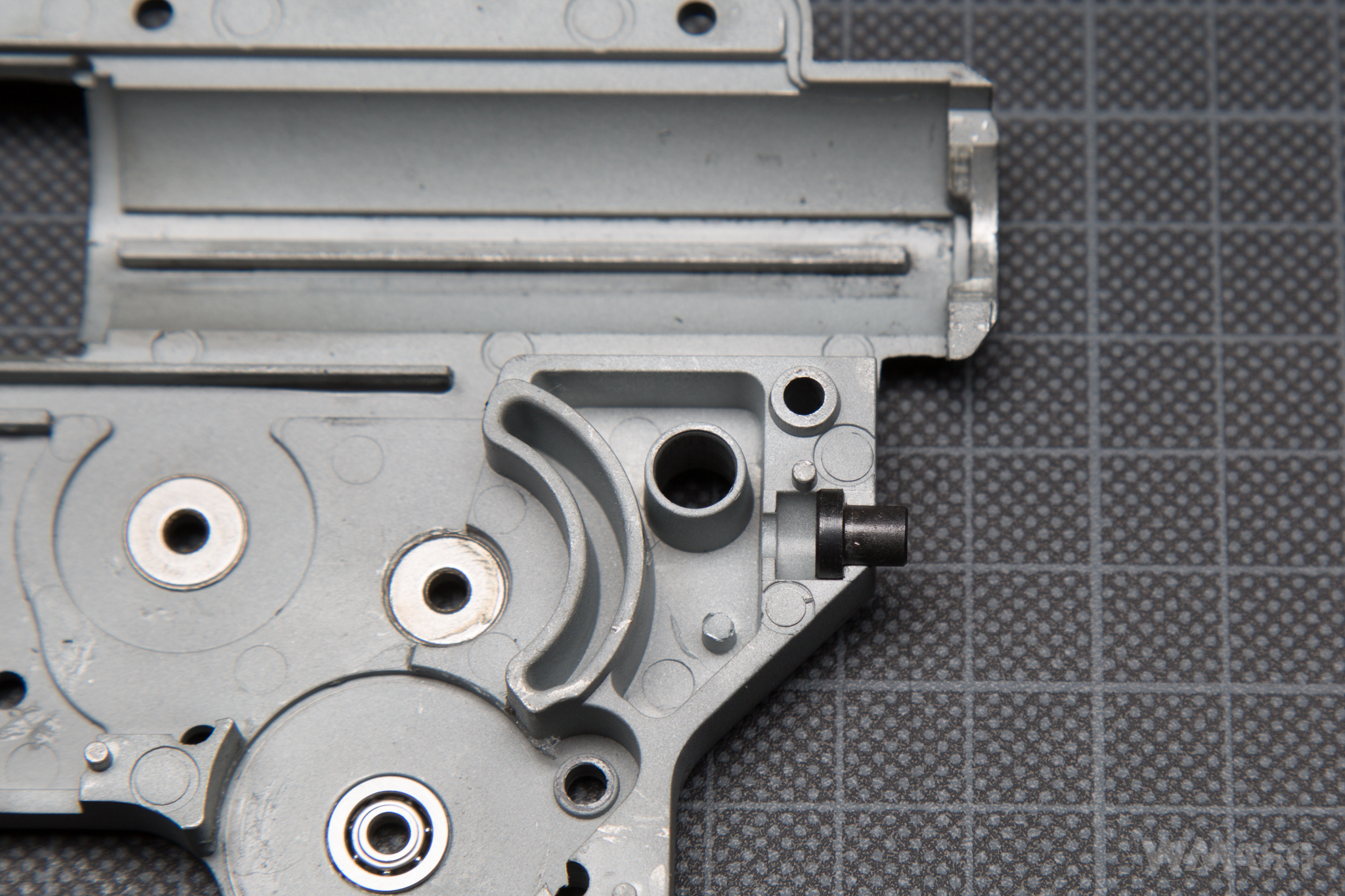

There are no mold marks or defects. In the left half there is a window through which the anti-reversal can be pulled back. The quick spring change system seems to limit the usefulness of this solution, but after releasing the latch, it also loosens the taped plate spring, which makes it easier to open the gearbox. By the way: to quickly and efficiently replace the spring you will need to work a bit with a delicate file - the hole through which the spring and the spring guide passes is too tight and requires grinding.

Below the opening for the spring, a steel part is used, which rests against the inner wall of the replica body and stabilizes the position of the gearbox.

The left gearbox half has an external conduit for placing the electrical wires in if it is to be mounted in a replica that has the battery up front.

