| Model: | Arcturus Centaur B | Muzzle velocity: | 402.17fps |

| Weight: | 3666g (3839g with the magazine) | Hop- Up: | present, adjustable |

| Pros: | + modern, ergonomic design + 2 magazines in the set: a hi-cap (320bb), a mid/real-cap (130/30bb) + many steel parts, including the sights base and the butt stock mount + 6.01 (+/- 0,01) mm inner barrel + quick spring change system + a microswitch that replaces the traditional switch | ||

| Cons: | - low quality butt stock | ||

First impression

The replica comes to us in a cardboard box with a large ARCTURUS logo on the front and a Dedicated For Collectors slogan below. On the side of the box there is a small sticker representing the replica. Inside the box is the replica witch lies in protective foam, with the flip-up sights folded, together with two magazines and a manual.

The replica makes a pretty good impression. Design nods to the Masada (currently known as the ACR) can be seen at at first glance. The manufacturer himself states that the inspiration for the carbine was to combine the reliability of the AK with the ergonomics of the AR-15. The weight of the replica is 3666g (3839g with the magazine), thanks to which we feel that we are holding a well made piece of metal in our hands. Everything is very well put together, we have not seen any major slack.

The receiver

The stamped receiver is made of steel and has a classical design, known from the AK rifle, lacking the side rail. The big advantage of the replica is the use of such a large number of steel elements. Another good news is the presence of the steel butt stock mount and a steel base of the sight. Other steel parts include the gas chamber, the safety selector lever, the magazine latch and the trigger. The dust cover is non-standard: it is connected to the gas tube cover, both of which are was made of aluminum using CNC technology and anodizied. The dust cover took on more aggressive, modern look, the rounded edges were turned into sharp ones resembling the receiver of the SR. In the upper part you will find a Picatinny rail that stretches across the entire top of the replica. The charging handle is made of steel has not been modified. It has a traditional shape and the same principle of operation. Let us hope that the tendency of the manufacturers to use steel parts instead of the dubious quality aluminium alloy, for which we had to deal with for quite a long time, will be permanent.

The front grip

A modern front grip, transforming the replica into the next incarnation of the classic AK rifle, is made of aluminum in CNC technology. The manufacturer has used the M-lok mounting system for attaching equipment on the sides, as well as traditional Picatinny rails at the bottom of the grip and above the gas tube. The front grip has an engraved Arcturus logo and a serial number in the place where it connects with the receiver.

The butt stock

A copy of the butt stock, inspired by the one used in the Masada (ACR) rifle, fits perfectly with the silhouette of the carbine, completing the design as seemingly completely new rifle which, at first glance, is difficult to associate with the canon of the AK family. The butt stock's length can be adjusted in six positions and the cheek pad in two-position. To pull out the butt stock you just need to pull it harder. Unfortunately, folding it is not so easy: the buttons for adjusting the length are placed on both sides of the butt stock and you have to press them simultaneously while pushing the butt stock, which can be very uncomfortable. The whole butt stock folds to the side, which facilitate transportation of the replica and will be helpful when using it in tight spaces. The pin in the hinge has, unfortunately, a tendency to slip down, so it is advisable to take notice of it from time to time, especially during frequent folding and unfolding of the butt stock as it just might get lost.

The safety selector lever

A very comfortable steel safety selector lever has a special tab that allows you to quickly change the firing mode. In contrast to the classic selector design, the fire mode can be changed with one finger, without letting go of the pistol grip. Unfortunately, the selector is operated with great effort, so changing the mode with one finger can be difficult. You have to loosen the screw on which the selector is mounted, but not to much so that it does not turn loose while using the selector lever. Thread glue will be helpful in doing this right.

The sights

Because of its modern design, the replica has plastic, mechanical flip-up sights. They can be unfolded by pressing the small two-sided tabs from the top or side. An interesting option is the possibility of using the sights in the folded position.

The external barrel and muzzle break

The external barrel was made of aluminum. At the exiting end it has a 14 mm counterclockwise thread. The muzzle break, inspired by the SLR SYNERGY BCF AK muzzle brake, was made of steel. The external barrel also has a steel dummy gas block and a mounting for the front grip.

The pistol grip

The polymer pistol grip is a copy of MAGE MAG's MOE AK + GRIP. The grip itself is large and comfortable. It has smooth sides and anti-slip ribs on the front and back. At the bottom, similarly to the original, there is a flap to access the storage compartment. Here, however, this is just a screw plug that connects the grip to the motor housing. The manufacturer decided to use an Allen screw, which seems to be the most sensible choice, especially after all the problems with self unscrewing Phillips screws of dubious quality.

