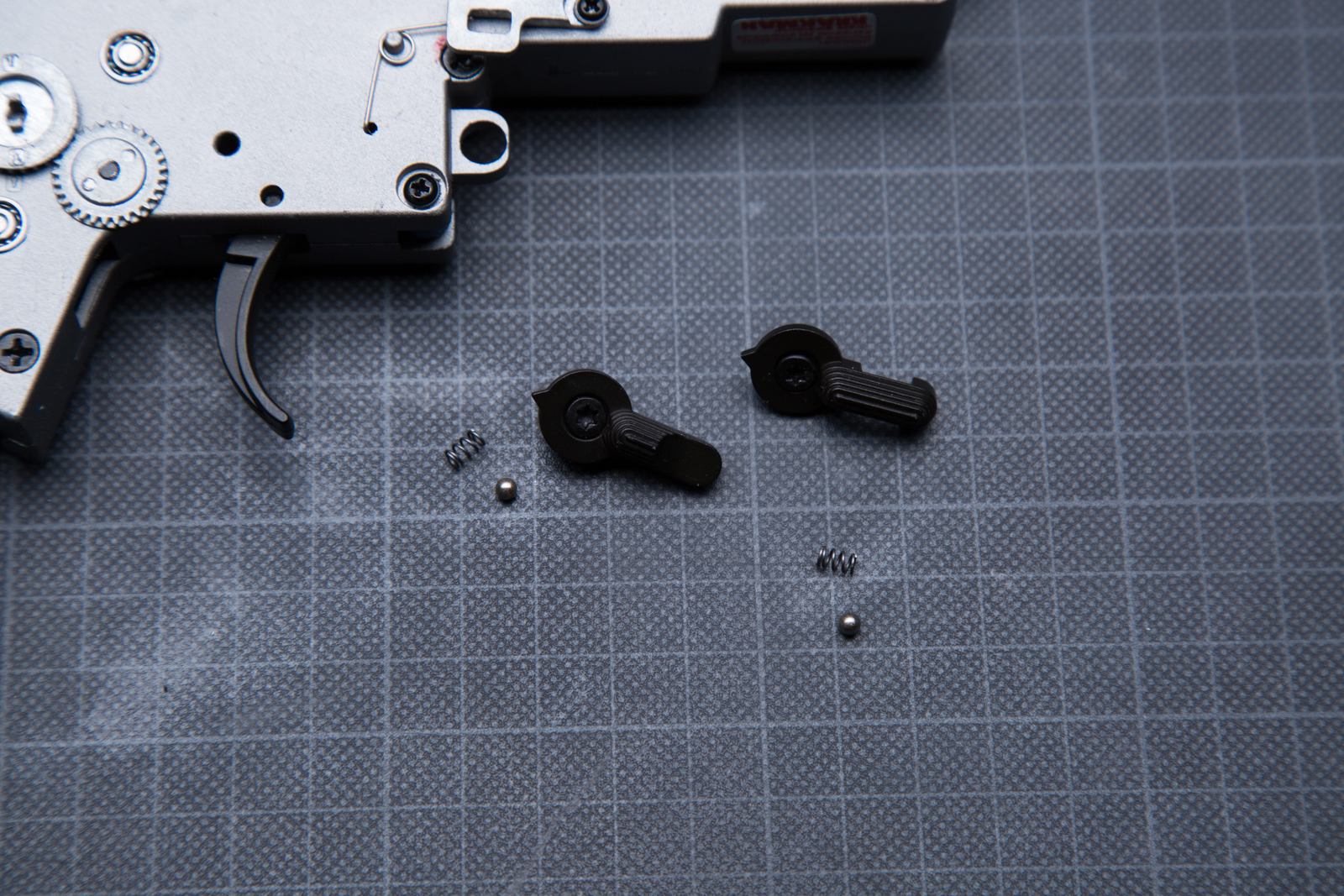

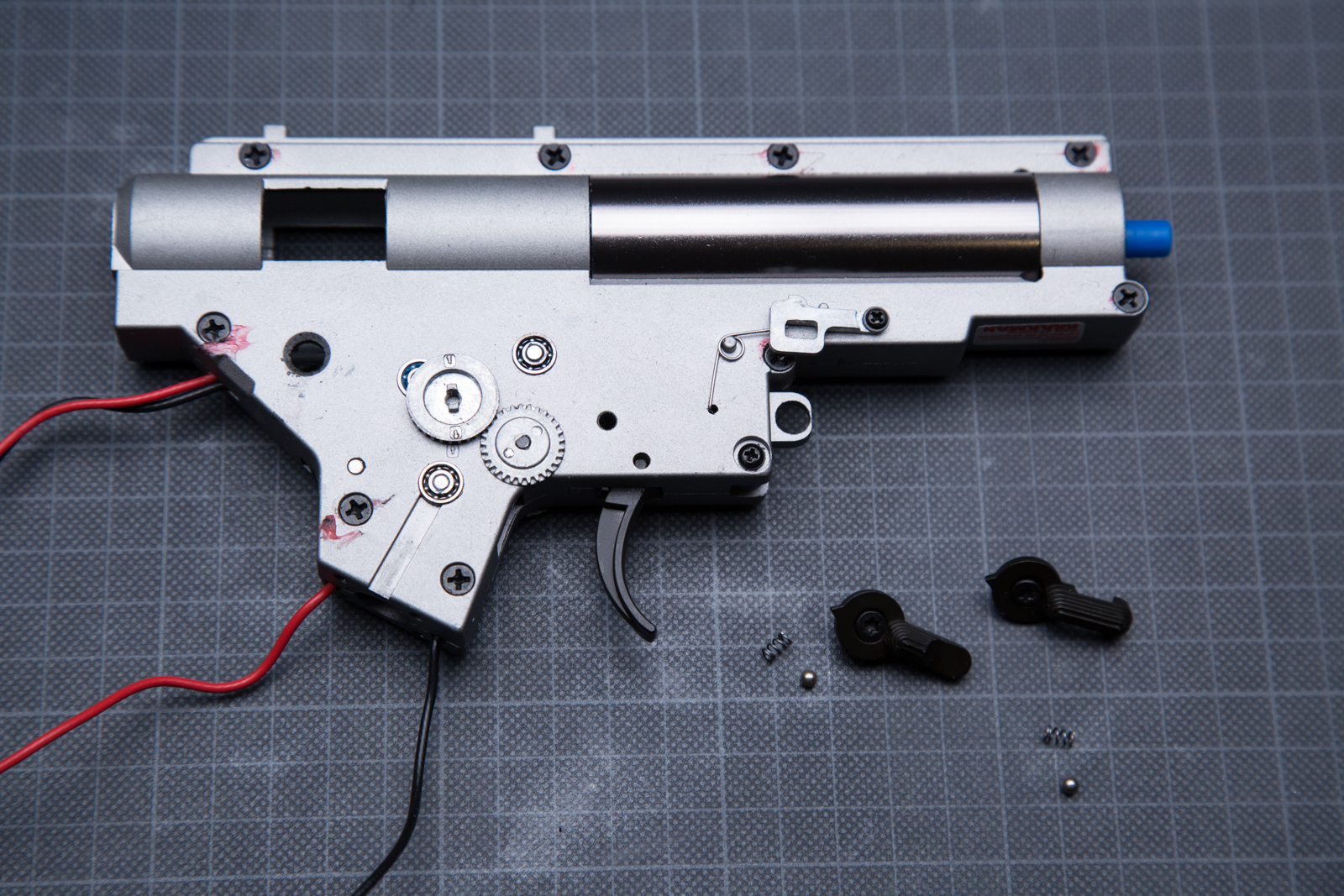

The safety/selector switches

To remove the mechanism from the lower receiver, both switches must be removed. It is easy because they are screwed from the outside. Just watch out for the springs and the small steel balls.

The frame

Visually, it looks very good. There are no mold marks and the texture resembles top brand products of more expensive manufacturers. The front corners of the cylinder port have been rounded to improve the distribution of stoke force. The small screw in front of the trigger, which is a part of the mechanical trigger safety, requires unscrewing, otherwise one will not be able to open the gearbox. Similarly, the dummy bolt carrier should be removed as it hinders access to one of the screws connecting both halves of the frames. The gears transmitting the movement of the safety/selector switches are made very well. When inserting the mechanism into the lower receiver we have to set the selector plate in the semi-auto position, then the rectangular cutouts in the small gears are set vertically.

