Replicas of the AK weapon system produced by LCT have been considered for many years as a top shelf product and a determinant of the quality of replicating a real firearm. This is supported by the materials used, production technology adopted and the quality of assembly. On the mechanical side, although they do not contain revolutionary solutions, they present above-average durability. Wait ... they don't contain revolutionary solutions? This is true for "normal" LCT replicas. But as it turns out that this does not apply to those belonging to the new series with a mechanical blowback system (EBB). But this will be described in a moment. Meanwhile, let's enjoy this photo ...

We receive the replica in a standard cardboard box. That's all I have to say about it. The set that comes in it is less than modest. Apart from the replica we only get a mid-cap magazine (130 BBs) and a printed instruction manual.

Basic technical paramaters:

- overall length: 930 mm;

- inner barrel length: 435 mm;

- weight: 3.45 kg;

- muzzle velocity: 420 fps (using 0.2 g BBs)

Due to the recreation of the bolt carrier and blowback system, space for the battery is provided in the buttstock. As you can see, the amount of space is quite large. It should accommodate an 11.1V 2200 mAh LiPo. During testing, we used an 11.1V 1100 mAh LiPo battery. Because LCT still uses mini Tamiya connectors, we had to use an adapter.

Impressions

Before we took the replica out of the box, we looked at it carefully for a moment. It made an impression on everyone. Wooden parts look very robust. Metal parts make a similar impression, mainly due to a semi-matt coating. In addition, the latter clearly differ from each other in color (shade of black) depending on the angle light shining at them. The coating used is not some "blackboard varnish", but some kind of electrochemical coating. Therefore, the replica will age beautifully while being used as slightly brighter patches will appear on its edges. This is great! Yet, I have one subjective "but". I would prefer that instead of the standard brown pistol grip there was a "bakelite" one, which is made by LCT. It would be even better if it was a slim type "bakelite", then I certainly would not have remarks.

After taking the replica in our hands, the good impression did not disappear. The replica has a hefty weight, is rigid and free of any looseness. Even the receiver cover rests in place and does not wobble like in many other replicas. The fitting of adjacent parts is simply good.

The aforementioned "wooden" parts are made of plywood and covered with a thick layer of varnish.

The steel buttstock plate, which has a working port for holding a toolkit, is screwed with flat head screws.

Similar screws were used elsewhere.

The rear sight looks equally good:

and the magazine:

In my opinion, some reservations can only be made about the way the bolt carrier touches the upper edge of the receiver. The bolt carrier is slightly oblique. The gap between the parts increases further to the back.

In general however, the replica looks as good as all previous LCT products. In addition, it should be noted that the LCKM EBB is, after all, just another variant of the already known carbine. It is identical in terms of replication accuracy, assembly quality and appearance. For this reason, I will put most of the photos showing details of its appearance in the gallery.

External design

From the outside, the replica is, in principle, built in a manner consistent with the design of a real firearm. What is supposed to be made of steel is steel (including the outer barrel). In most cases, the method of joining/assembling individual parts is done the right way (with retaining pins). But as usual with LCT, they are often additionally secured with screws. This solution is not surprising because, as I wrote a moment earlier, LCKM EBB is a version of an existing replica and uses most of its parts.

Disassembly of the gas tube with the upper handguard, after turning the locking lever.

Similarly, to disassemble the lower handguard with the retainer, which also has a carrying sling swivel, a locking lever has to be turned.

The toolkit port, set on a spring, is also built in a manner consistent with the original.

Slightly worse, but in a way typical for LCT, is with the parts attached to the outer barrel which, in principle, mounted on pins:

but also "fixed" with screws. The rear sight base:

The gas block:

And the front sight base:

In some AK replica" systems", the main pin holding the outer barrel in the mount is a dummy. This is because there is not enough material that would hold the pin in place. The same applies to the LCT replica (red arrow below), but also to AK replicas made by G&G. This is probably the biggest deviation from the design of the original.