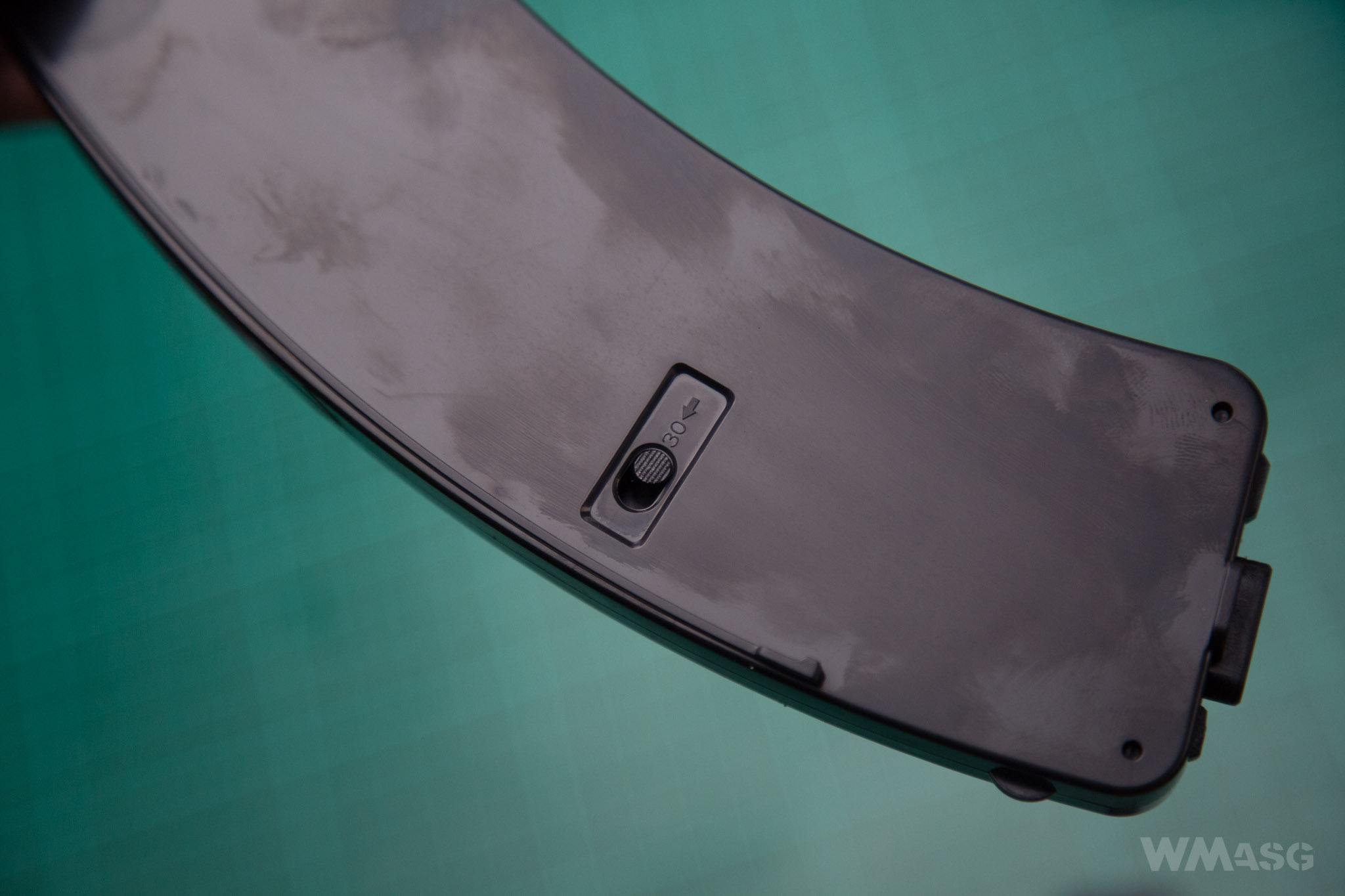

The magazine

It is rare for two magazines to be delivered with a replica, even more so if they are two different ones. Yet this is the case with this replica. Moreover, one of them has two modes: a mid-cap and a real-cap mode, which means that at the beginning we have access to every kind of magazine available on the market. Both magazines are copies of well-known P-mag AK magazines by MAGPUL. One of the magazines is a traditional hi-cap with the wounding wheel at the bottom, the other has a very interesting option of changing its capacity from 130 to 30 BBs. Changing the capacity is done very quickly: just dismantle the bottom plate by pressing a button at the bottom of the magazine. Then we slide the bottom plate back and we are able to pull out the BBs feeding mechanism, and there, on the side, is the magazine capacity switch. Access to the loading spring disassembly system is also located there. Thanks to it, we can quickly and easily clean the magazine without its complete disassembly.

