Technical details

The gearbox frame

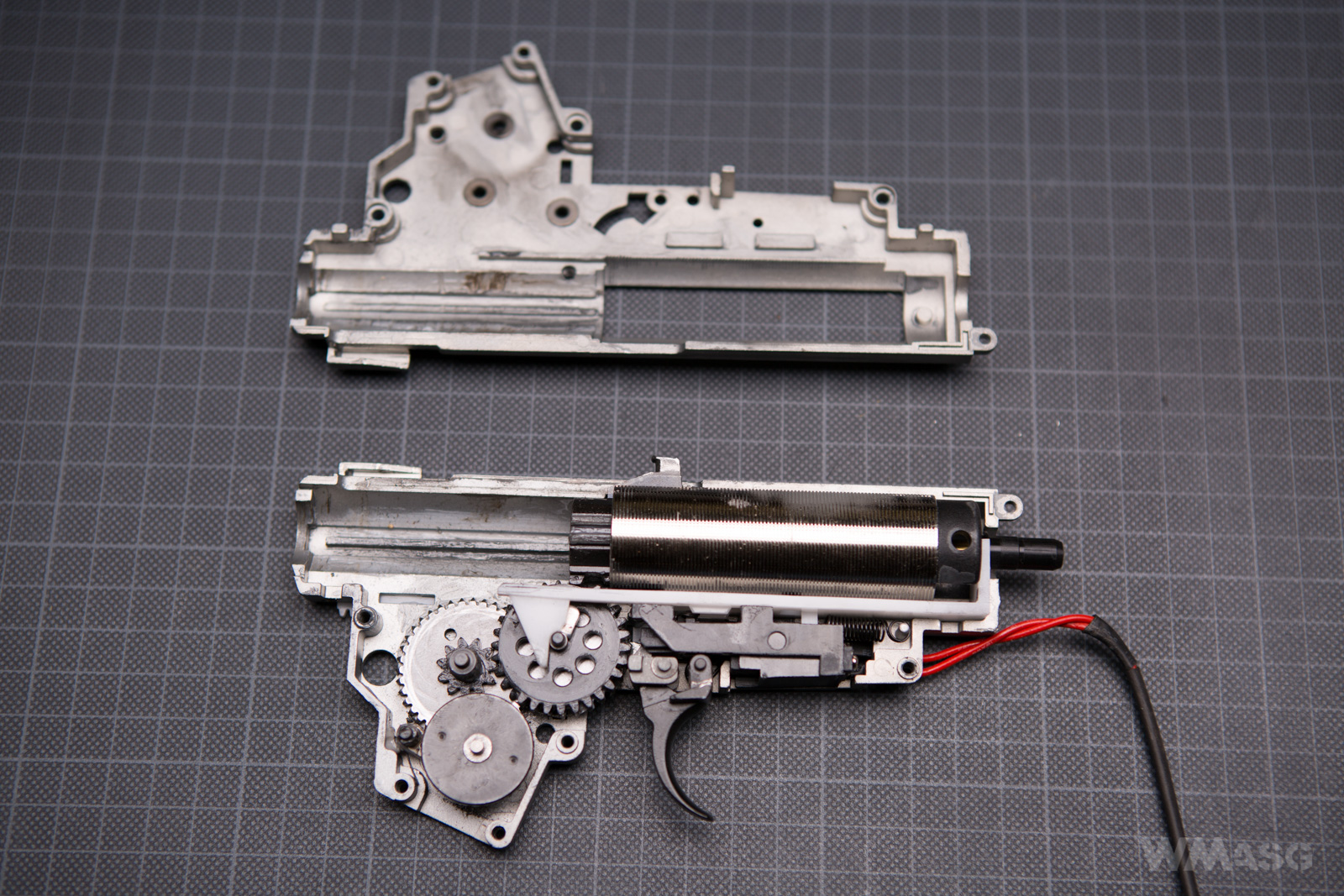

As I mentioned earlier, the frame of the gearbox driving mechanism is a V3 modified for the EBB system and slightly reinforced in the critical front part of the cylinder port. Apart from that it is a typical V3, so in the event of a breakdown you can replace it with another frame, possibly forfeiting the blowback function. All cams and levers responsible for the safety/fire selector settings are standard. Similarly, the selector plate.

All cams and levers responsible for the safety/fire selector settings are standard. Similarly, the selector plate.

