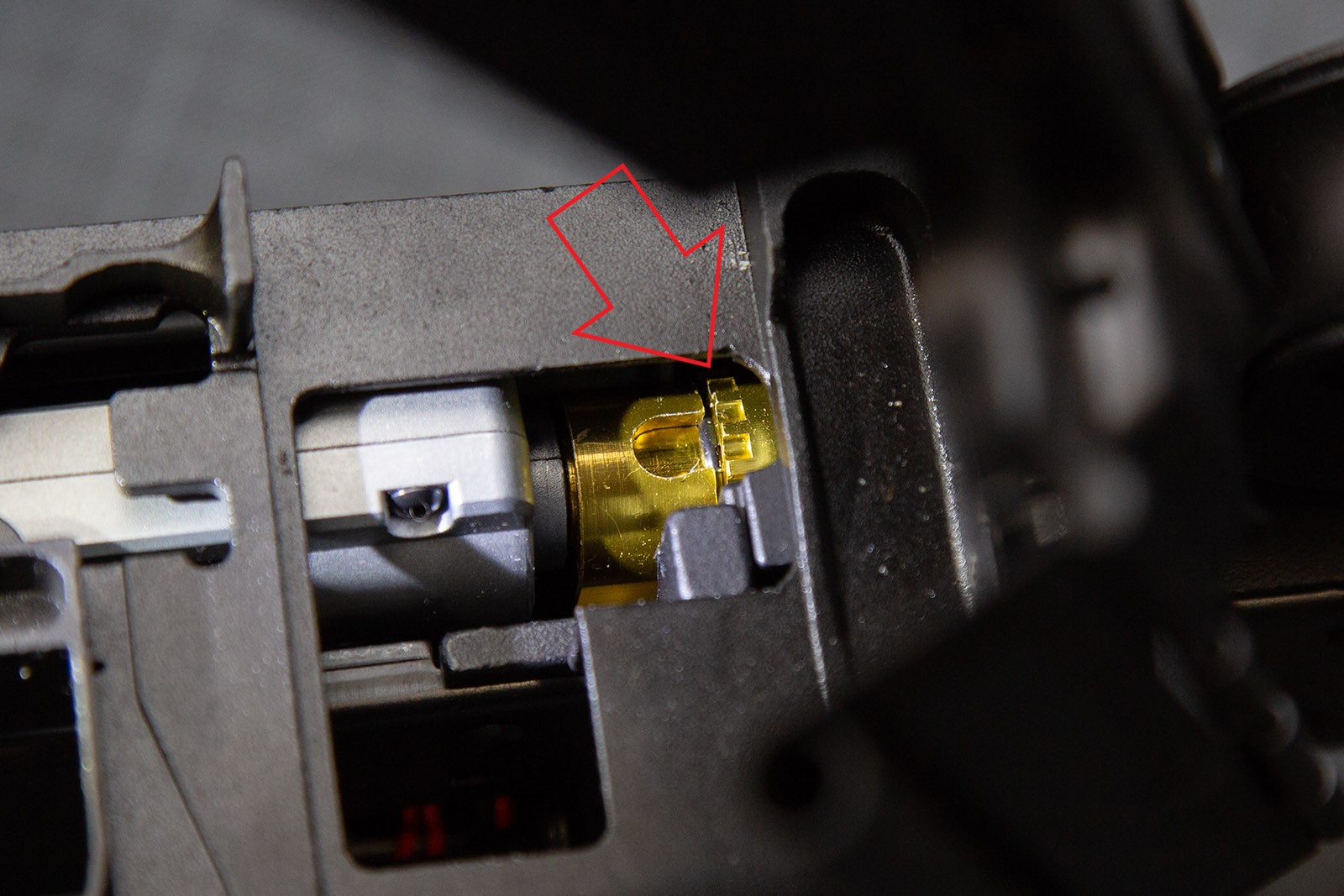

I already mentioned that the access to the HopUp adjustment is obtained after opening the receiver cover which in the original, opens all the way up to the vertical position. In the photo, the cover of the replica is raised to its maximal position.