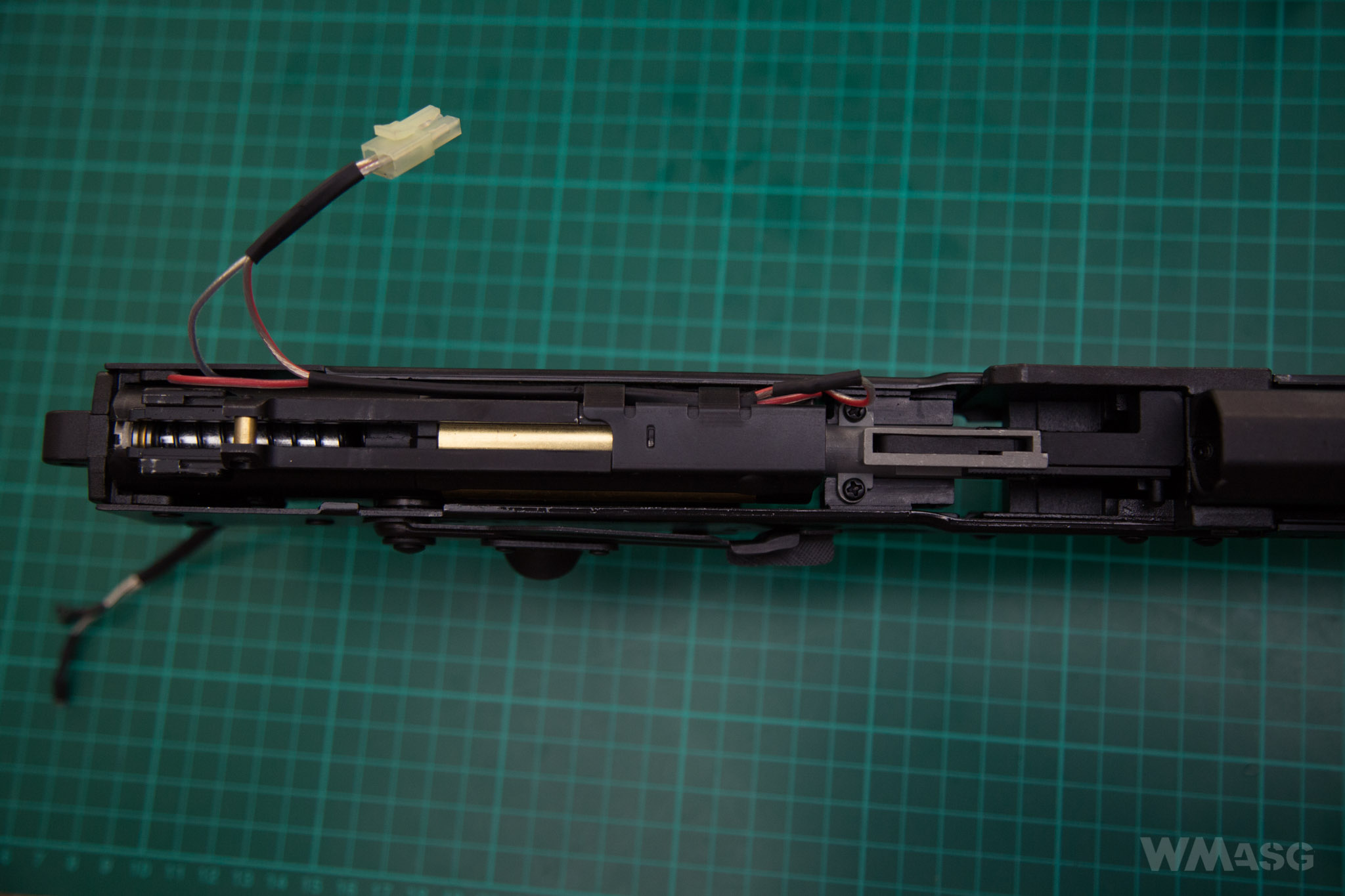

Disassembly

Despite the fact that the design of the replica is based on the standard AK by VFC, it is slightly different. In order to remove the dust cover, we remove two pins: one near the base of the sight, the other - at the height of the butt stock latch (there are two pins there, one of them is used to dismantle the butt stock). After this operation, the rest is practically the same as in the traditional system, i.e. we disassemble the pistol grip by unscrewing the screw at the bottom of the grip (under the flap). Next, we disassemble the safety selector lever, the L shaped block which presses the hop-up chamber to the gearbox and we can pull the gearbox moving it backwards and up. At the same time, we have to watch out for the safety selector mechanism, which sometimes likes to lock inside the receiver which makes it difficult to pull out. Then unscrew the two Allen screws located under the base of the sight, then take out the pin and slide the front forward. To disassemble the hop-up chamber, it is still necessary to unscrew it from the plastic mount.

The hop-up chamber

The metal hop-up chamber was made in the VFC standard. To get to the hop-up bucking, pull out the plastic inner barrel stabilizer and unscrew the bar of the spacer lever in the upper part of the chamber. The spacer is a standard, rubber, hollow cylinder. The replica has a black hop-up bucking of medium hardness and a standard BB spinning nub. When pulling the inner barrel out of the chamber be careful not to accidentally damage the bucking as it sits quite tightly inside.

The inner barrel

Another surprise is the PCPGrade Extreme Percision inner barrel, which was made of steel. According to the manufacturer's information, its diameter is 6.01 mm (+/- 0.01mm), the Polish distributor reports that it is 6.02 mm. We learned, however, that it was exactly the same barrel. As you will see later, the barrel gives very good grouping and repetitiveness of shots. It has a length of 430 mm, has been beveled at the exiting end and is finished using QPQ Processed technology.

