A bit of history

The history of the HK G33 began in the late 1960s, when Heckler und Koch began work on a 5.56x45 mm chambered weapon. Serial production of the new rifle began in 1968.

In the Western world, the G33 rifle did not make a great career, although you can find information on the Internet, which are backed up with in photos, that small quantities of the rifle were used by the American Navy Seals during the Vietnam War. Non the less it was the main infantry weapon of the armed forces of Thailand, Malaysia, Brazil, Turkey and Chile. Interestingly, the G33 has never been adopted by the Bundeswehr, but was often used by the German Police.

The presented LK-33A2 is a new product of LCT Airsoft. As you can guess, this is the HK33A2 replica, which was the basic version of the rifle equipped with a fixed stock made of plastic and a barrel with a length of 390 mm. We have no information whether LCT will complement the offer with the A1 and A3 models which in the original had a collapsible stock.

The original HK33 visually resembles the legendary G3 assault rifle. The same is true of replica. We have already reviewed the G3 replica. The HK33 presented here was made using the same technology and with the same care and accuracy of replication of details.

Basic technical parameters:

- overall length: 925 mm;

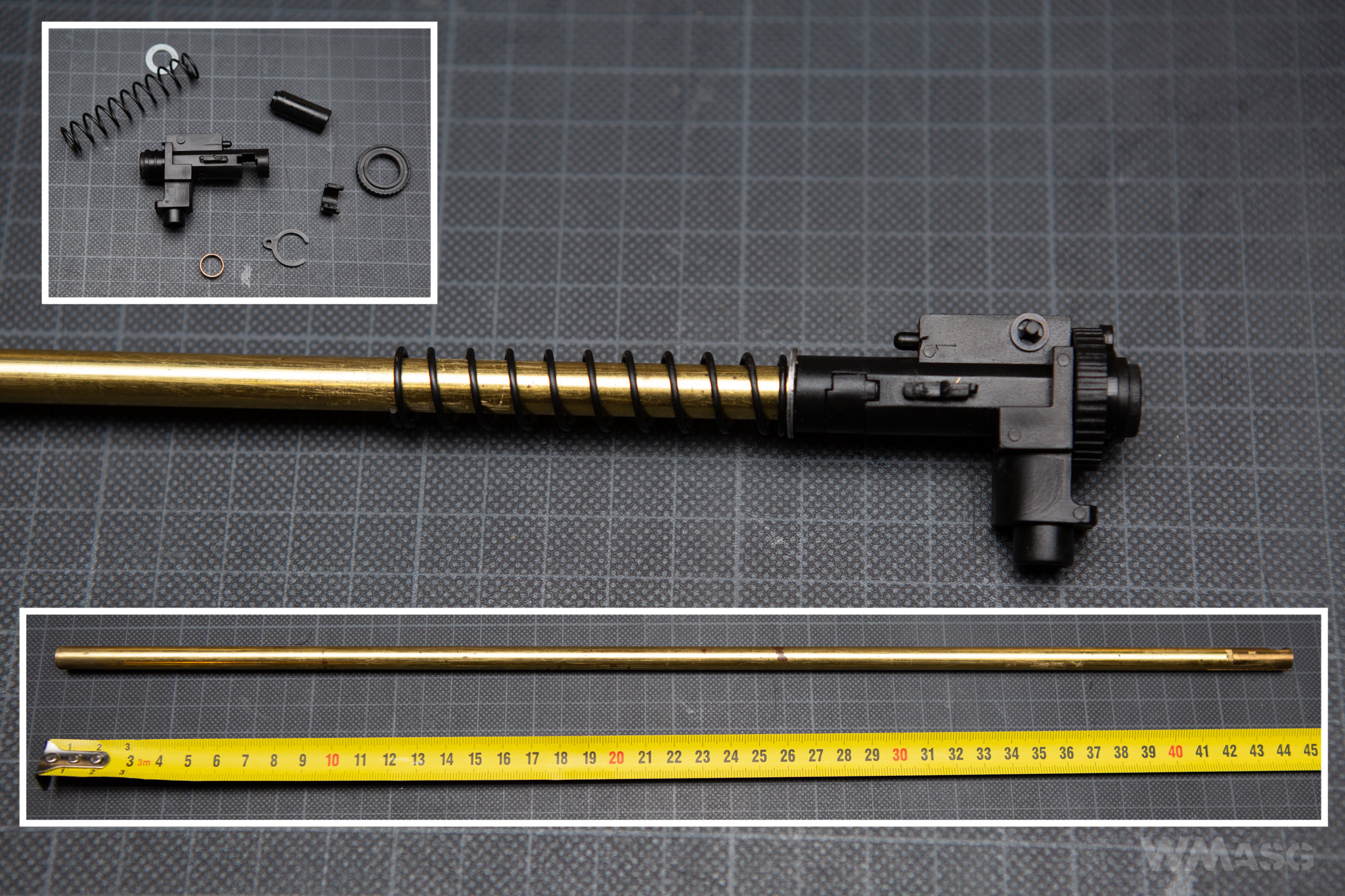

- inner barrel length: 445 mm;

- weight (with an empty magazine, without a battery): 4200 g;

- magazine capacity: 100 BBs;

- declared muzzle velocity: 410 fps

From the outside

All external metal parts of the replica are made of oxidized steel. Thanks to this, the structure is very stiff and stable. Unfortunately, this clearly increases the weight of the replica, as an empty one, i.e. without a battery and with an empty magazine, weighs just over 4 kilograms. But first things first.

The oxidized receiver with the integrated magazine well is pressed from thick (over 1.5 mm) steel sheet. In its rear part, a rotating diopter drum sight with four settings, typical for HK products, has been permanently mounted. The correct setting is selected depending on the distance between the shooter and the target. In airsoft use, the setting intended for shooting at the shortest distances will probably work best, which is the only one that does not have a round aperture but rather a traditional notch. The sight base is permanently welded to the receiver and the sight itself is attached to it with a flat head screw. In addition to changing the setting depending on the distance, the rear sight also has the ability to be adjusted in the horizontal plane. The small screw on the right (red arrow) is used for making this adjustment. By turning it clockwise the sight is moved to the left, turning its counterclockwise moves the sight to the right. Before starting the adjustment process, it is necessary to loosen the already mentioned top screw, securing the sight to the base, and after adjustment is made, tighten it firmly again (white arrow).

