The design

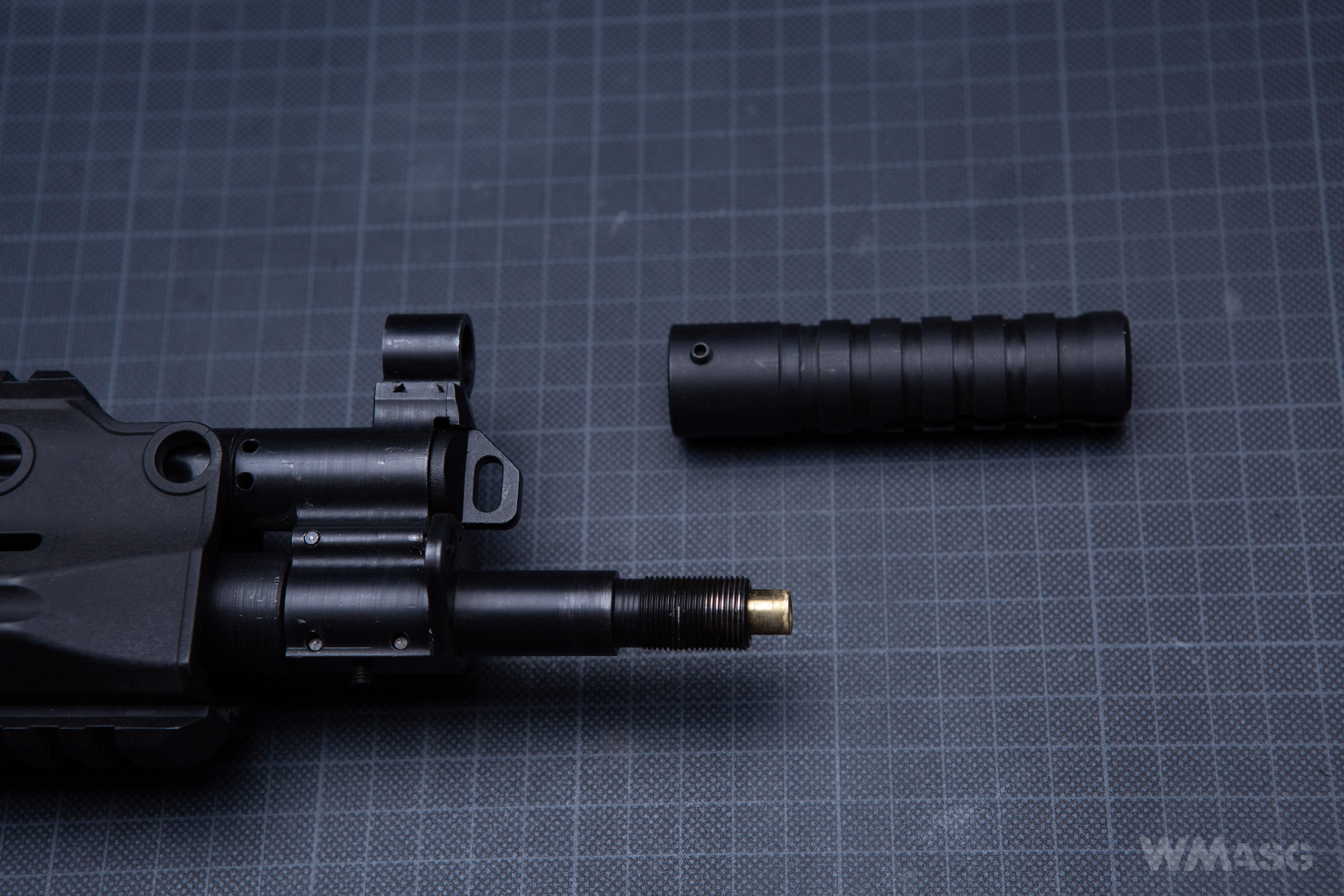

The steel slotted flash hider is mounted on a standard 14 mm thread and secured with a setting screw. The photo also shows the previously mentioned imperfections of the inner barrel.