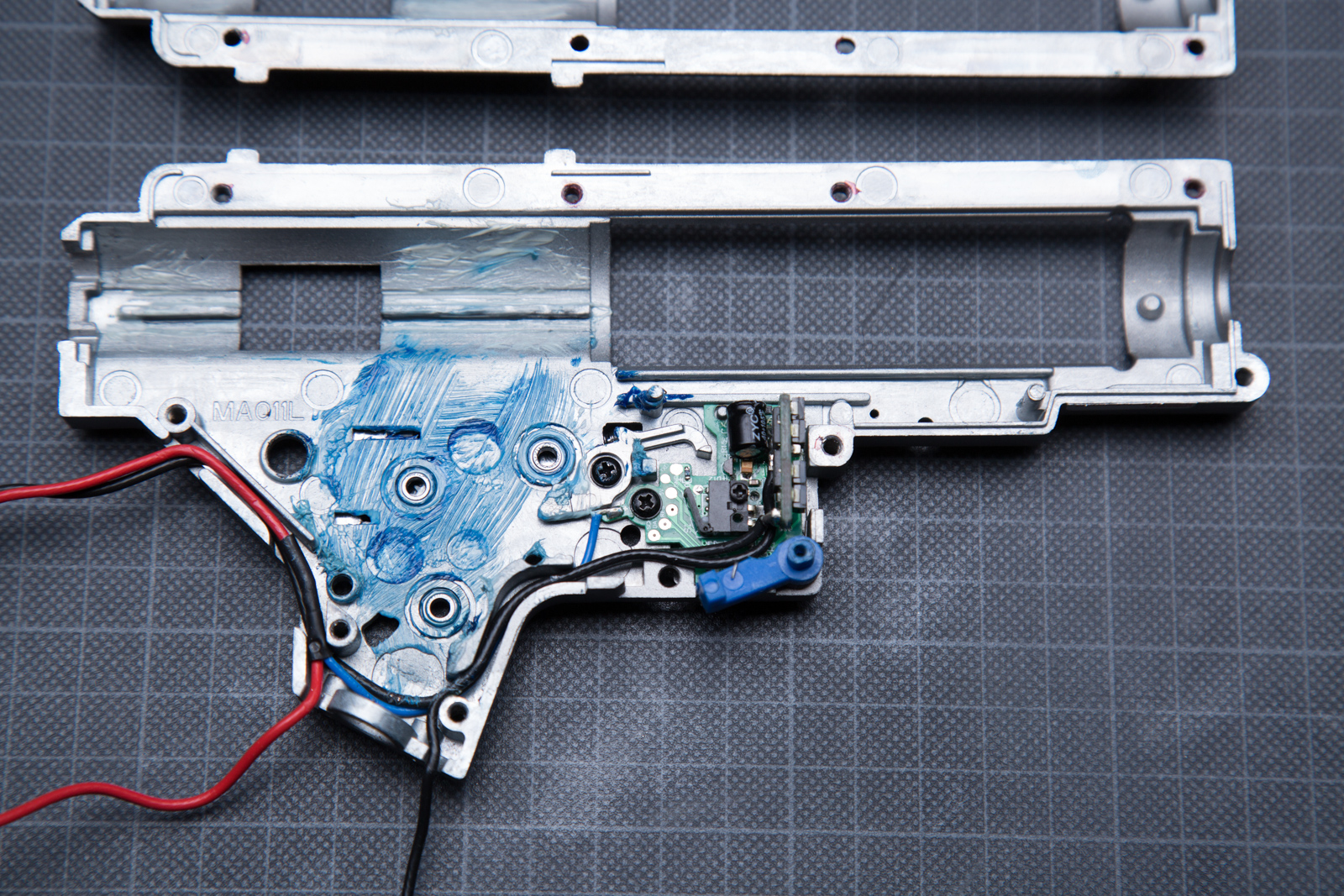

There is too much grease inside and it can stick the gears together and increase the drag, and thus power consumption.