The outer barrel is held in place with two setting screws.

In the case of the LCKM EBB, the lack of screw heads is particularly important, because this is where the part where the gas piston dummy is moved by the EBB system.

In the case of the LCKM EBB, the lack of screw heads is particularly important, because this is where the part where the gas piston dummy is moved by the EBB system.

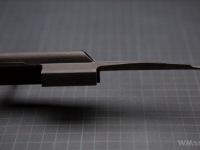

The bolt carrier with the return spring and its guiding rod looks almost as they should:

The shape of the slide is slightly different, but this is a requirement of EBB system design. The elongated rear part is a latch, which is connected to the hook of the piston working inside the gearbox.

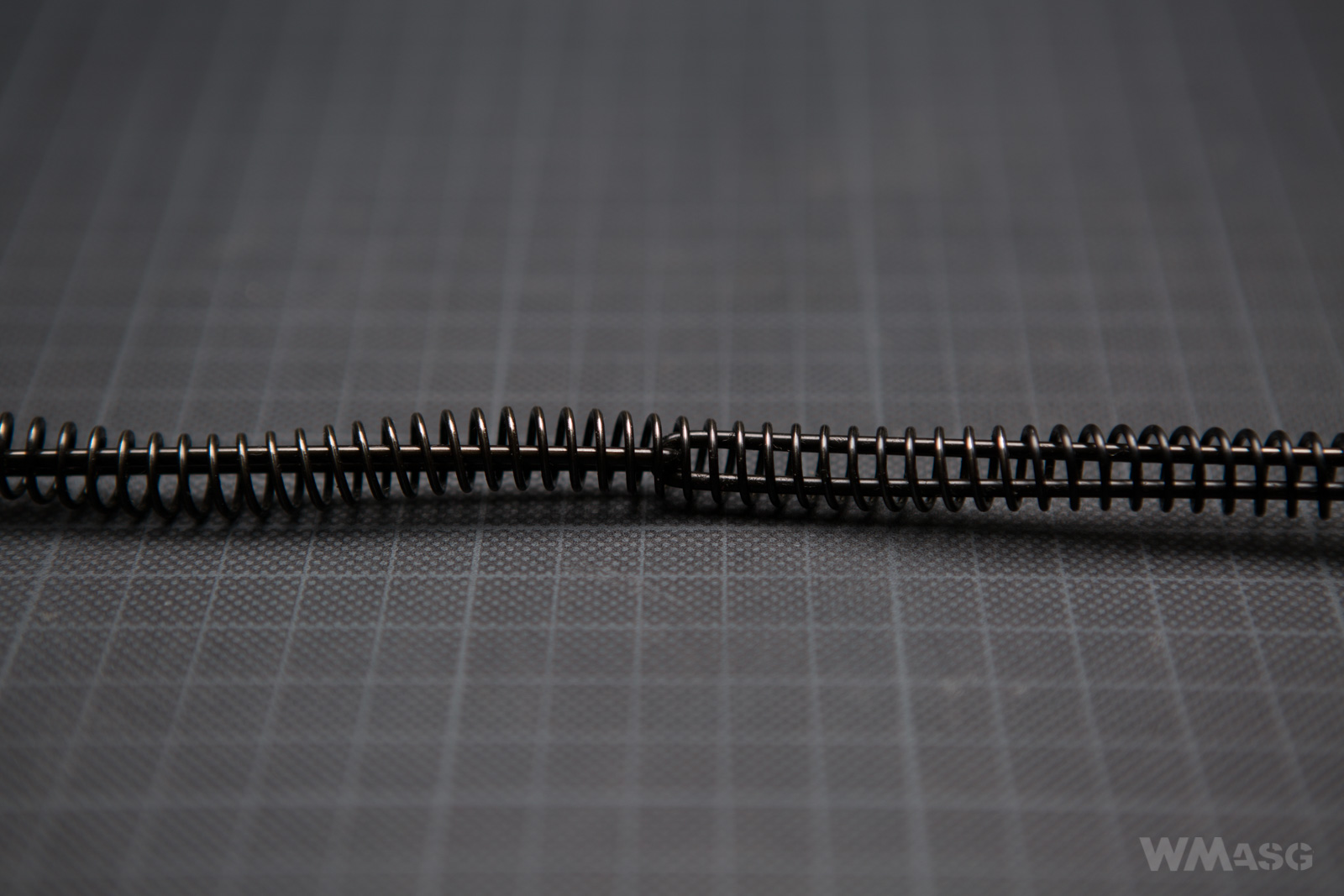

It is worth noting the design of the return spring assembly as it is true to the original: a rear guide, a front guide, a spring and a spring resistance.

It is worth noting the design of the return spring assembly as it is true to the original: a rear guide, a front guide, a spring and a spring resistance. A set made by LCT, consisting of the same spring and a bolt carrier can be bought and mounted in a "regular" replica without the EBB system. In this case the bolt carrier has no piston latch and looks even more realistic. Current price at Gunfire: 315 PLN.

A set made by LCT, consisting of the same spring and a bolt carrier can be bought and mounted in a "regular" replica without the EBB system. In this case the bolt carrier has no piston latch and looks even more realistic. Current price at Gunfire: 315 PLN.

The black block marked with a red arrow is also present in the LCMK EBB and it plays an extremely important role in it. I will explain this later. But going back to the external design ... The last thing that draws our attention is the use of a steel insert for the magazine well.

It is designed to slightly facilitate (and speed up) the insertion of a magazine. And it actually does the job. Of course, this is not a revolutionary solution. Similar inserts are available as additional accessories and E&L, in their second-generation AK replicas, also mounts them at the factory as standard. How does it work? For those of you not familiar with AKs, a common problem occurring when trying to quickly exchange a magazine in an AK replica is inserting the magazine too deeply into the receiver's magwell, so that the protruding magazine latch is much above the place designated for it. In addition, despite not properly locking the magazine