Problems with feeding of brand new magazines from a brand name manufacturer are strange occurrence in my opinion. But I can not argue with the facts. I received five completely new magazines, none of which worked as they should. The owners of LC-3 (G3) replicas exchange ideas on how to solve this problem. We present a proven solution.

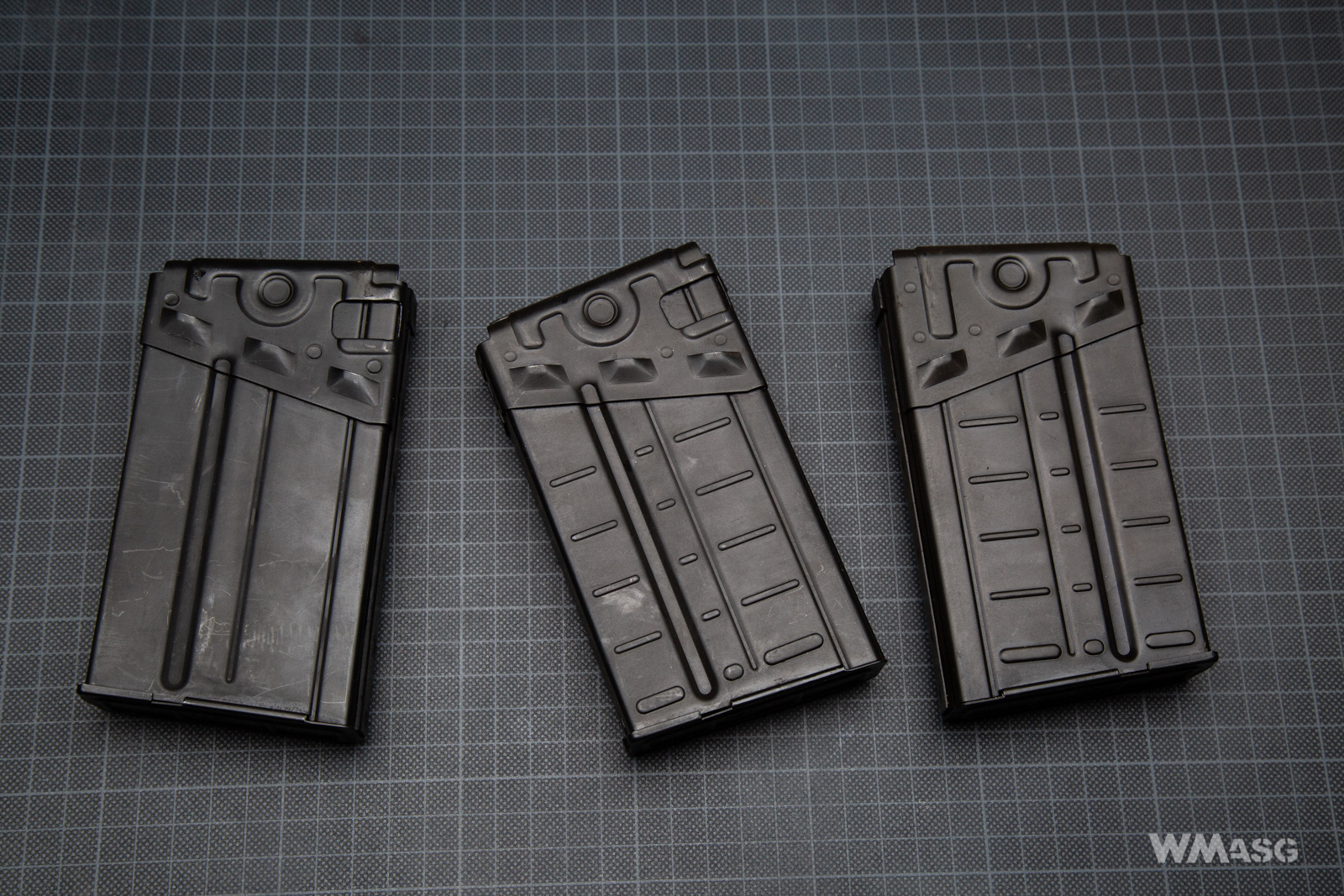

Above, from the left: a mid-cap holding 140 BBs in the flat version, a mid-cap holding 140 BBs in the ribbed version still in the package, and the same mid-cap already unpacked.