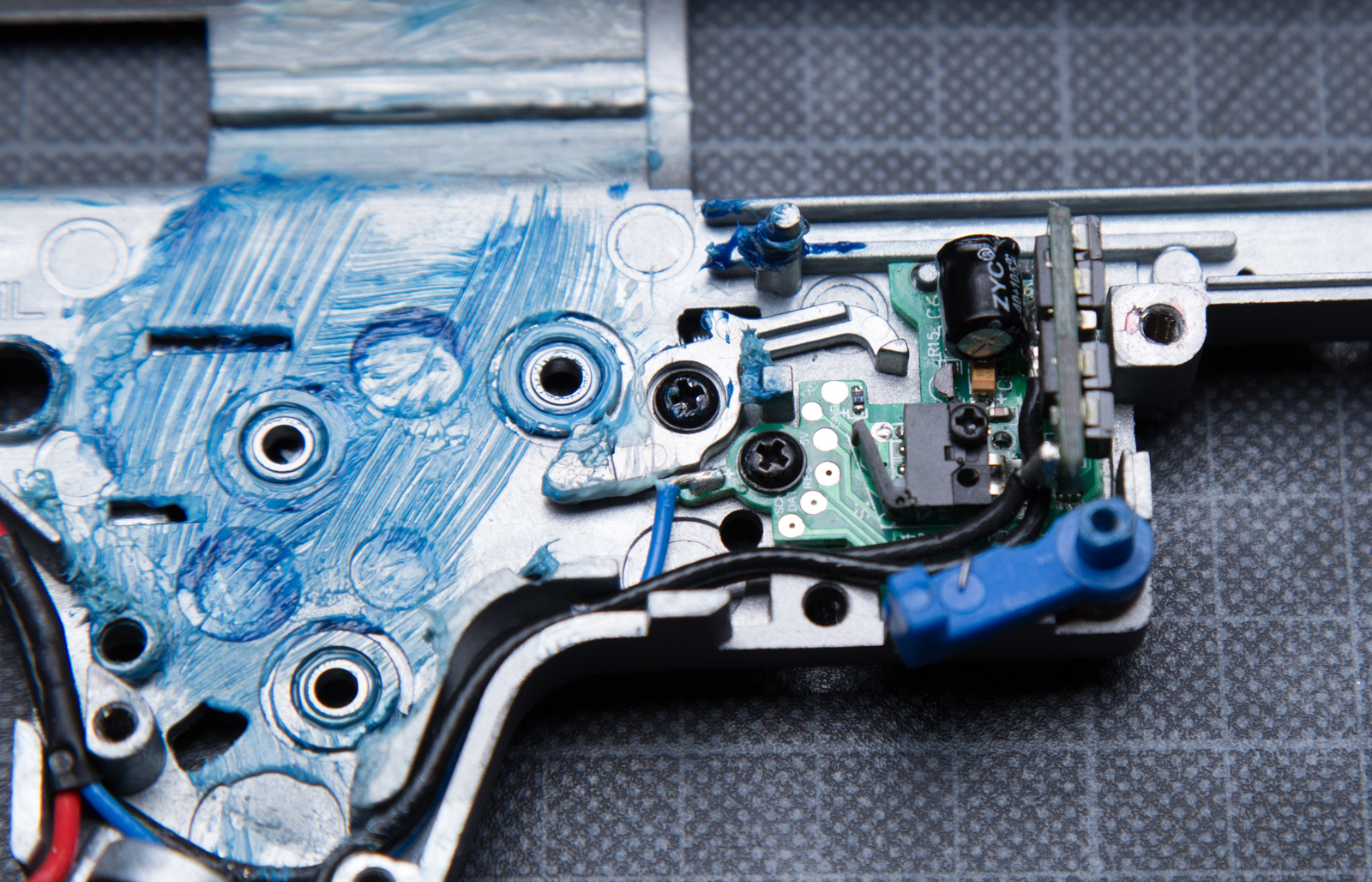

The electronic system with a microswitch, already known from the CM.097.

Luckily, it works with a standard-shaped trigger. So the path for using aftermarket, vertical speed triggers is open.