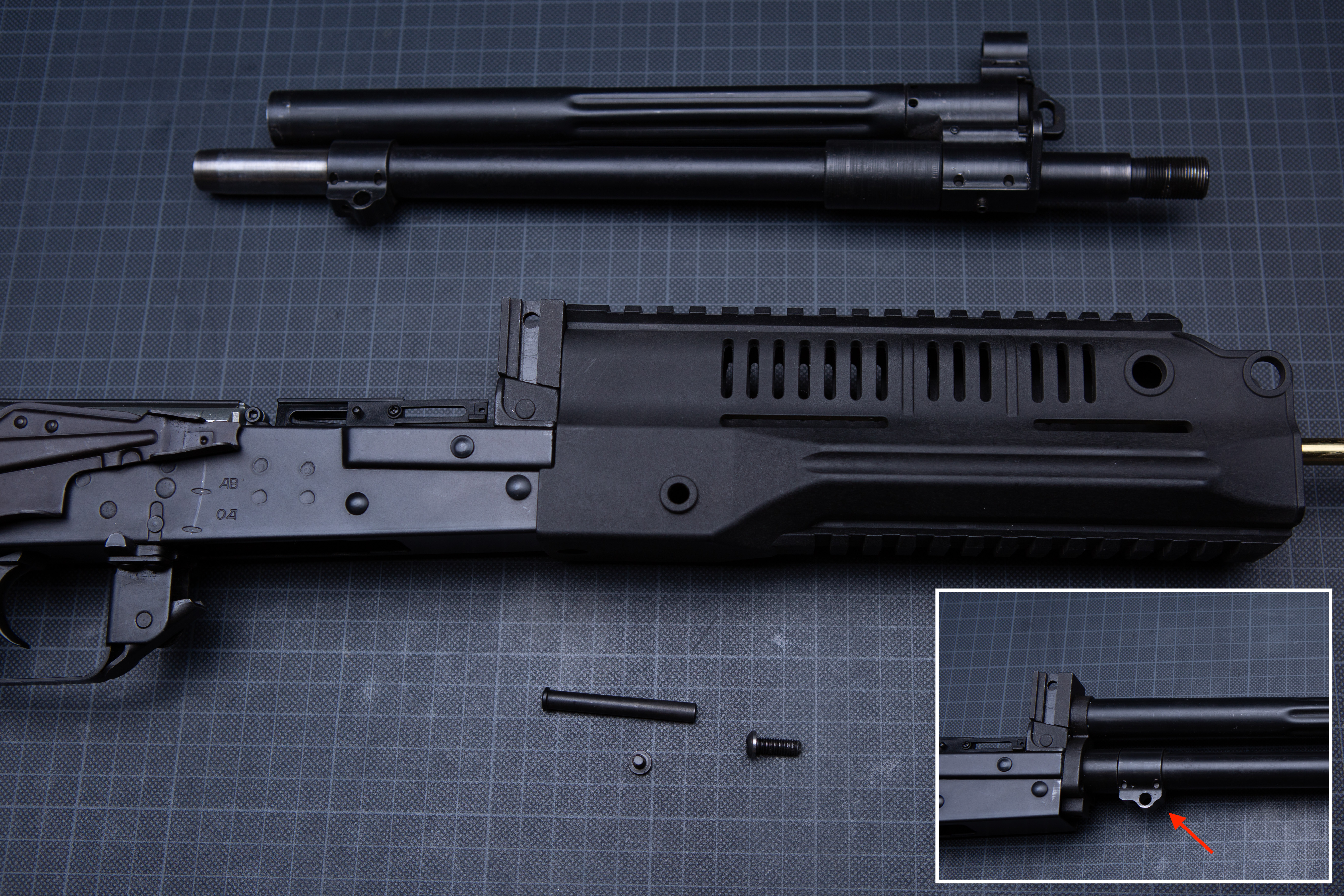

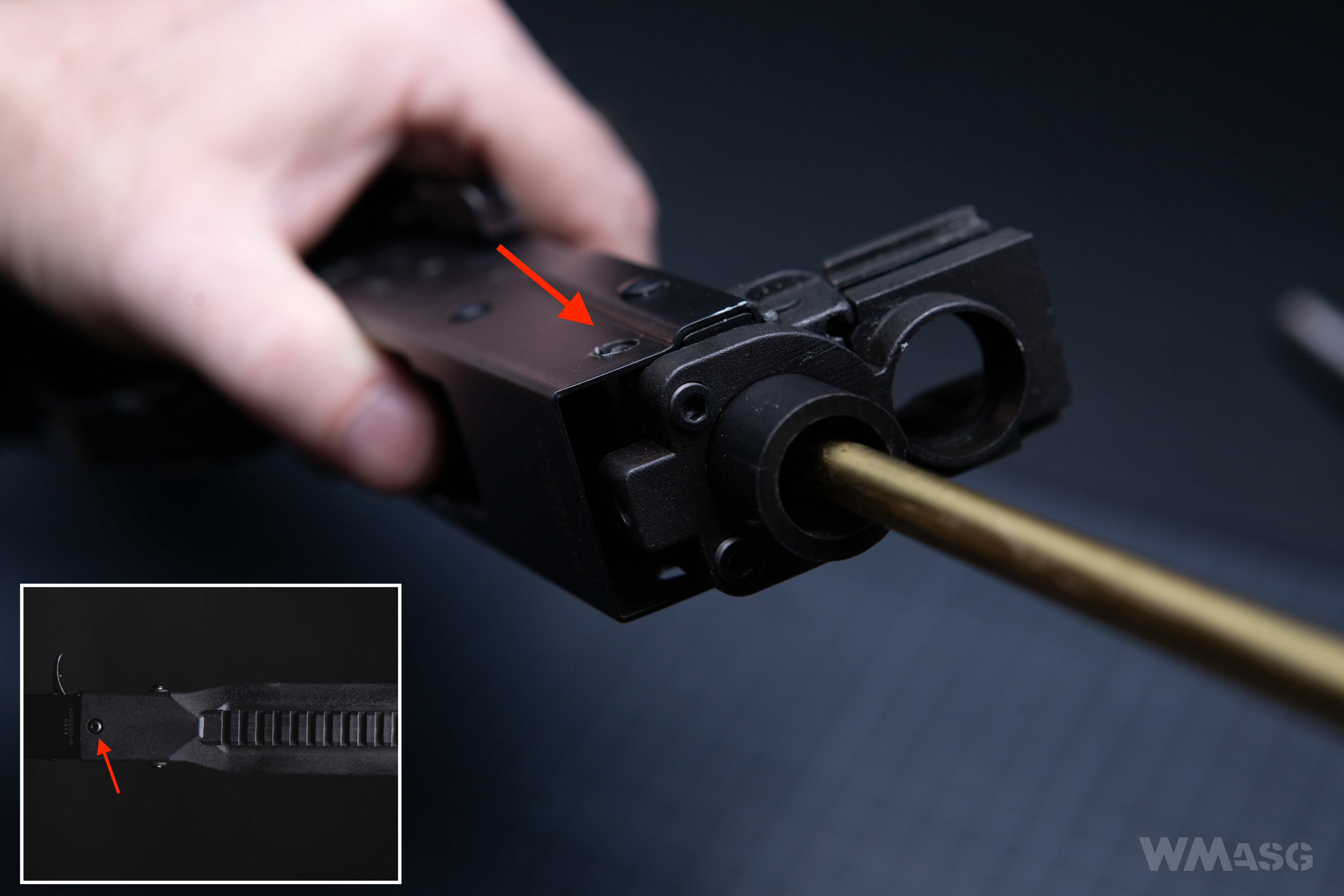

Removing the pin indicated by the red arrow allows quick disassembly of the outer barrel.

The pin is secured with a screw. After removing it from the handguard, you can slide out the outer barrel. And here we have two comments. First of all, if a longer outer barrel will appear on the market, then changing the length of the replica will be child's play. Secondly, the method of locking mechanism o the outer barrel in its mount (the mentioned pin) does not result a rigid connection. There is a small looseness of the outer barrel, which results in the aforementioned light clatter. The barrel is just inserted into the mount and the pin fastens it to the handguard rigidly connected to the receiver. The red arrow on the thumbnail below indicates the place where the pin passes through.

Disassembly of the handguard requires unscrewing the bottom mounting screw and taking out the pin passing through the replica's receiver.