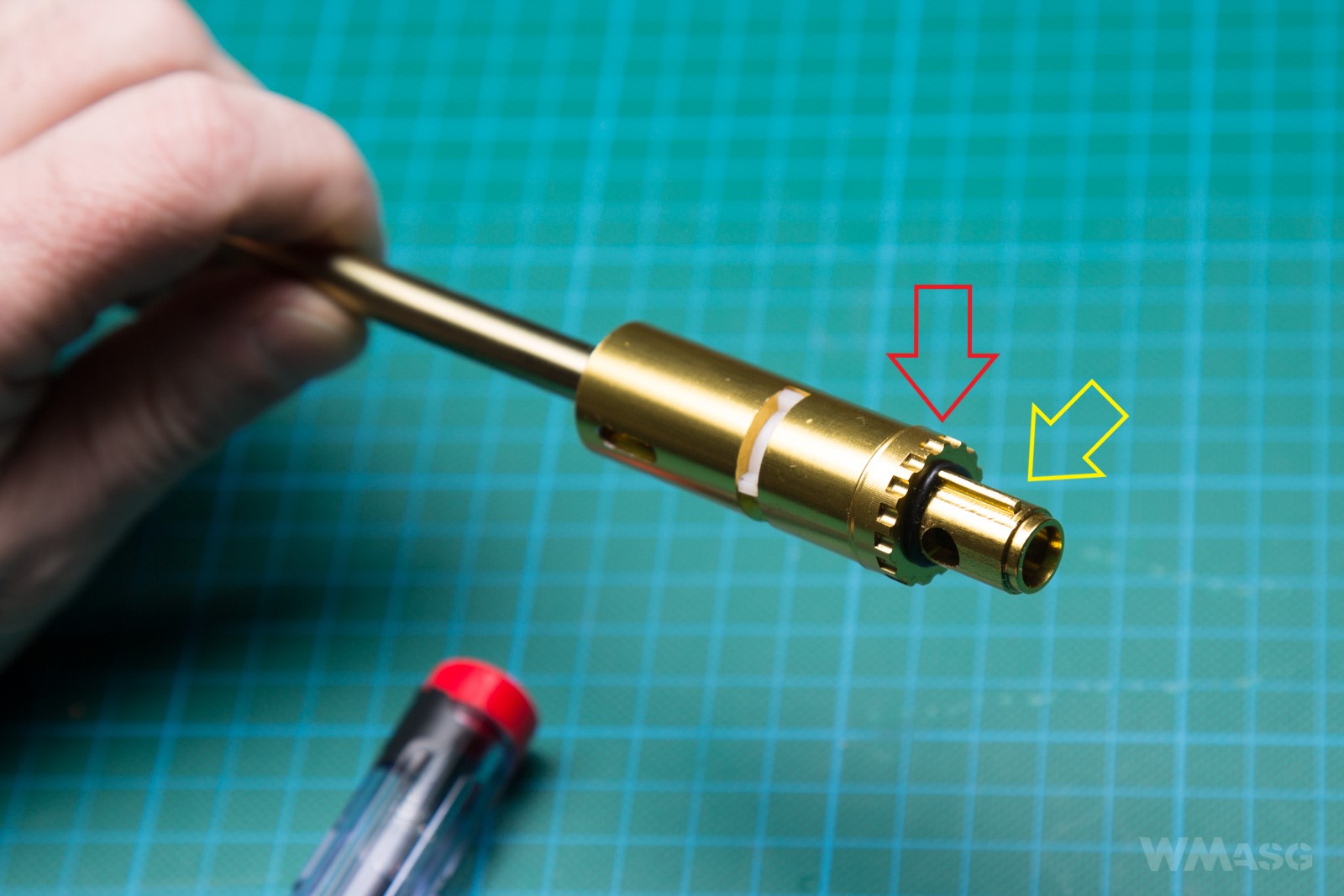

The adjustment is carried out by turning the ring around the barrel axis. In the next photos, to make everything clear, we will show the removed chamber, but I will repeat it: to adjust the HopUp it is enough to lift the cover.