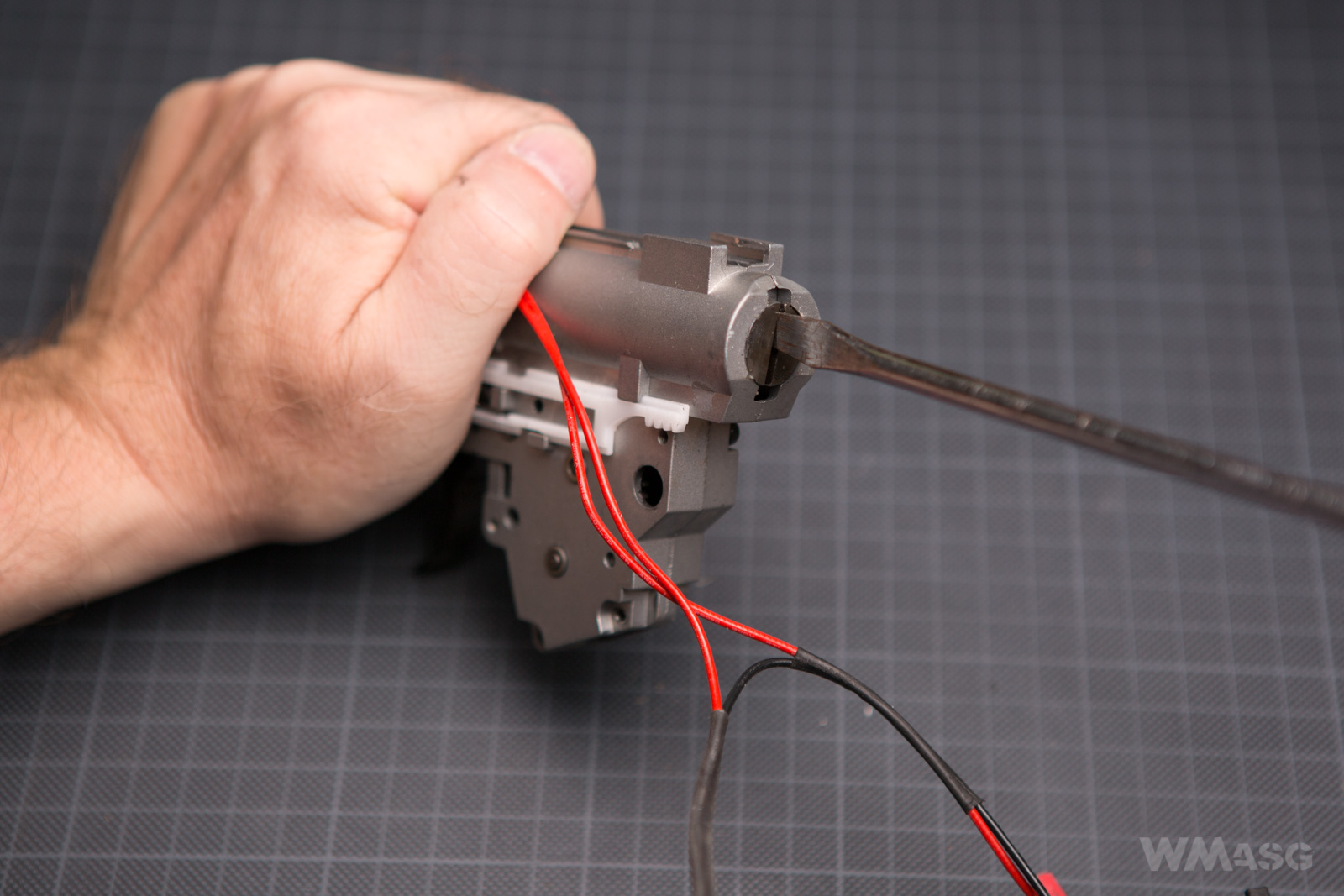

The frame offers the possibility of a quick spring replacement, but only after removing the mechanism from the replica's receiver. A flat screwdriver must be used to release the spring guide, which has a ball bearing. The operation itself is typical, the guide needs to be lightly pressed in and turned a quarter of a turn.

The motor

As with all AK replicas, the replica uses a short shaft motor, but the LCKM uses a stronger one called the T2-Torque Motor, which has stronger magnets, thanks to which it has more torque. According to the catalog data, this motor, without any load and powered by a 8.4V battery rotates at 27500 revolutions per minute. To improve cooling, the motor has an aluminum bottom plate and additional holes in the housing. The pinion mounted on the shaft is a D type.

According to the catalog data, this motor, without any load and powered by a 8.4V battery rotates at 27500 revolutions per minute. To improve cooling, the motor has an aluminum bottom plate and additional holes in the housing. The pinion mounted on the shaft is a D type.

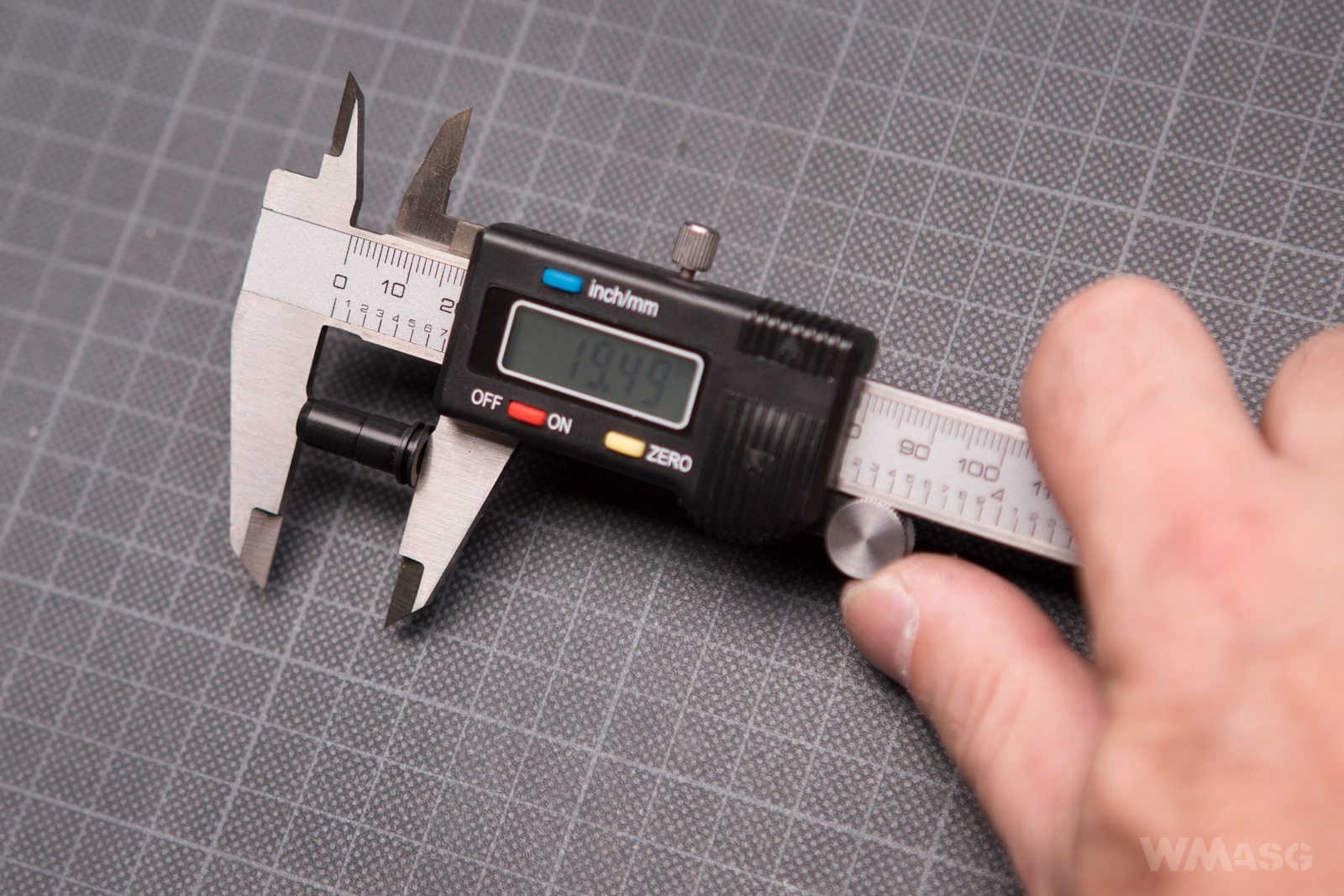

The bearings

The frame is designed to work with 6 mm bearings. Why did LCT decide to stick to the original (Tokyo Marui) standard, while nowadays bearings with a diameter of 8 or 9mm are the most common ones? I do not know. However, I know for sure that increasing the diameter of the bearings changes the distribution of forces in their sockets and therefore delays their wear (deformation). Well ... they certainly know it too at LCT ... The factory supplies the gearbox with 6 mm steel bushings mounted in the frame. This is a better choice compared to 6 mm ball bearings. While the friction is clearly higher (but still acceptable), the service life of good steel bushings is far higher than for comparable ball bearings.