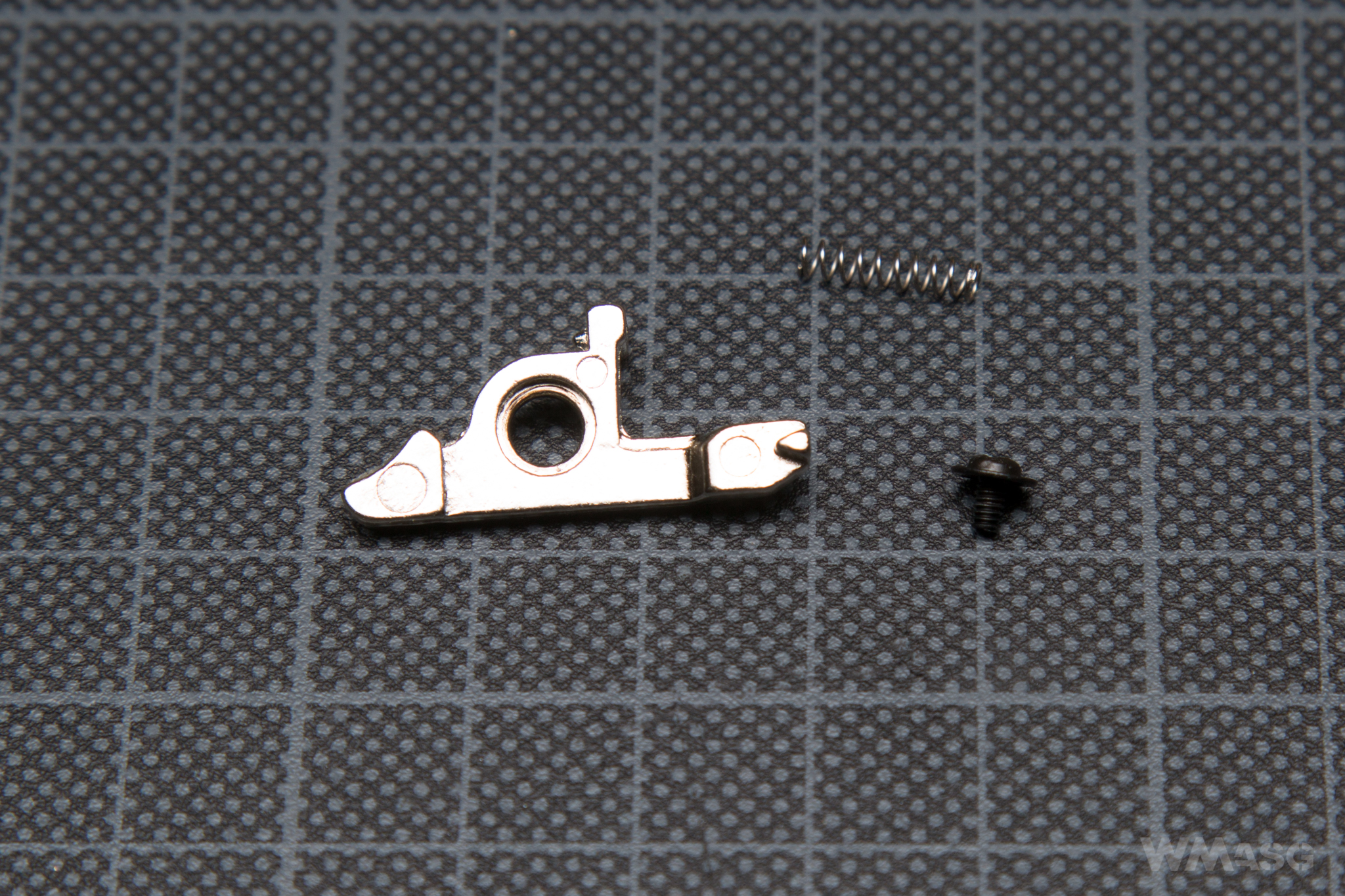

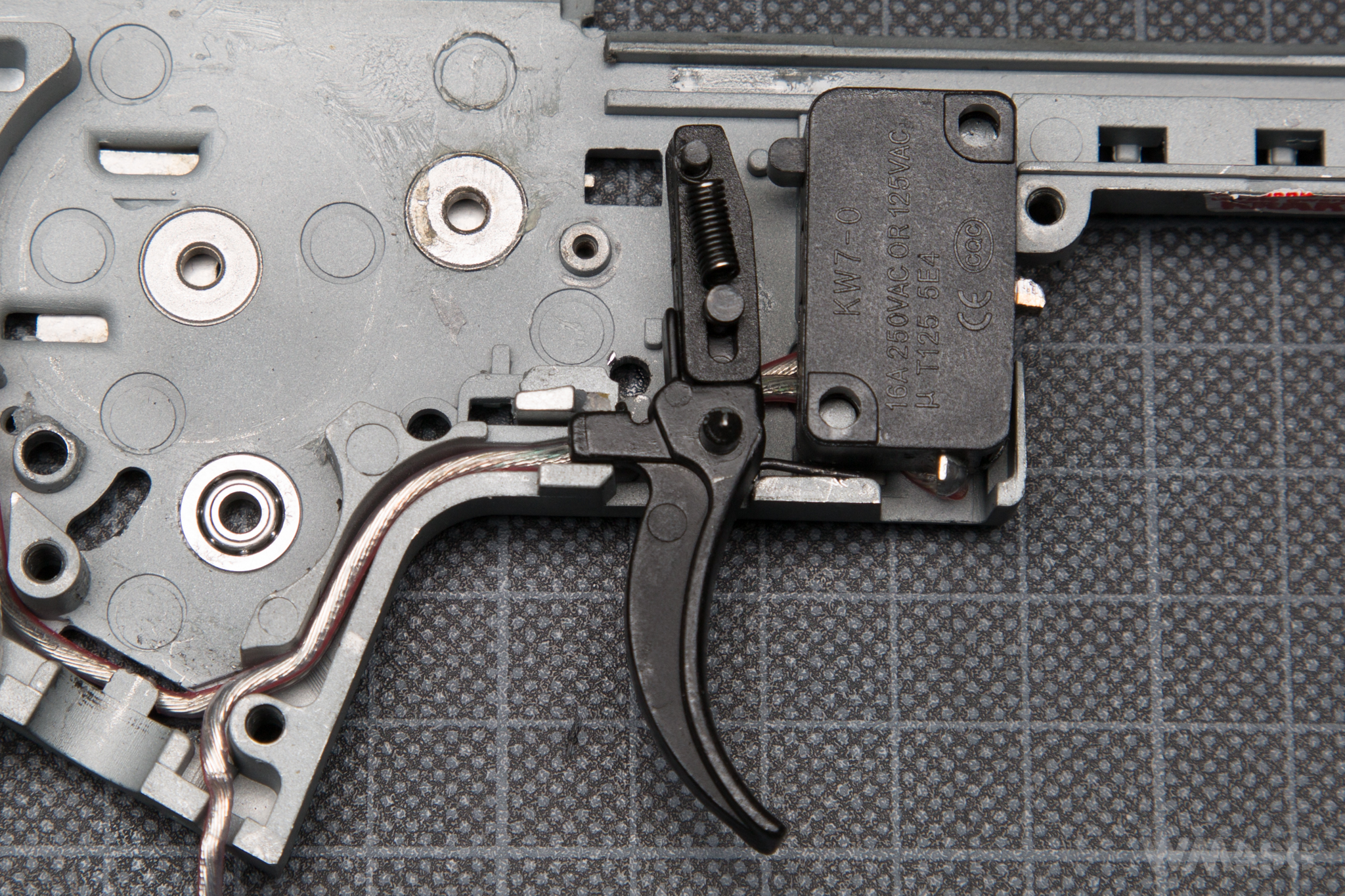

The custom selector plate is made of steel. It works together with an aluminum cast part that is responsible for physically locking the trigger when the replica is in safe setting. The standard trigger locking does not occur here.

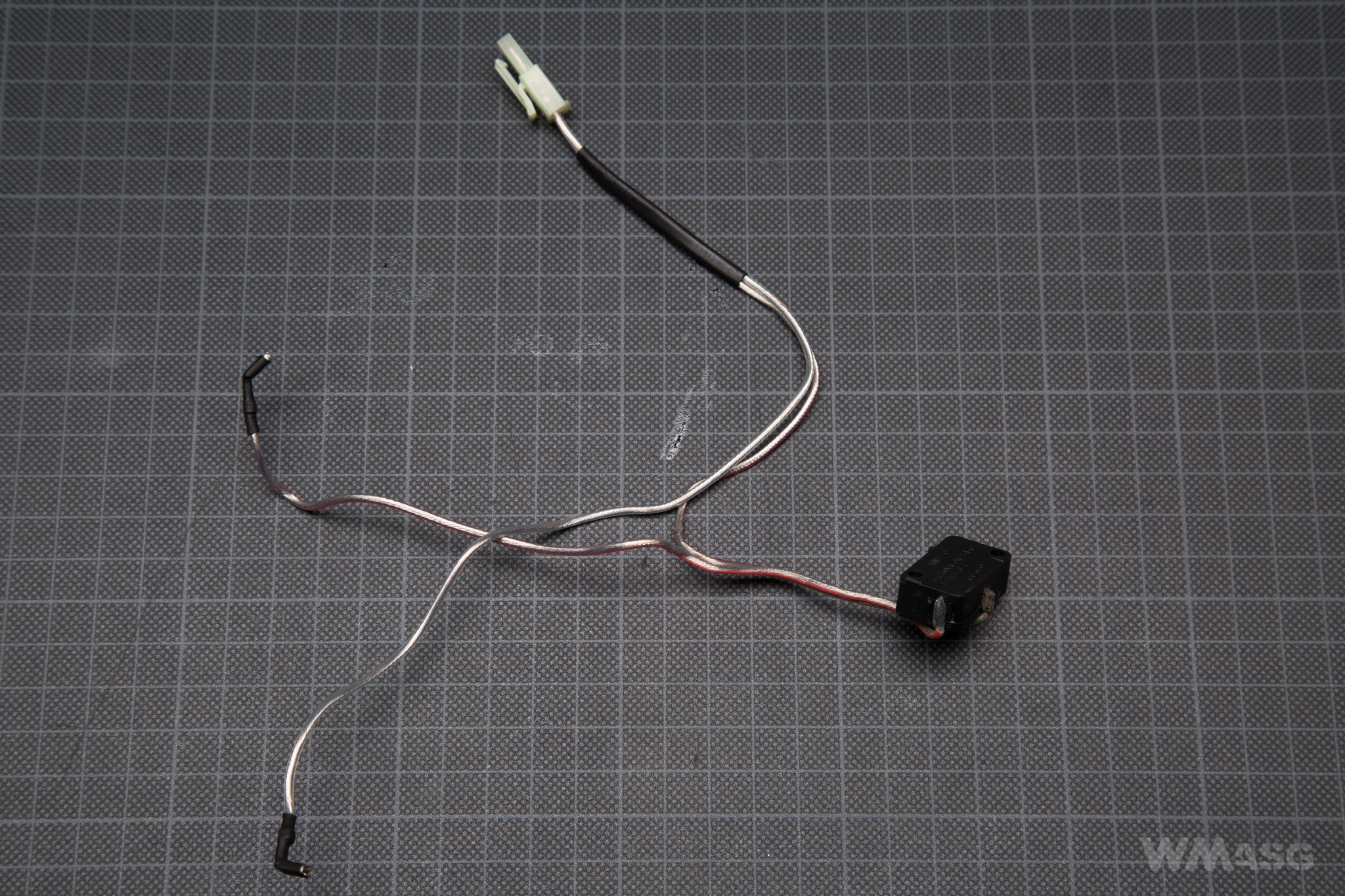

Other non-standard parts are the cut off lever and the trigger made of alloy, which works with a micro switch.

While the use of a micro switch in V3 gearboxes raises my doubts due to the presence of the part transmitting the trigger movement on the micro switch, the solutions used in the Arcturus PDW V2 gearbox does not. It is simple and durable. You just have to forget about using advanced internal control systems like the Titan or the ASCU.

It is possible, however, to use external circuits that will work with the factory made Arcturus micro switch. One example: the MERF 3.2 Gate.

Other internal parts are made in the unwritten standard.