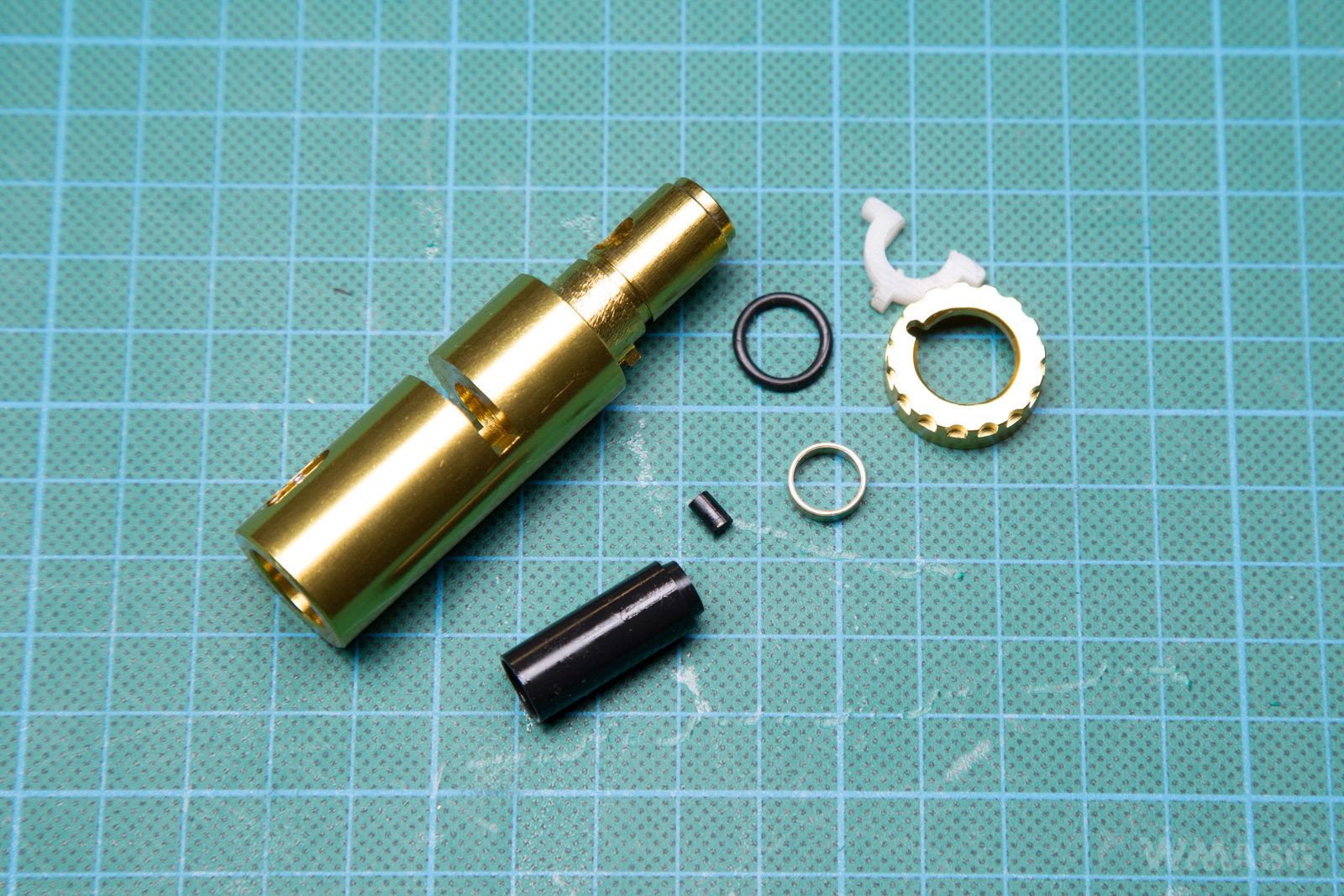

The HU chamber made of aluminum

The red arrow indicates the adjustment ring. The yellow, the guide setting the position of the chamber in the replica.

A standard HopUp bucking was used as well as a full spacer operating in the vertical position.

Therefore, the inner barrel is made in a standard manner. LCT does not give any information about the diameter of the inner barrel.