The non-adjustable front sight is placed in a base the encloses the barrel. This is the same part that was previously used in the G3 rifle (and the LC-3 LCT Airsoft replica). The front sight itself is, of course, made of a sheet steel, and the entire element is a steel forging.

The charging handle located on the right side of the gas tube is also taken straight from the G3/LC-3. The lever is made from steel and the handle's cap is made of reinforced nylon. It is also equipped with a hinge. In the front position, i.e. when shooting is done, the handle remains folded close to the gas tube, locking on a short pin sticking out of it. When it is pulled, it unfolds perpendicularly to the axis of the barrel. In the extreme rear position, it can be locked in a large notch designed for this purpose.

The handle is connected to the dummy bolt carrier. Its movement retracts the dummy opening the spent casing ejection port and allows access to the HopUp system adjustment. Locking the lever opens the ejection port permanently and allows one to conveniently adjust the system. Releasing the dummy bolt carrier lock after completing the adjustment, which can be done even with a light touch on the handle, makes a specific metallic sound.

The outer barrel is also made of black oxidised steel. It is worth noting that LCT has used a single-piece barrel in its G3 replicas, which has a positive effect on their durability and accuracy of replication. Visible to the naked eye and palpable marks that are a result of using a turning tool give the barrel a very credible look. The barrel ends with a slotted flash hider, which is simply mounted on it and secured with a steel ring spring. The flash hider can be turned freely as it is not attached to the thread and until the ring is removed it can not be disassembled.

The trigger group has been done differently in the HK33 than in the G3. In the G3 it is a part made of steel with a detachable pistol grip. The HK33 uses a group similar to the one used in the HK MP5 submachine guns. It is a single piece polymer element with an integrated shaped pistol grip. In the MP5 submachine guns this type of grip is sometimes called the "early type". Its characteristic features are: the already mentioned profiled ergonomic shape, reinforcing ribs on both sides and a one-sided, slightly rounded safety/selector switch. The shortened versions of the real HK33, i.e. the HK53A2 and A3, have a later, plain grip pattern and a safety/selector switch on both sides, also modeled on the MP5 submachine guns versions once known as the Navy type.