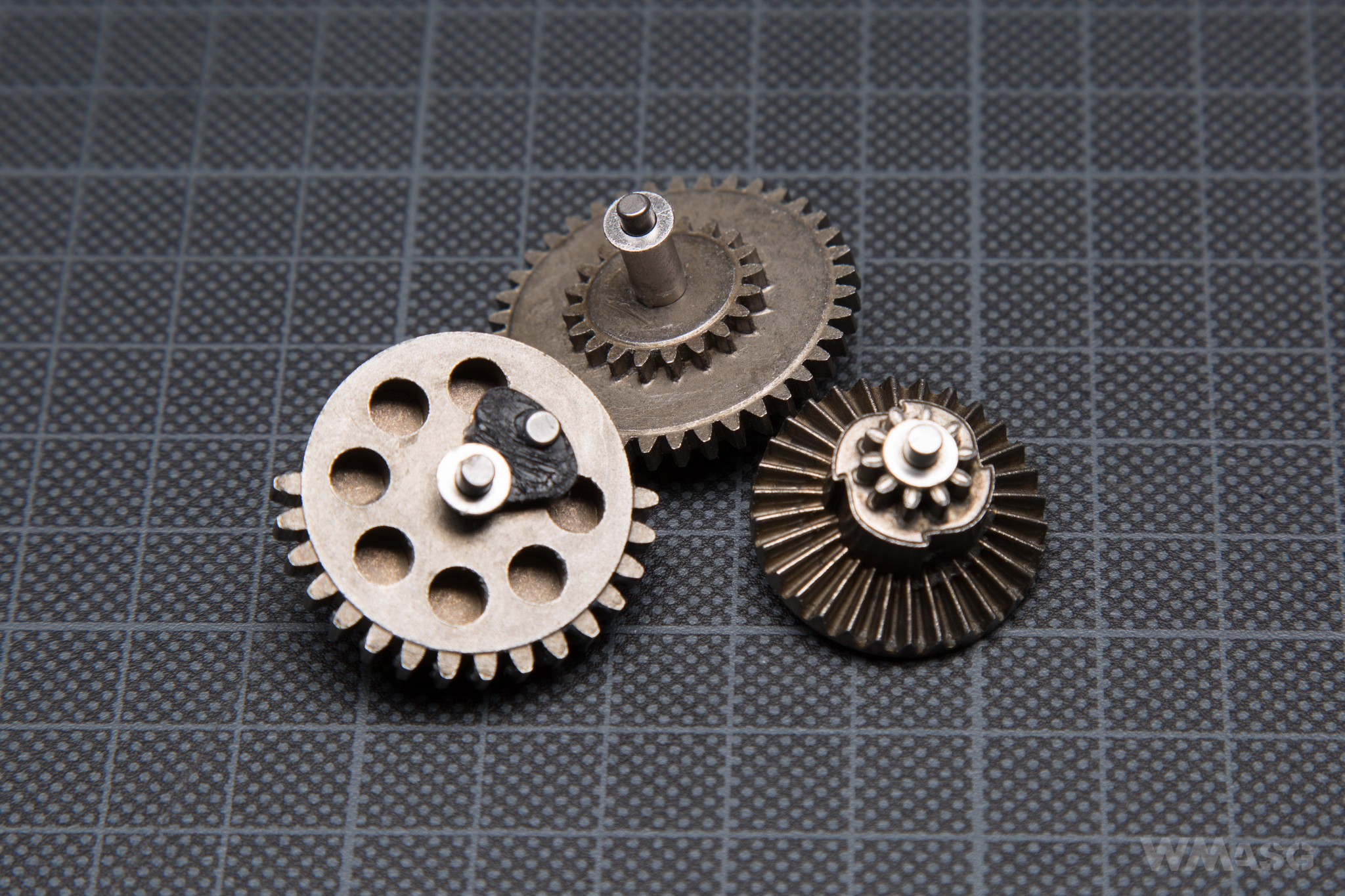

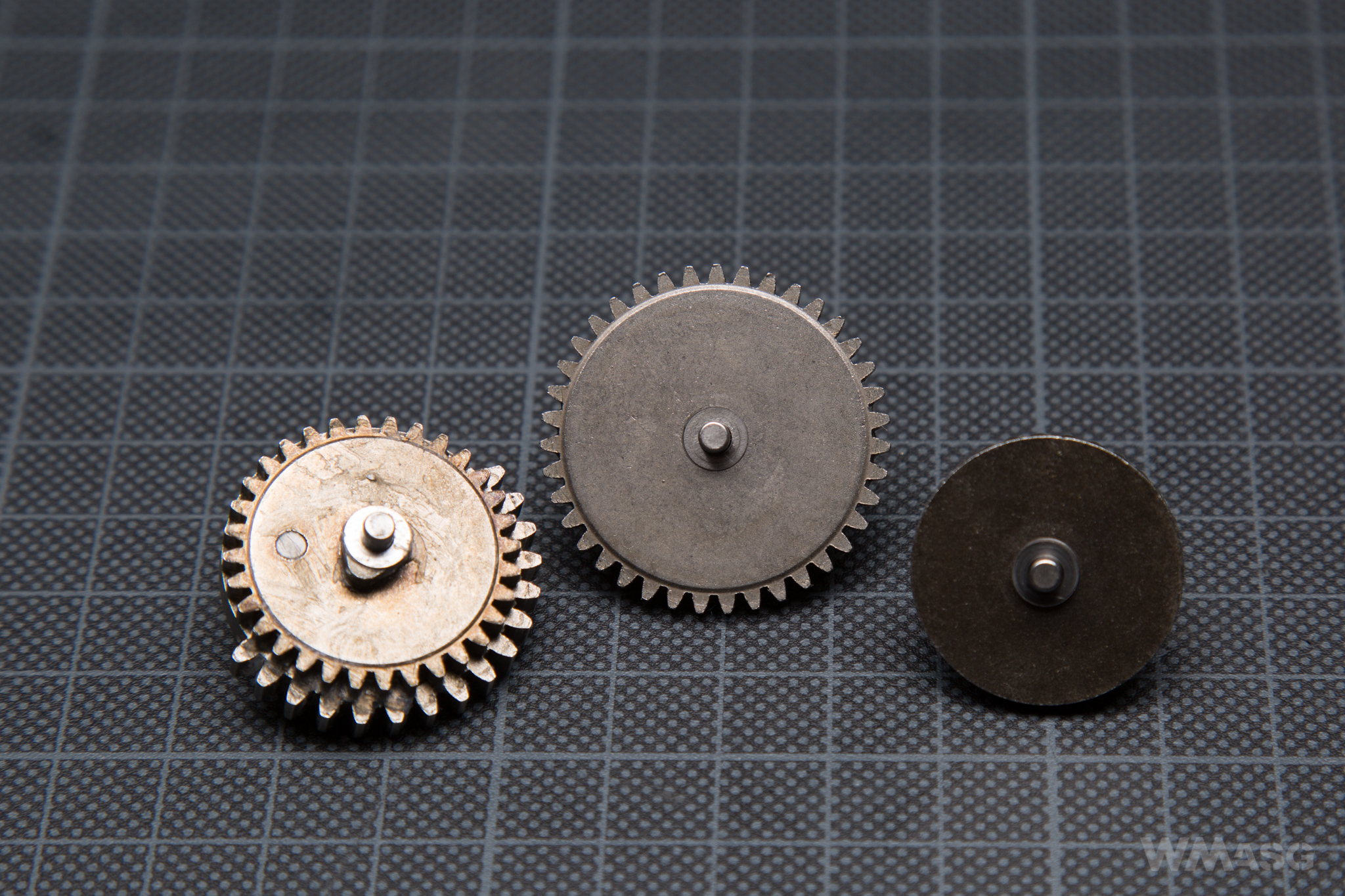

The gears

The gears are made off sintered steel. They resemble factory made gears used in medium and high-end replicas. The sector gear has a plastic delayer which limit any problems with BB feeding.

The sector and spur gears rotate on steel slide bearings and the bevel gear is mounted on ball bearings. The diameter of all bearings is 8 mm. Why so? The period of failure-free operation was extended with a minimum reduction of performance of the mechanism. By the way - in the described unit the gears are perfectly shimmed! No horizontal slack, no resistance when turning. I don’t remember another factory made replica which was shimmed this well. However, I have reservations about lubrication. There is simply no lube on the gears and bearings.

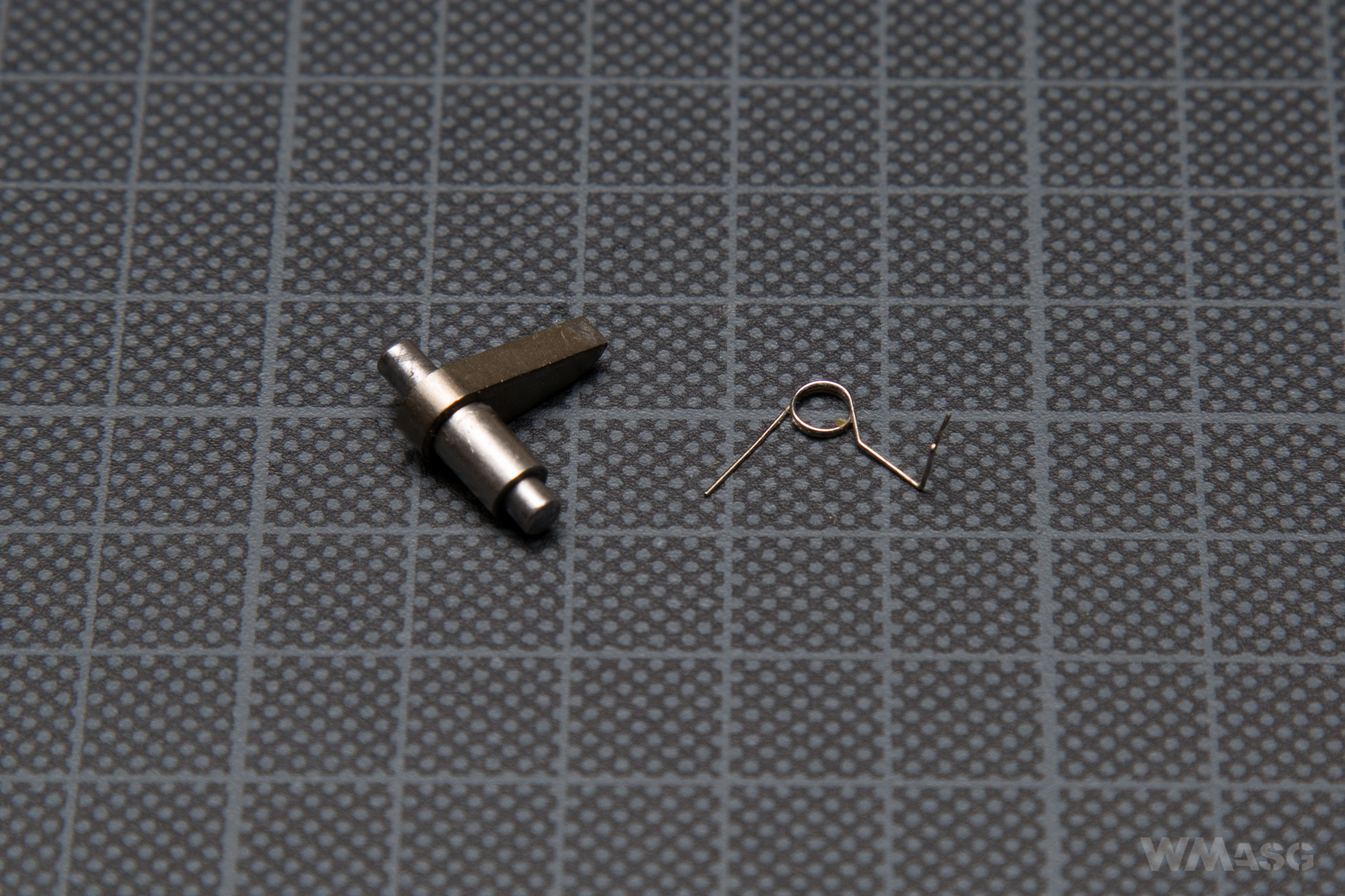

The anti-reversal latch is made of steel and has a standard spring.

The pneumatic system

A steel type 3 cylinder.