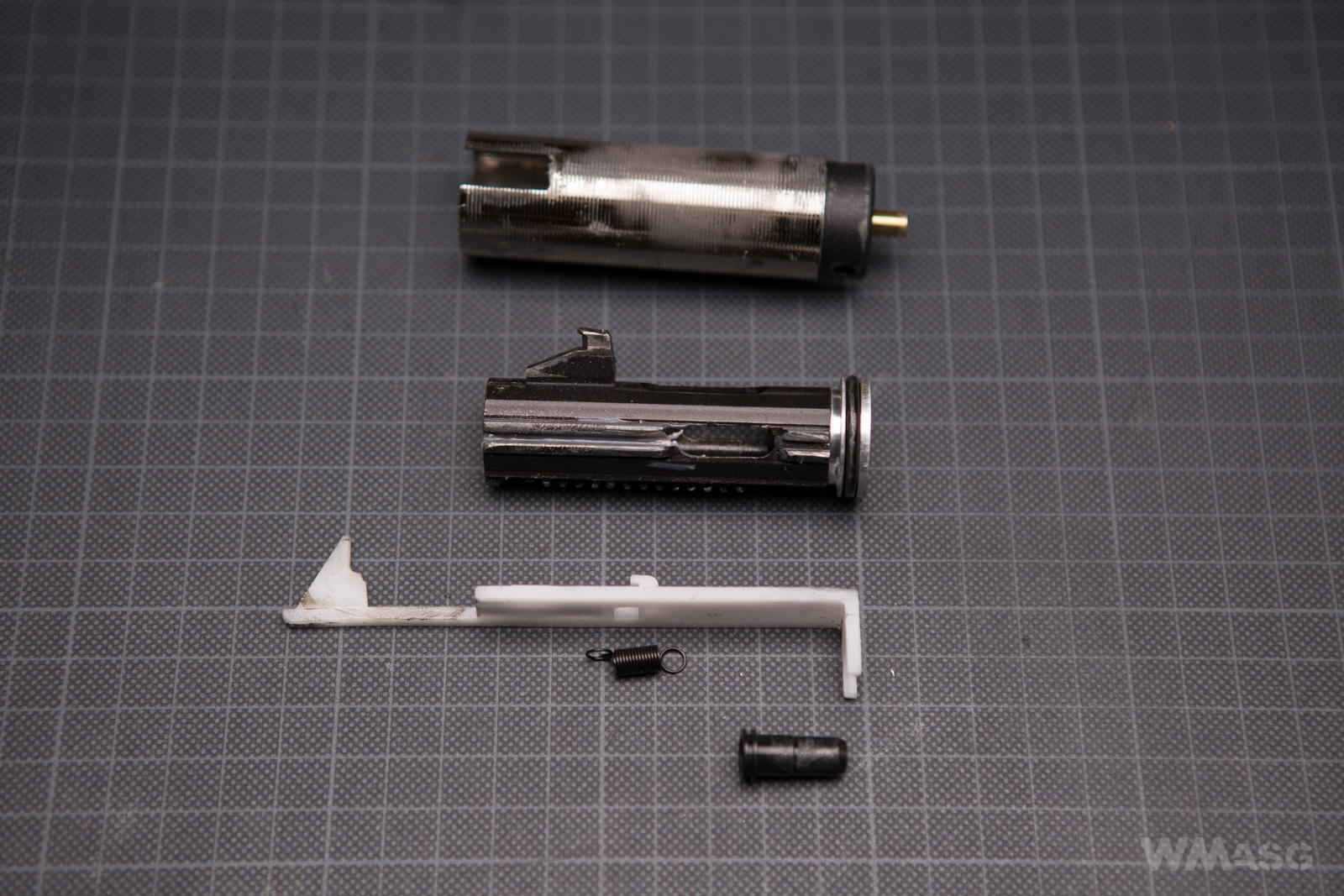

The pneumatic system![]()