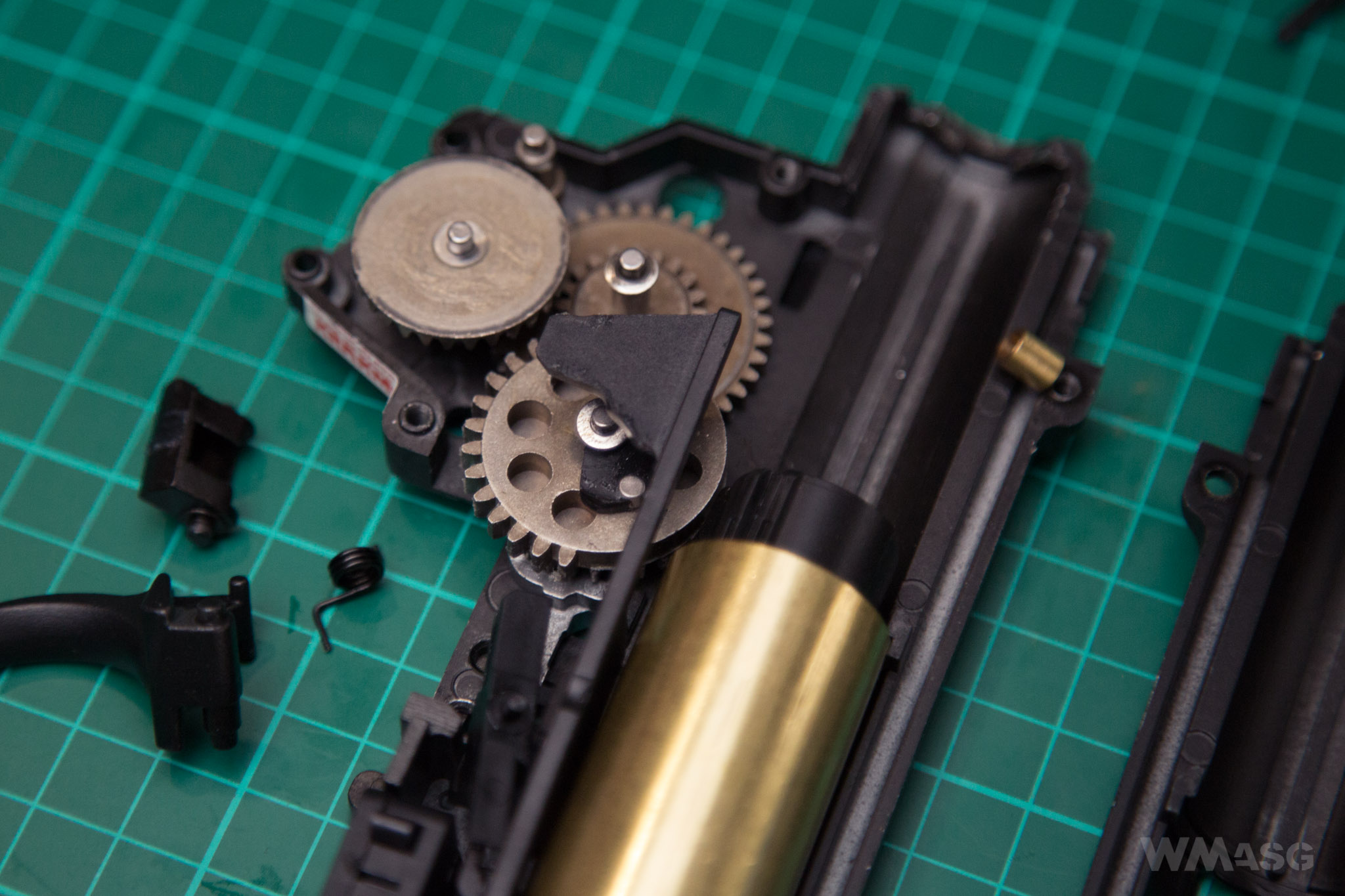

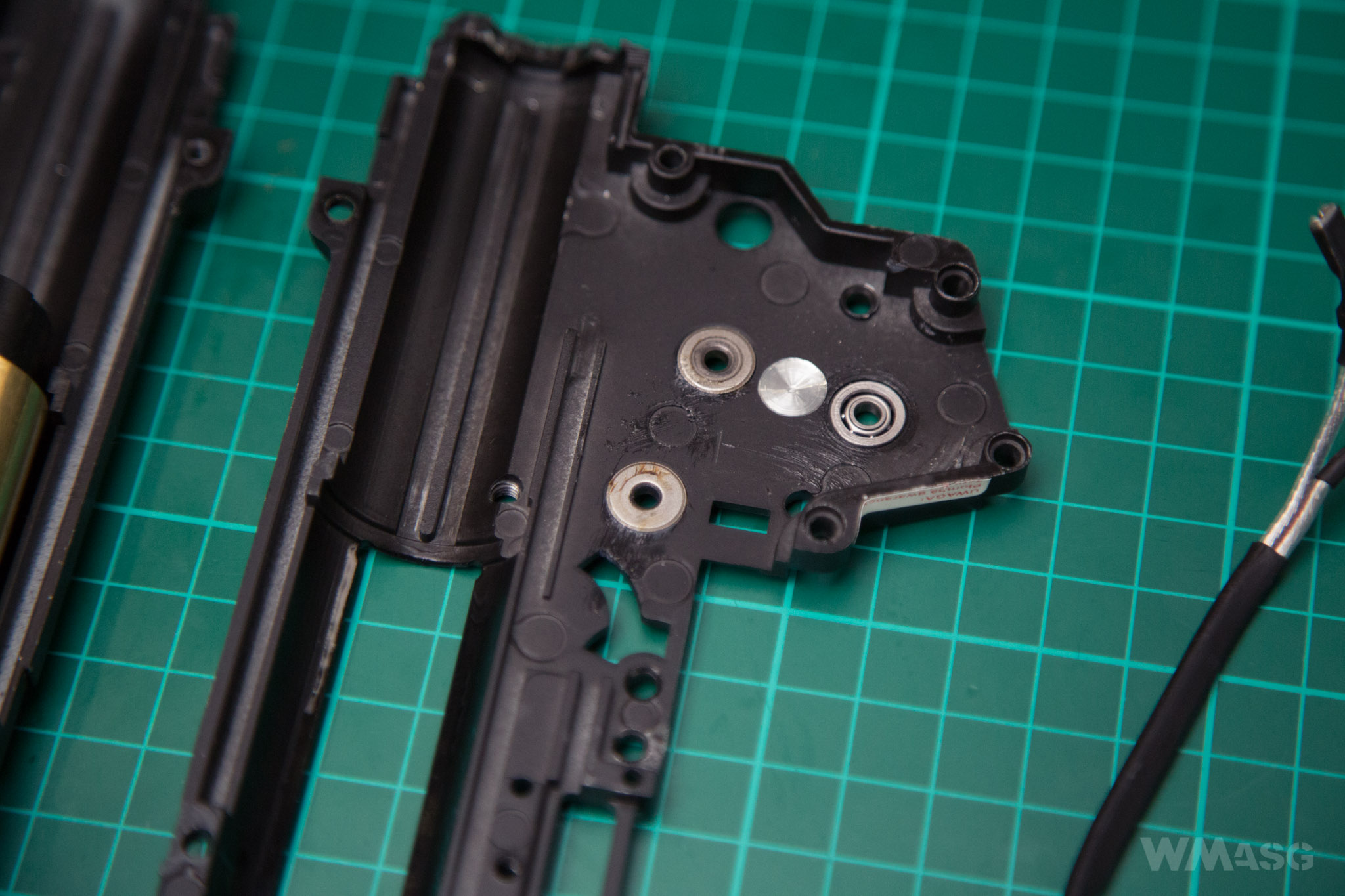

The gearbox

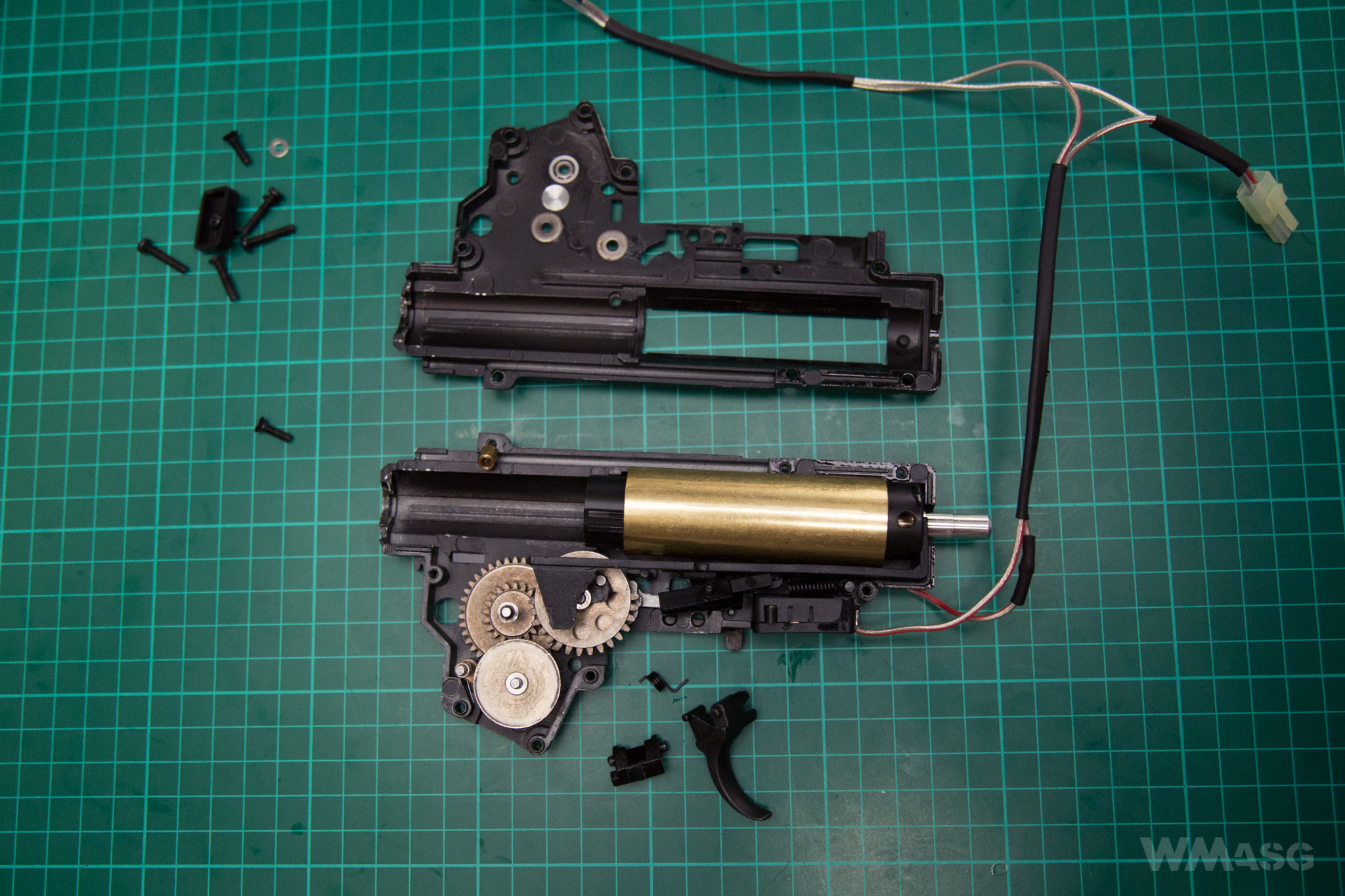

The replica uses a modified V3 gearbox. It has reinforcements in places where cracks occur most frequently and is beveled in places where right angles usually are, which serve to evenly distribute pressure at the front of the gearbox and reduce the likelihood of it cracking. The gearbox has the ability to quickly replace the spring, unfortunately, to use it, we will have to pull it out of the body, and for this we need to do it in workshop conditions. The frame, made using Zinc Die-Casting technology, is taken apart by pulling out the plastic cover of the bevel gear located near the trigger and the steel, shortened top plate, and then unscrewing 5 Philips screws.