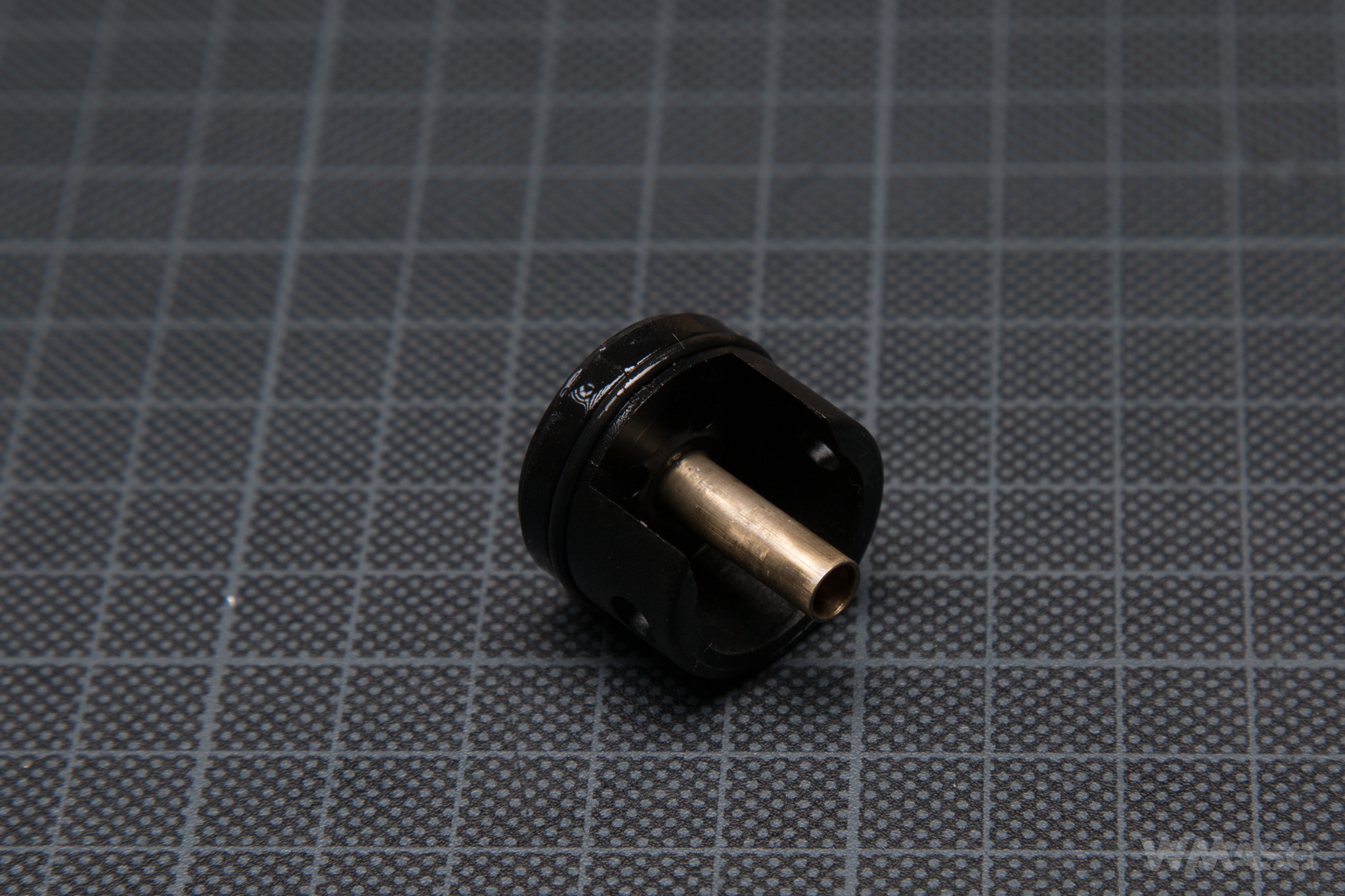

The cylinder head is made of polymer, with 1 o-ring and brass nozzle.

The flat rubber bumper is over 4 mm thick.