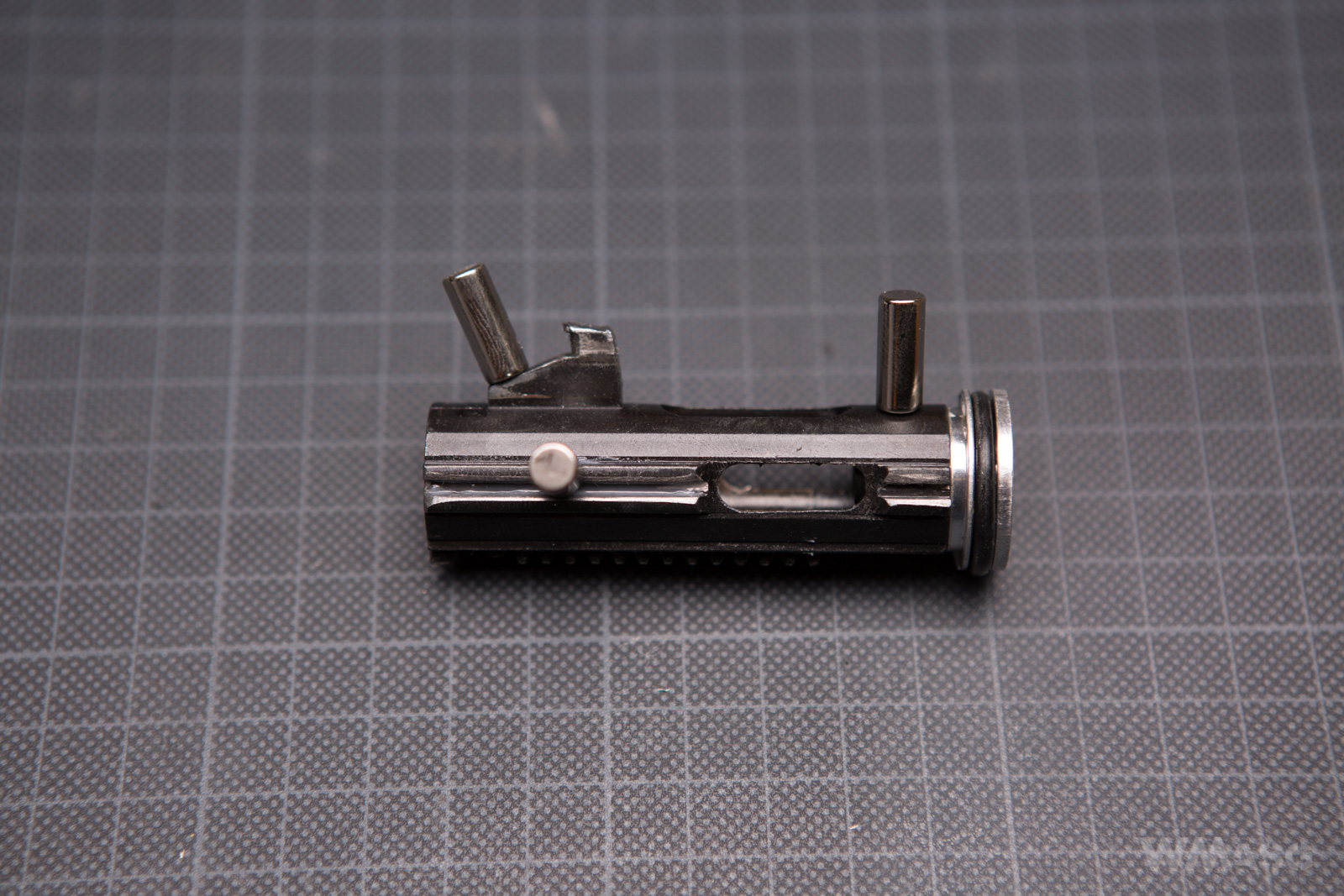

The pneumatic system visible in the photo above consists mostly of components of quality typical for LCT. The exception is the chromed cylinder with a cutout in the back, in which the blowback system hook works

and the piston itself with the above mentioned hook.

I have to devote a few words more to the piston. This is because it is the only factory supplied piston I know of, that is made entirely of steel. The second characteristic feature is the fact that it was cut completely from one piece of material. The blowback hook and teeth are an integral part of it. The carbon steel it is made of guarantees high durability. However its mass raises concerns. The piston itself weighs 58.2 g. For comparison, a standard LCT polycarbonate piston with a full steel teeth (the red one) weighs only 16.8 g. The total weight of the piston with a stock head, with a bearing, made of aluminum is 68 g and 29.6 g, respectively. It's a big difference. The frame will need to take hits of more than twice the weight. Will the reinforcements of the front part shown earlier be enough? Probably so. It's hard to assume that LCT decided to shoot themselves in the foot and expose themselves to an avalanche warranty claims consisting in the cracked gearboxes. But some anxiety remains.

(Of course, any frame will give up sooner or later. We're talking about cracks appearing after a relatively short period of use.)

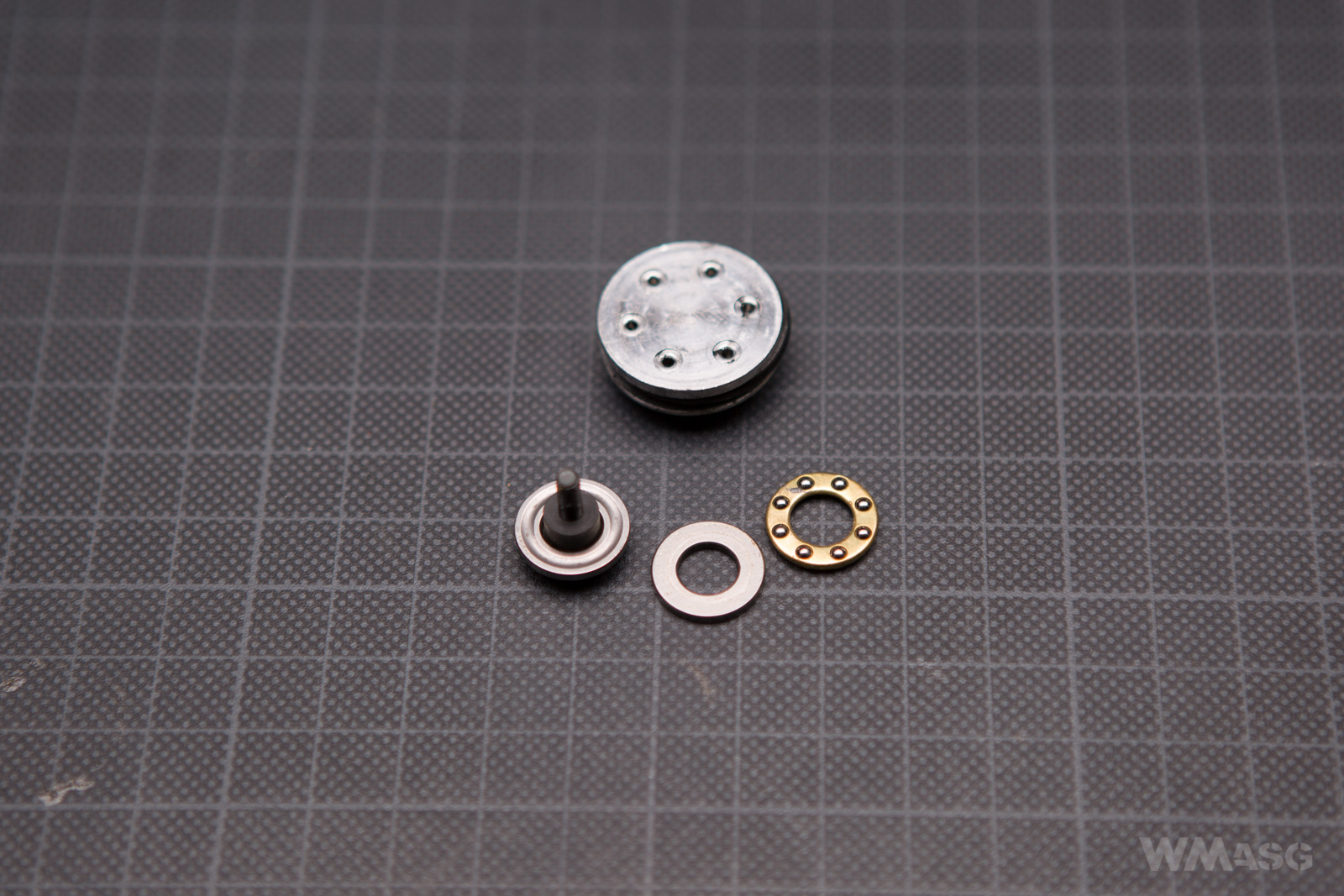

Other parts of the pneumatic system are the already mentioned and shown aluminum piston head with a bearing;

polymer cylinder head with a thick rubber bumper;

