Technical details

Apart from the disassembly of the stock guide described earlier, the replica is disassembled like most currently produced replicas of the AR-15 system. The front pin connecting the receiver parts has to be removed the upper receiver has to be moved forward. It is worth noting that the pins connecting the receiver parts are protected against falling out and getting lost.

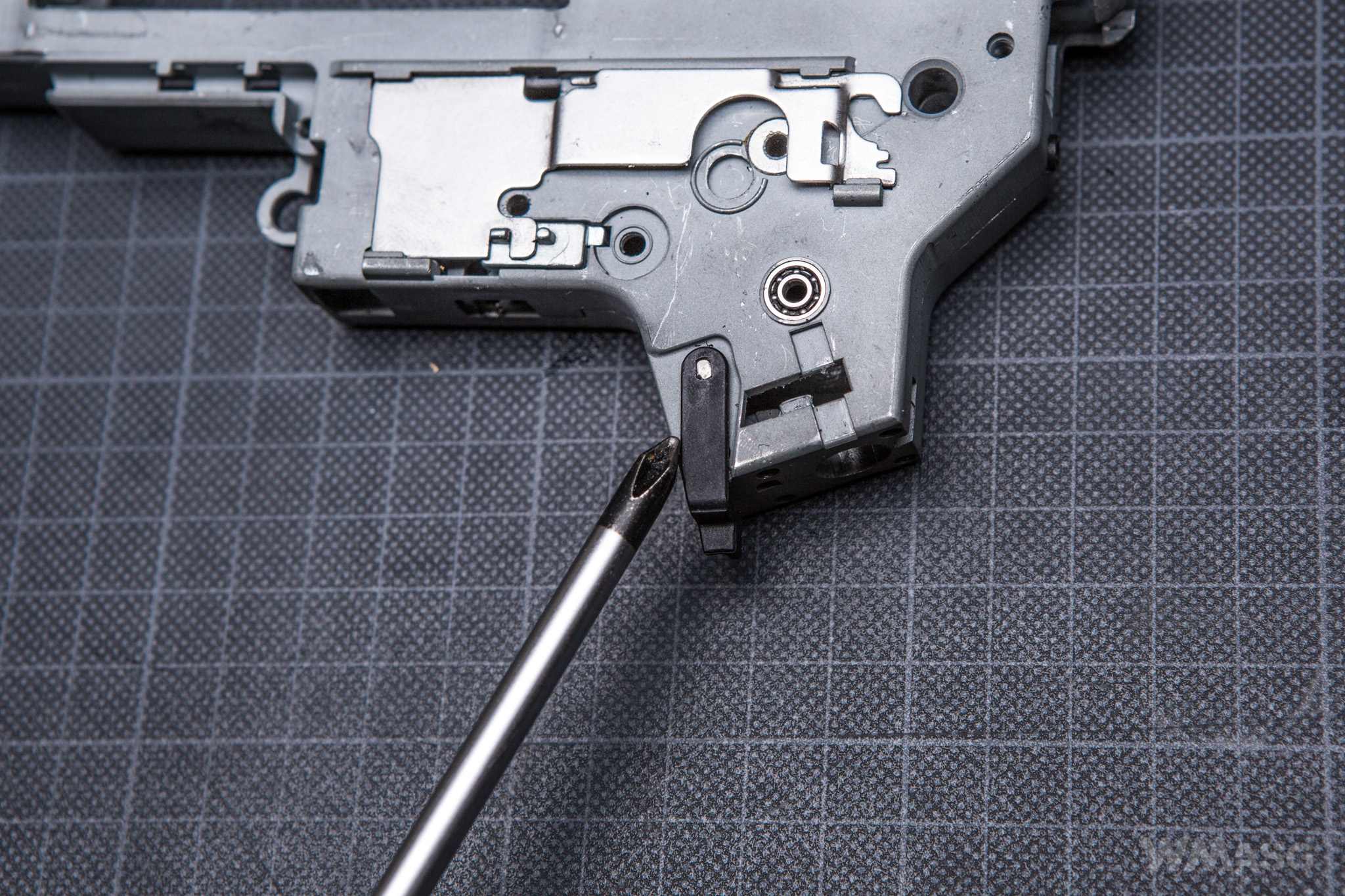

Removing the gearbox from the lower receiver requires disassembly of both safety/selector levers. They are screwed from the outside with Allen head screws. The spring and the clicking "mushroom" are only under the left lever. That is why using the one on the right is less responsive.

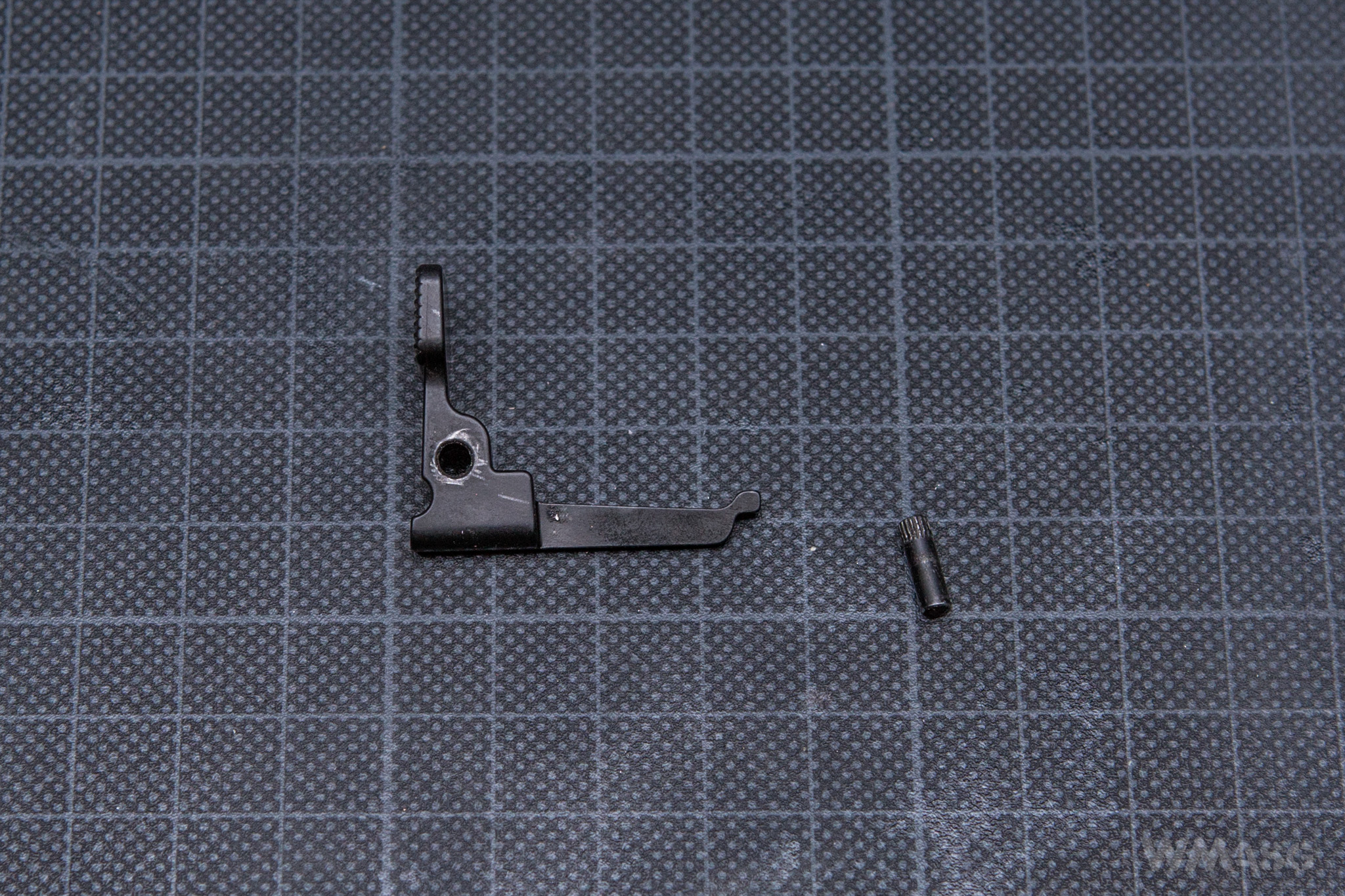

It is also necessary to remove the bolt catch. It is attached to the receiver with a hammered in pin.