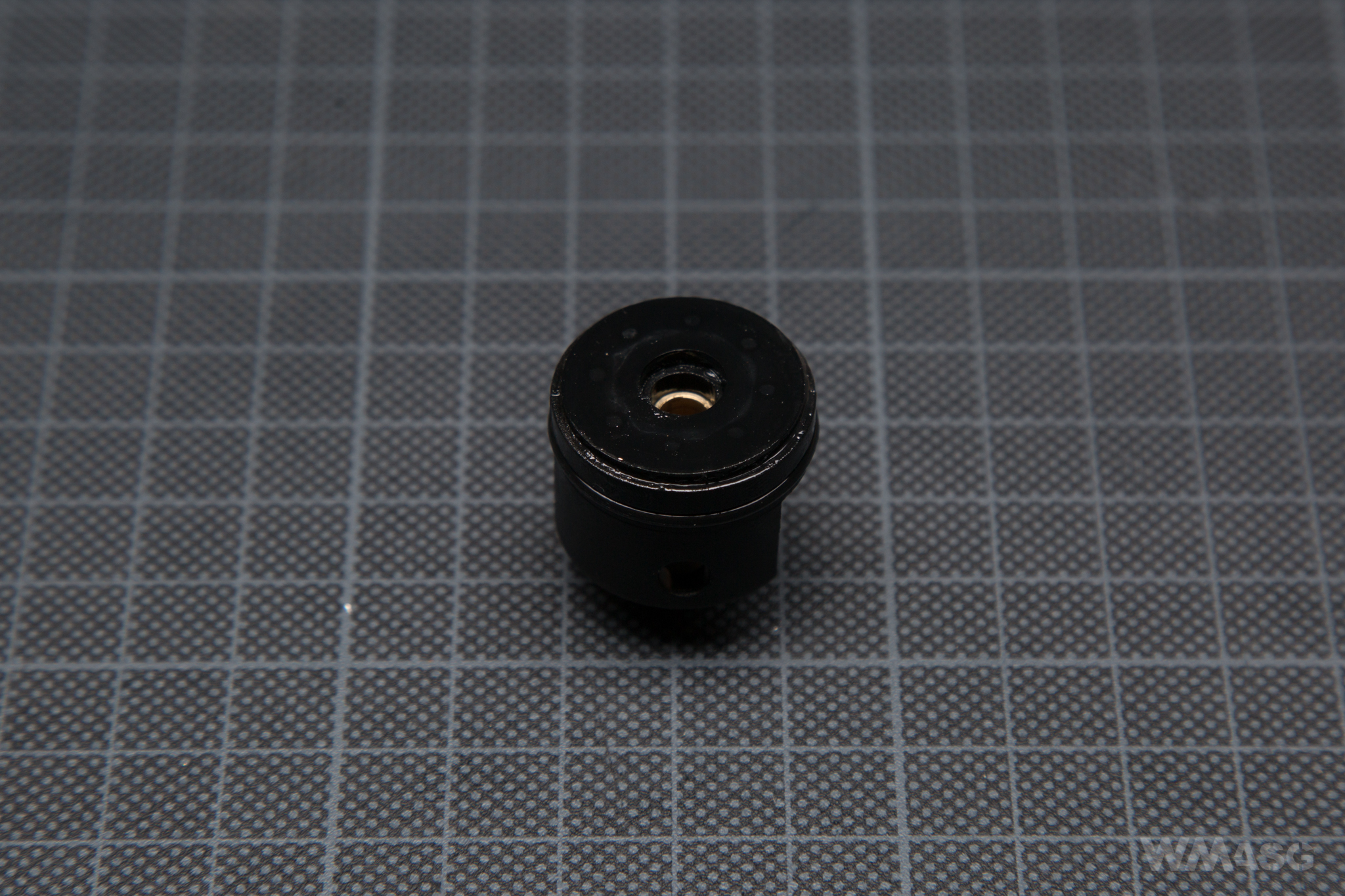

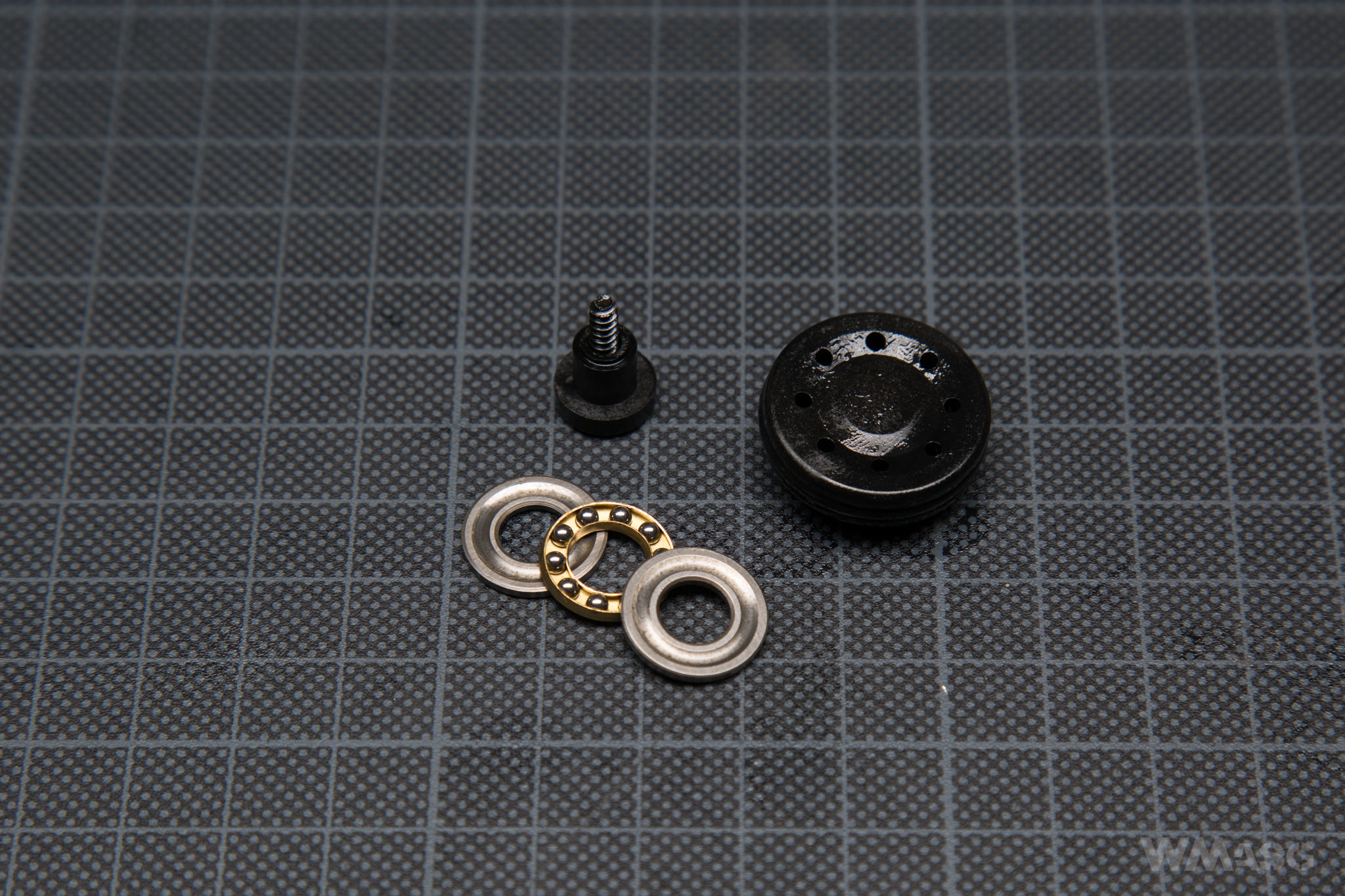

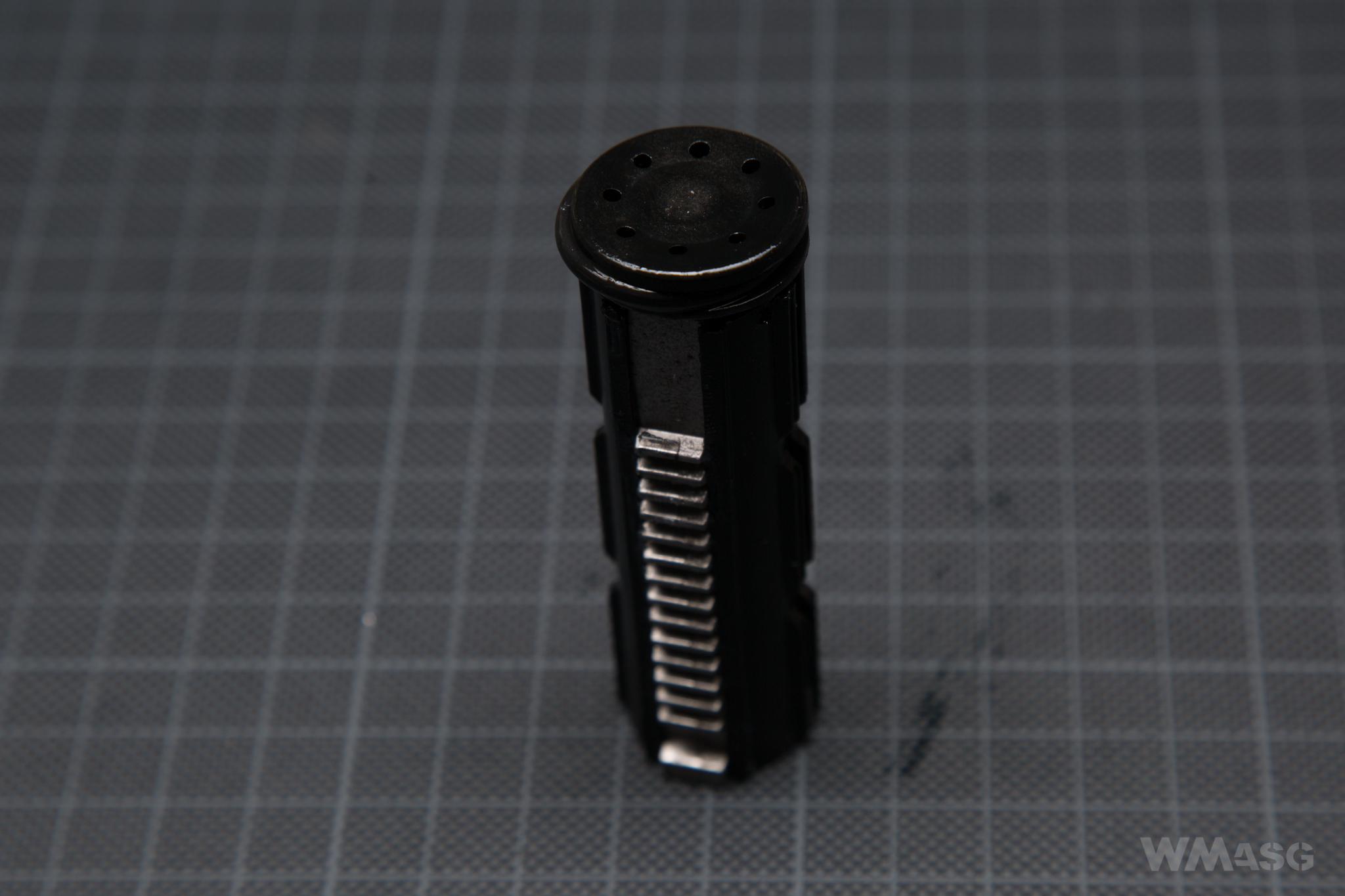

The piston head is also made of plastic, has ventilation 8-holes and a ball bearing.