The pneumatic system

The replica uses a brass type 0 cylinder. It has a polymer piston and on it a polymer piston head with a full bearing. The standard cylinder head sealed using a single o-ring is also made of plastic. The nozzle is, however, made of aluminum and also has an o-ring. The reinforced (according to the information from the manufacturer) tappet plate is made of plastic and fulfills its function well. The spring guide is metal and has bearings. The spring used in the replica is the declared to be an M120, which allows you to achieve a muzzle velocity of 420 fps.

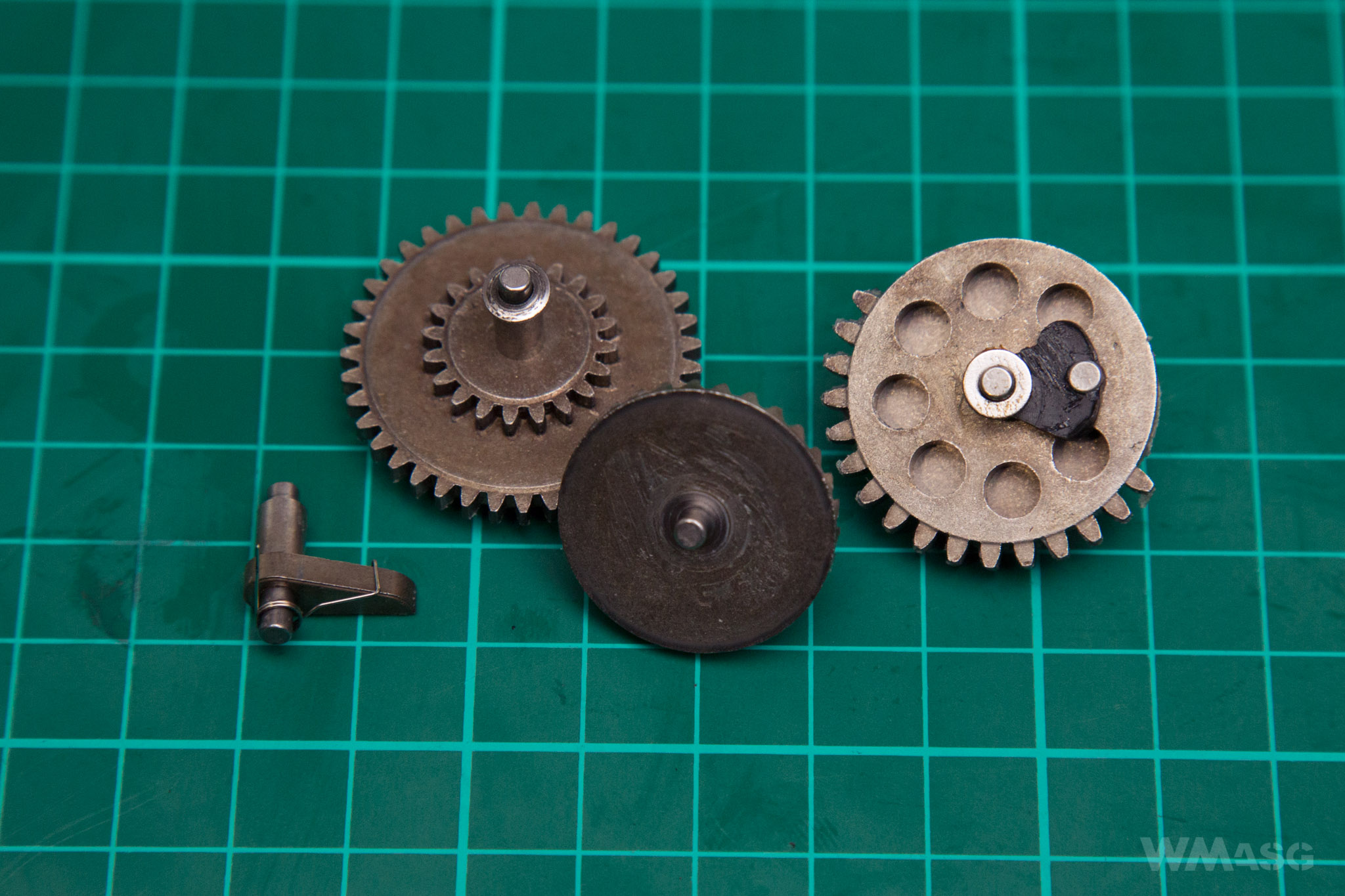

The gears

Reinforced steel gears, used in previous models by this manufacturer, are of good quality and should easily deal with an M130 spring. They rotate in 7 mm bushings.