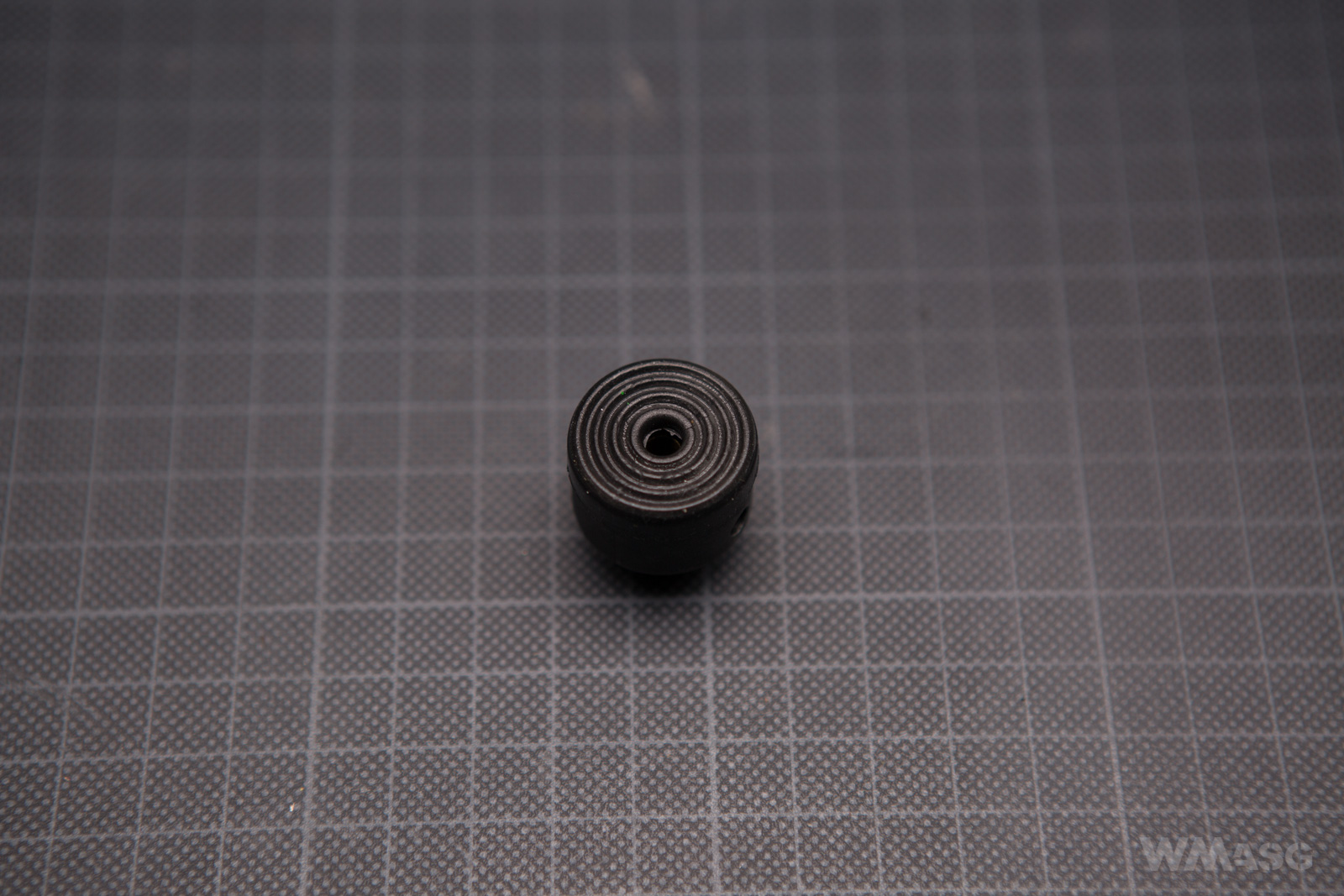

and a polymer 19.5 mm long nozzle with an o-ring.