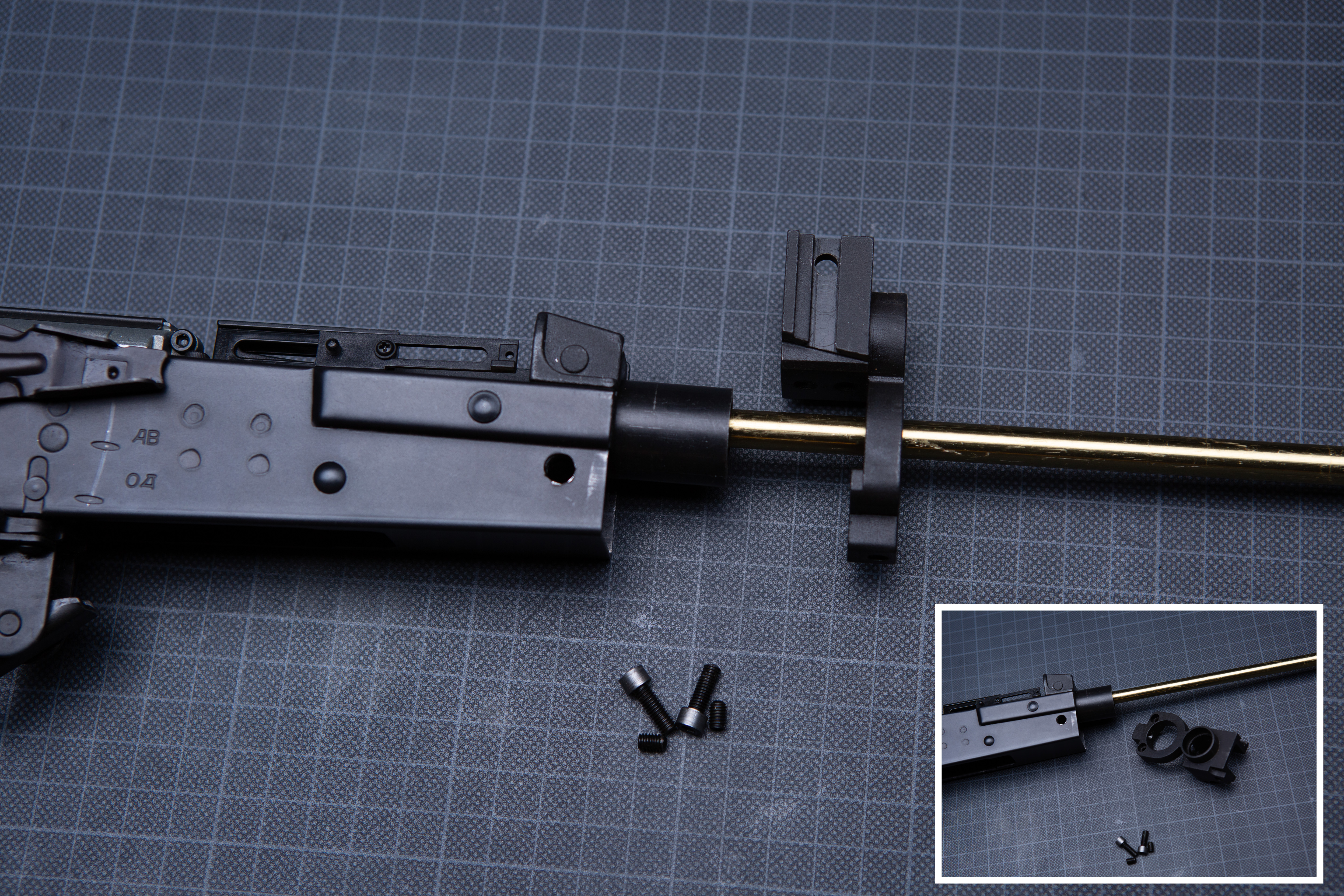

Two screws with Allen heads fasten the gas tube socket.

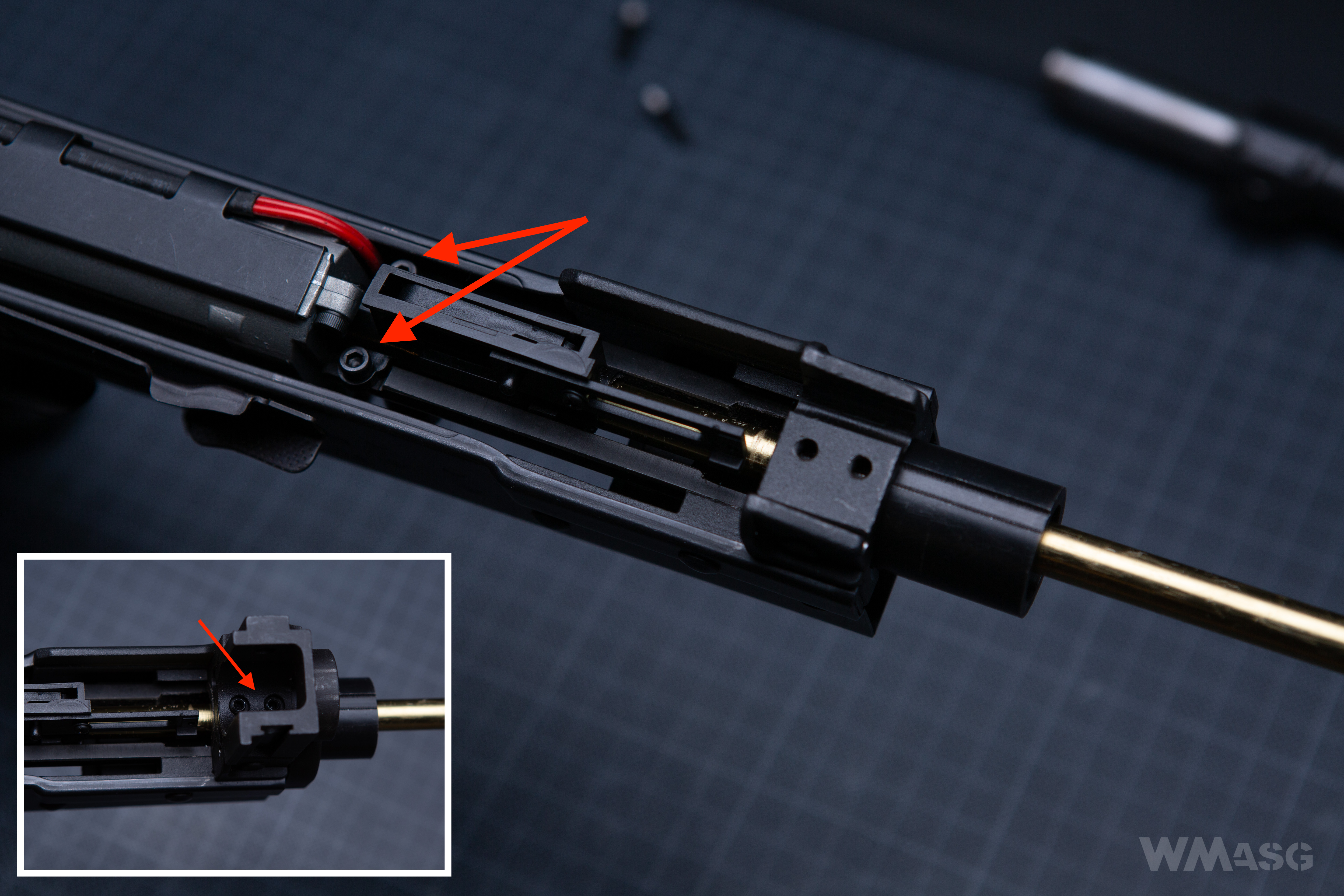

The HopUp chamber fixing element can be removed by unscrewing the 2 screws marked on the thumbnail and the screws holding the chamber.

All pieces of the puzzle:

The fire selector lever, with an additional extension, is mounted in a typical way for AK replicas. In the initial period of using the replica, it is difficult to change the setting with the index finger of the right hand. However, after some time, the cooperating elements are mutually arranged and operating the lever becomes noticeably easier.