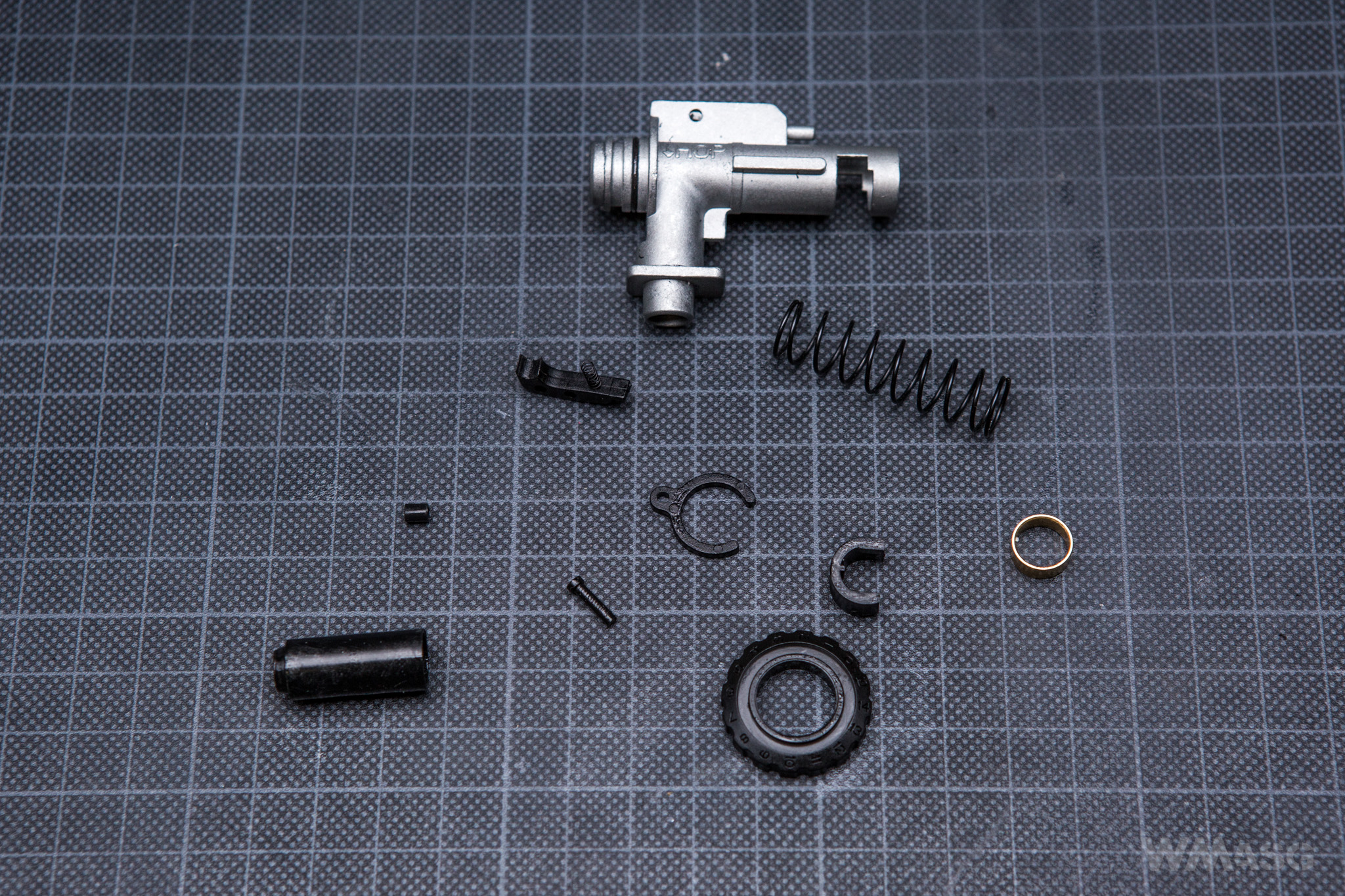

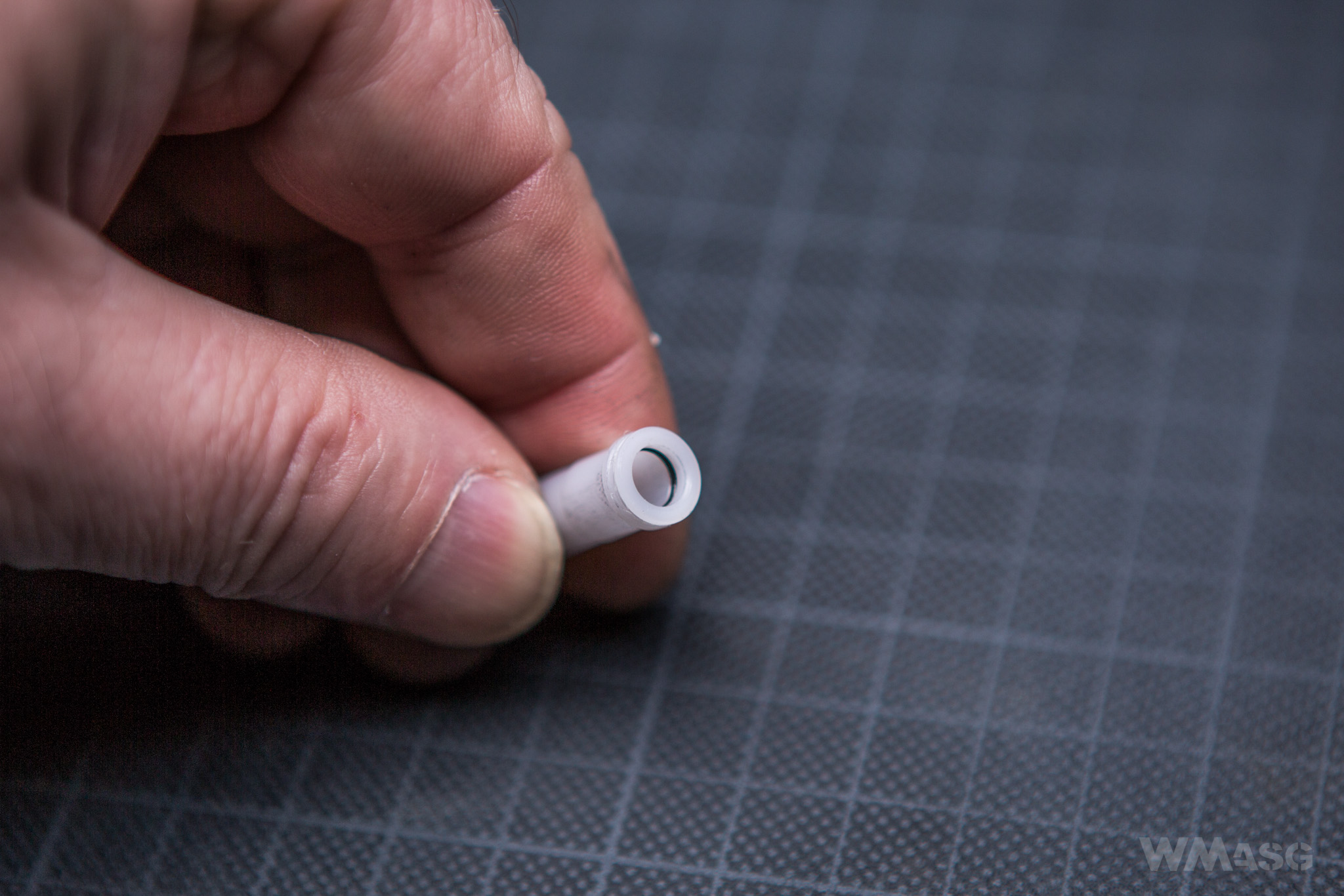

The precisely adjustable HopUp chamber works with a standard bucking and a cylindrical spacer. During the tests, we had no remarks about the system's operation.