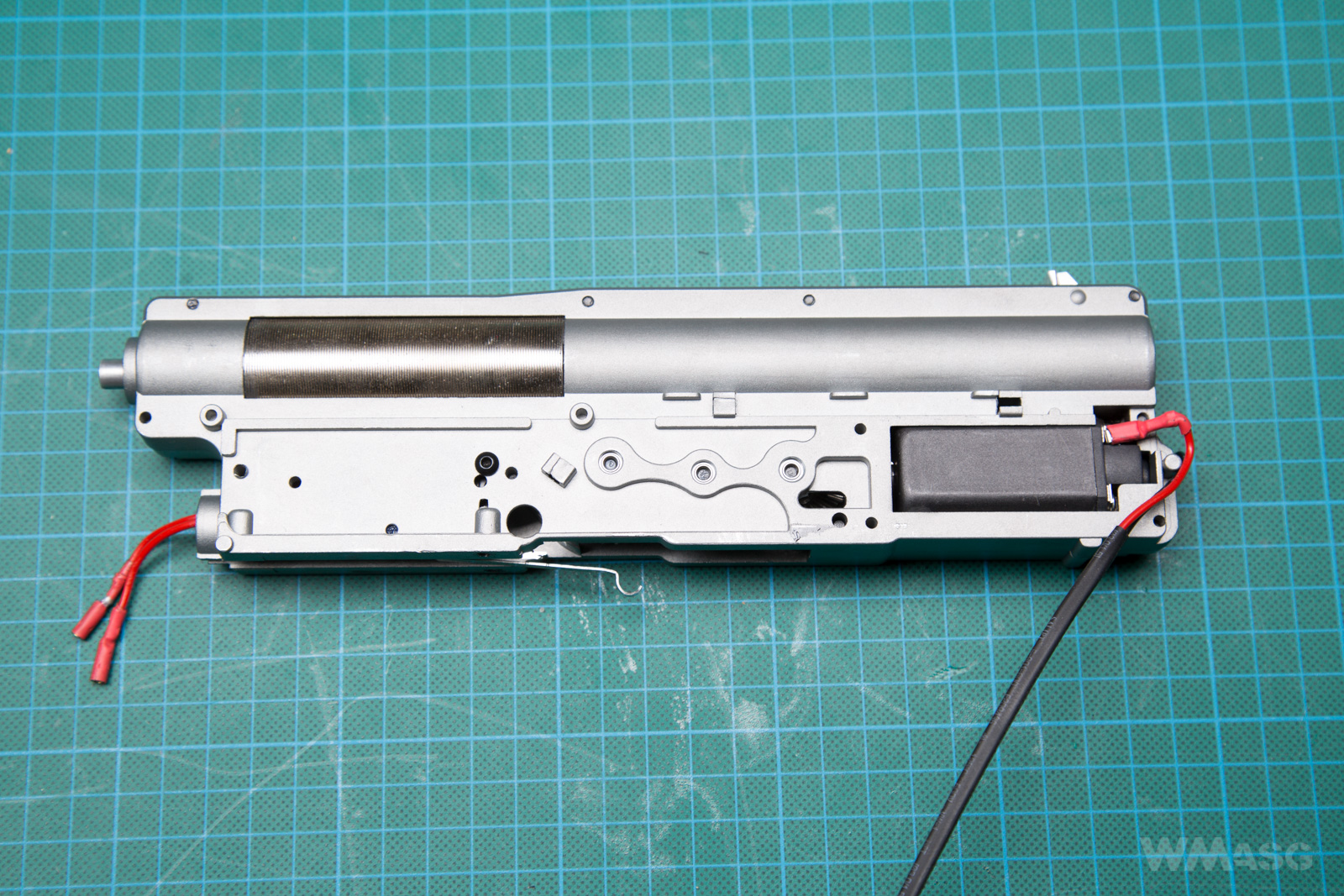

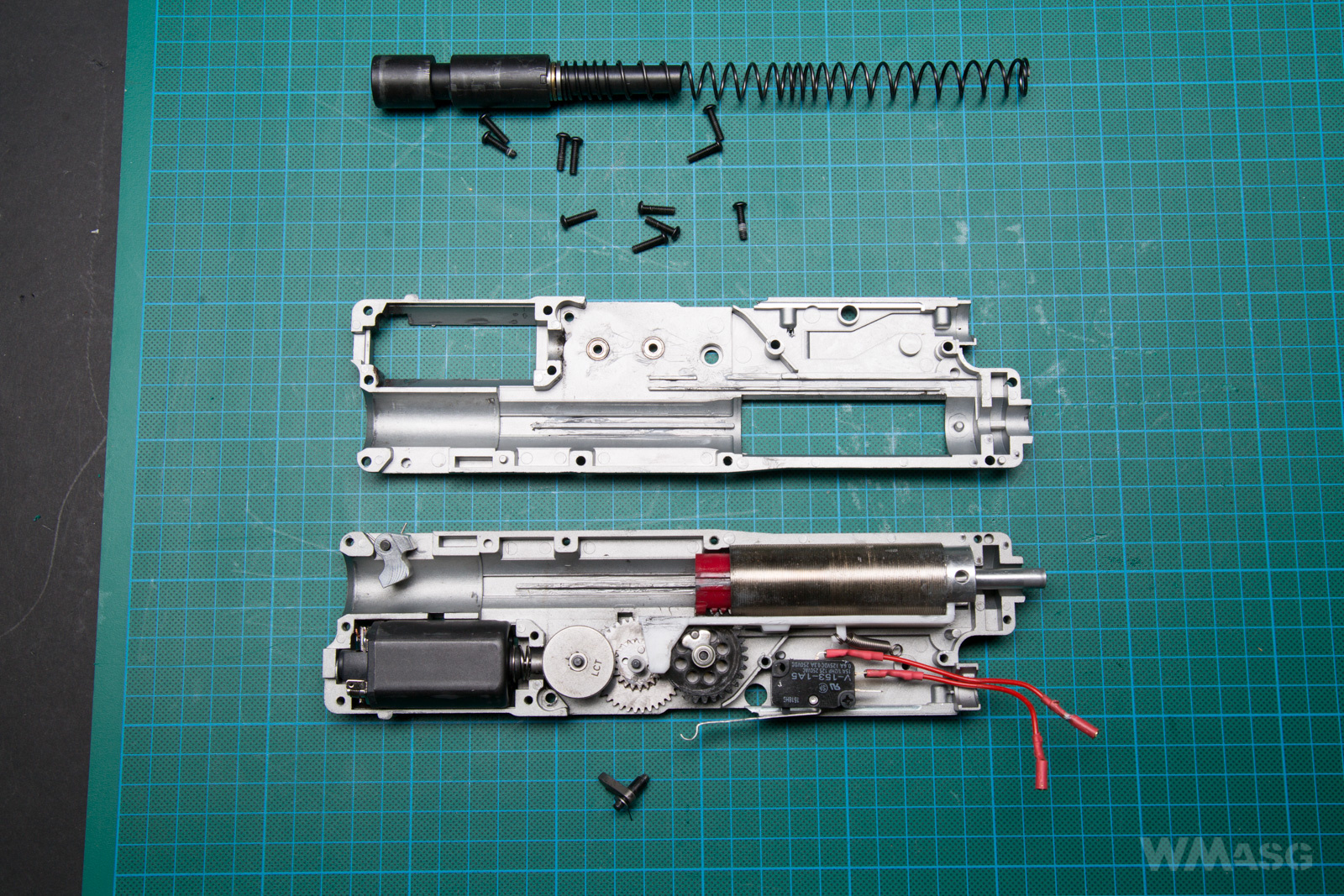

The gearbox

The LCT PKP gearbox is, in principle, very similar to those used, for example, in the A&K replicas. I did not check it, but I do not think they are interchangeable. I think so just by looking at the front part, which in the A&K is simply flat.

Generally, the frame makes a good impression, although it is not as reinforced as in the A&K. In many places, the walls are simply thinner.

For comparison, the PKM A&K gearbox:

Photo from the review: AEG replica of the PKM light machine gun by A&K: http://wmasg.com/en/articles/view/3845