The similarity of the trigger group to the MP5 obviously also results in an identically constructed, positioned and working magazine release button. The first of the two buttons for releasing the magazine is located between the magazine well and the trigger guard (photo above). The second button is located a little higher, but on the right side of the trigger group. Contrary to the appearances, the button cannot be operated with the index finger of the hand holding the grip as it is too far away. Thus, every G33 user (and MP5 for that matter) must work out their own method of changing the magazine.

The similarities to the MP5 do not end with the trigger group. The stock and the method of its mounting are also identical. In the case of the G3, the steel stock mount is slid over the receiver of the rifle and secured with two pins. In the HK33 it is done on similar principle, but the receiver profile is different (as in the MP5), and the stock is secured by only a single pin.

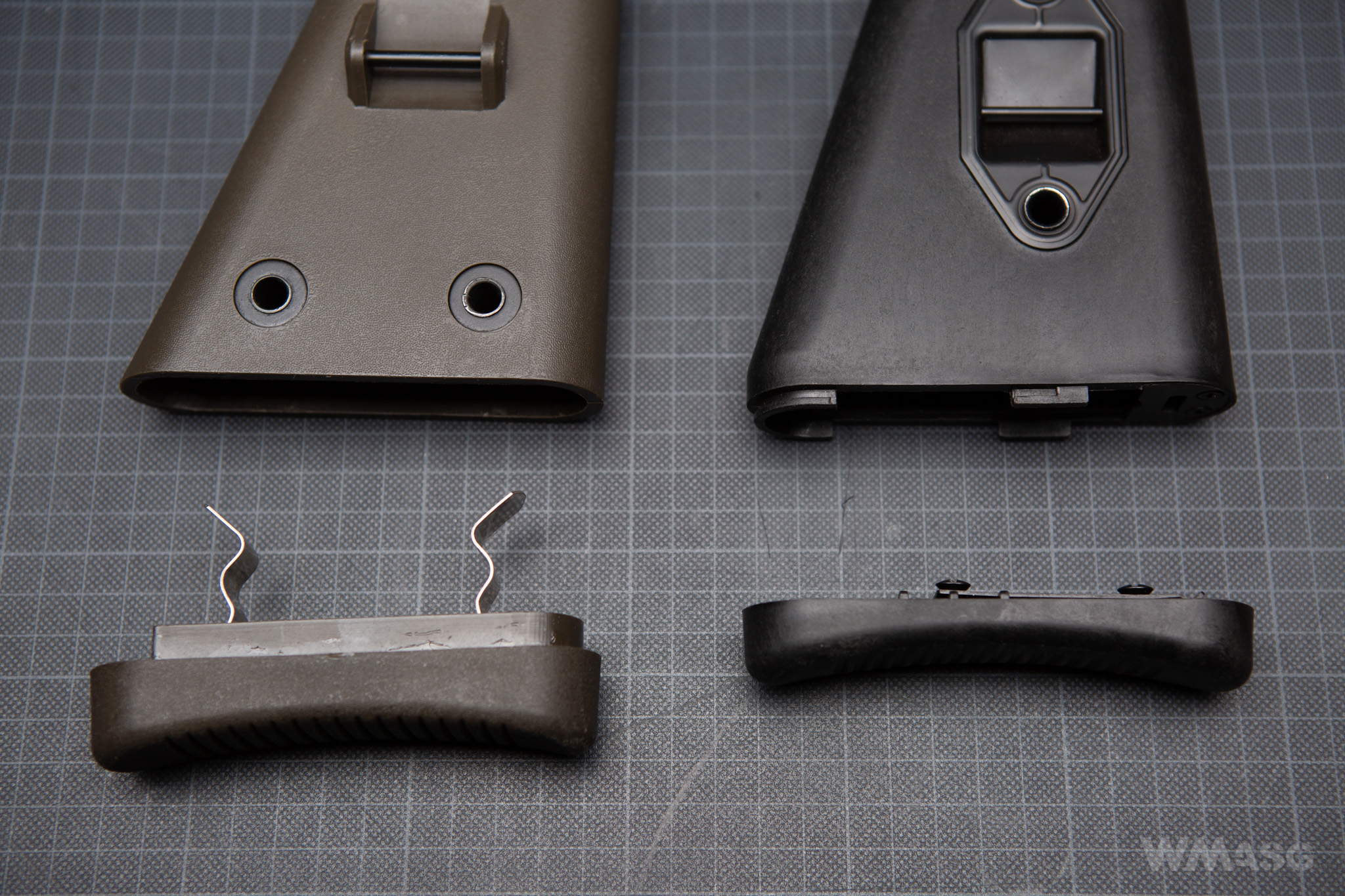

The following is a comparison of the LK-33 stock (top) with the LC-3 stock (bottom):

The stocks also differ in the way the butt plate is attached. In the G3 these are two springing like pieces made from a metal sheet In the HK33, the butt plate is inserted into the guide rails from below.