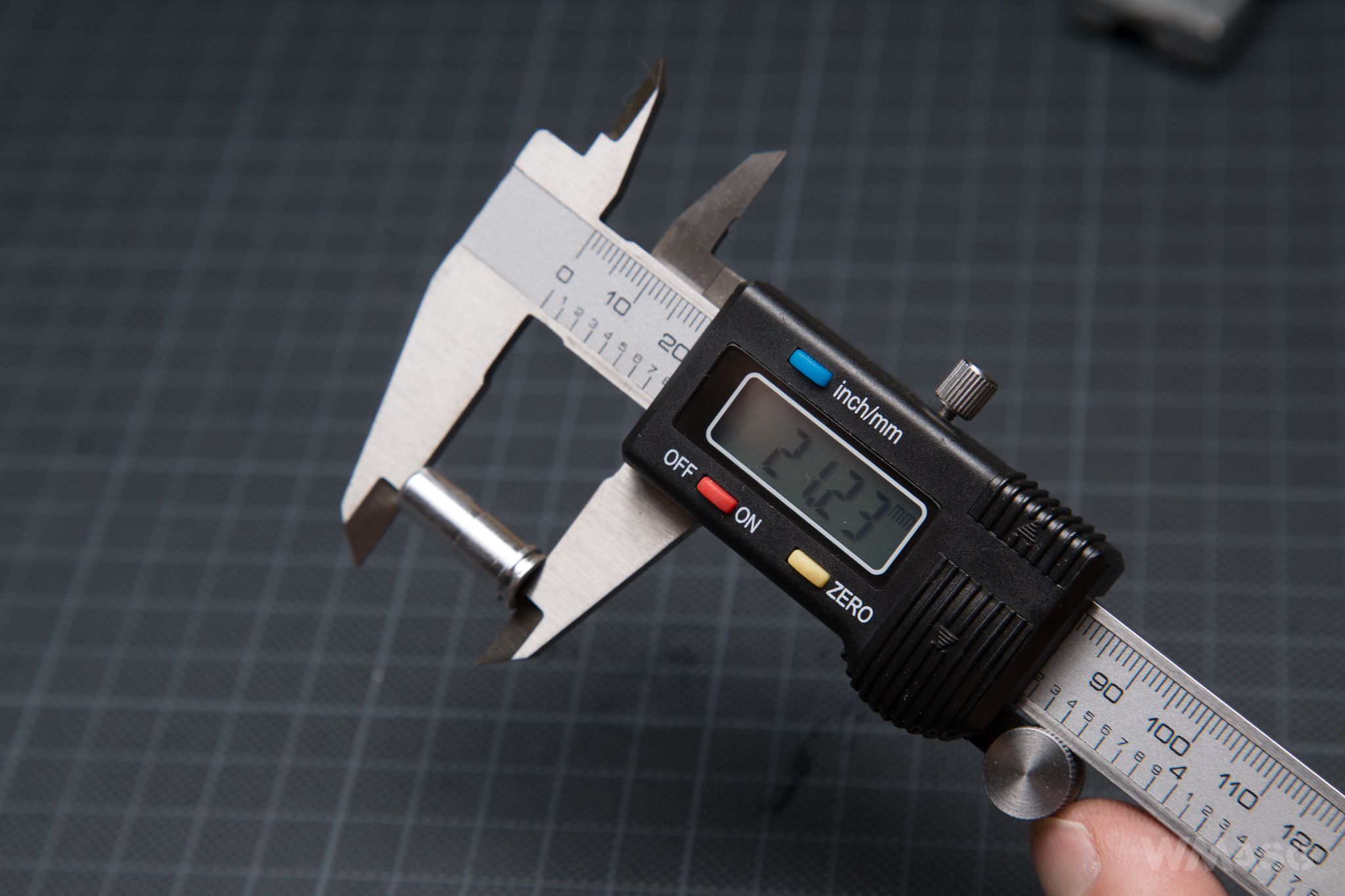

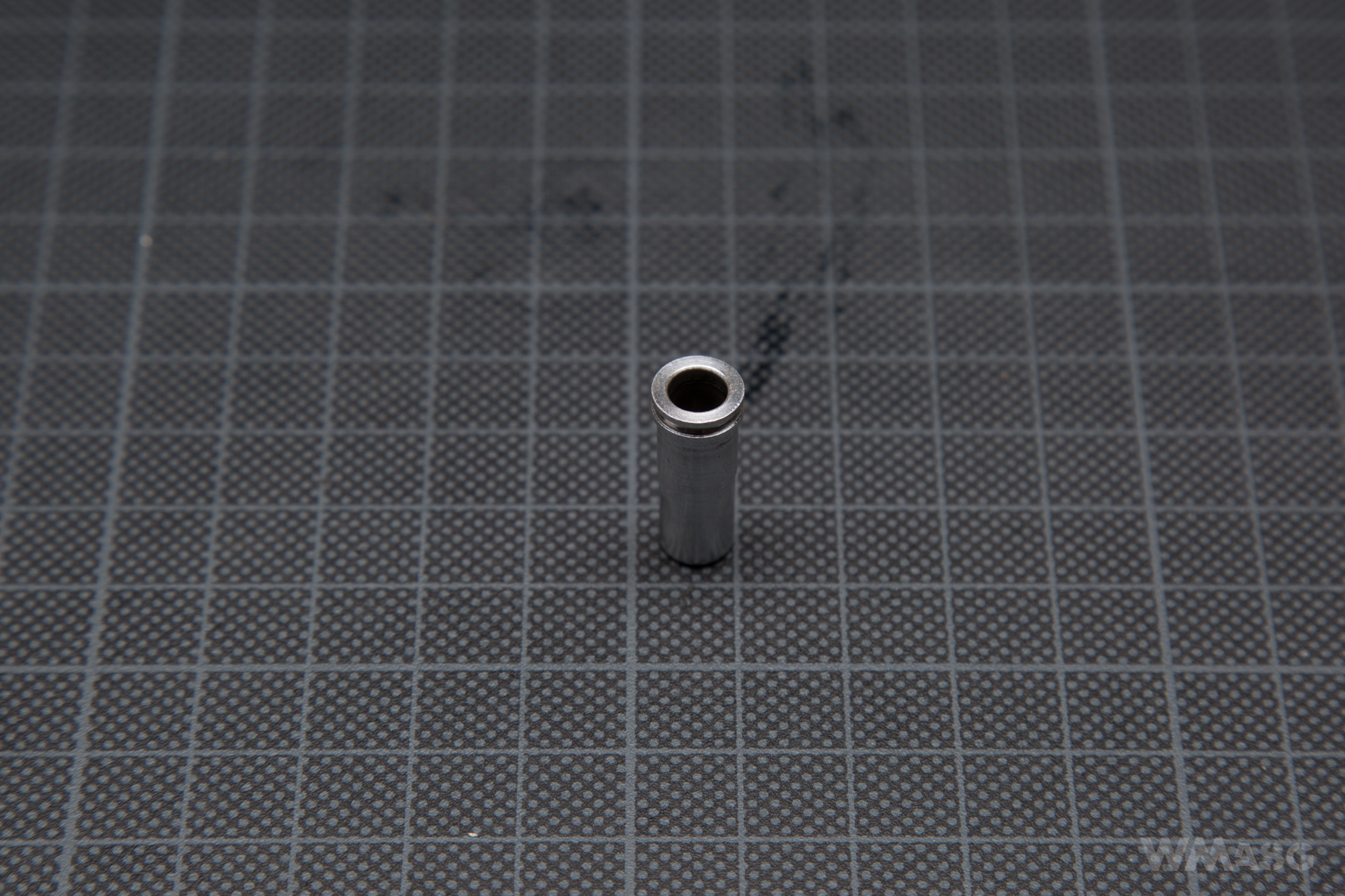

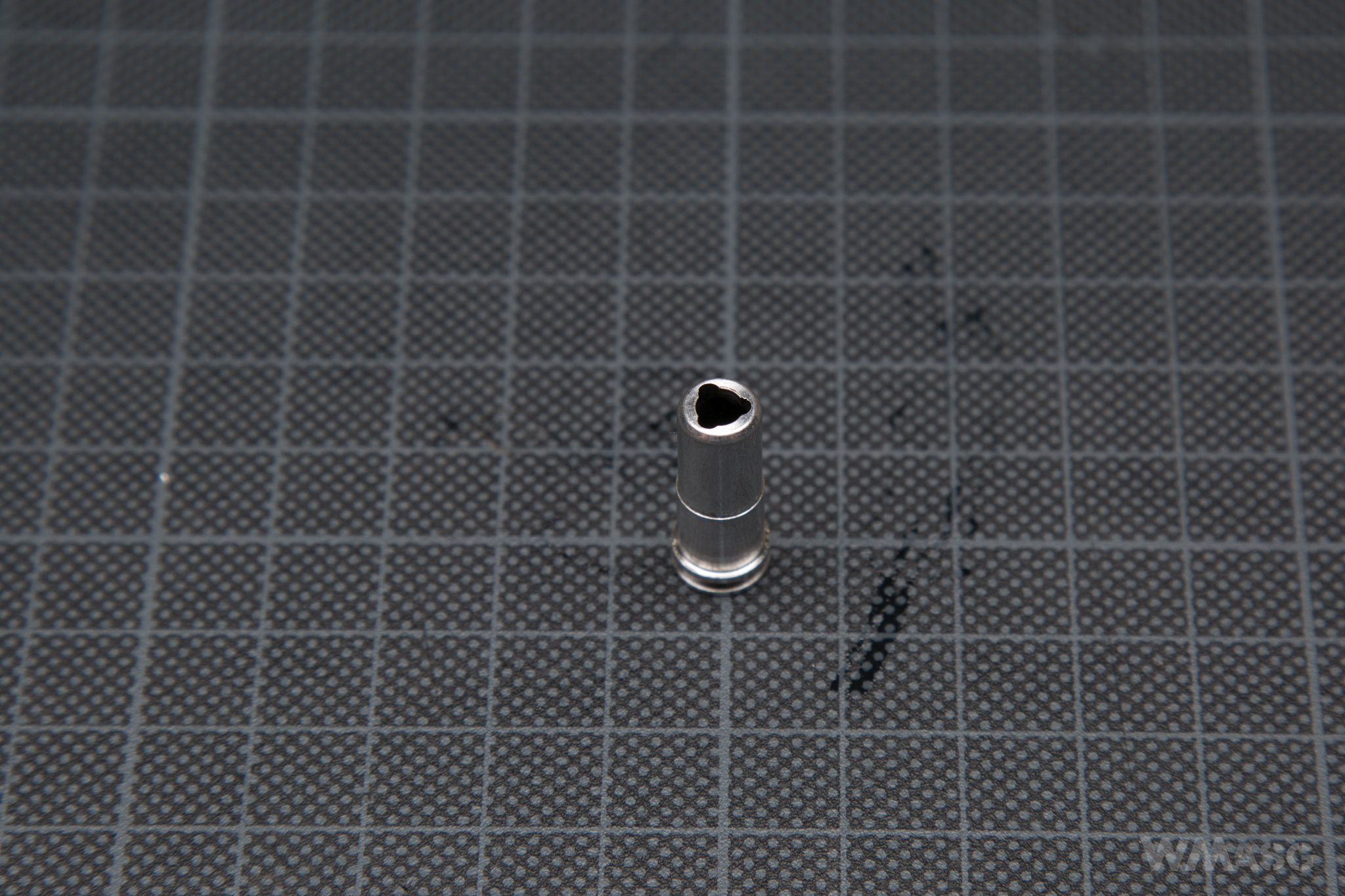

The aluminum nozzle has a rubber o-ring and is 21.23 mm long. It is finished with a directional venturi with a triangular shape.

The tappet plate is standard and has a very strong spring.

The piston is made of a black polymer, it has 15 steel teeth. (By the way, to clarify a bit: the popular 14 teeth pistons have, in fact, 15 teeth, and the more common 15 teeth versions have 16).

The system is very tight. The syringe effect is also present during the test with the nozzle.

The spring is a linear type and measures 147 mm in length. The wire thickness is 1.47 mm. The ball bearing equipped spring guide is shaped a way that facilitates quick replacement. It is made of metal (not steel - aluminum?).