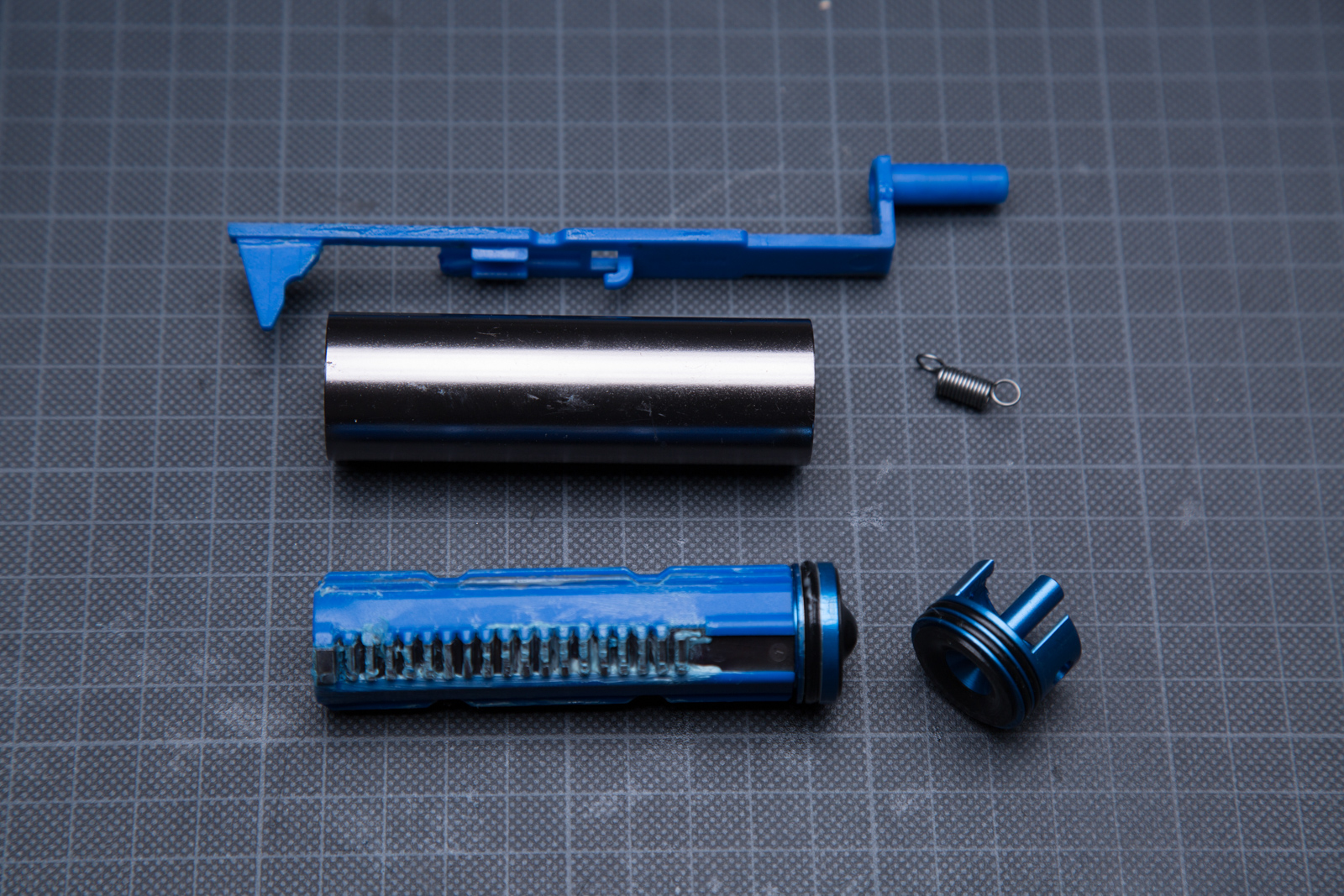

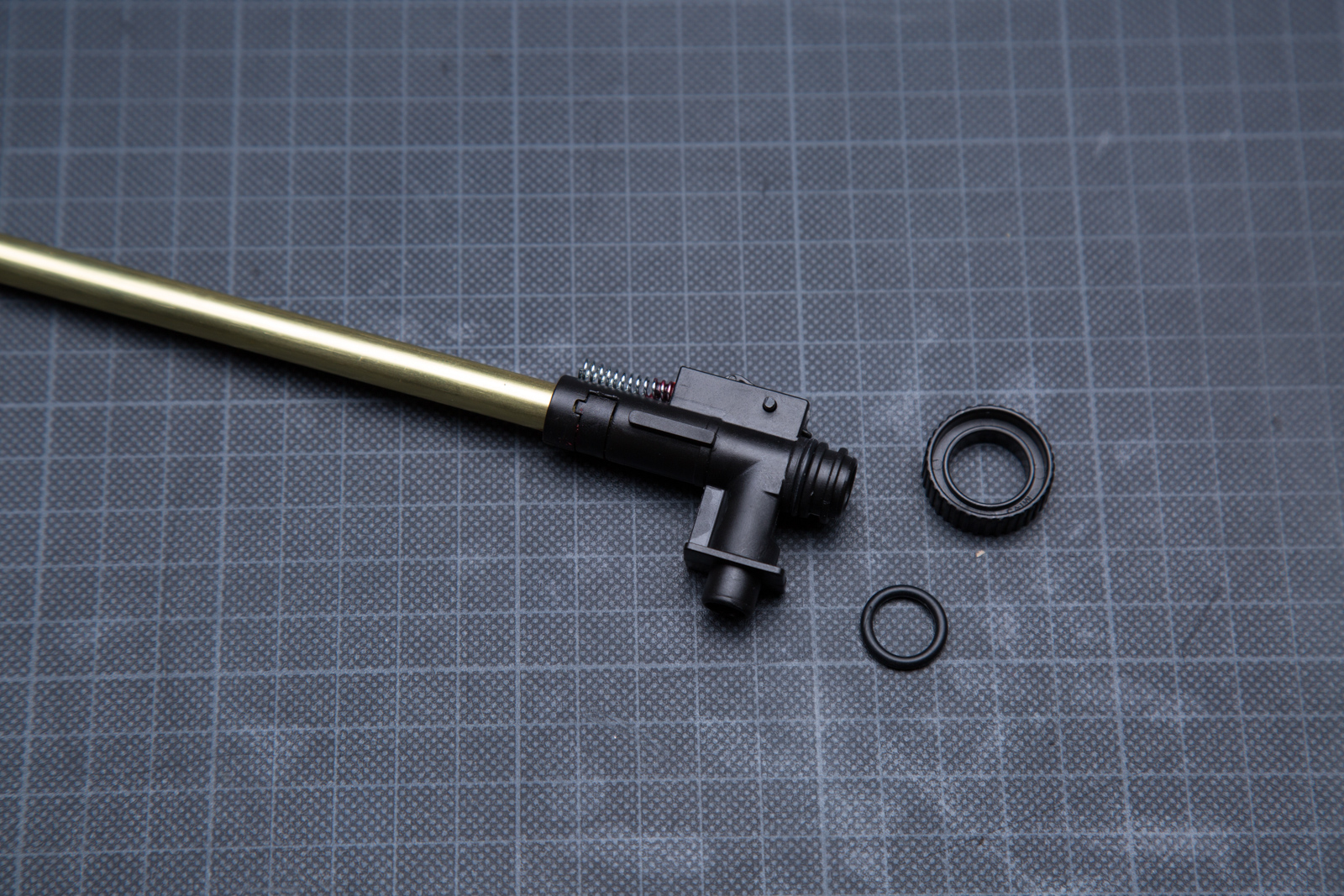

Reinforced pneumatic system parts

The cylinder and piston heads are "silenced", which does not have a significant impact on the sound of the shot, but slightly extends the life of the frame. And anticipating any question - no, this is not a bore up set, it has standard diameters. The cylinder head has a double O-ring and the piston head has a ball bearing. The extended piston has a complete set of full-width steel teeth. The whole system is characterized by correct, but not stunning air tightness. The weakest part is the nozzle which does not have an O-ring. By replacing the nozzle you can get a significant fps increase.