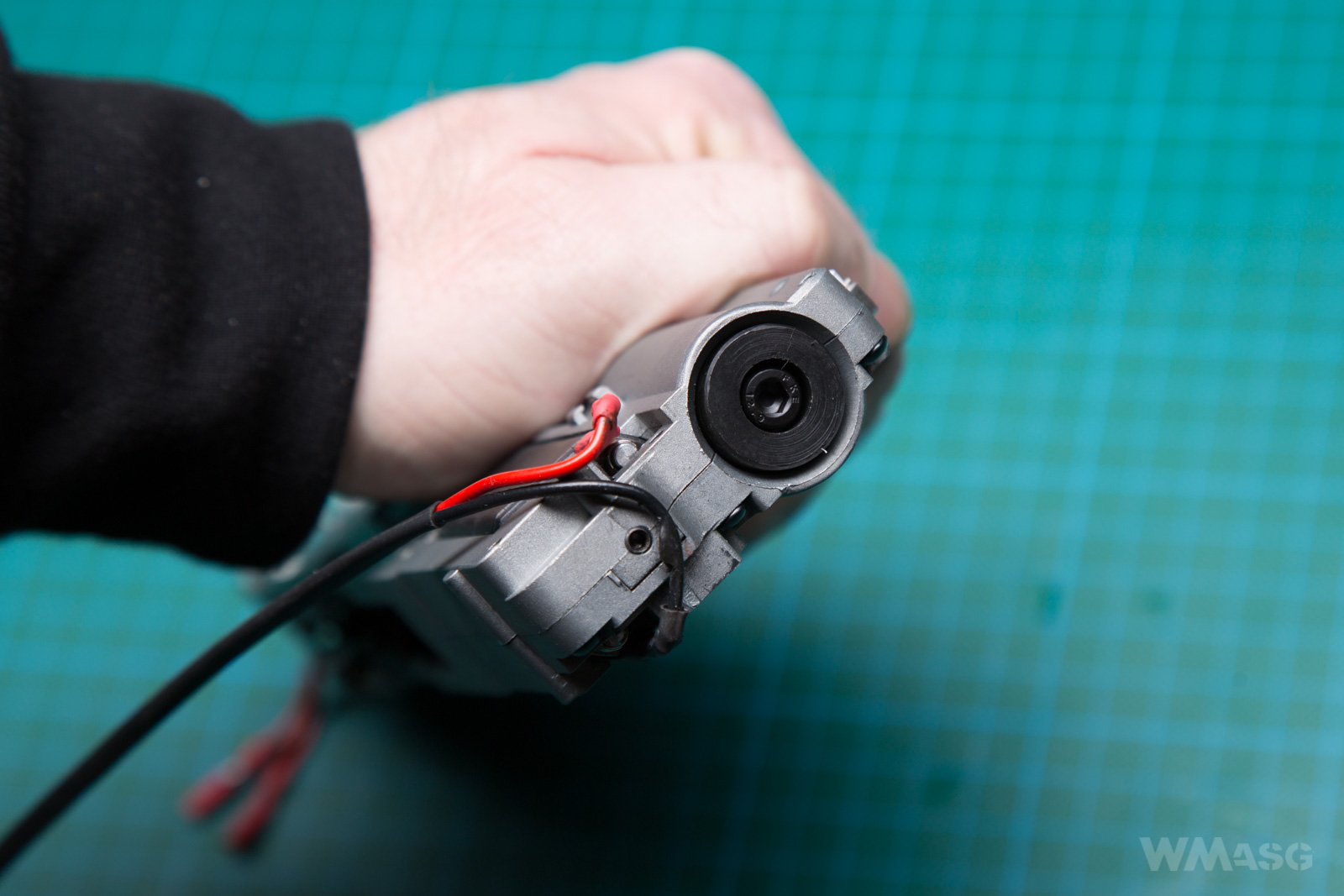

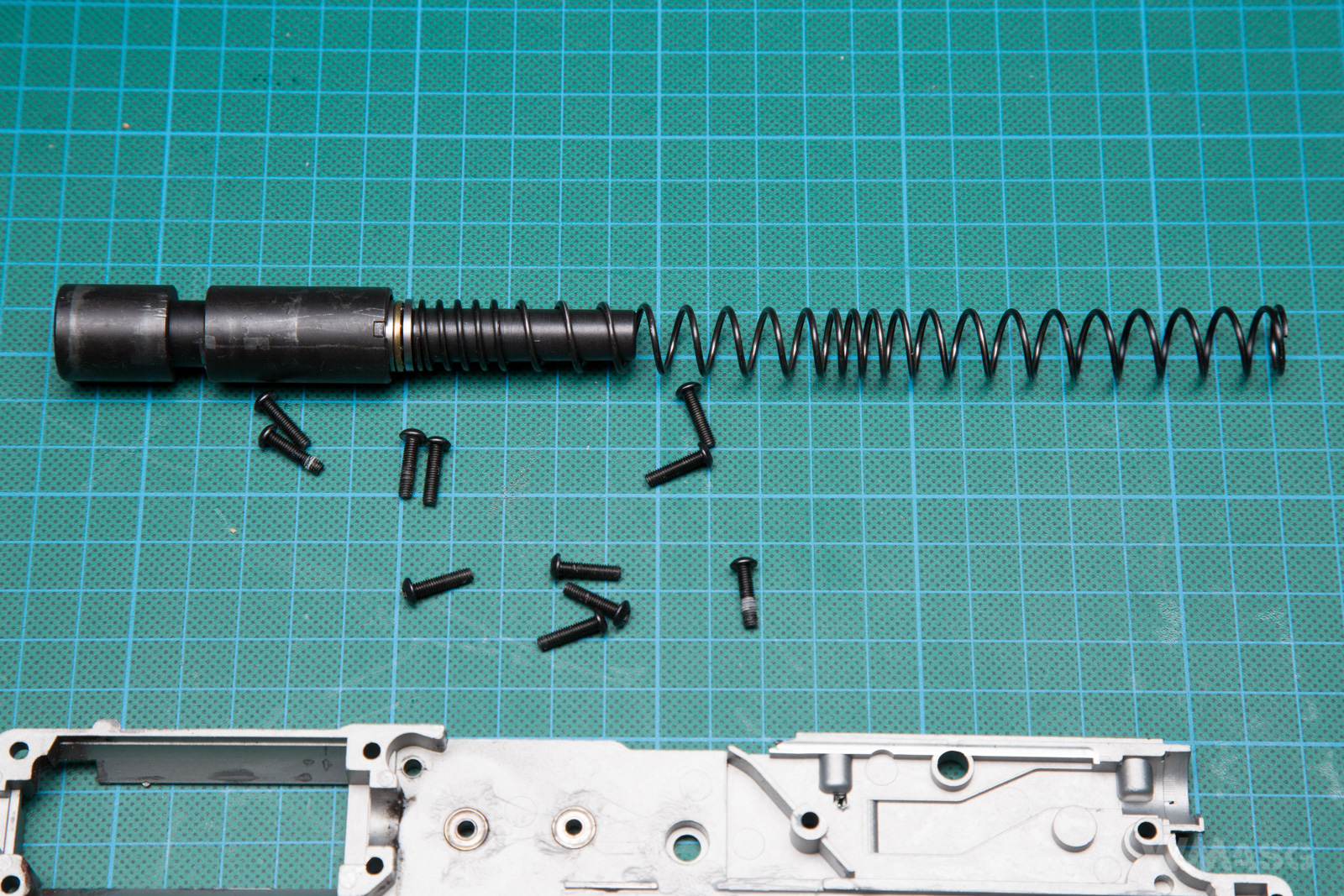

Just like other gearboxes built according to a similar concept, the PKP frame has the option of replacing the spring without opening it. Unfortunately, there is no possibility of making the replacement without removing the mechanism from the replica's receiver.