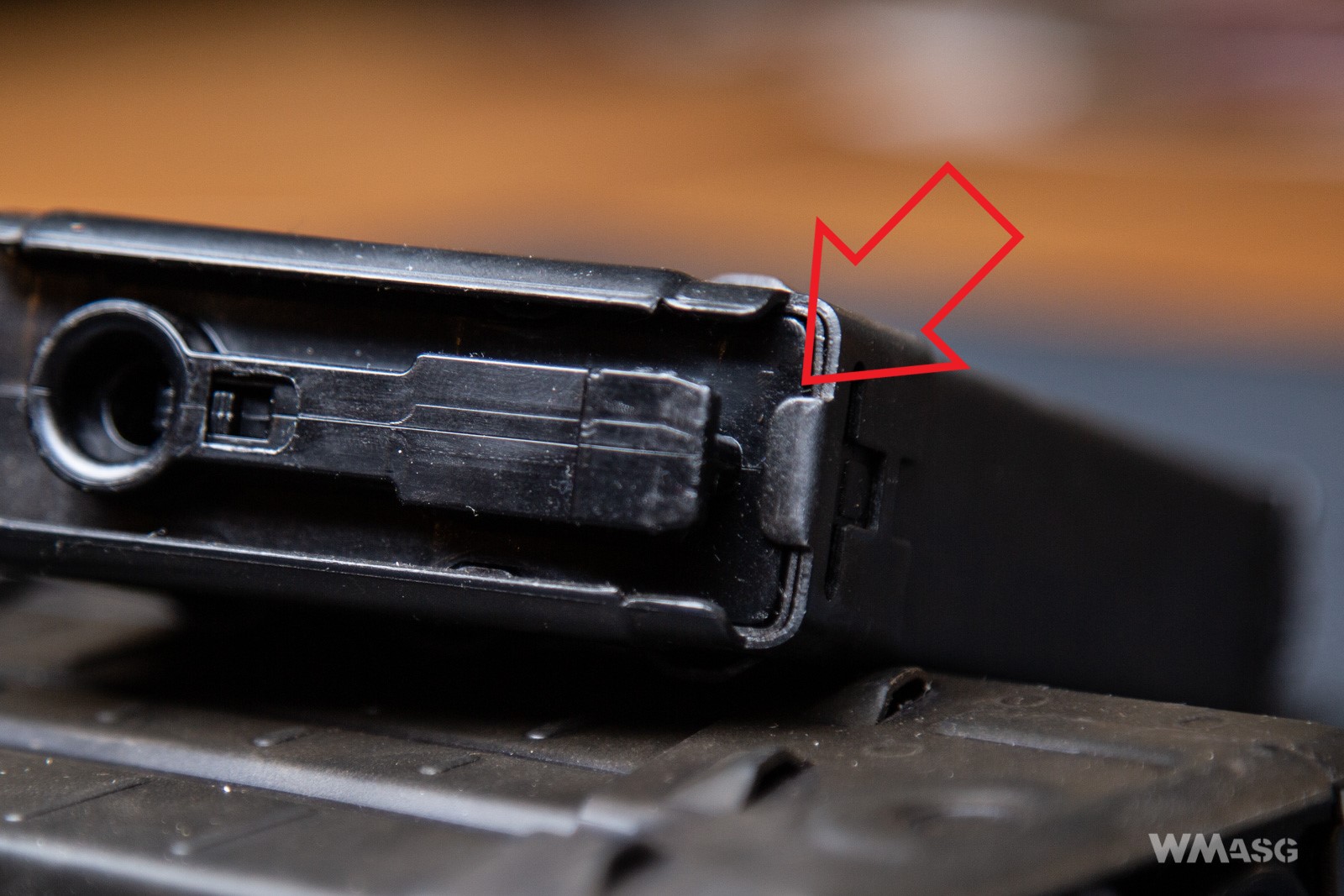

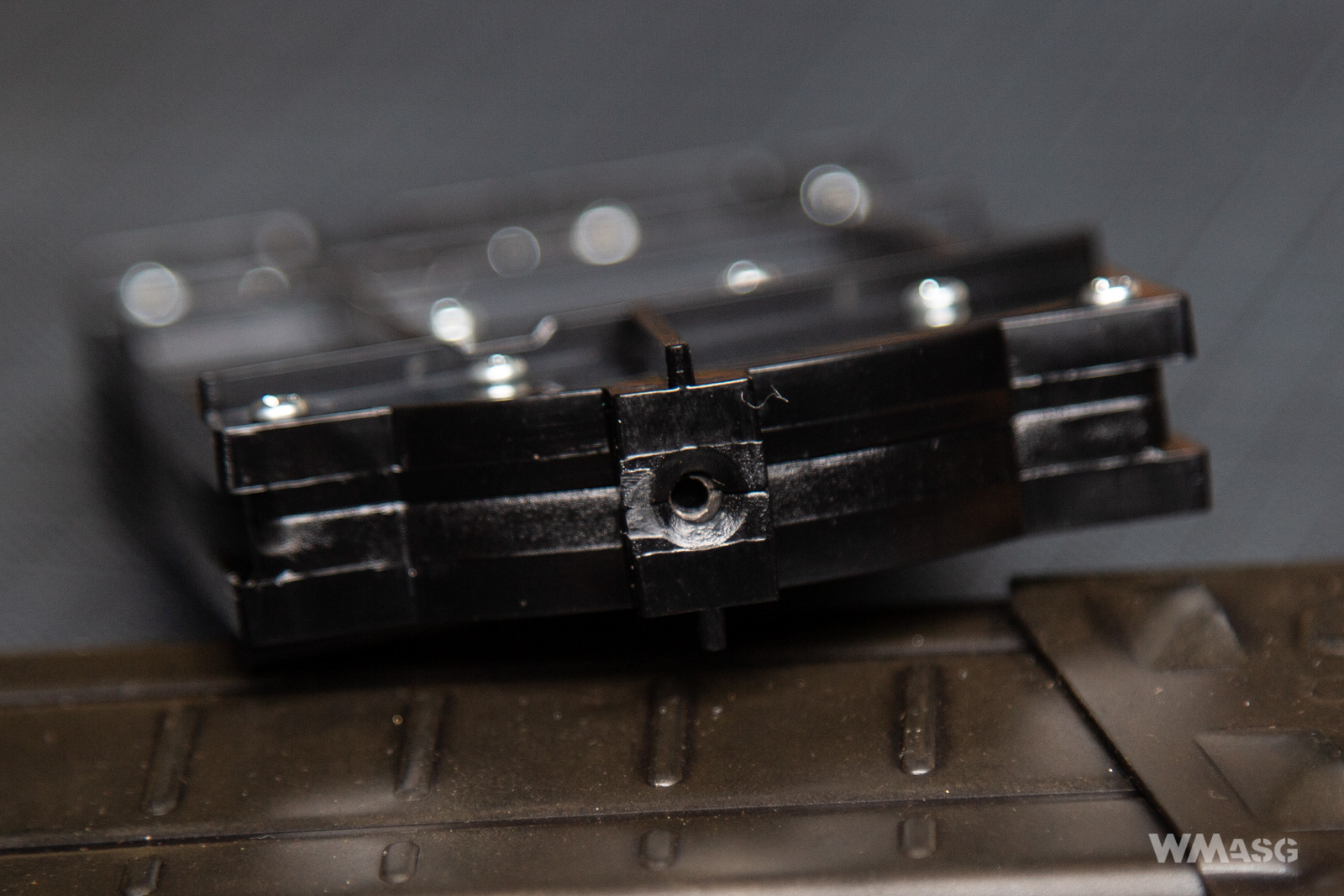

The reason why the magazines do not work correctly is the incomplete retraction of the latch holding the BBs inside. The problem lies not in the shape of the latch or the HopUp chamber working together with it, but in the height on which the upper part of the magazine is located after inserting it into the mag well. In other words, the plates that hold the internal part of the magazine are bent at a 90o angle, which causes the internal part of the magazine to be too low and the HopUp chamber does not sufficiently retract the latch.

The solution is quite simple

FIrst of all - we pull out the plastic internal part of the magazine.