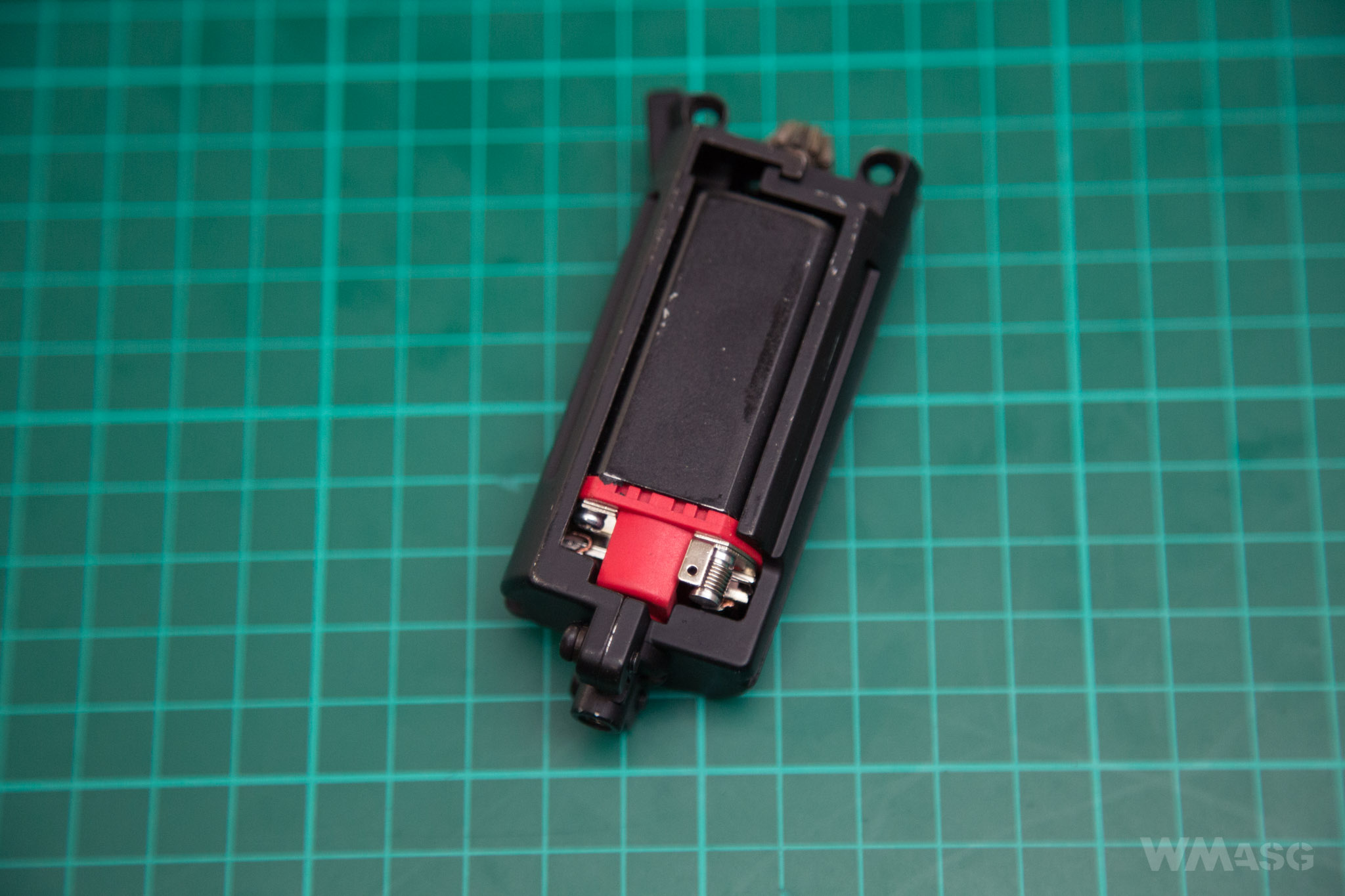

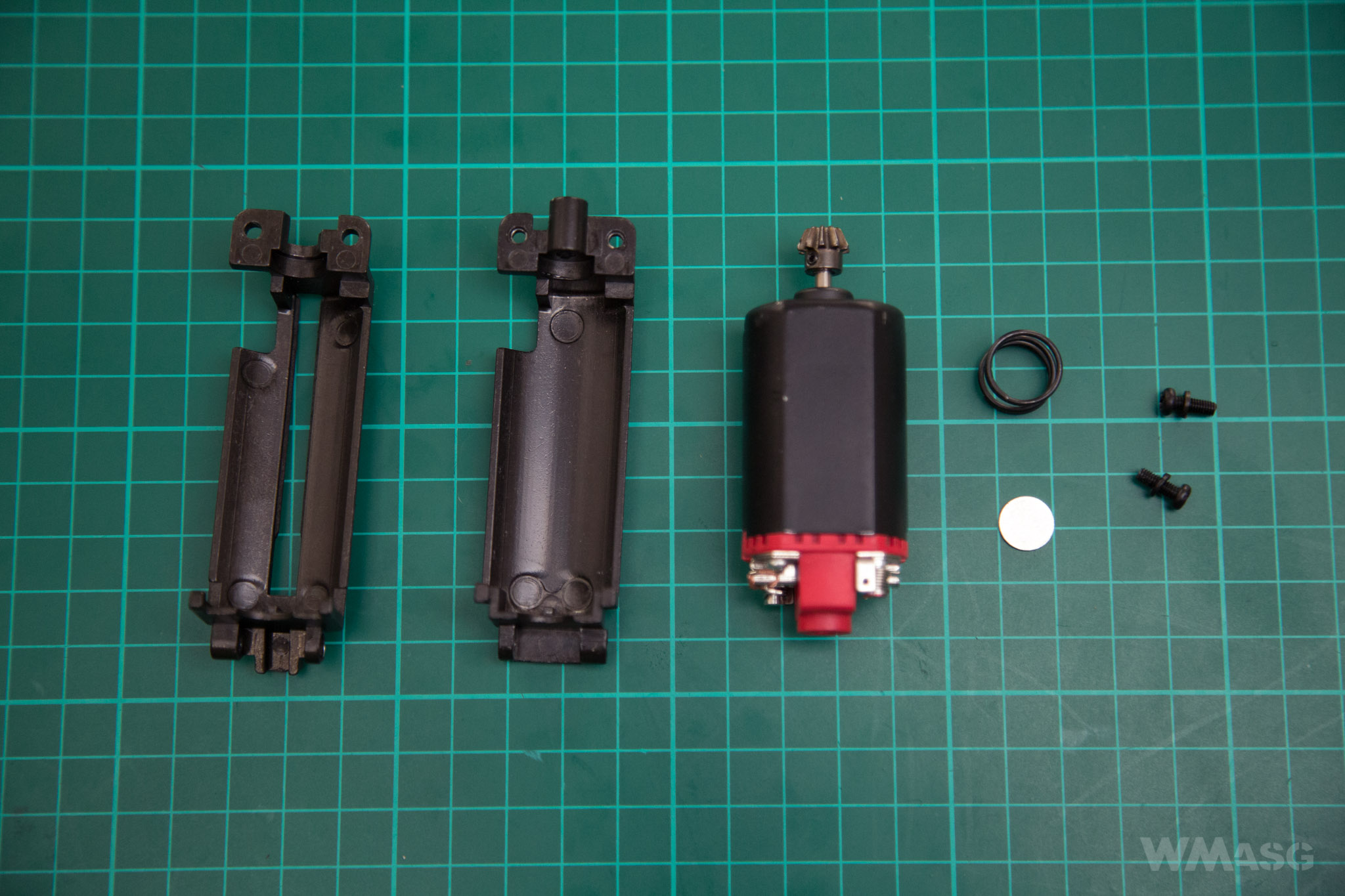

The motor

The short type motor used in the replica does not have very strong magnets. It is a pity considering the fact that the earlier models of Cyma has stock motors with neodymium magnets that worked really well with strong springs. The motor itself is in a metal housing and in order to get to it we first have to unscrew the housing.

Muzzle velocity

Below we present result of our muzzle velocity test of the replica using the XCORTECH X3500 chronograph (the test has been carried out right after the replica was taken out of the box), :

Arcturus Centaur B AEG