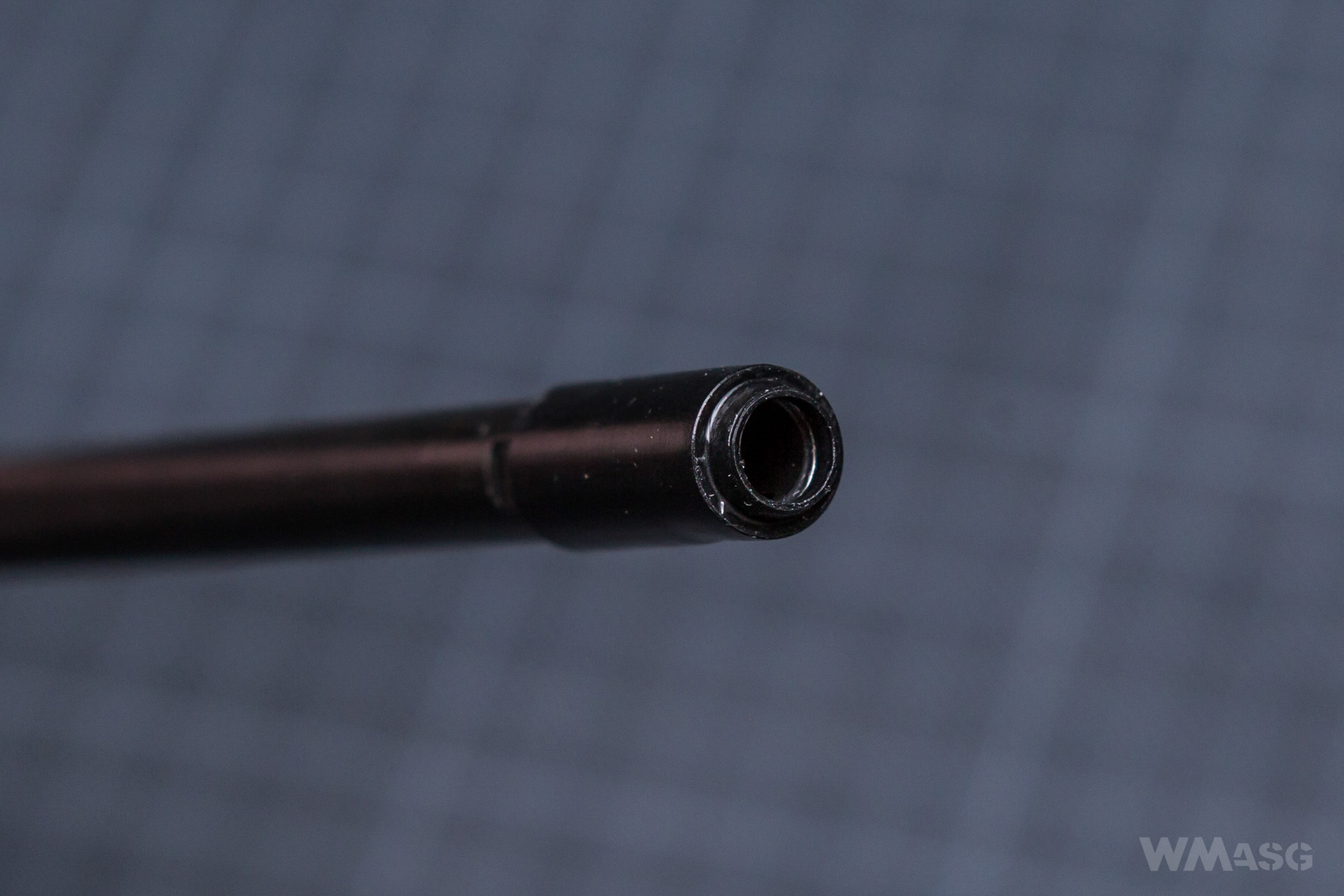

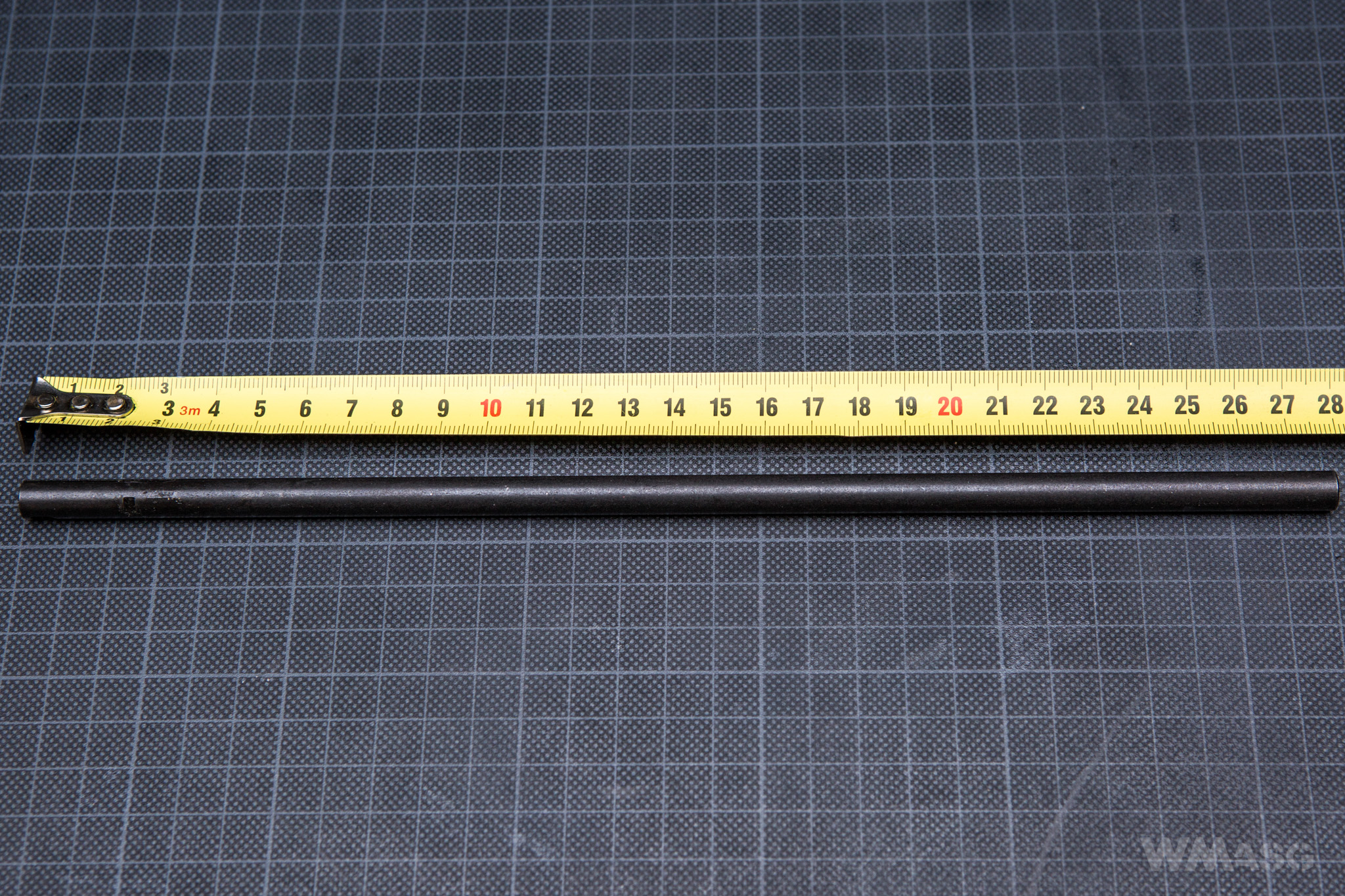

The inner barrel with a diameter of 6.01 mm is made of steel. The barrel's length is 280 mm.