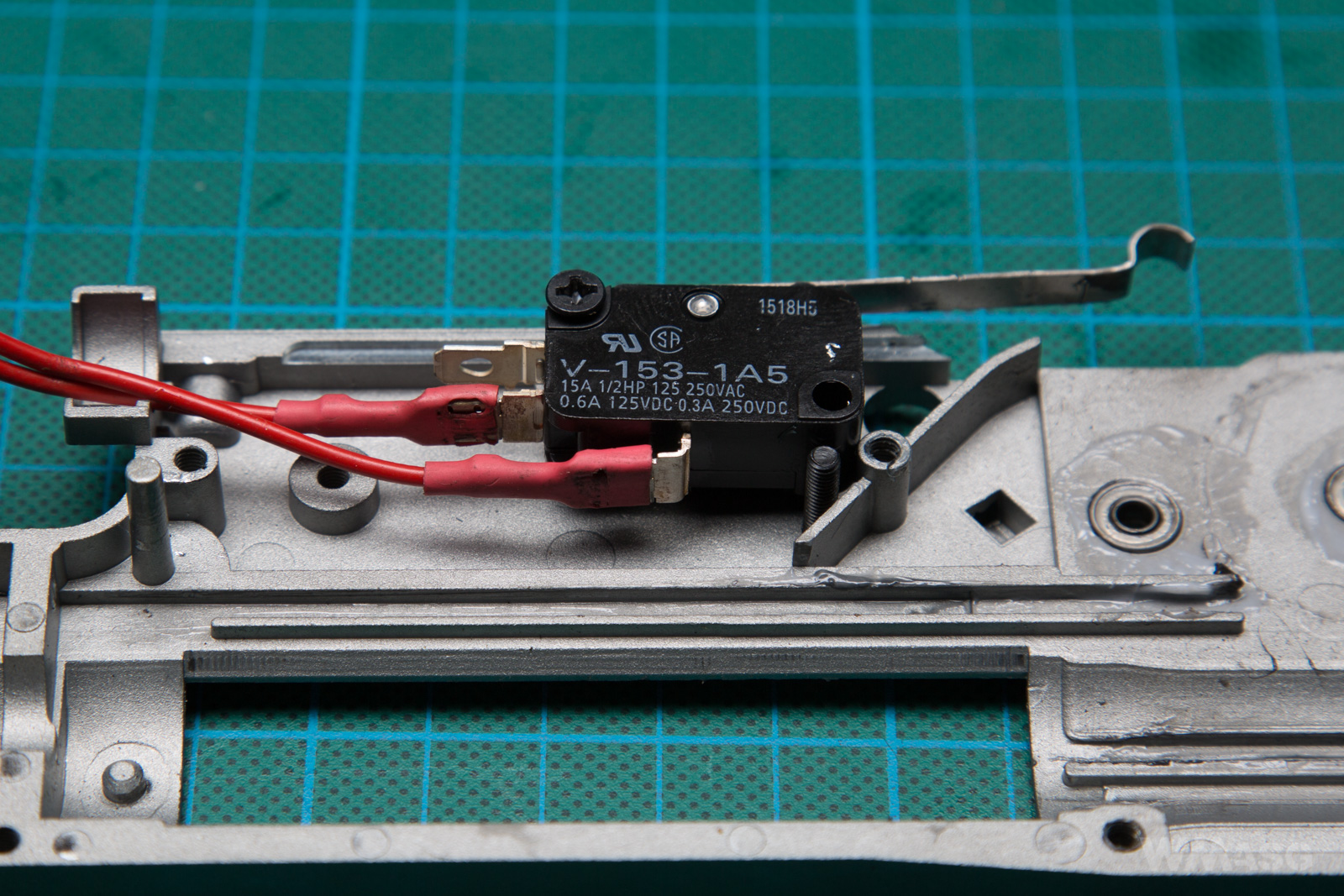

The microswitch used by LCT is also similar to the A&K, but it has a clearly longer arm and a slightly different shape.