at the front, it happens that the magazine release lever secures it normally and we have a problem. A simple, but extremely effective solution are the inserts in the magazine wells which prevent the magazine from being inserted too deeply into the well. The latch is located at the correct height. Simple but brilliant! For design reasons, this does not apply to replicas built in the "old" Tokyo Marui system with a plastic or aluminum alloy receivers (those are mainly replicas of the first AK with the original milled receiver, not AKM replicas and later versions with a stamped sheet metal receivers).

It is designed to slightly facilitate (and speed up) the insertion of a magazine. And it actually does the job. Of course, this is not a revolutionary solution. Similar inserts are available as additional accessories and E&L, in their second-generation AK replicas, also mounts them at the factory as standard. How does it work? For those of you not familiar with AKs, a common problem occurring when trying to quickly exchange a magazine in an AK replica is inserting the magazine too deeply into the receiver's magwell, so that the protruding magazine latch is much above the place designated for it. In addition, despite not properly locking the magazine at the front, it happens that the magazine release lever secures it normally and we have a problem. A simple, but extremely effective solution are the inserts in the magazine wells which prevent the magazine from being inserted too deeply into the well. The latch is located at the correct height. Simple but brilliant! For design reasons, this does not apply to replicas built in the "old" Tokyo Marui system with a plastic or aluminum alloy receivers (those are mainly replicas of the first AK with the original milled receiver, not AKM replicas and later versions with a stamped sheet metal receivers).

Internal design

Without going too deep into details: the replica is powered by a modified V3 gearbox.

Modifications visible from the outside are delicate reinforcements in a place critical for all frames, i.e. in the front corners of the cylinder port,

and the undercut for the piston hook belonging to the EBB system

The mechanism has the ability to quickly replace the spring, but for this it is necessary to remove it from the replica's receiver.

There are two unique parts working inside, which cannot be omitted even in a brief description. The first one is a piston made entirely of steel (!) with an integrated EBB system hook (a single piece part).