The gearbox

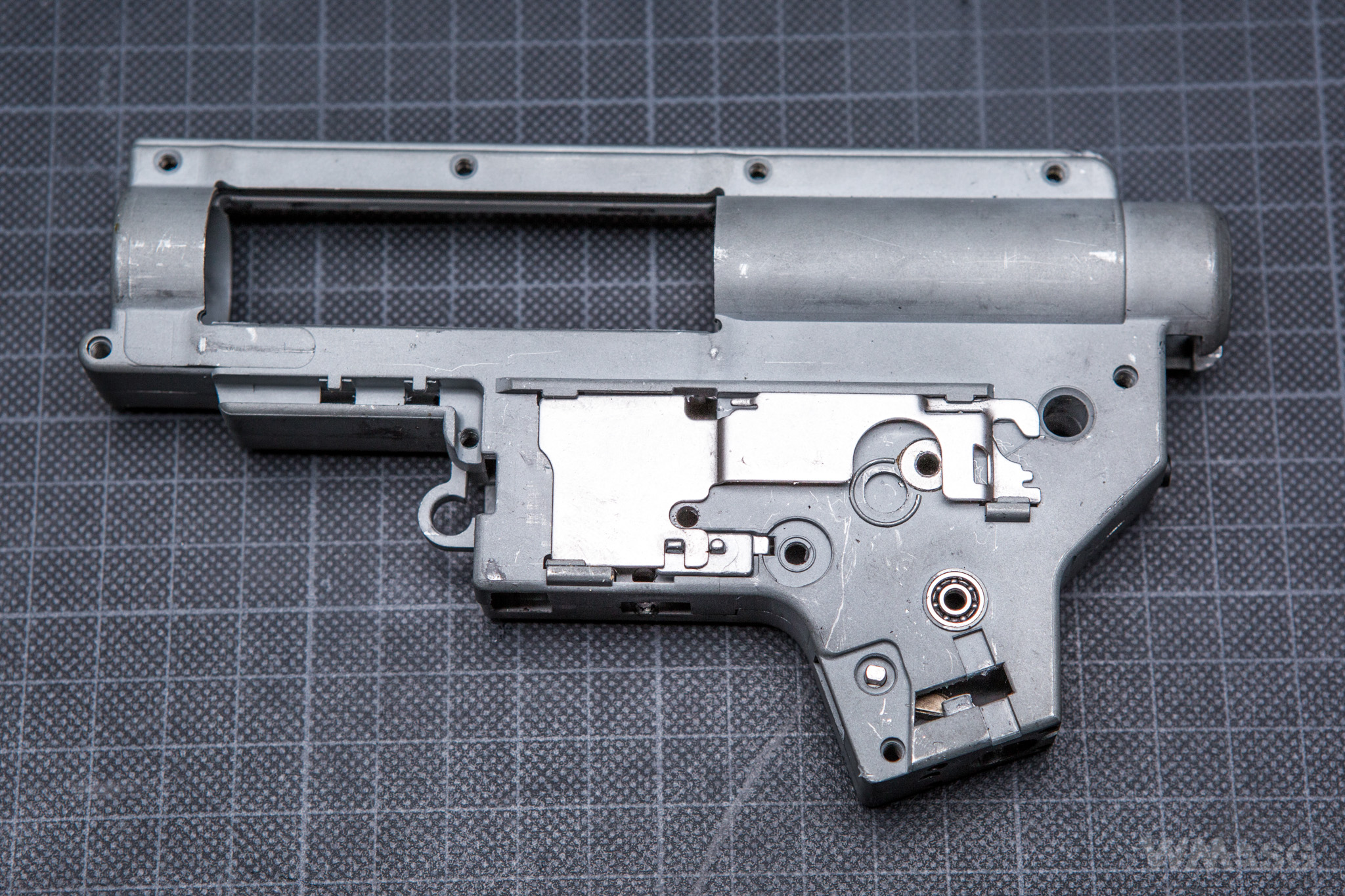

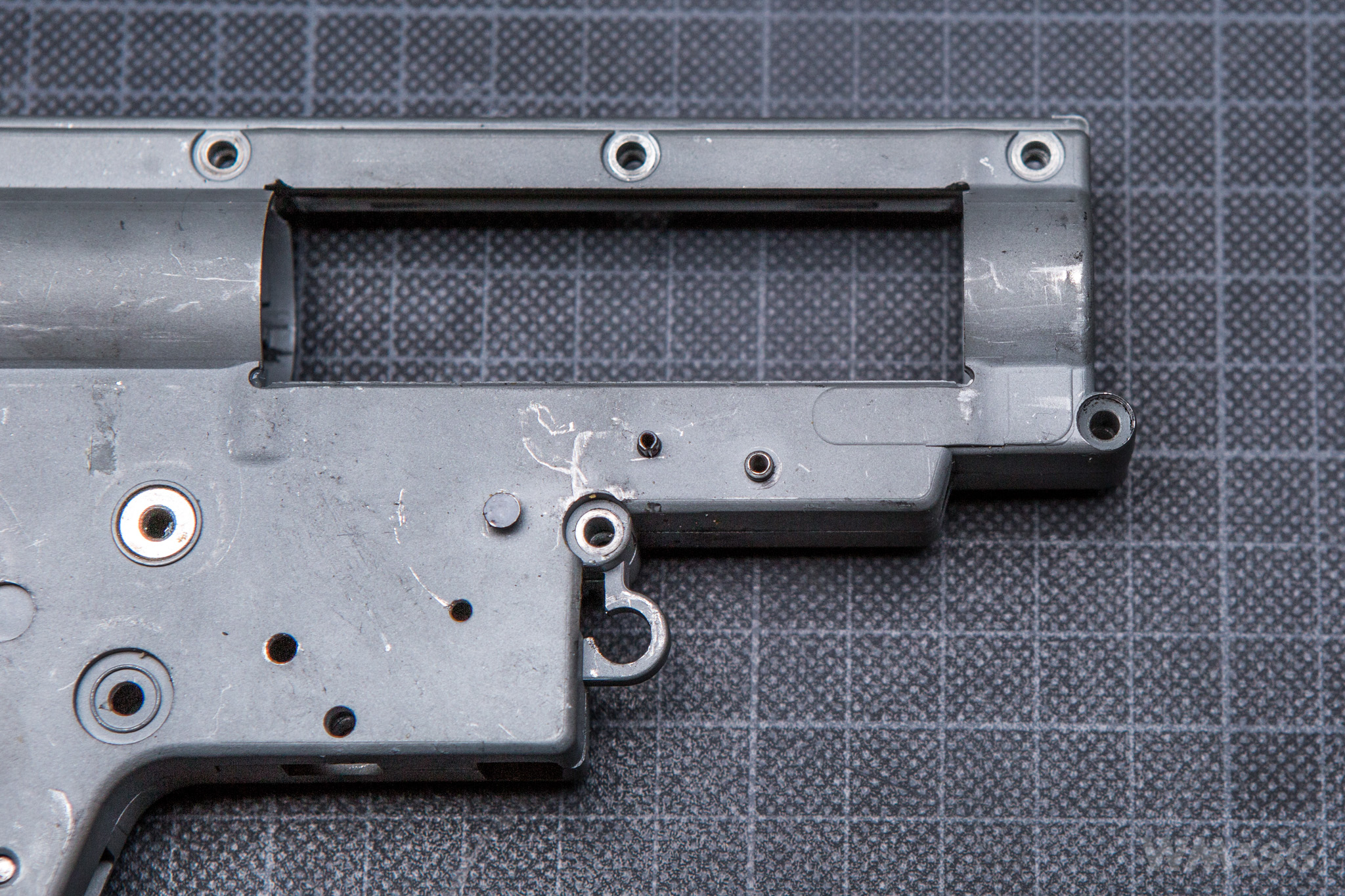

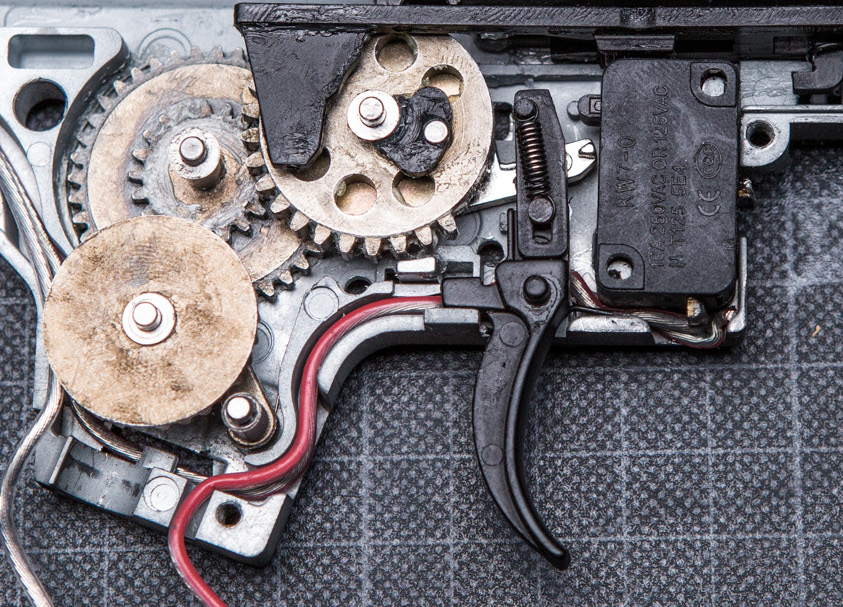

The frame is a modified V2 and is not interchangeable classic-shaped frames. The shape of the rear part is different, the selector plate is different and the mechanical trigger safety solution in the safe position is also different. There is also a different