Of course, the stock in the replica has space to store a battery inside.

The polymer handguard is very similar to that used in the G3SG1 rifle and also has an integrated bipod. But the similarities are only superficial. First of all, the HK33 replica's handguard is shaped to mount the SG1 bipod, but it is not included in the set. Secondly, and more importantly, the HK33 handguard is shorter. Therefore the handguards are not interchangeable. Similar to the G3 replica, the handguard is made with extreme care for details as even the invisible aluminum thermal shields are reduplicated on the inside.

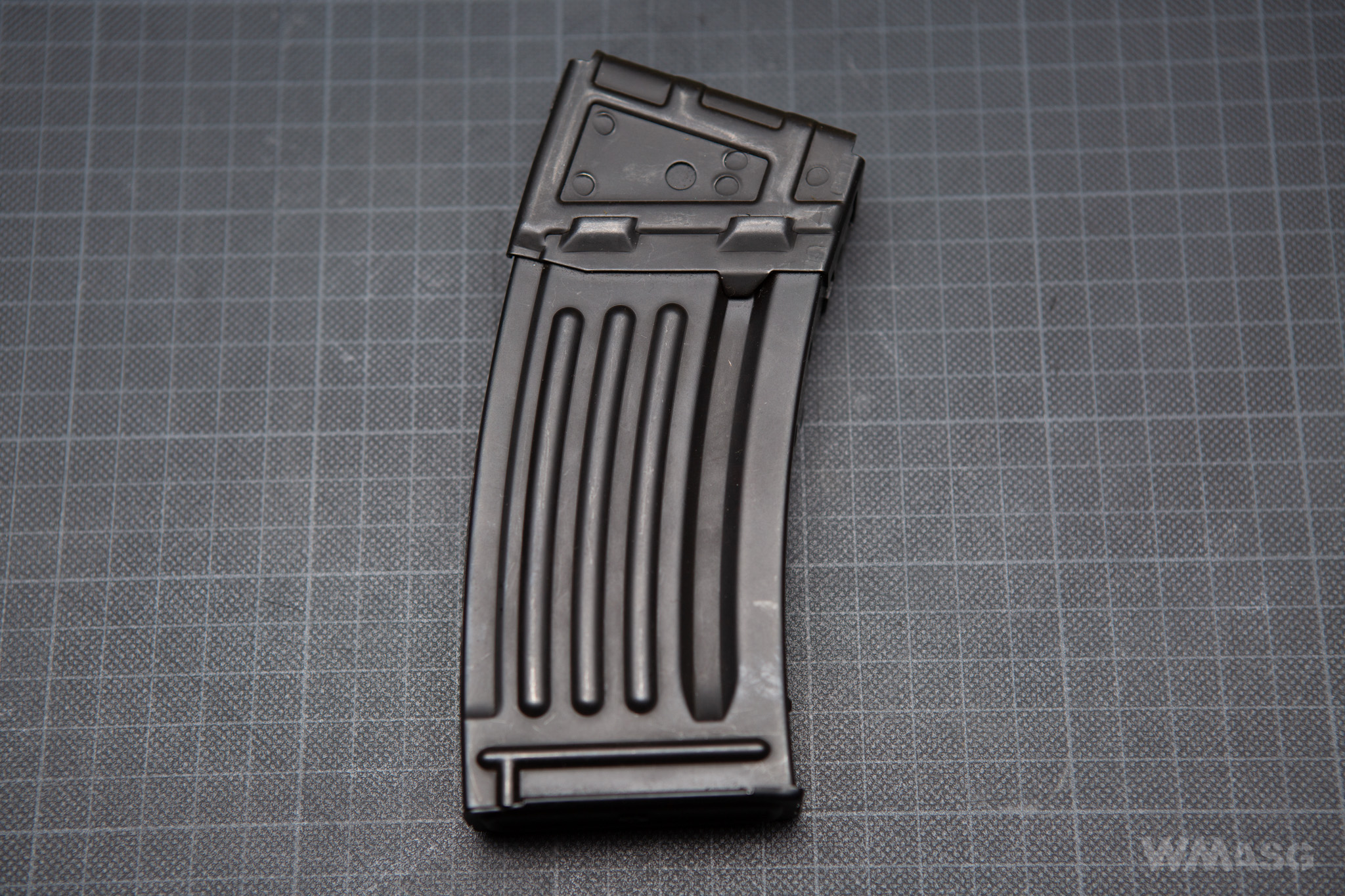

Completing the segment of the review devoted to the external design of the replica, we have to say a few words about the magazine that comes with it. It is a mid-cap made of steel sheets, with a capacity of 100 BBs.