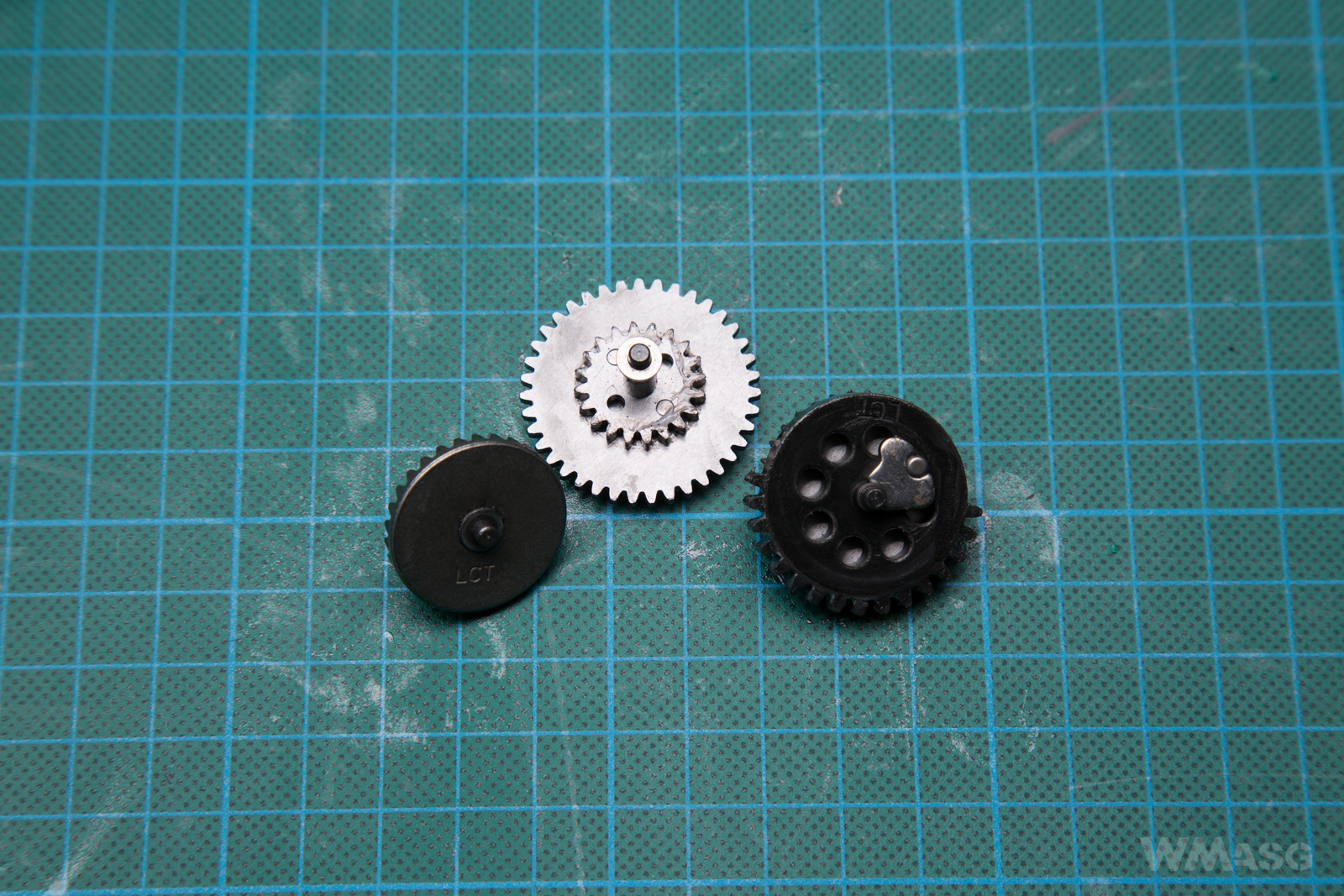

The internal parts of the mechanism are standard parts used by LCT - very good in quality. As standard, we have steel gears working in ball bearings,

As standard, we have steel gears working in ball bearings, a piston with full steel teeth and an aluminum cylinder and piston head, the latter having a full ball bearing,

a piston with full steel teeth and an aluminum cylinder and piston head, the latter having a full ball bearing,