So first we unscrew the screw in the bottom, and then slide the magazine floor plate towards the front of the magazine (towards the hook, not the funnel feeding the BBs). Then, from the top, push the plastic internals out from the metal shell of the magazine.

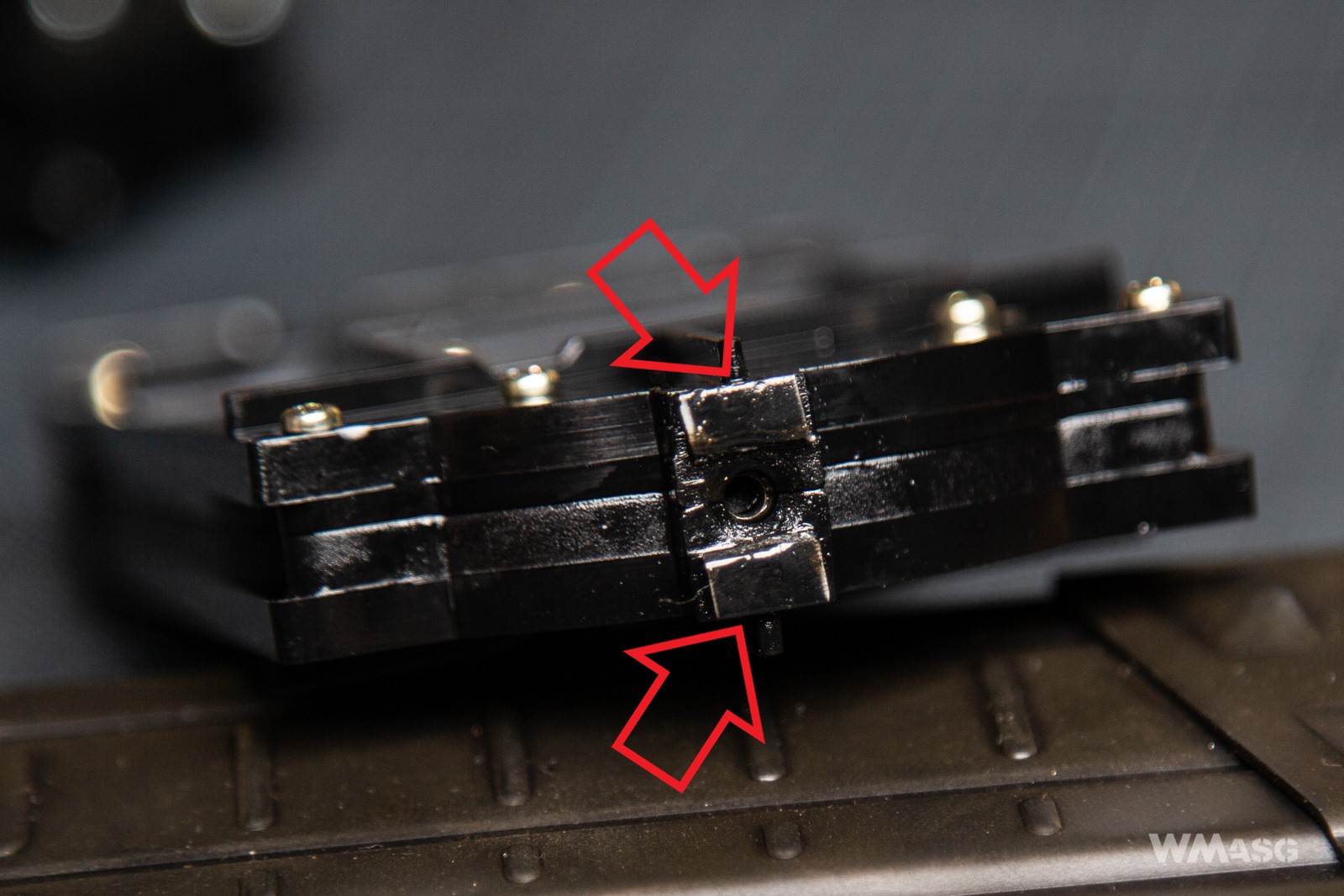

Secondly - we bend the blades of the magazine's metal shell slightly upwards, the ones which secure the internals from the top from being pulled out.