ROF 12.7 (NiMH 9.6v 1100mAh)

404,3 fps

405,6 fps

404 fps

403,4 fps

400 fps

399,7 fps

401,4 fps

402 fps

401,4 fps

399,9 fps

Average: 402.17 fps

The manufacturer states a +/-2 fps difference between shots, which was very close to the results produced by our replica.

Grouping

Below are the results of a grouping test of the replica at a distance of 15 m. The Hop-up was set to 0 and shots were fired from a support in an enclosed space.

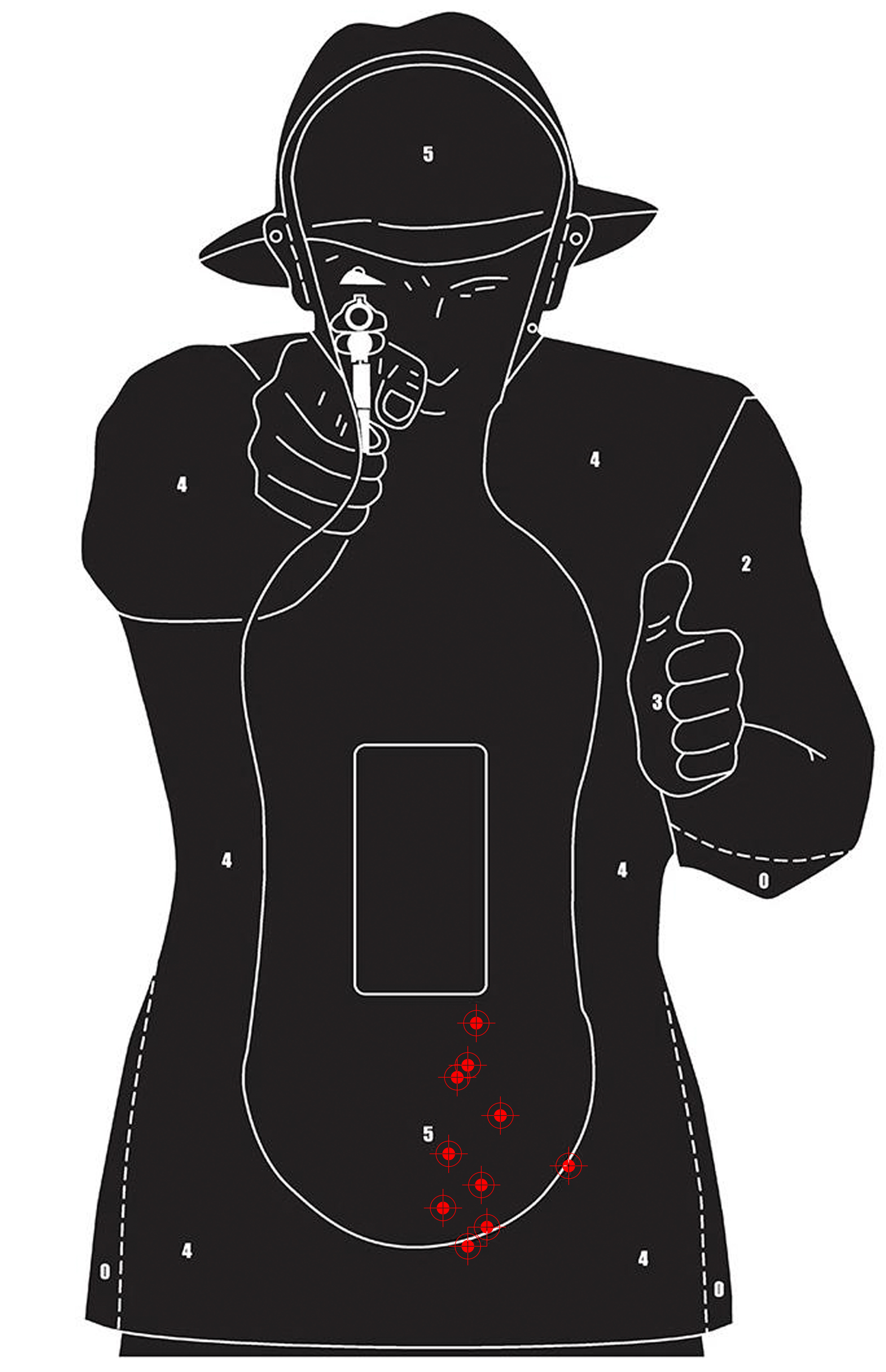

Single fire

The replicas has very good grouping. Hits were placed to the bottom and right off the center of the target with the 5 cm horizontal and 9 cm vertical grouping.