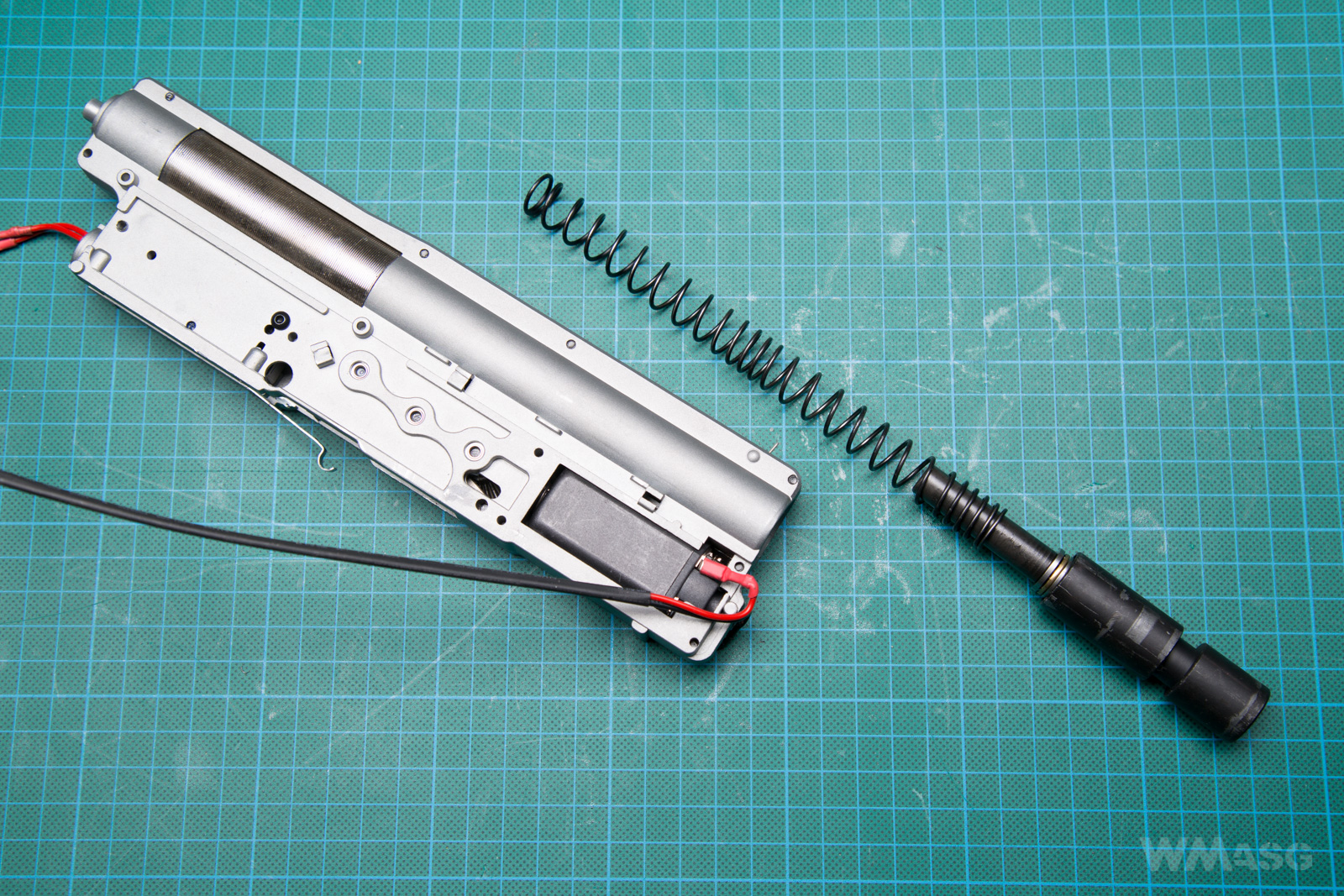

and a spring with irregular coils and a guide with a bearing,

and a spring with irregular coils and a guide with a bearing,

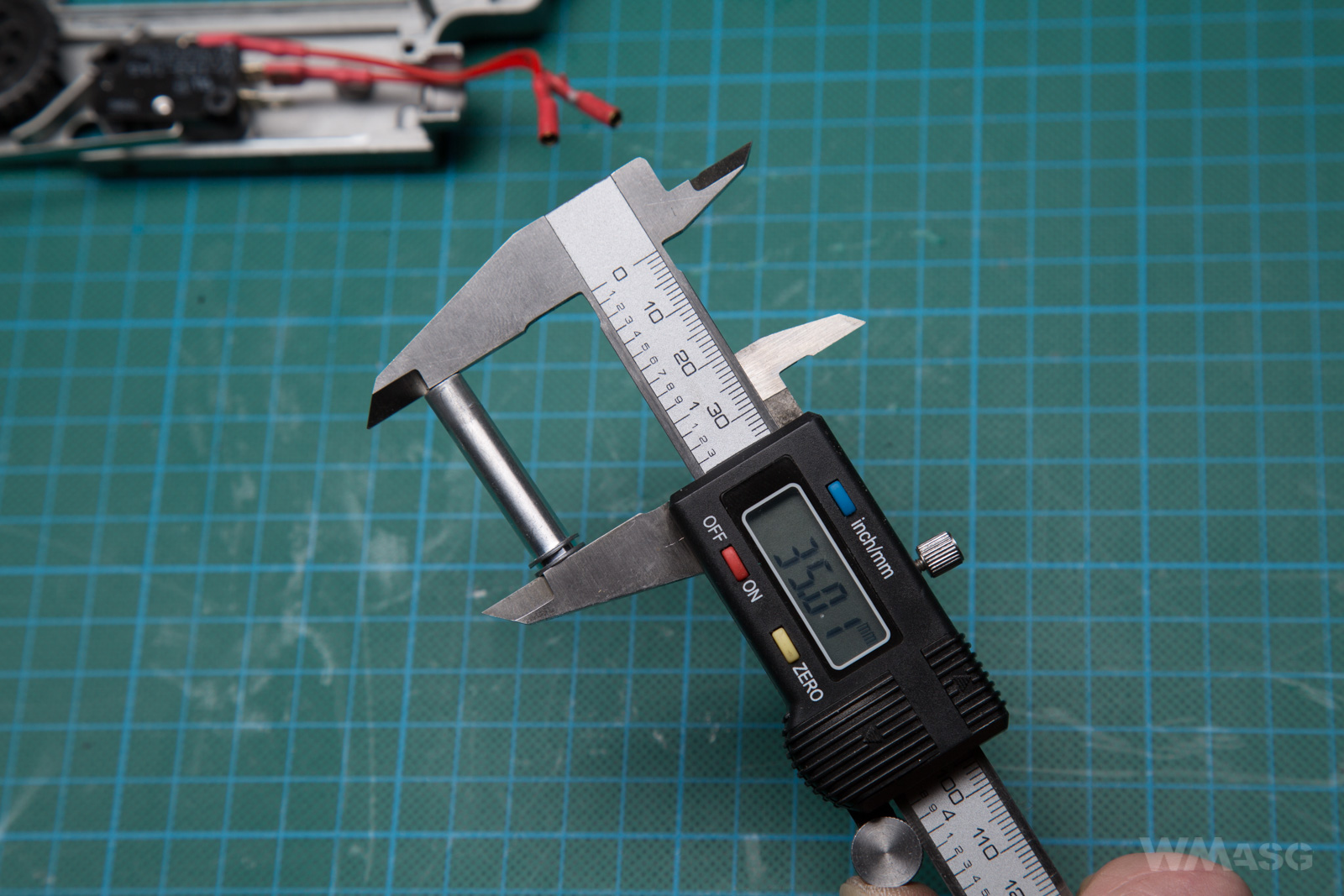

and sealed aluminum nozzle with a length of 35 mm.

and sealed aluminum nozzle with a length of 35 mm.

The mechanism works smoothly and efficiently which, apart from the quality of the parts, also confirms the quality of assembly. Although I would prefer bevel and sector gear to be slightly more precisely shimmed.

On the next page: the ammunition box (magazine), the muzzle velocity measurement and the target shooting test.