trigger and a cut-off lever and the position and shape of the anti-reversal latch is also different. Access to the latch release lever is gained only after removing the pistol grip.

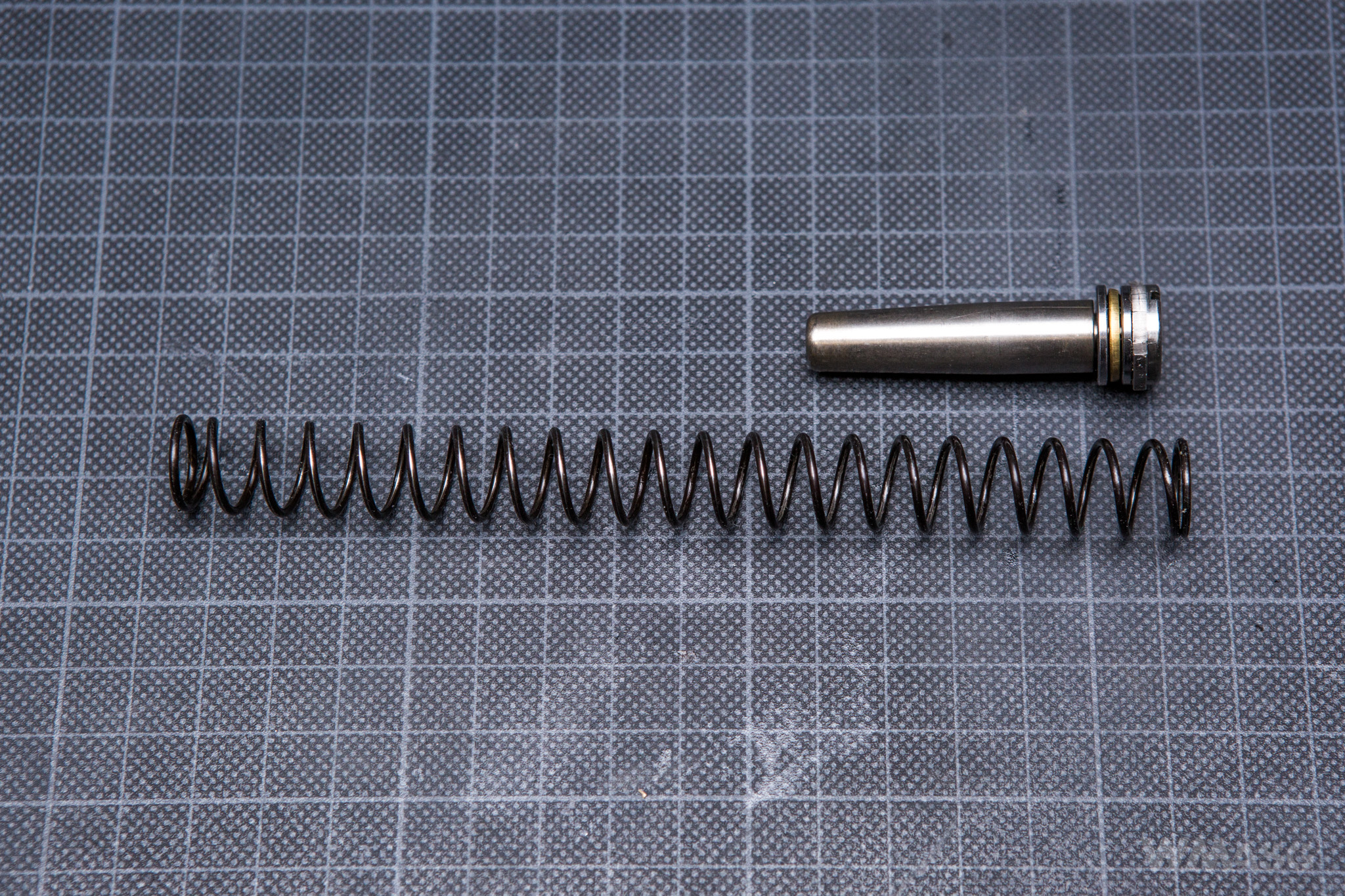

The quick-change spring guide has 2 mounting tabs.

The cylinder port corners are slightly reinforced with more material and rounded edges which change the distribution of forces.