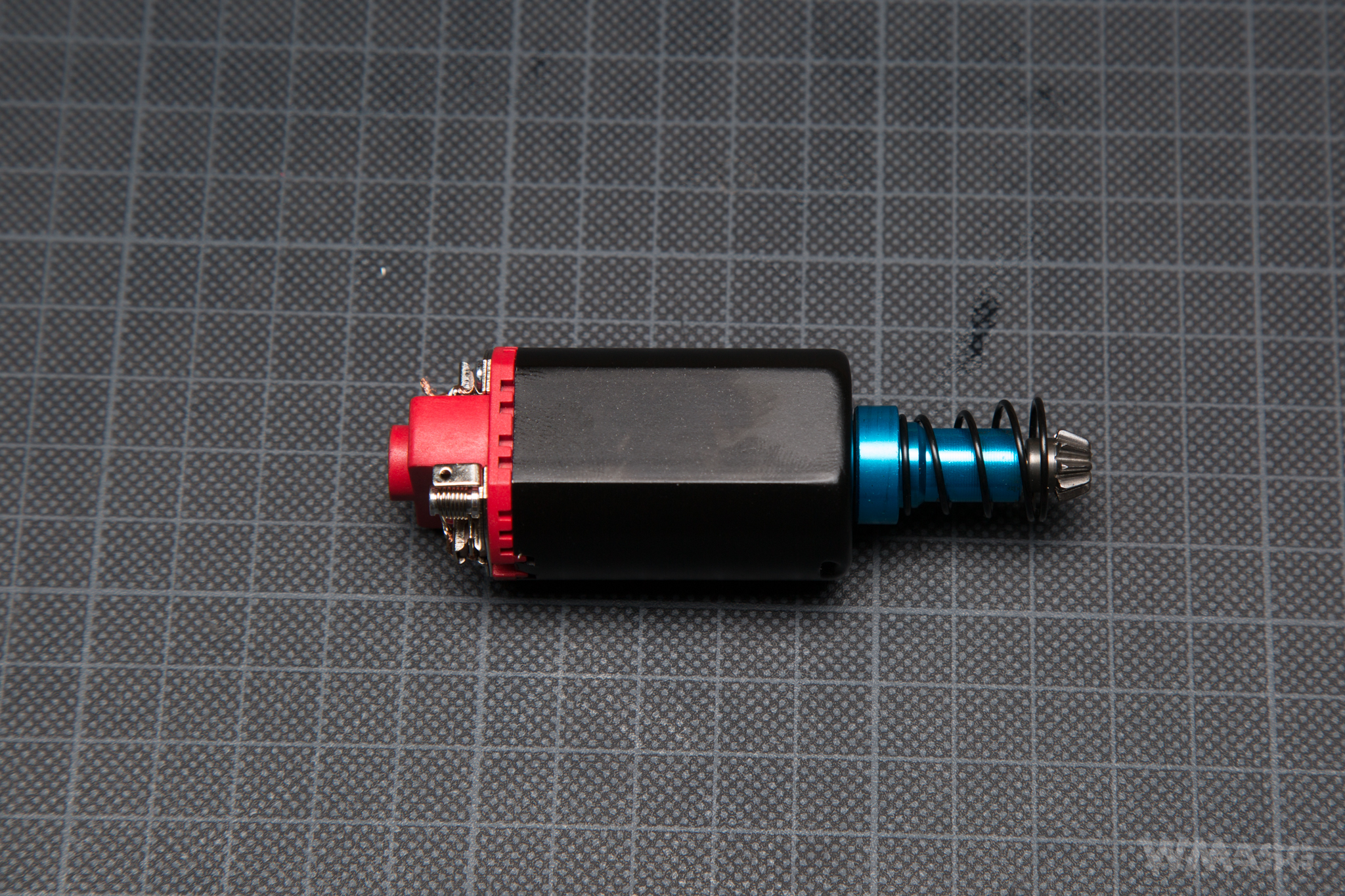

The motor is a long type with moderately strong magnets. It has no markings. It was manufactured very well. It resembles aftermarket upgrade motors. The motor gear is an "O" type.

The wires are referred to as low-resistance ones, are in a thin but mechanically robust colorless insulation. They are connected to the battery with the mini Tamiya plug.