The teeth (narrowed, "half" type) are also an integral part of the piston. They were cut out in the production process.

The second one is a set of steel gears with increased gear ratio (super torque-up - only for pistons with narrowed teeth) giving the impression of being extremely robust and durable.

Other parts of the mechanism are completely standard.

The HopUp chamber as well as access to it and its adjustment method are typical, as in all AK replicas. In the front of the slider there is no lever facilitating the adjustment of HopUp although there is a hole for the fixing one with a screw.

The brass barrel with an internal diameter of 6.05 mm has a length of 435 mm.

Shooting

I will say this: ... AWESOME! The replica is has a proper kick. You really need to hold it firmly to keep your sights on the target. Of course, it is impossible to compare it with shooting from the real carbine, but in my opinion it is more than good. After firing dozens of magazines in total, I will dare to say that shooting with it is more pleasant than with gas powered replicas, in which the pressure drop is clearly noticeable. In gas powered replicas, each subsequent shot is weaker and the replica's work less dynamic. There is none of this in the LCKM. This replica work in the same way all the time. With the first, second and subsequent magazines. For me its a blast. But...

The replica has a standard electrical installation with a simple (mechanical) contact switch. There are no electronics tracking the mechanism workings and controlling its cycles. Therefore, the mechanism stops when the trigger is released. Therefore it sometimes happens, that the replica stops with the bolt carrier in a random place which, as you know, does not happen in real AKS during normal operation. But this is the only downside I've noticed.

During the tests I used a 11.1V 1400mAh 20C battery, which means that is has an average discharge rate. Despite this, the measured rate of fire was close to 15 shots per second, which corresponds to the theoretical rate of fire around 850 shots per minute. This is much more than in a real AK, but in turn far below what most of us are used to. Changing the battery to a more efficient one can slightly improve this result, but remember that gears are super torque-up with a ratio of about 32:1. You cannot expect RPM miracles from them.

Muzzle velocity test

Open Blaster 0.2 g BBs, XCORTECH 3500 chrono, ambient temperature about 26 °C.

1. 419.8

2. 422.6

3. 420.6

4. 422.6

5. 420.7

6. 420.9

7. 423.6

8. 419.4

9. 423.9

10. 418.1

Average: 421.2 fps. Spread: 5.8 fps

Target shooting test

Editorial closed shooting range, distance to the target 25 m,ambient temperature about 26 °C, G&G 0.28 g BBs, HopUp was preset, lying position. The replica was supported on a backpack. A recreational approach.

Single fire (fast)

Full-auto fire

Grouping is not exceptional, but the purpose of the test was not to prove that we shoot from a replica of a rifle suitable for a DMR. Rather, it was about showing the impact of the moving bolt carrier on accuracy. When firing a single fire, the shots were fired in quickly succession, without taking time to properly aim at the target again. The weight of the moving bolt carrier is nearly 300 g - great fun!

Summary

LCT has already accustomed us to an almost perfect external recreation of real weapons. The LCKM EBB does not differ in this respect from other replicas of this manufacturer. Visually, it's just great, although I won't venture to say that it's the best. Personally, I have two candidates (manufacturers) for this title and I cannot determine the winner. LCT is one of them.

Technically, there is nothing pick at. LCT has significantly strengthened those parts that are exposed in EBB replicas to increased mechanical loads. Noteworthy and worth praising is the use of steel gears with an increased gear ratio which, on the one hand, makes it easier for the motor to overcome the resistance of two springs (the main spring and bolt carrier return spring), and on the other hand, it limits the rate of fire slightly, which somewhat brings it closer to the original value and will definitely have a positive effect on the mechanism durability/longevity. Speaking of durability ... There is also some doubt about the significantly increased piston weight and how will that influence the reliability of the mechanism overall.

Is it worth buying it then? Probably not to ordinary airsofting. However, if someone is looking for something more than a regular "workhorse", it is probably worth it. At the same time, this "worth" will be also reflected in the purchase price.

On the next page - technical details