Just like the G3 magazine, you have to get used to it, because of the method of inserting it into the replica. Despite having a similar shape to the AR-15 system magazines, which are simply inserted into the magwell, in the case of the HK33 the method is completely different. In the upper part, the magazine has a latch which must be placed into the corresponding notch in the socket.

In other words, the magazines are inserted with a curve like movement. First the latch is inserted into the notch in the magwell and then, moving on a curve, the magazine is inserted in to the rear part of the magwell. This principle and its execution is very similar to the one known from the AK rifles.

The internals

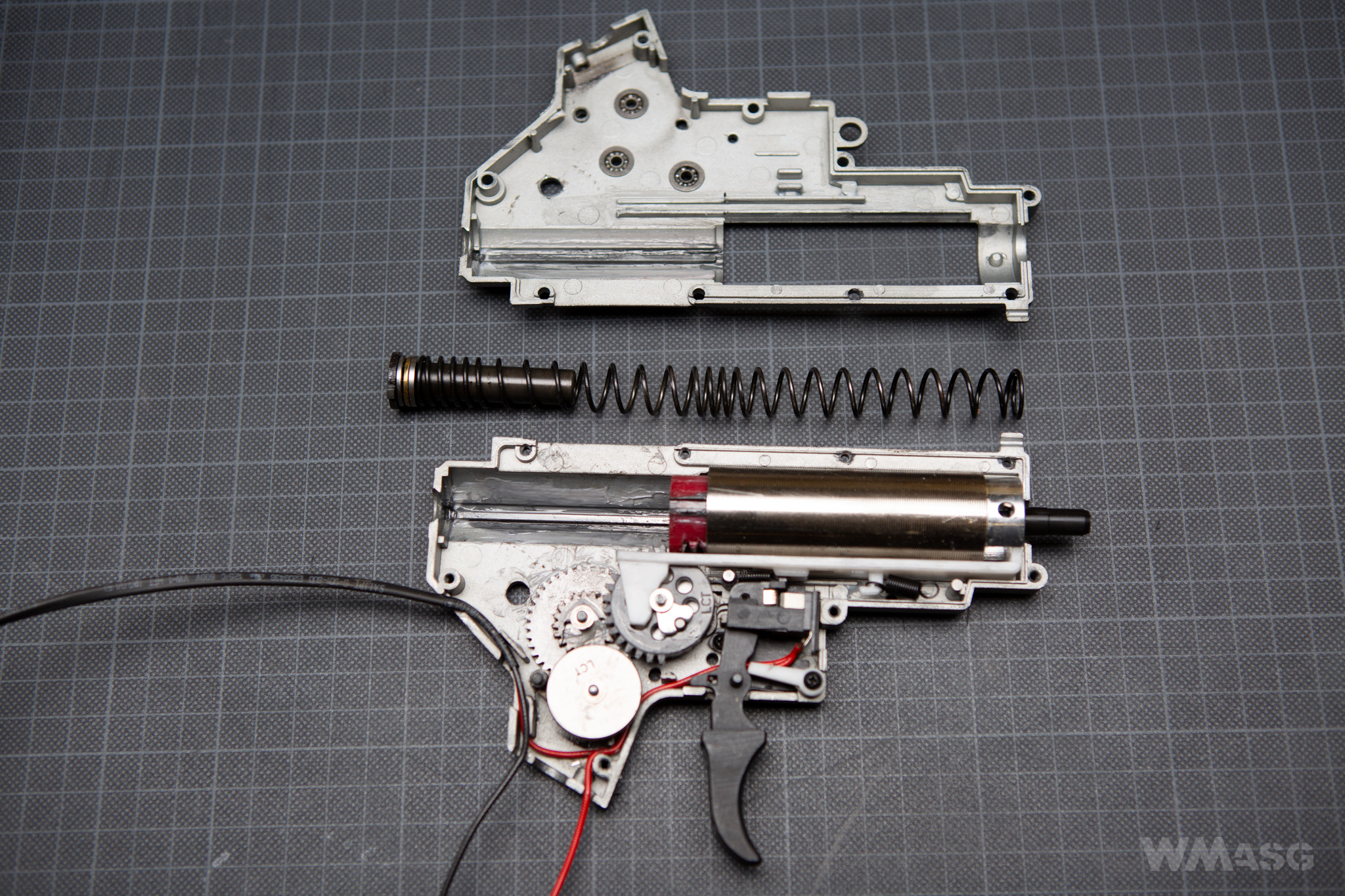

The replica is powered by a V2 gearbox configured in a typical LCT manner. It has a frame without the possibility of a quick spring replacement, but is ready to work with an EBB system.

Inside there gears made of cut steel, mounted on 9 mm ball bearings. Other parts are also of very high quality. The polycarbonate piston has a full set of steel teeth and the cylinder assembly is characterized by exemplary air tightness. Both heads are made of aluminum, and the piston head has a bearing. The bearing can also be found on the spring guide.

The brass inner barrel has a length of 445 mm, so it is almost identical to that of the AK carbine replicas. This is a good basis for any tuning. The Hop-Up is adjusted with a knob perpendicular to the barrel axis as in the all rotary type chambers, which have become a fashion in AR-15 replicas for some time now. This is the same chamber that was used earlier in the G3 replica. We wrote about comfortable and precise system adjustment earlier. The ejection port that remains opened works perfectly.

Target shooting test and muzzle velocity test

During our shooting tests, the replica did well, although its relatively high weight was very noticeable. We also noticed that, despite the fact that the place for the battery was designed in the stock, the center of gravity was clearly shifted forward. In other words, this replica is neither handy nor maneuverable. However, it is a heavy piece of equipment with a durable, even armored structure. In the field, the total range with the adjusted Hop-Uo and using 0.25g BBs (G&G) oscillated around 60 meters. The Hop-Up worked correctly and finding the optimal setting did not cause any problems and did not require too many corrections. The muzzle velocity measured by us turned out to be in accordance with the manufacturer's declarations and average of our measurements was 413 fps.