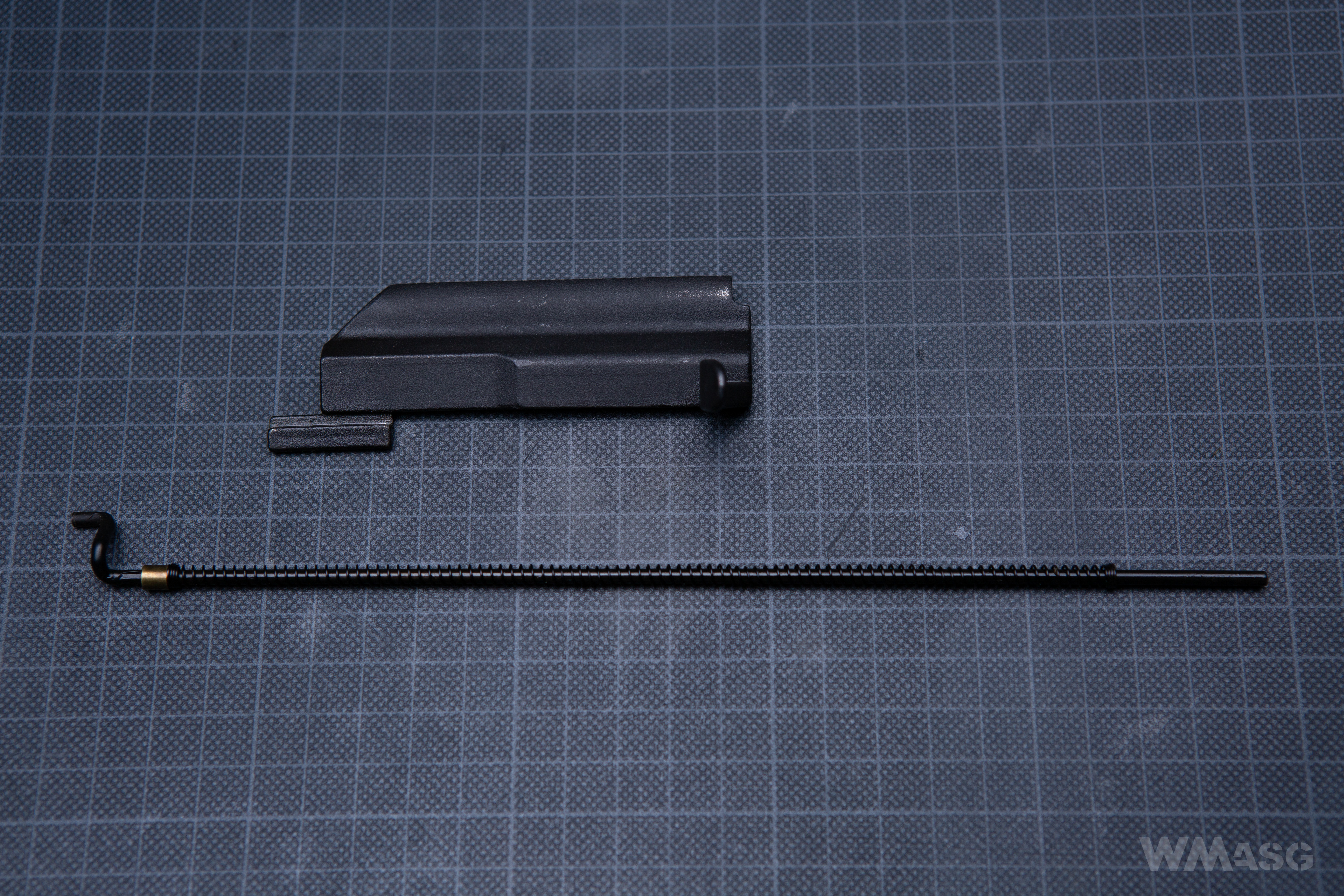

The dummy bolt cattier is also made and assembled in a manner typical of other replicas, hence the presence of the part already mentioned in the first portion of this text, which in other replicas acts as the latch of the receiver cover. In the RPK-16 it is invisible from the outside and holds the dummy bolt carrier guide rod in place.

Internal parts

The HopUp chamber, the bucking and the inner barrel

The RPK-16 uses a standard AK replica chamber attached with 2 screws to the base shown above. The chamber is not connected to the gearbox, as is the case in, for example, the E&L replicas. The bucking is standard, typical for LCT products. It worked flawlessly in the tested carbine, but we didn't do tests at low temperatures or at higher muzzle velocities.

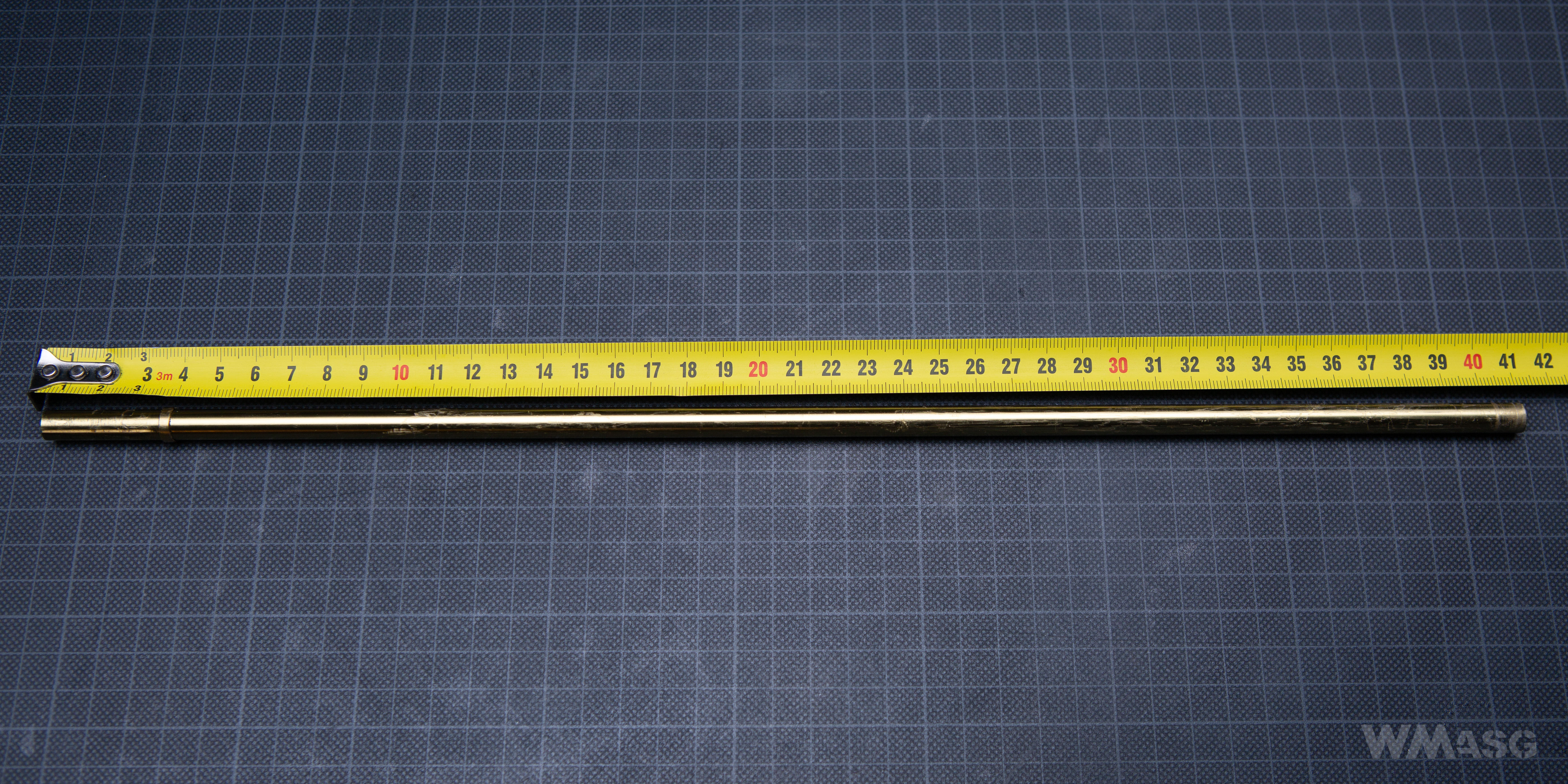

The barrel with a flawed muzzle is 410 mm long. It is shorter than the standard AK barrel by 40 mm.