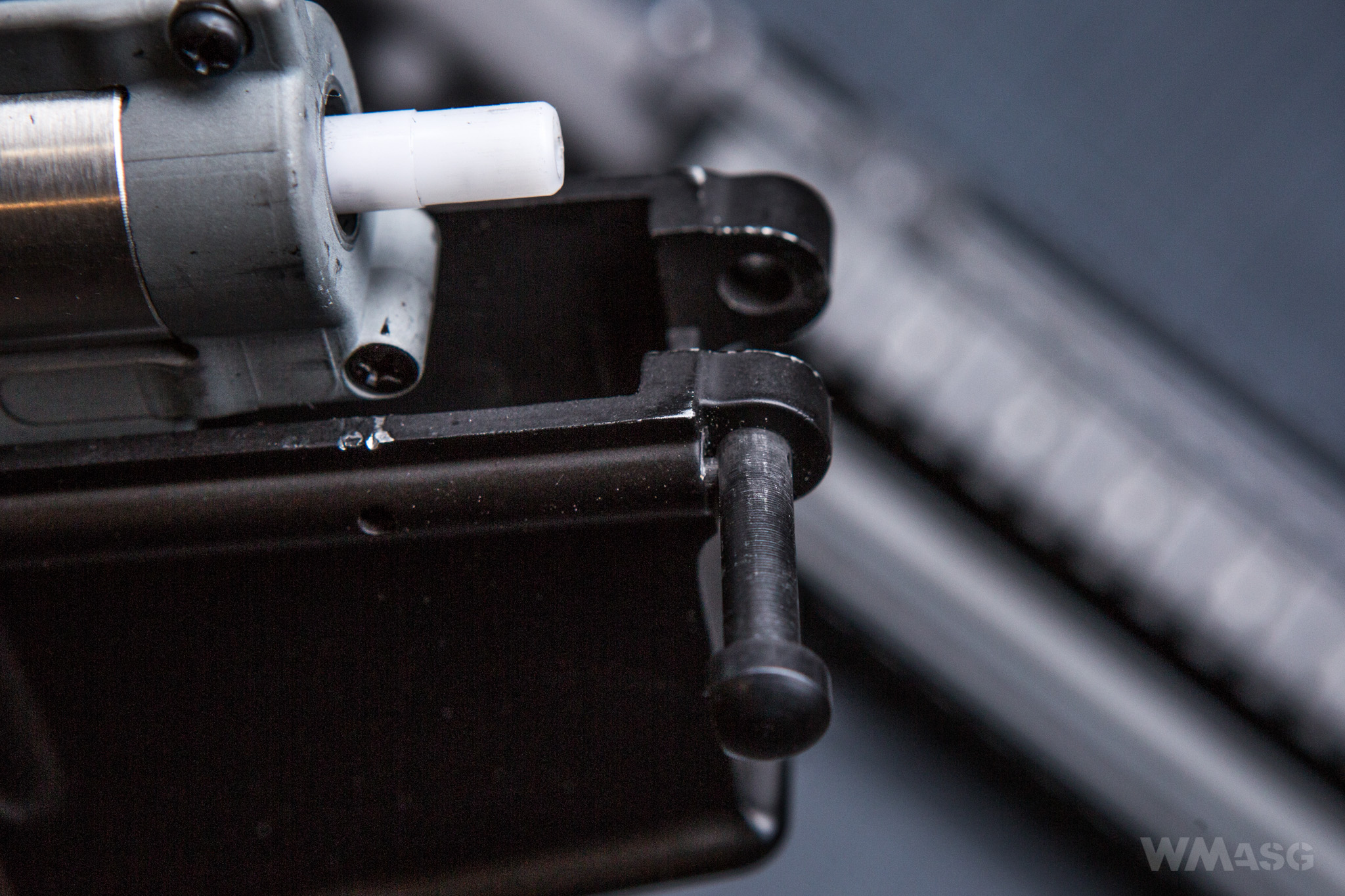

The hole for the motor shaft is not centrally located due to the shape of the frame.

Internal parts

The cylinder assembly is airtight. The cylinder is type 2 and made of steel.

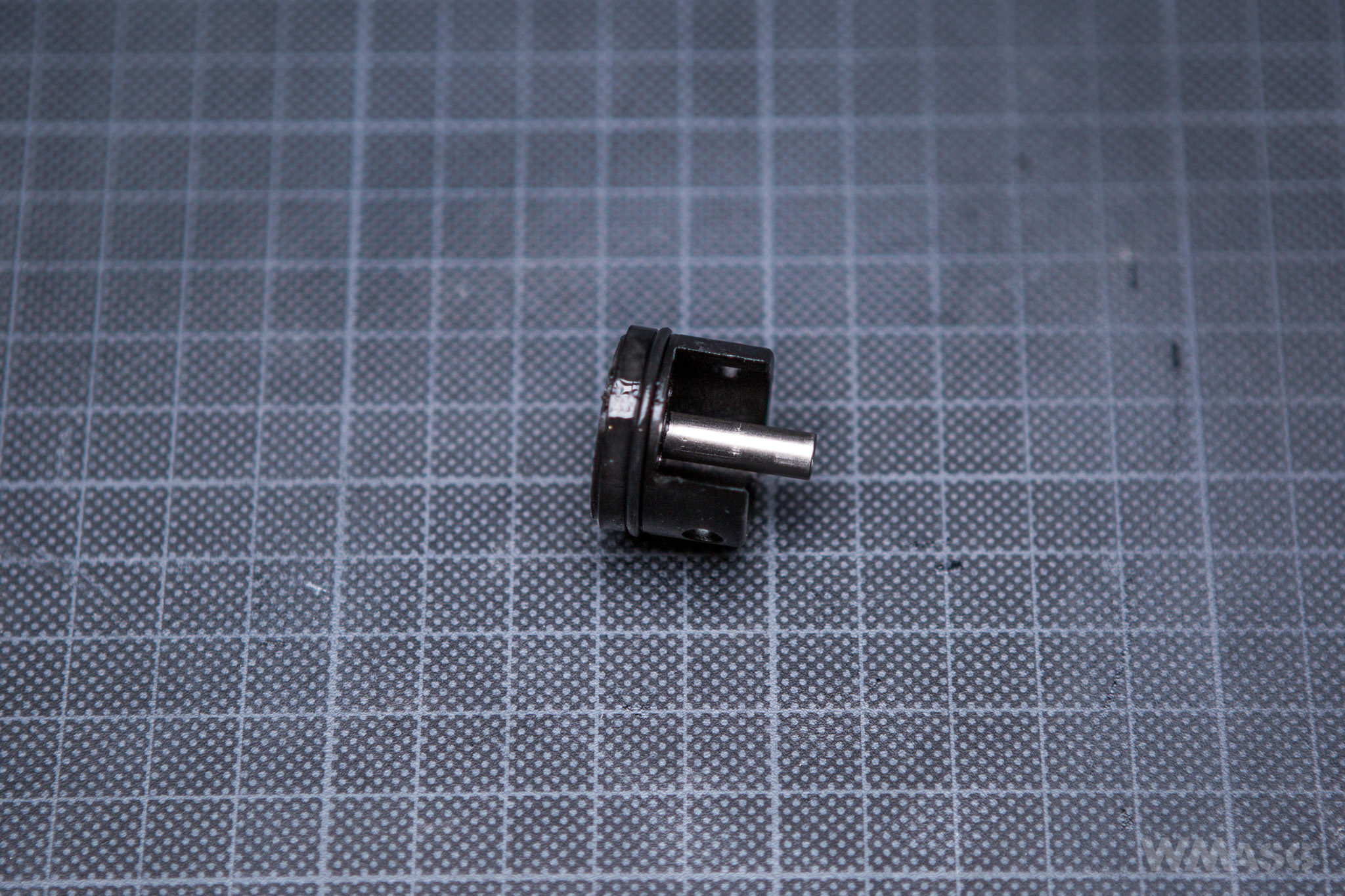

The cylinder head and piston head are made of polymer. The latter is has a ball bearing and not, as sometimes encountered, a sleeve.

Unlike the previously described Arcturus replicas, the 416 has a 21.4 mm long nozzle with an O-ring also made of polymer. However, it has 3 elements designed to slightly channel the stream of air flowing through it. This is exactly what Tokyo Marui has been using for years.

The piston has teeth made entirely of steel and lacks the a second tooth.

Steel spring guide has a ball bearing.