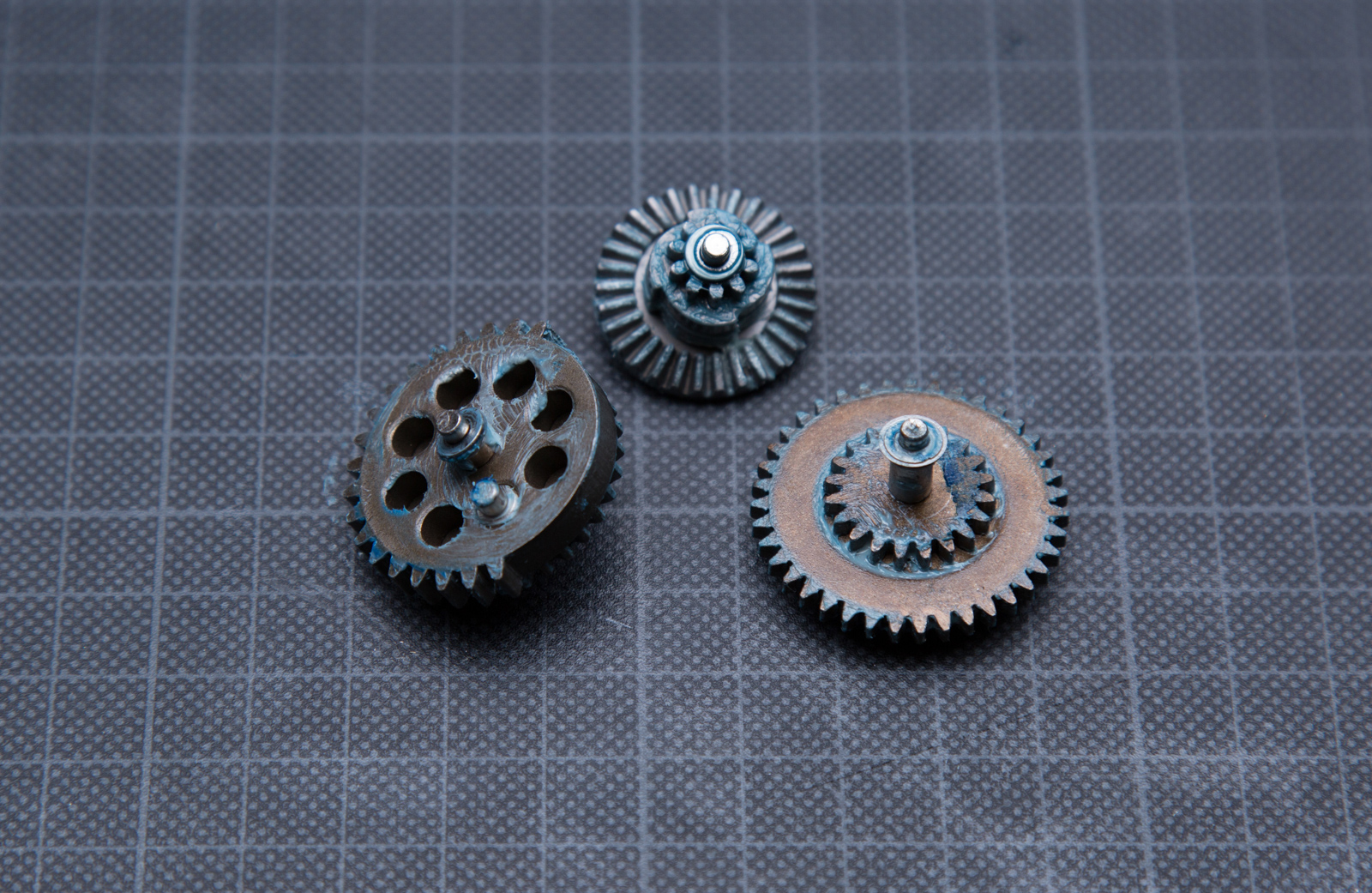

The gears

The are made in the traditional sintering technology. They are not distinguish themselves with anything, except that it is a set dedicated for an extended gearbox. If you want to change them, you need to look for such a set. We tested them using an M150 spring. The replica operated without any disturbing symptoms. However, we fired too few shots to be able to say that "they work with stronger springs". Excess grease could cause a decrease in the rate of fire and increased power consumption, but the gears have as much grease on them as needed.

The main spring ans the spring guide

The characteristic guide is mounted (screwed) into the lower receiver. The working part is identical to the standard guides. You could probably use a standard one, but this would involve replacing/modifying the stock guide.

The factory spring had a slightly squeezed last coil. Because of this, it got stuck on the guide, preventing the bearing from working. A trivial problem solved with pliers and a file.

The motor and the pistol grip

The wires are routed slightly differently than in most replicas. The motor's negative connector is at the front, the positive is at the rear, from the side of the stock.

The motor itself does not bear any significant markings, but the manufacturer describes it as high torque. It's neodymium magnets are strong therefore rotating the shaft with your fingers is a bit difficult, although there are certainly more powerful motors on the market.