The gearbox

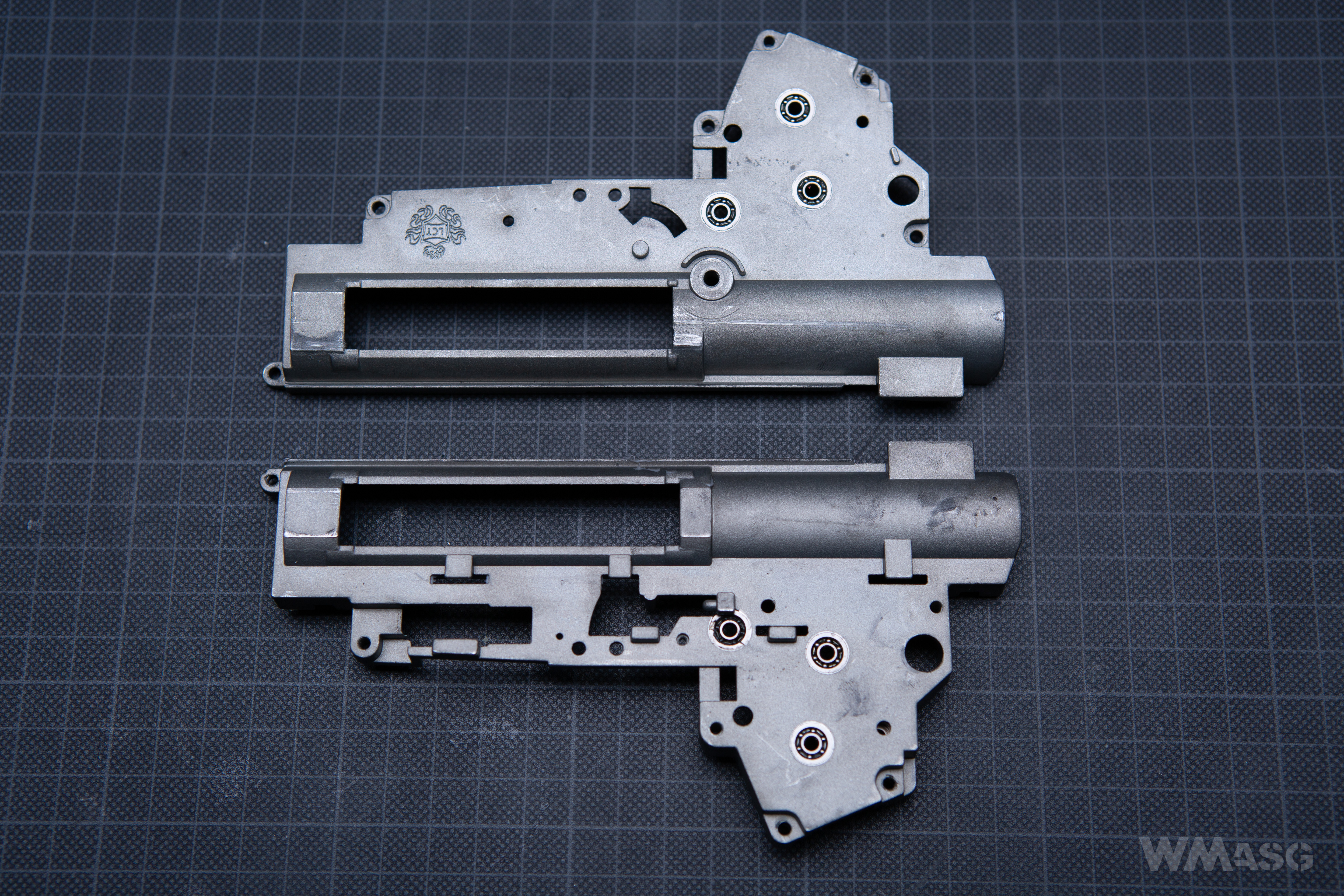

The frame is a standard V3 gearbox. The fire selector levers are the same as in all AKs.

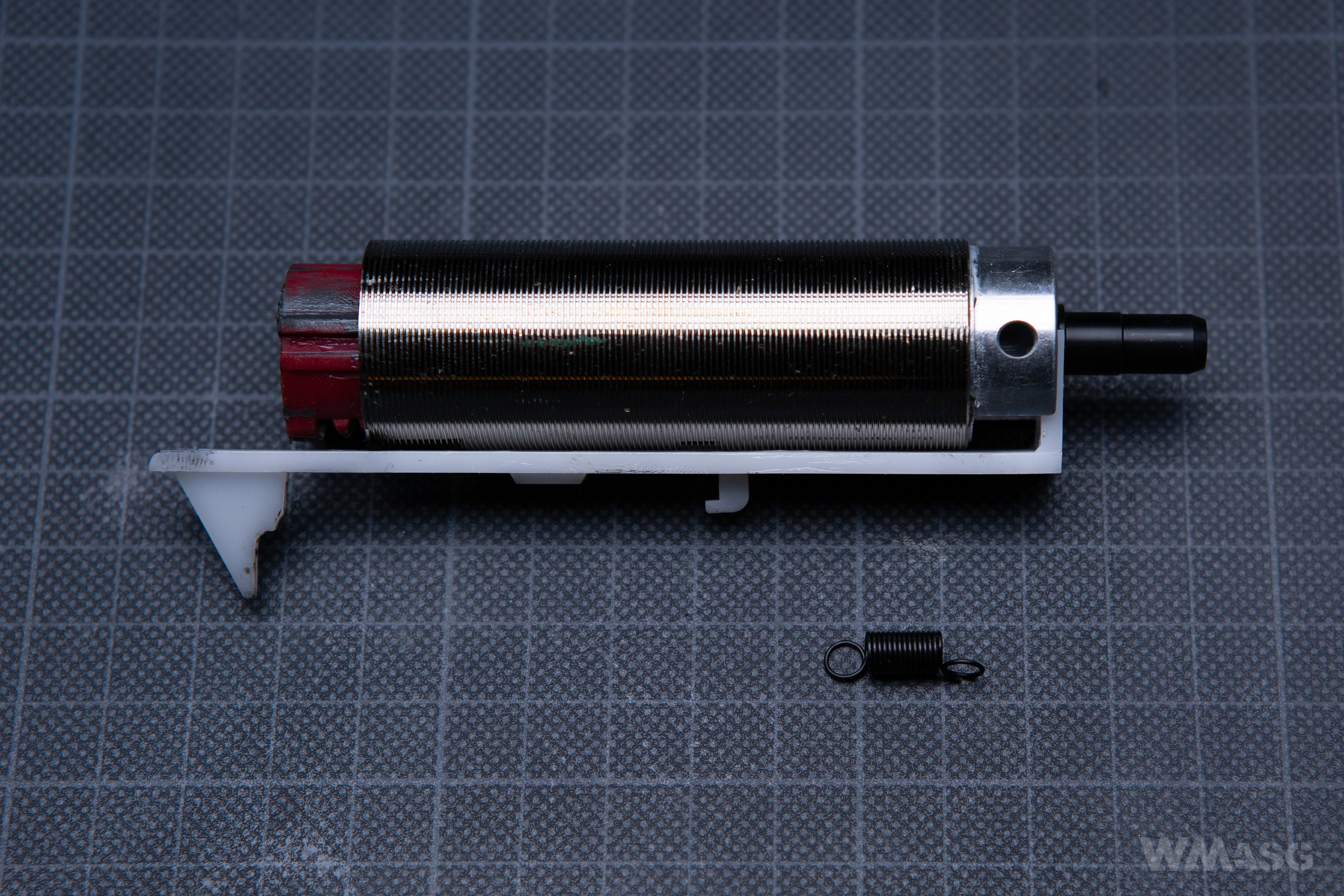

The gearbox offers the possibility of quick spring replacement, but only after removing it from the replica's receiver, so more than the "speed" of the spring replacement, the ease with which less skilled service technicians will do it matters. The spring guide has a bearing.