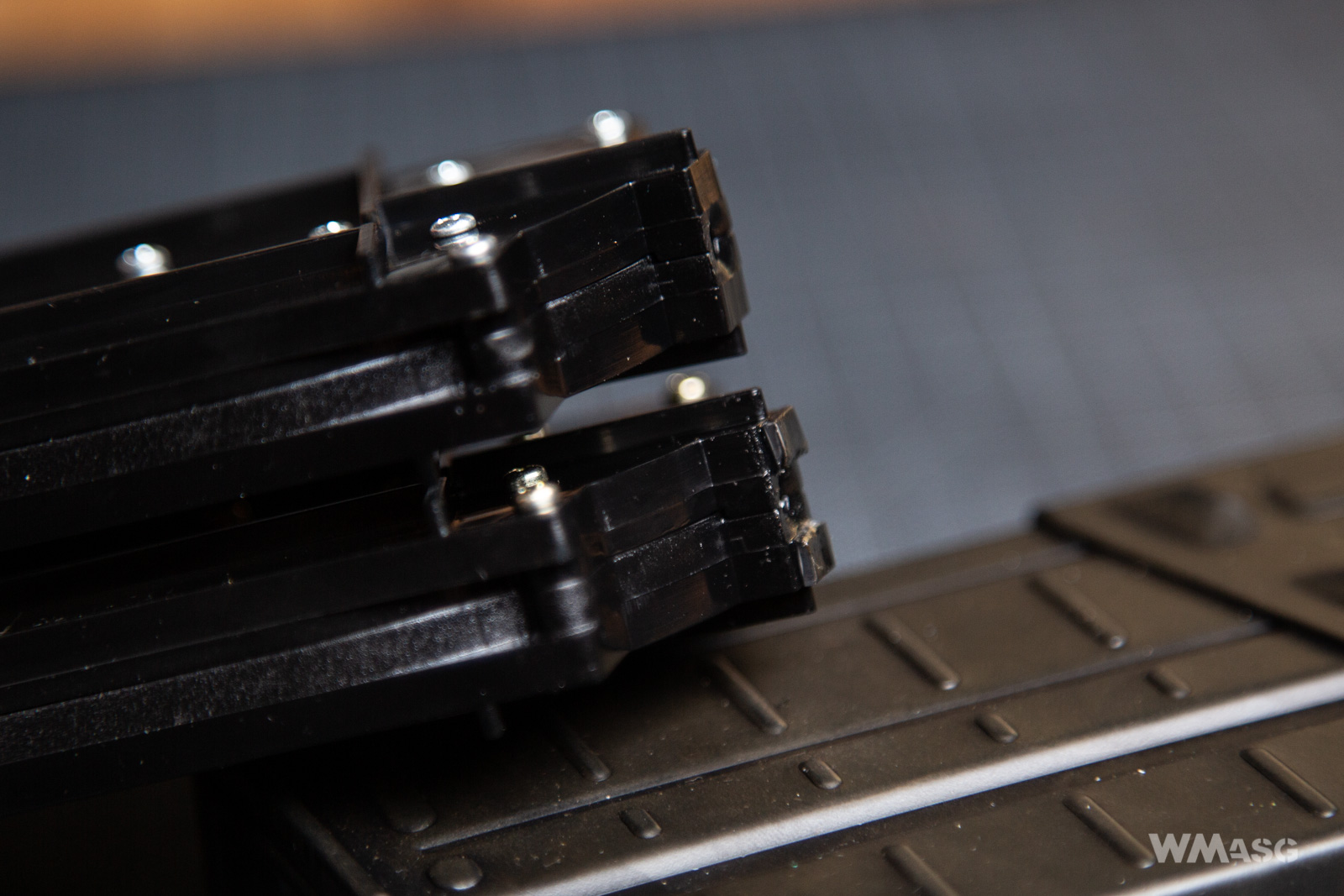

Below is a comparison of magazines with bent plates (upper) and factory ones.

Banding the blades allows you to lift the magazine insert, which in turn causes the full retraction of the latch and the free movement of BBs through the hole in the magazine.