Measurements results:

(XCORTECH X3500, Open Blaster 0.2 g BBs, ambient temperature of around 14°C, Hop-Up set to zero)

1. 409.7

2. 410.4

3. 411.3

4. 414.7

5. 414.3

6. 413.7

7. 413.6

8. 415.2

9. 415.1

10. 413.8

Average - 413.2 fps, which we have written about above. Spread: 5.5 fps - this is due to the aforementioned airtight system.

Rate of fire using an 11.1V LiPo battery - 17.8 rps.

Target shooting test

(editorial enclosed shooting range, G&G 0.25g BBs, ambient temperature around 17°C, adjusted Hop-Up, distance to the target was 20 meters)

Single fire

Full-auto

Summary

In terms of operation, factory configuration and tuning potential, the replica is by all means good and presents a standard level of all products made by LCT Airsoft. Both the mechanism and the whole replica were assembled very carefully as we did not notice any shortcomings. The standard LCT configuration (selection) for of internal parts will withstand a tuning to the increasingly popular (at least in Poland) limit of 450 fps for assault rifles without any problems. The only part that will need to be replaced is the main spring making the cost of tuning to the upper limit is dependent on the choice of the spring manufacturer and ranges from 20 to about 60 PLN (5 to 14 EUR) - you can't go cheaper than this. And if someone would need more, it seems that the mechanism can also withstand springs generating a muzzle velocity above 500 fps. But remaining with the 450 fps... Tuning a replica to such a muzzle velocity for +/- 50 PLN, which is a small amount of money, it is worth to use the "saved" money to improve the accuracy of the replica. Our tests showed that it is not bad, but since mechanical tuning was can be done extremely cheap it is also worth considering installation of even a simple mosfet.

The looks and ergonomics of the HK33 are a different matter altogether and a strongly debatable at that. But in most cases, we choose the replica primarily for its looks, also taking into account what association one has with the original weapon. Therefore, if someone has already paid attention to HKG33 then the decision to buy it will definitely be a good one.

We tested the replica thanks to the courtesy of

On the next page - technical details