The frame is designed to work with 9 mm bearings. LCT uses ball bearings.

This is the same frame that the LCT uses in replicas equipped with mechanical blowback (EBB). This is good news, because there the frame can withstand the work of a heavy steel piston.

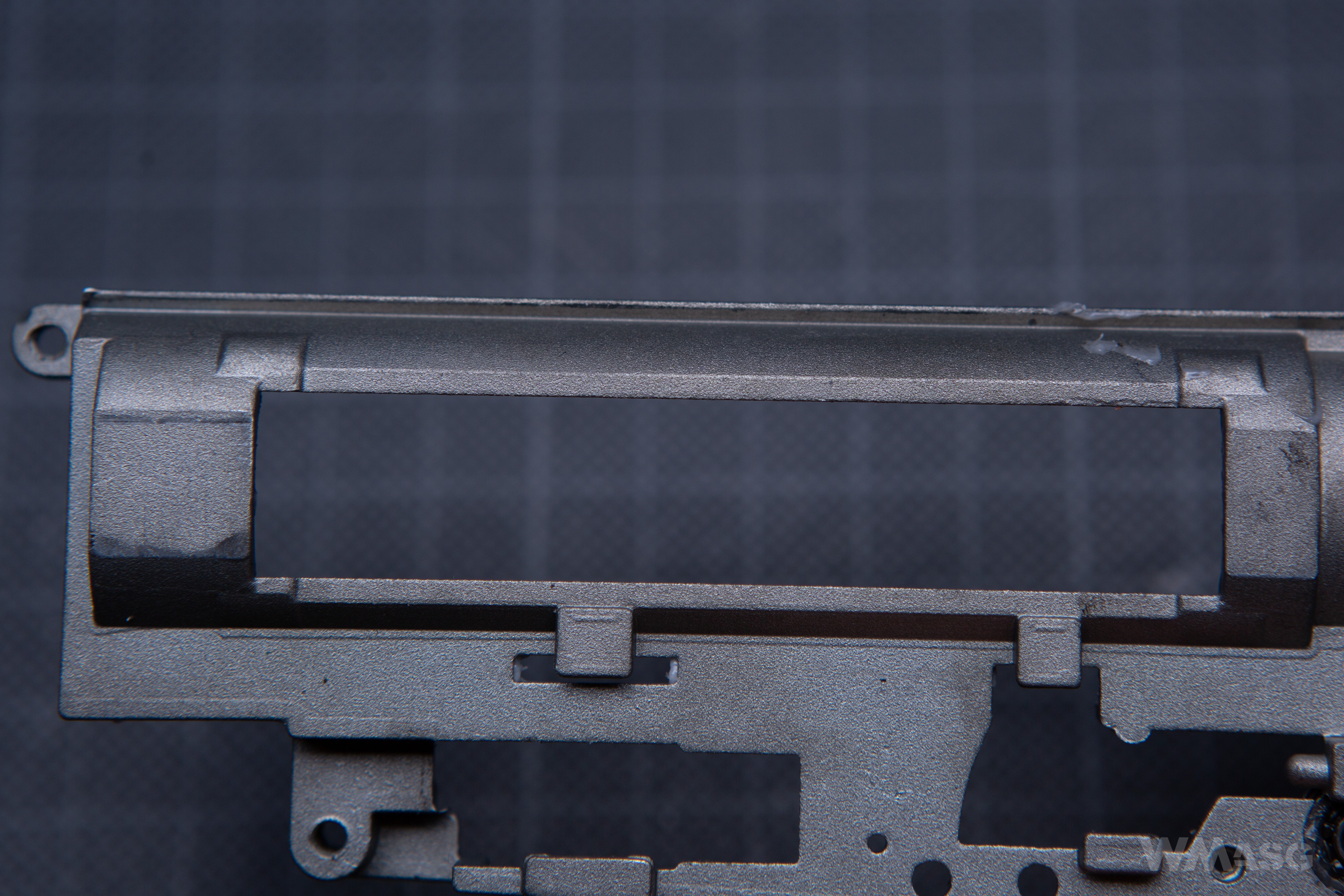

The cylinder port corners are, unfortunately, still sharp. Only some manufacturers round the inner corners, which changes the distribution of forces and additionally extends the frame's life slightly.