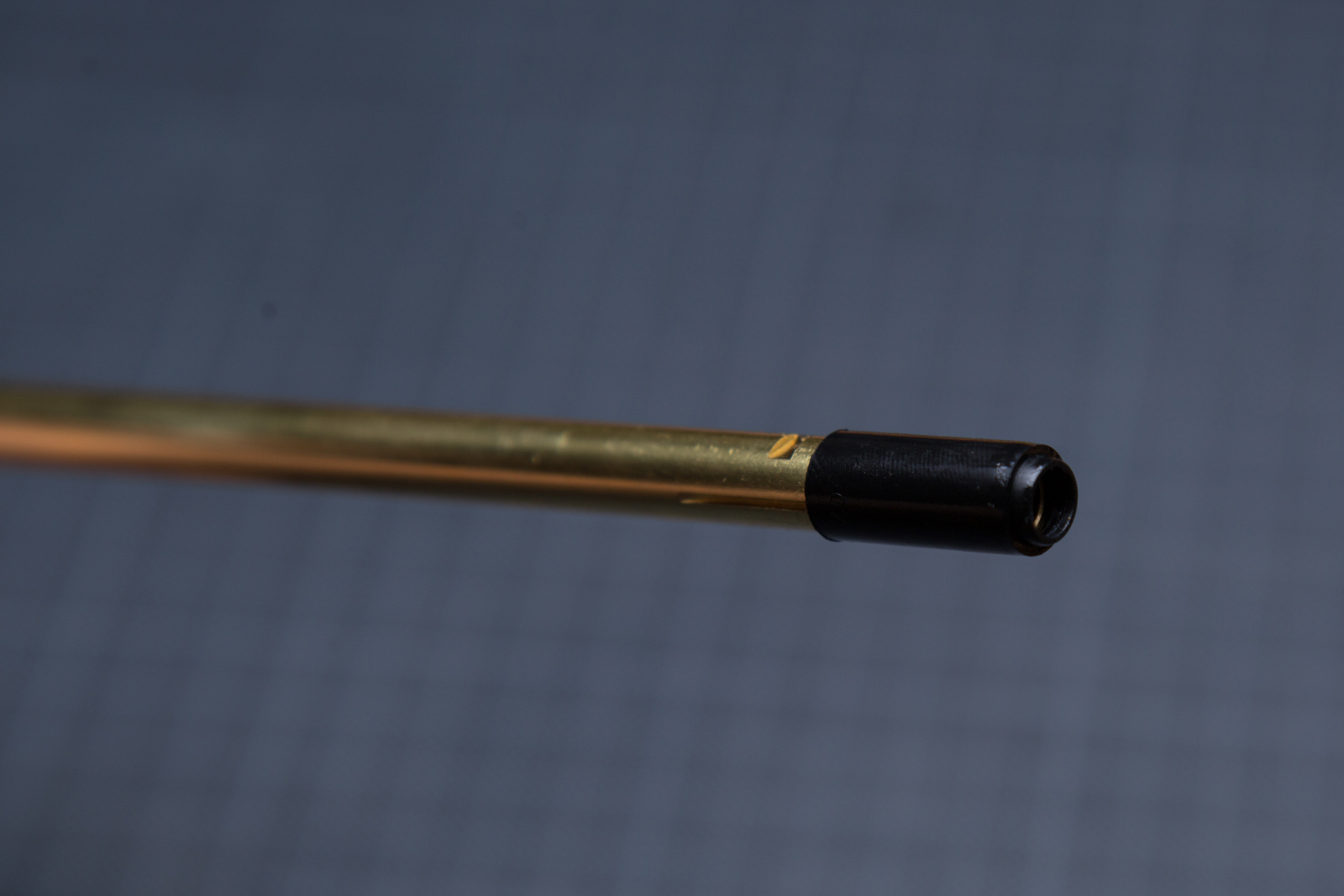

The HopUp chamber and the bucking

The chamber, already described on the first page, has an adjustment ring placed in a plane perpendicular to the axis of the barrel. The ring is secured with a rubber O-ring. This is a good solution, because in other chambers of similar design, plastic clips holding the ring are prone to breaking during disassembly. The chamber is different than the one used in the CM.097X models. There it was metal, with adjustment done using a classic gear system. The one in the CM.098 is made of plastic.

The HU bucking is standard but the spacer is different. This innovation seems sensible and justified. We'll see how it works in the long run.

What's important, the atypical pressure arm should easily work with other spacers, including flat ones dedicated for flat hopups.