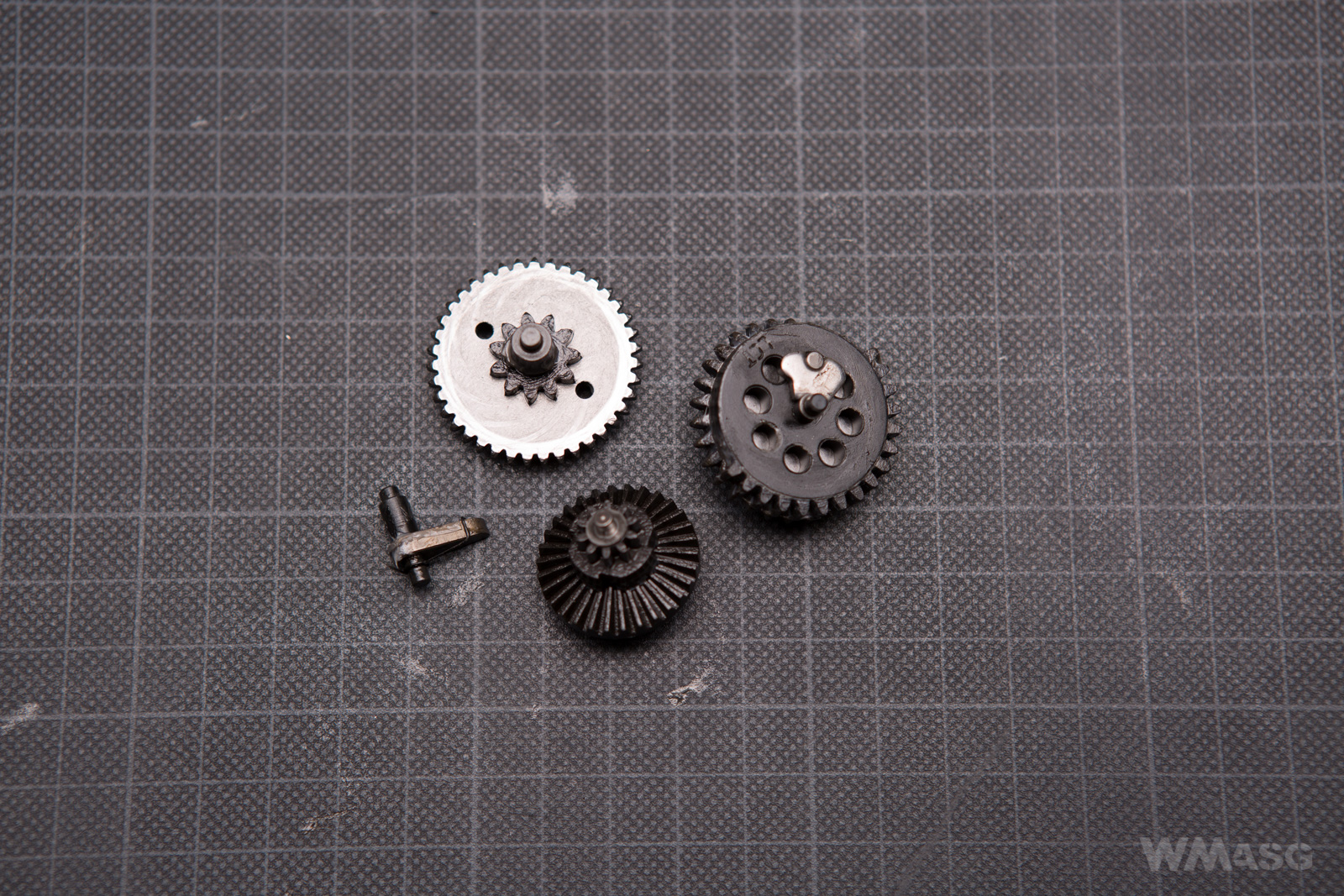

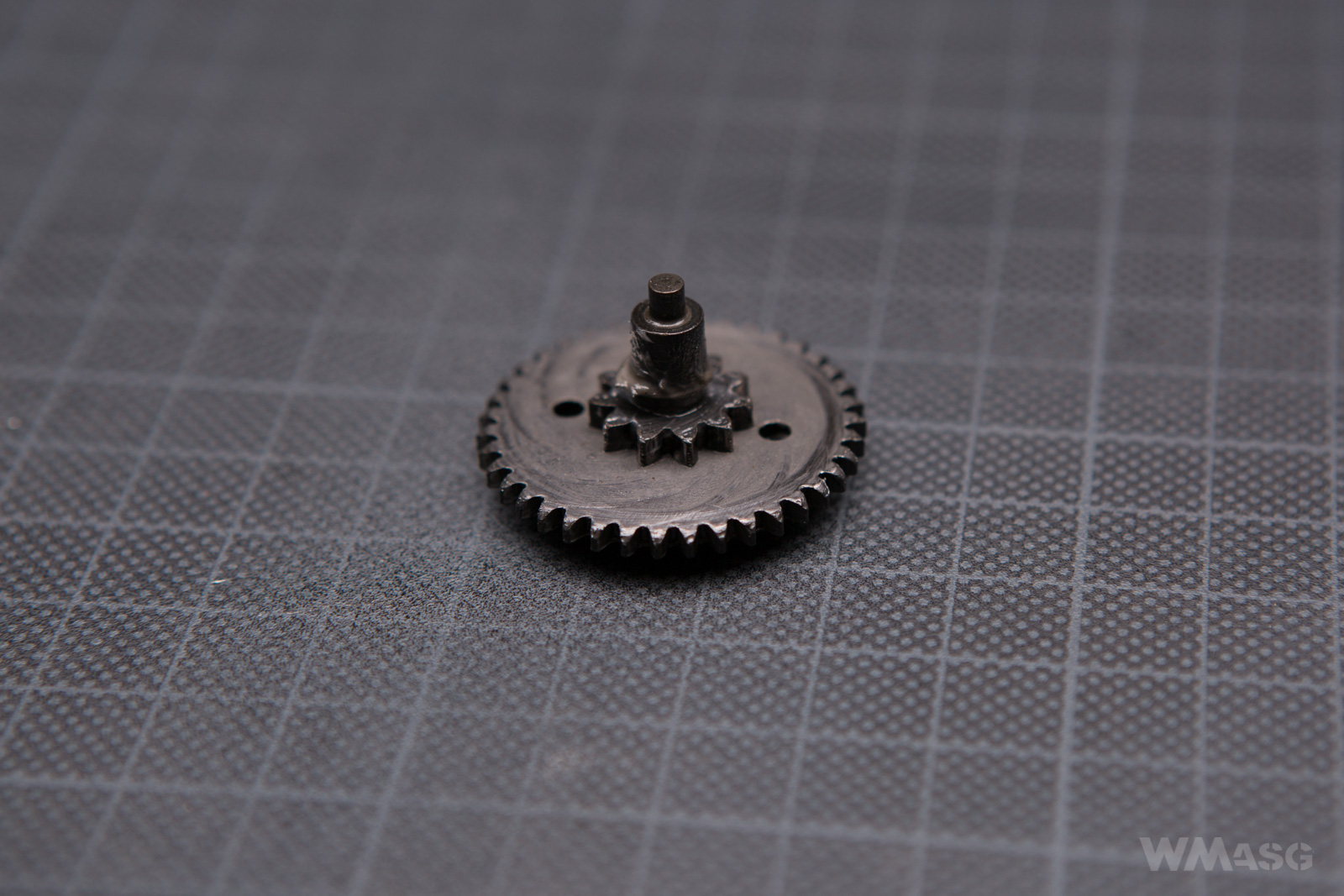

The gears

The increase in piston weight and the EBB system prompted LCT to use, for the first time in a factory configuration, a set of gears with increased ratio. These gears really make a very, very good impression. The manufacturer states that, like the piston, they are made entirely out of carbon steel.

The increased ratio is easy to recognize after a first glance at the sector gear, where the teeth working with the spur gear are aligned with the sector teeth working on the piston (larger diameter of the disc working with the spur gear).

Inevitably, the spur gear has a correspondingly smaller plate cooperating with the sector gear (the smaller, inner one).

The large ratio forces narrowing of the teeth on the piston (narrowed teeth, half teeth).