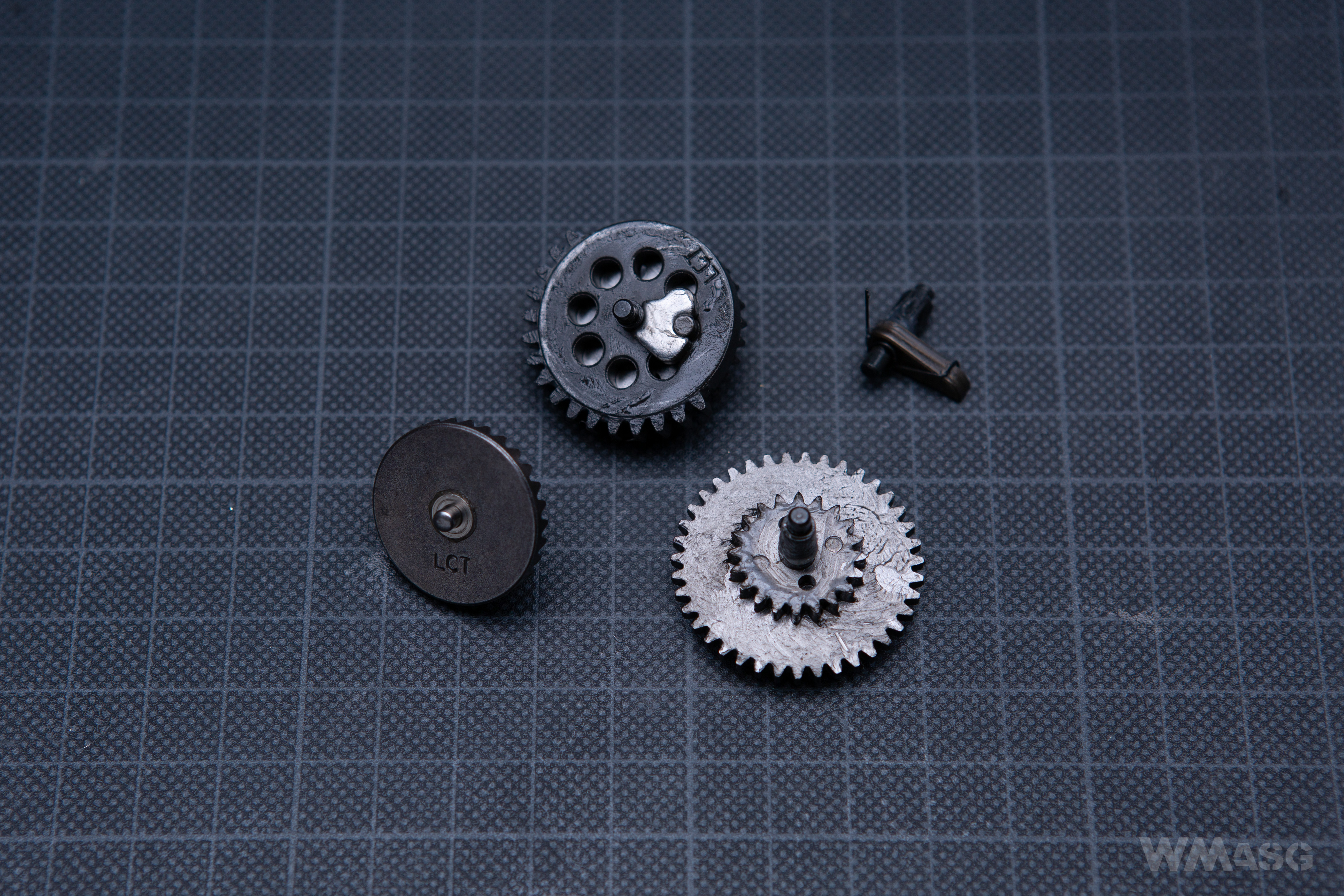

All internal parts of the mechanism are standard. Steel gears are typical for LCT. Thanks to precise manufacturing, they work smoothly and quiet.

The cylinder assembly is airtight, as evidenced by muzzle velocity measurements.

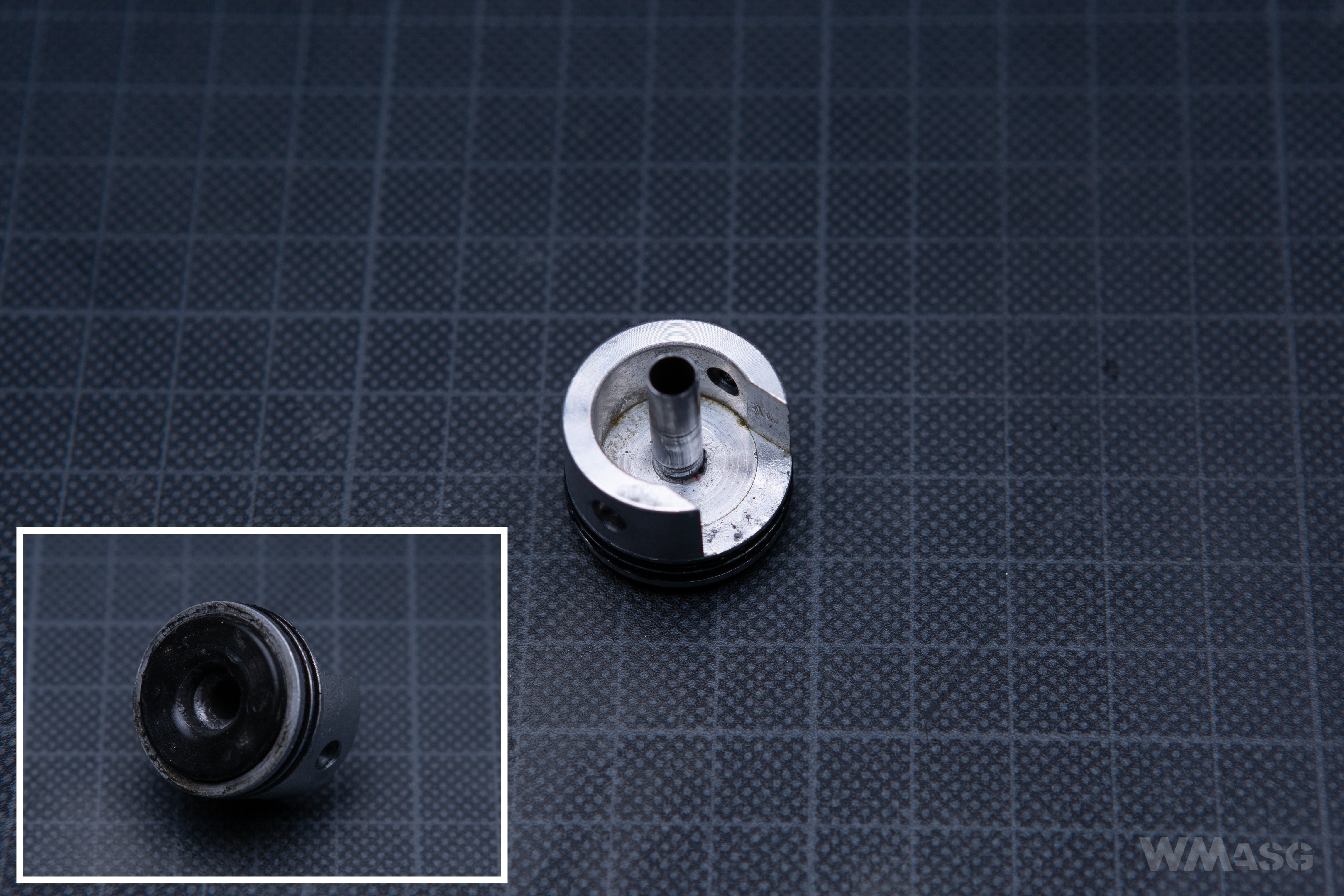

The nozzle is sealed with an inner O-ring and is 19.4 mm long.