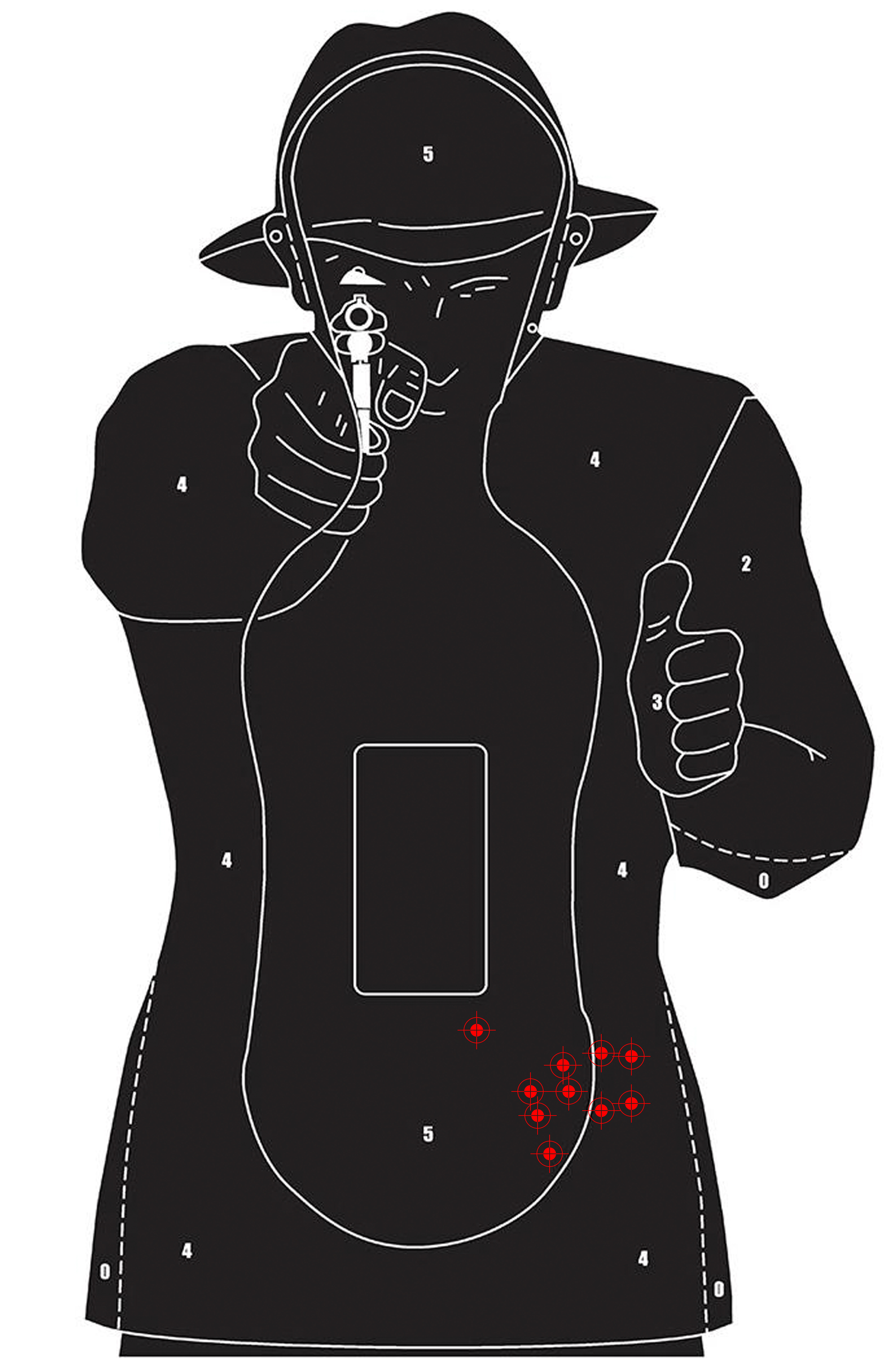

Full auto

Similarly as with single fire, the results were very good: vertical grouping is better than horizontal. Hits were placed to the bottom and right off the center of the target yet no BB aligned with the centre of the target. Despite this, as shown on the photo, hits have very tight groping being 7 cm apart horizontally and 5.5 cm apart vertically.

Using the replica during an airsoft game

I can not say that the replica surprised me, rather proved that what has inside results in great performance. Target shooting already showed good grouping and repetitiveness of shots, and during an airsoft game I became convinced that the BBs were flying in a very stable, flat trajectory, went far and exactly to the place where I want to send them. Using the terminology of the world of firearms, I had the impression that we are dealing here with a great candidate for a DMR. Another issue is easy of use: the replica great to hold in one's hands, which add to the precision of shots. The linear arrangement of the barrel with the butt stock may not add to it as much as in the case of a real firearm, but after putting the rifle to the shoulder, I felt the ergonomics characteristic of the AR-15 standard. I am an enthusiast of light front grips, especially in ASG, and here the use of an aluminum barrel is, for me, a very positive trait. At out office, someone rightly pointed out that if a steel external barrel were to be used, the center of balance would move forward, making the carbine more realistic and, in theory, it would have a smaller "recoil" (if you can talk about that in an AEG at all).

Summary

Arcturus is another example of the fact that the AK system is still developing and you can go even further than our native Beryl, refreshing, modernizing and, above all, improving the functionality of the legendary design. This one draws a handfuls of modern rifles' solutions, improving its ergonomics and functionality. The replica itself looks great, the manufacturer took care of virtually every part of it: the inner barrel is already a precision one in the stock version, the ability to quickly replace the spring, steel teeth of the piston, the microswitch, anodized, abrasion-resistant external components, two magazines in the set, of which one with the mid/real-cap option - all this adds up to the image of a great replica. There are some things that can be picked at, like the heavy working of the butt stock length adjustment and its hinge pin, which likes to spontaneously pop out. There is also a lack of sleds preventing one from inserting the magazine the wrong way, but we quickly forget about these details when we see how accurately it shoots. In summary, Arcturus Centaur B is a great solution for those who love the AK system and a modern, ergonomic style, known for the AR-15 designs.

We would like to thank Taiwangun.com for making this review possible