The inner barrel and the Hop-Up chamber

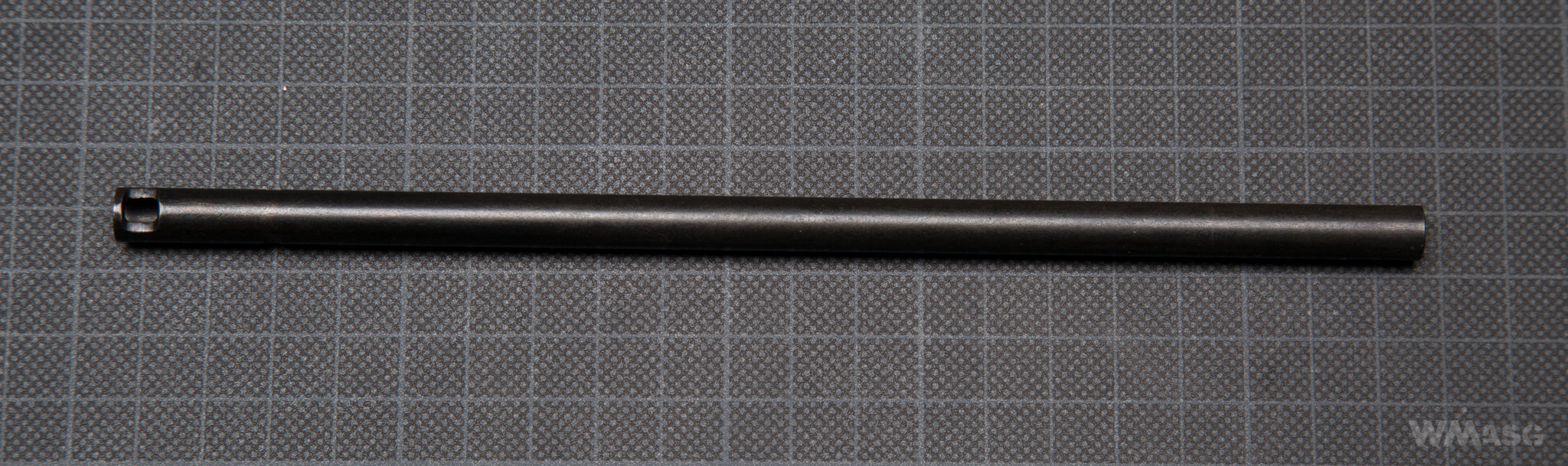

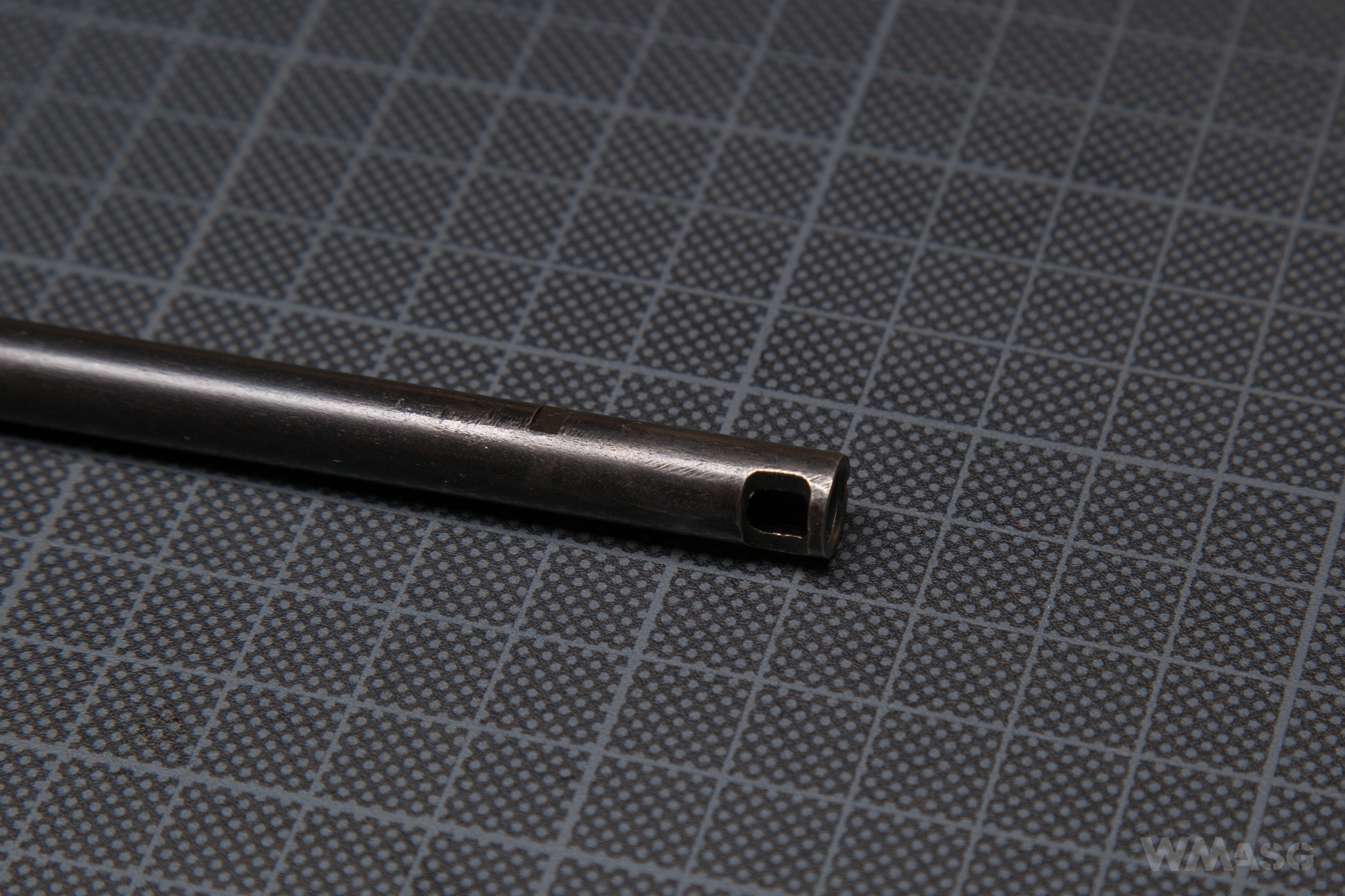

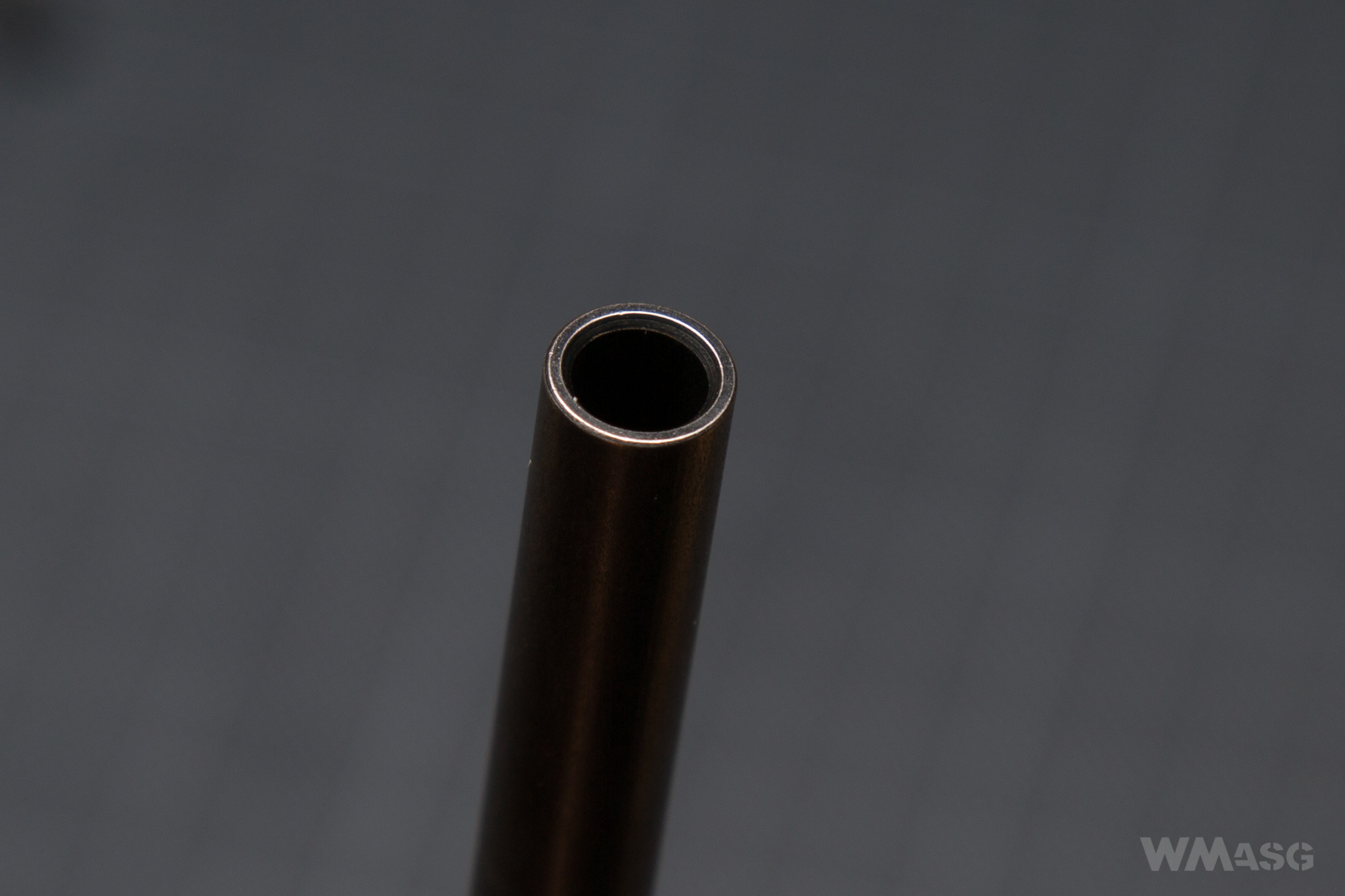

The inner barrel is made of steel and is 200 mm long. The internal diameter declared by the manufacturer is 6.02 mm, therefore falls into the precision barrel category. The insides of the barrel, when viewed with a naked eye, look clean and polished.

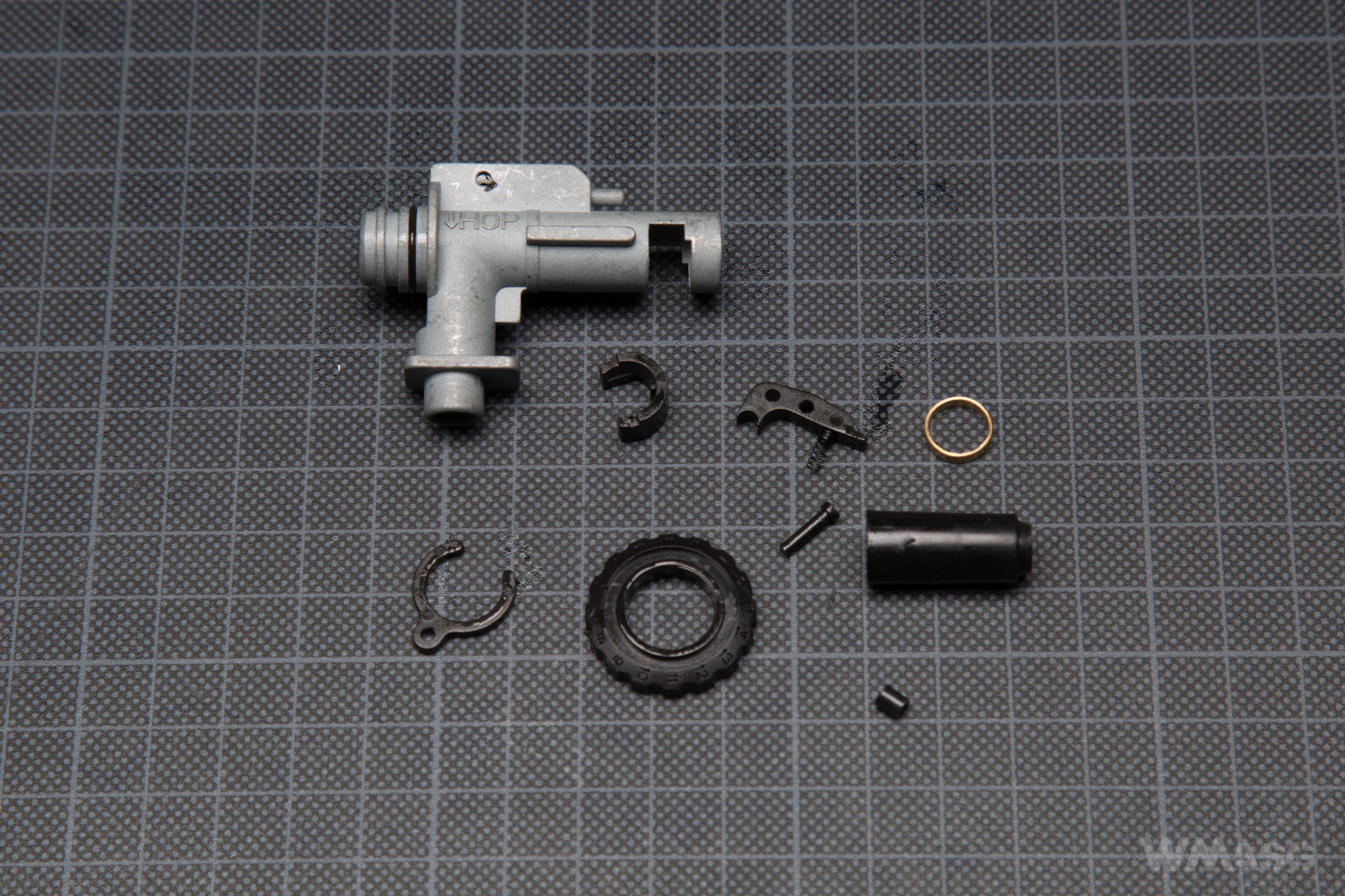

The Hop-Up chamber is made from cast ZnAl with a polymer lever and adjustment knob. The adjustment takes place in a plane perpendicular to the axis of the barrel. The chamber has markings with an arrow showing the adjustment direction: stronger BB spin is downwards, weaker is up. The bucking is soft and black, with a distinct (long) sealing neck. The spacer is standard and is in a form of a cylinder. The chamber is pressed against the gearbox with a large and strong spring attached to the barrel.

Measurement of muzzle velocity and target shooting test

The tests were carried out on our own enclosed shooting range, at an ambient temperature of 26ºC, the Hop-Up was set to zero. The measurements were made with the XCORTECH X3500 chronograph using Nurpol 0.2 g BBs.

The results (in brackets, the results of measurements taken as part of the preliminary checkup done by Taiwangun.com store where the reviewed replica comes from, for comparison):

1. 372,9 (365),

2. 372,0 (366),

3. 370,6 (365),

4. 369,7 (368),

5. 370,5 (368),

6. 366,3 (363),

7. 366,4 (368),

8. 365,4 (366),

9. 365,2 (367),

10. 363,5 (369).

Average: 368,2 fps. Average measurements on the shop’s website: 366.5 fps.

The measured rate of fire (using a LiPo 11.1 V 2400 mAh, 15 C battery) is 19 BBs/s.

Target shooting test

We used biodegradable 0.25 g BBs by Nuprol for this test. The distance from the target was 25 m. The shooting was done from the K-Zone shooting rest. 10 shots were fired from a replica pulled straight out of the box. We did not adjust the sights. 10 shots using single fire - all shots hit the target, the largest distance between BBs - 12 cm.

10 shots using full-auto - all hit the target, the largest distance between BBs - 8.5 cm.

Summary

In my opinion the Arcturus AR15 PDW is a very successful replica.

In my opinion the Arcturus AR15 PDW is a very successful replica.

On the plus side:

- very well made, configured and assembled mechanism (a complete gearbox);

- very solid and careful manufacture of external parts;

- very functional sights;

- multi-position stock;

- two magazines in the set;

- aggressive look.

The drawbacks:

- non-standard parts of the mechanism (it will not be a problem if the importer ensures a constant availability of spare parts);

- uneven Picatinny rails of the front grip and the upper receiver (its not too bothersome, it just looks bad);

- hard to remove buttstock slack (due to the lack of a rare tool). It is possible that this applies only to the reviewed unit.

- A poorly functioning selection of the mid/low-cap magazine capacity - this can also apply only to the reviewed unit.

We would like to thank Taiwangun.com for making this review possible.