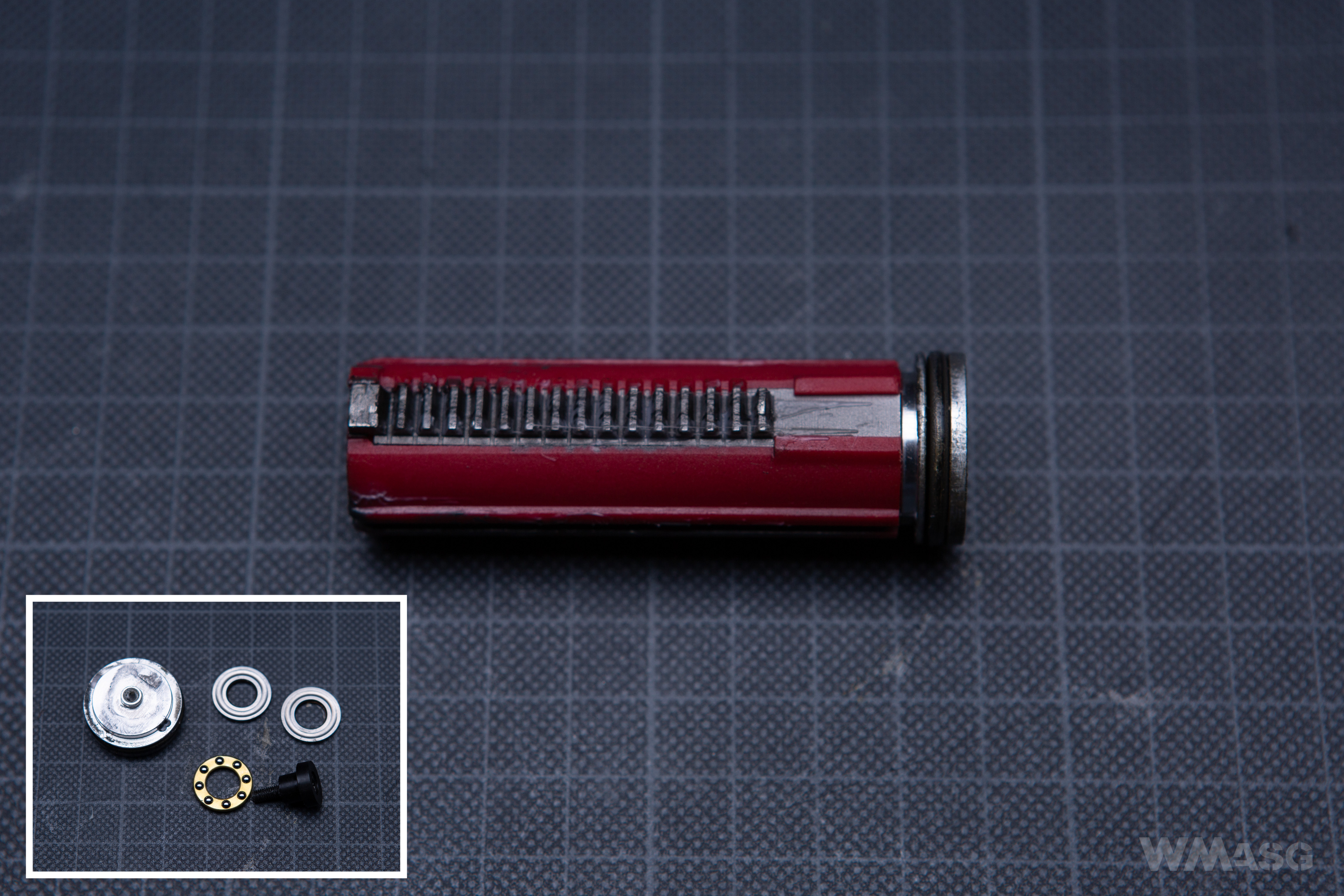

The polycarbonate piston with a flat aluminum head, equipped with a ball-bearing is mounted, has all teeth made of steel.

The aluminum cylinder head is sealed with 2 O-rings and has a prominent bumper.

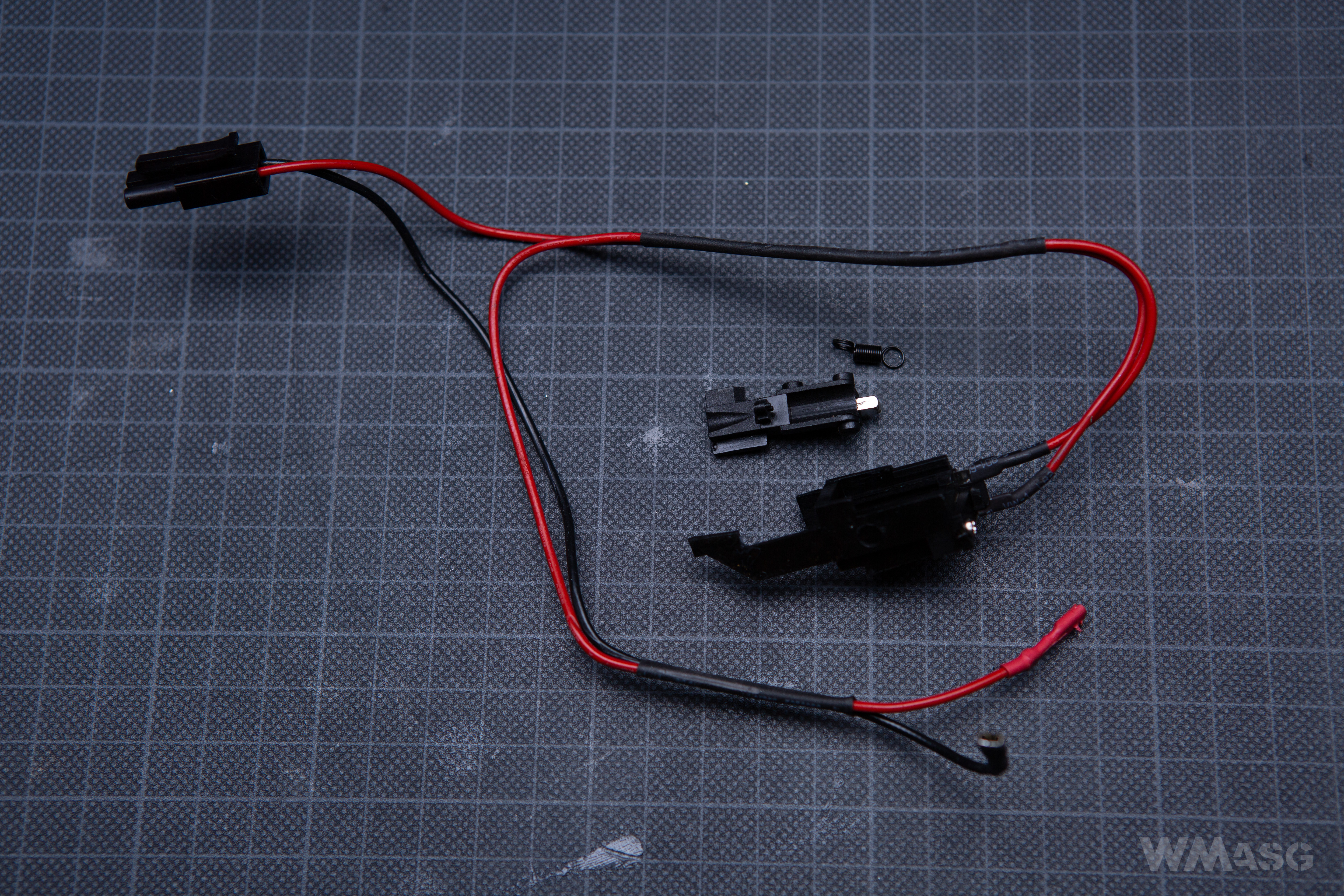

The classic contact switch, cut-off lever, selector plate and some other small components are completely standard. The wires are thin, rigid, with mechanical insulation resistant to damage. The plug is a mini-Tamiya type.

A typical, short type motor. It has no markings. The motor adjustment screw is hidden under the push-in grip bottom plate.

The method of assembly of the mechanism raises no objections. The selection and quality of individual components allow for cheap and trouble-free tuning. In our opinion, the commonly accepted limit for support weapons can be reached by just replacing the spring. Unfortunately, then you have to deal with the need to have several (that is more than 2) batteries, or find a way to mount and use a larger than stick type battery.