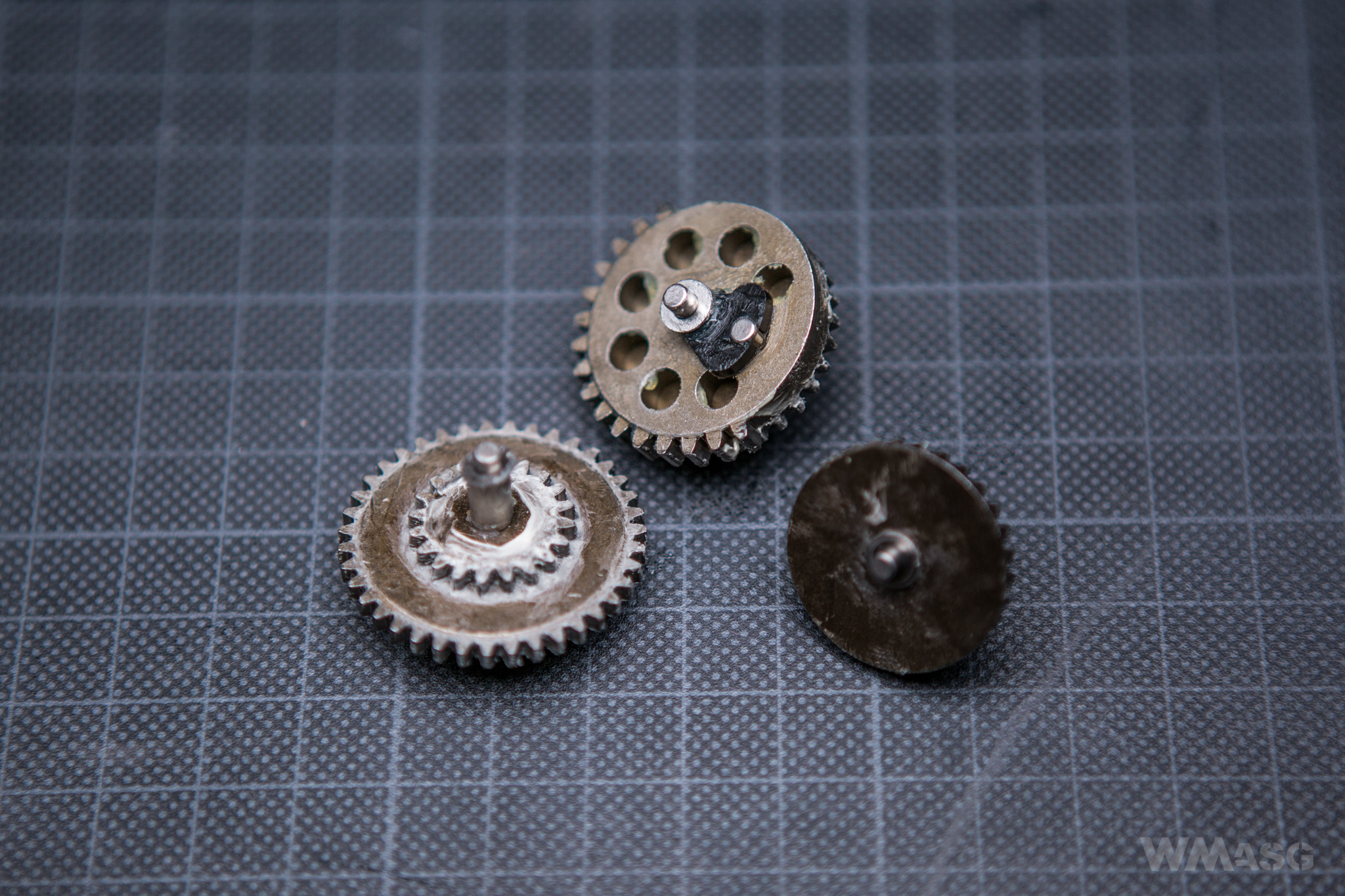

Standard gears are made of sintered steel. A polymer delayer was placed on the sector gear.

The anti-return latch, already mentioned several times before, is on the opposite side than usual, and its axis is ends in a way that allows installation of an external lever.