Electrical instalation

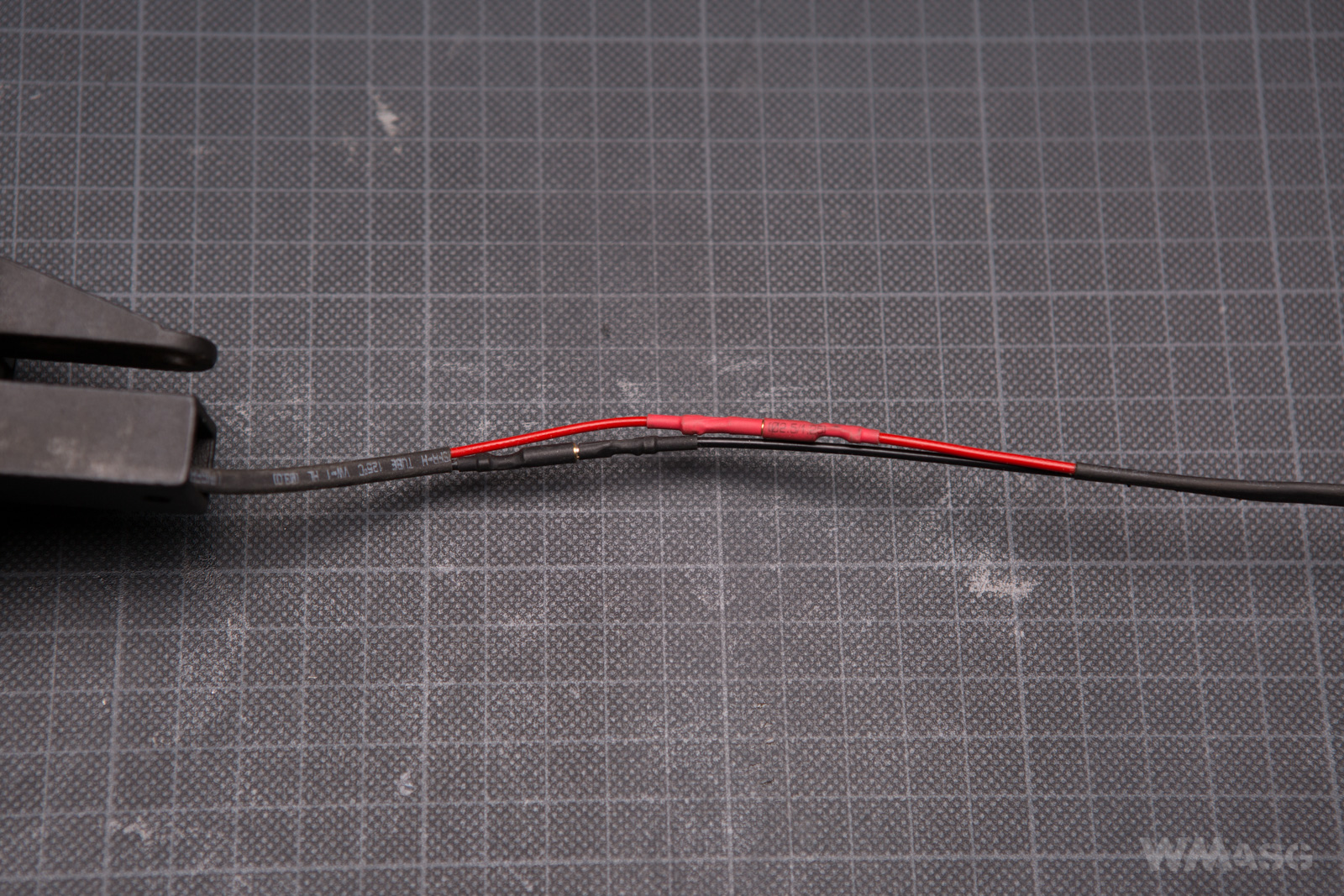

The LCKM, like other LCT replicas, has an electrical installation made of rigid wires in hard insulation with high mechanical durability. The manufacturer decided that instead of uniform wires it would be more beneficial to introduce additional connections using ordinary flat connectors hidden somewhere inside the buttstock.

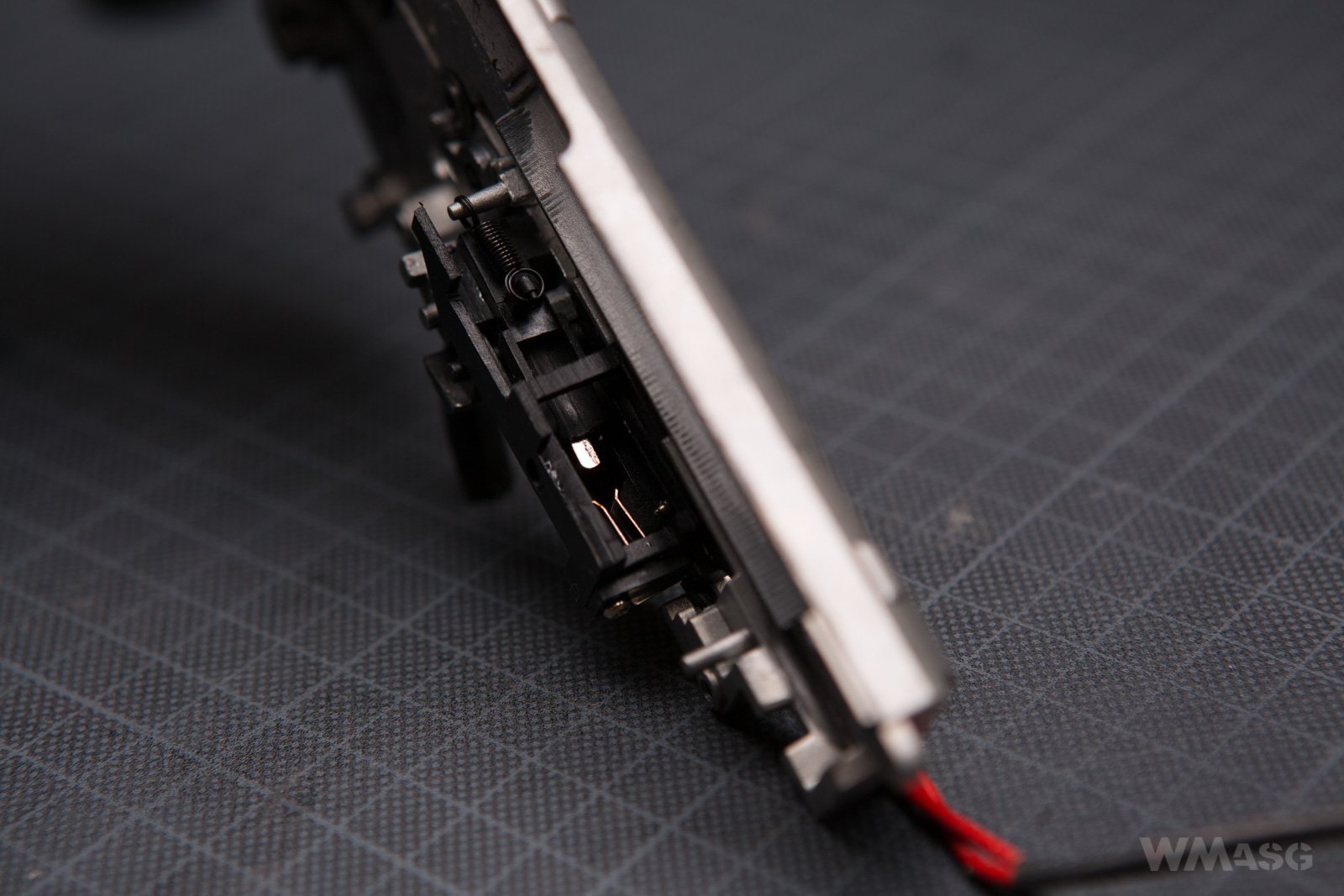

The electric circuit is closed with a normal, typical contact switch designed for V3 gearboxes. There is no MOSFET or any other electronics.