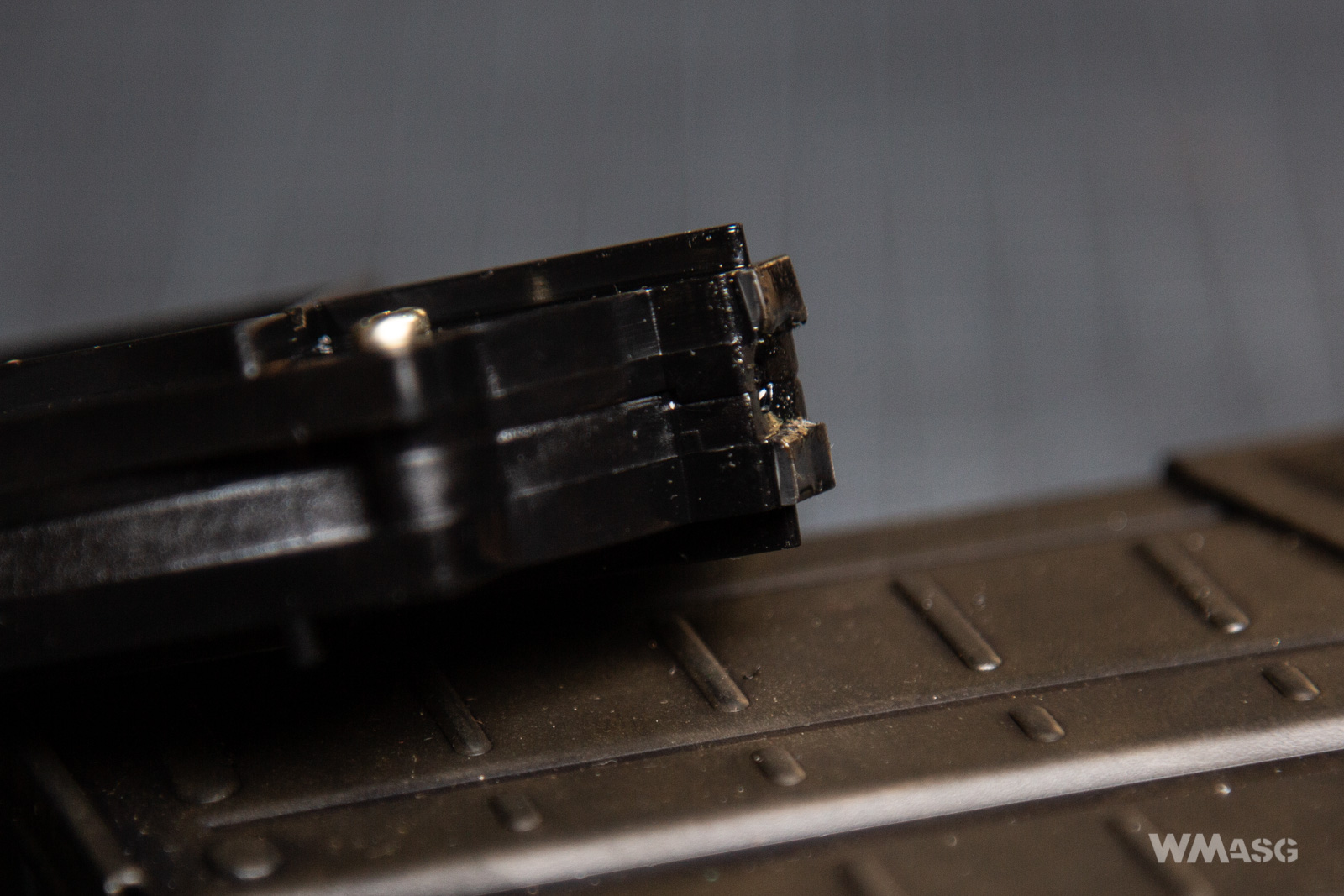

Thirdly - you need to raise the magazine's internals somehow. The factory made internals look like this at the bottom.

Our solution was to glue two pieces of plastic, which act as additional spacers. I used a scrap piece of material and the most common cyanoacrylate glue (the brand is irrelevant). Of course, you can use any other materials.

The glued parts have a thickness of about 1 millimeter.

Comparison:

At the end we put everything together in reverse order. It works. The arrows will allow you to understand how slightly you need to raise the magazine's internals.

Do you have other problems? We'll be happy to help. Please write.