Unfortunately, this results in the previously described symptom of the bolt carrier stopping in a different position than the front one. It's a bit annoying, because on the one hand, a powerful blowback system makes the use of the replica much more realistic, but on the other, the real AK doesn't behave like that. The solution is to use some advanced electronic control system that monitors the rotation of the gears and stops the mechanism with the piston always in the front position (and therefore also bolt carrier). To do that one could use the Titan Gate system, for example.

The blowback

I wrote a few sentences above about the operation of the EBB system. I will repeat it again: it works very well. The target test showed that if you want to shoot accurately, you really need to hold the replica properly. One can live with the issue of the bolt carrier not always returning to the front position. Or solve it definitely as described in the previous paragraph.

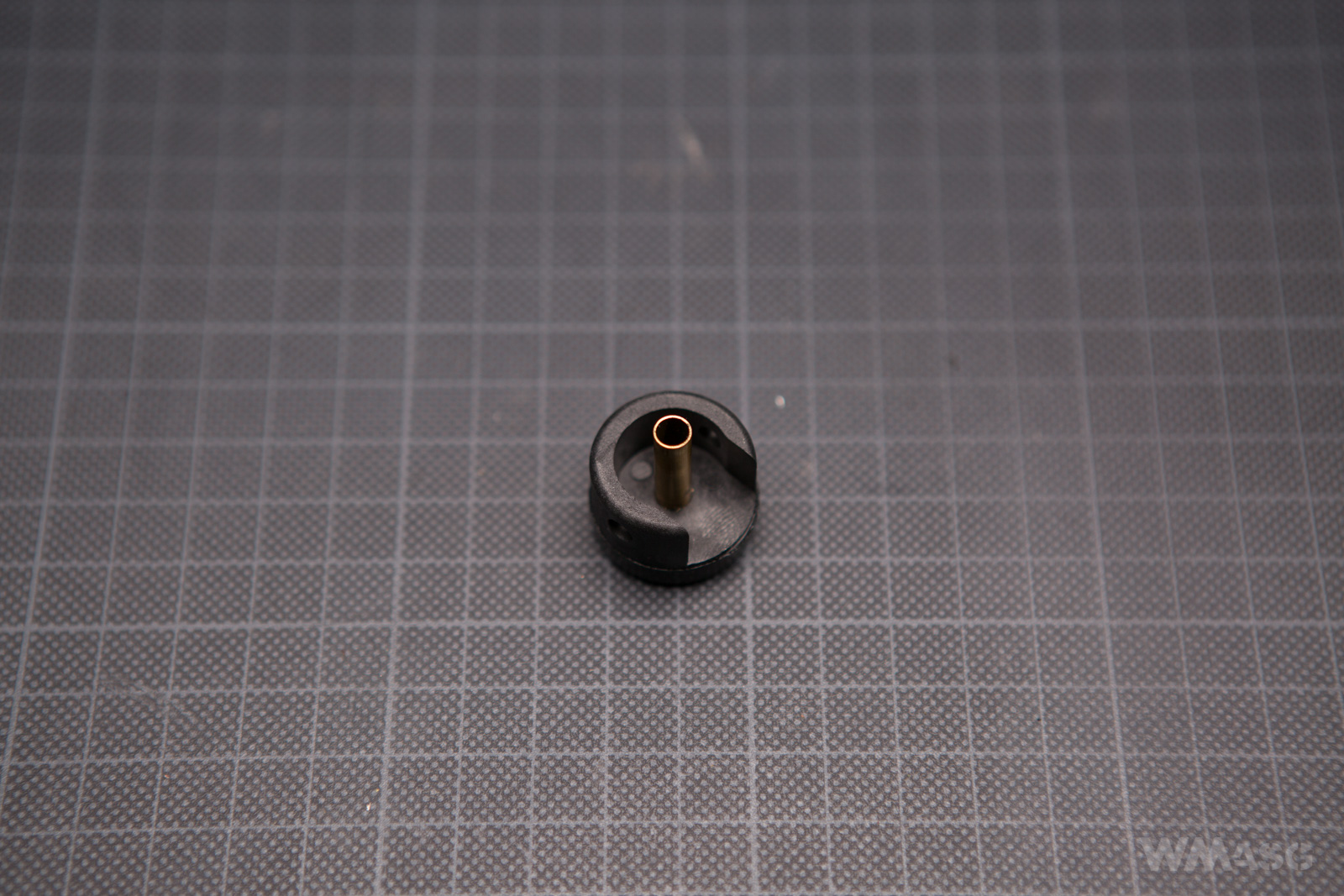

However, there is one thing about the EBB system that you need to pay attention to. Having a replica with an EBB designed in this way you will probably be asked to remove the cover and show the bolt carrier with the piston. And here lies a trap that I wrote about earlier and which I fell into during this year's Mission Afghanistan event. It's about this little black block shown earlier:

During Mission Afghanistan, while demonstrating, yet another time, how the blowback system work in this replica, I was putting it back together in a hurry and I have put the black block in the opposite way and the blowback broke. That is, it worked very rarely, the bolt carrier was falling from the piston hook and then hooked on again. It was terrible. I can only explain myself with the completely non-intuitive shape of the part and, in my opinion, an equally non-intuitive place where it should be placed. Well, this black block should be placed at the base of the rear sight, from the inside. It is to be located directly above the gas piston mounted after is has been set it to limit its possibility of the bolt carrier upward movement, which leads to loss its connection with the gearbox. Because the part is only loosely inserted into the right place, it is easiest to mount it by holding the replica with the magazine socket upwards or on the side. In this position push the gas piston into the base of the rear sight. After installing the bolt carrier in this way, the blowback miraculously started working and continued to work flawlessly throughout the entire testing period. And it still works. The LCT video below illustrates the assembly of the EBB system. The assembly the "black block" can be observed from the 15th second.