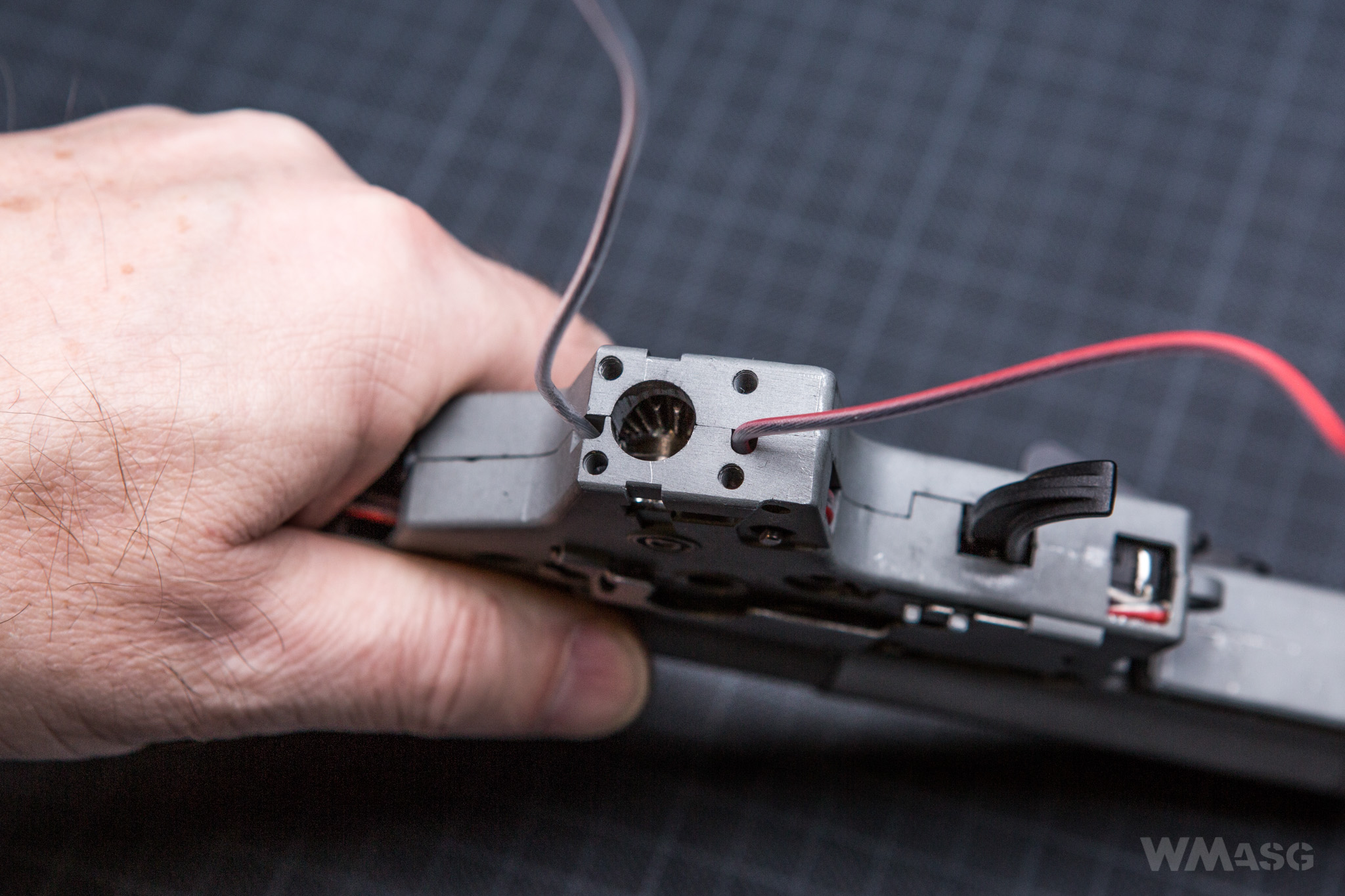

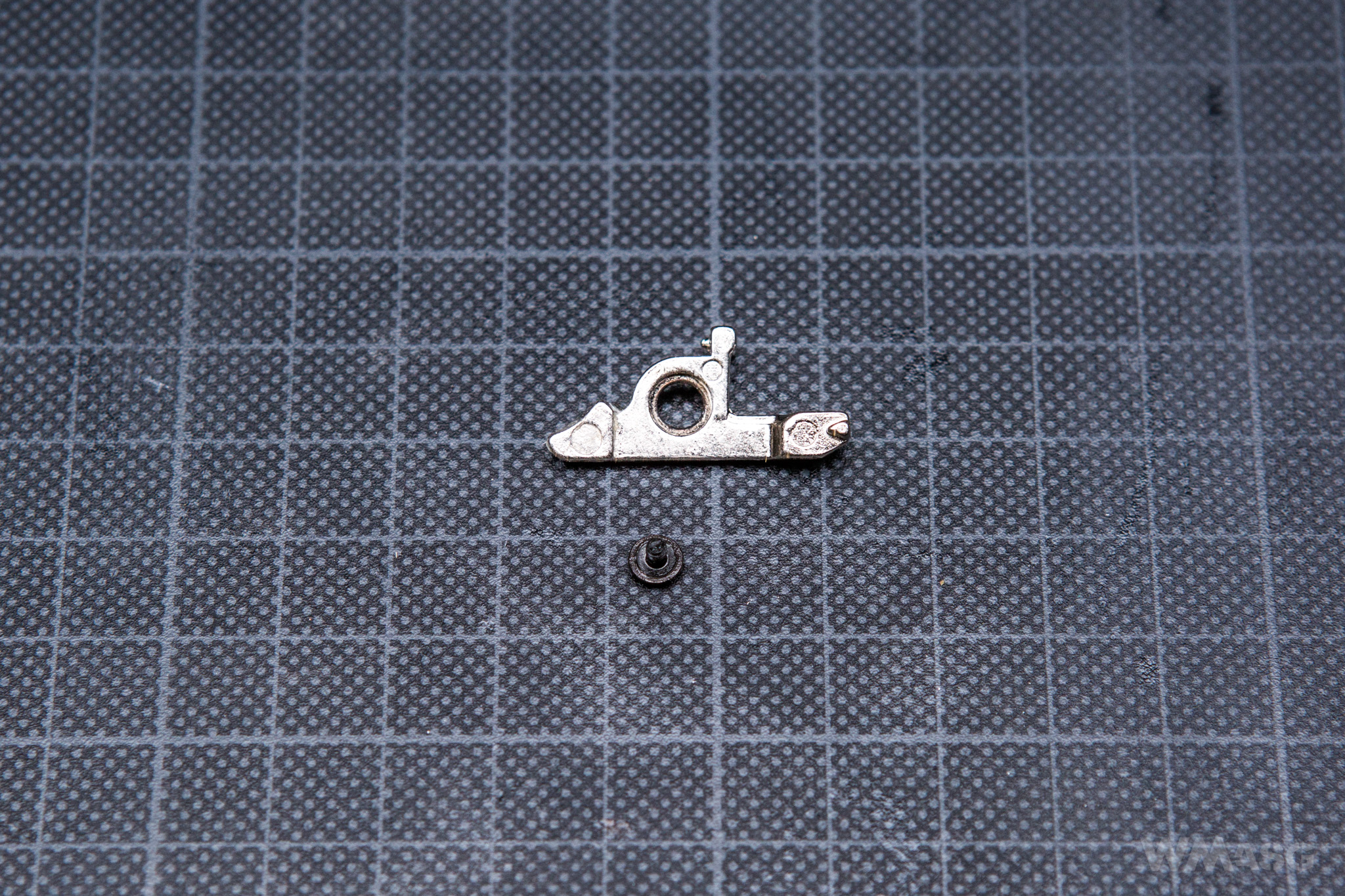

You can also clearly see the completely different trigger shape, which was a result of using a micro switch. This change, in turn, necessitated modification of the cut-off lever.

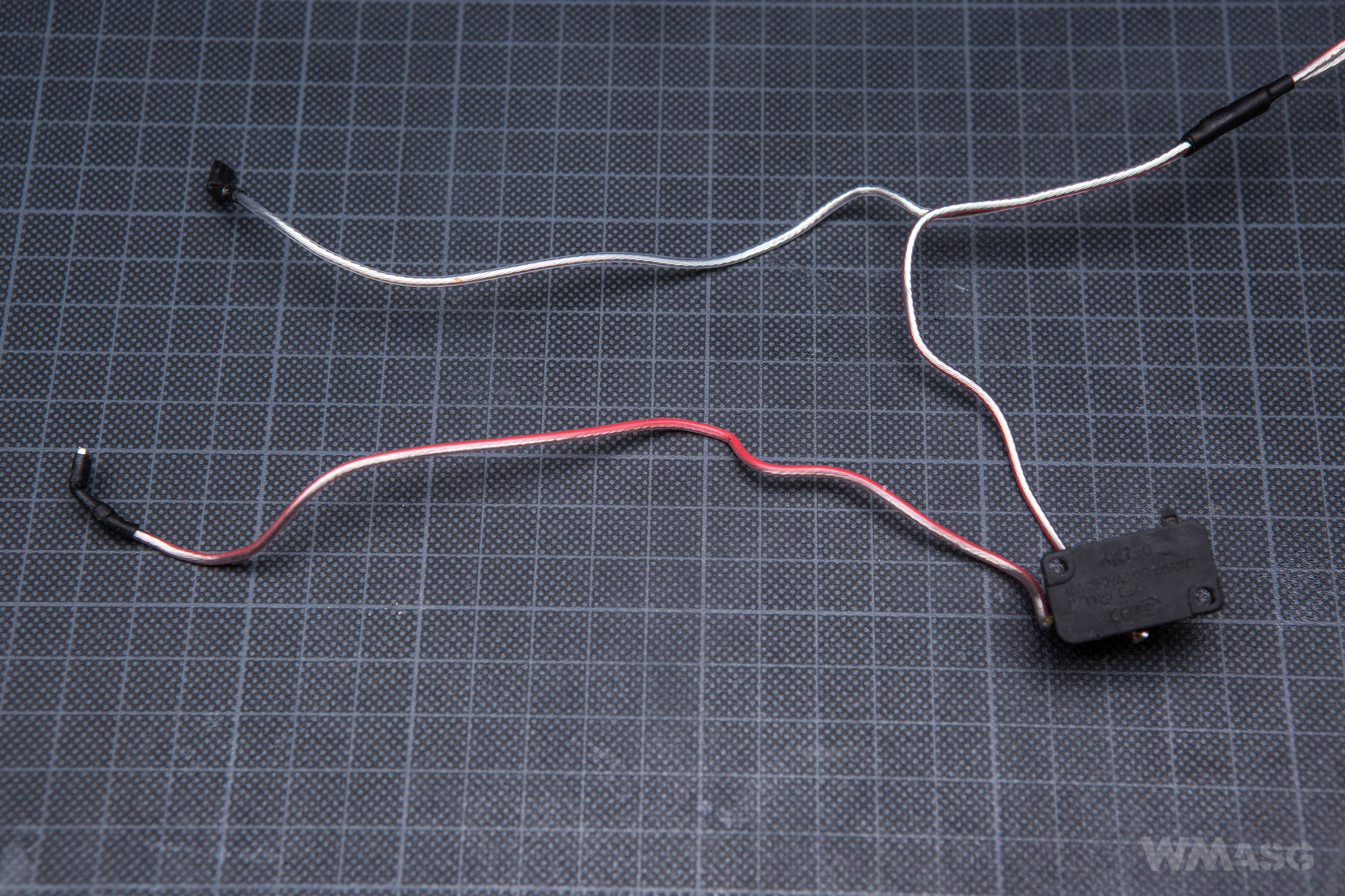

The high-current micro switch is connected to the battery and the motor with durable-looking wires encased in hard insulation.

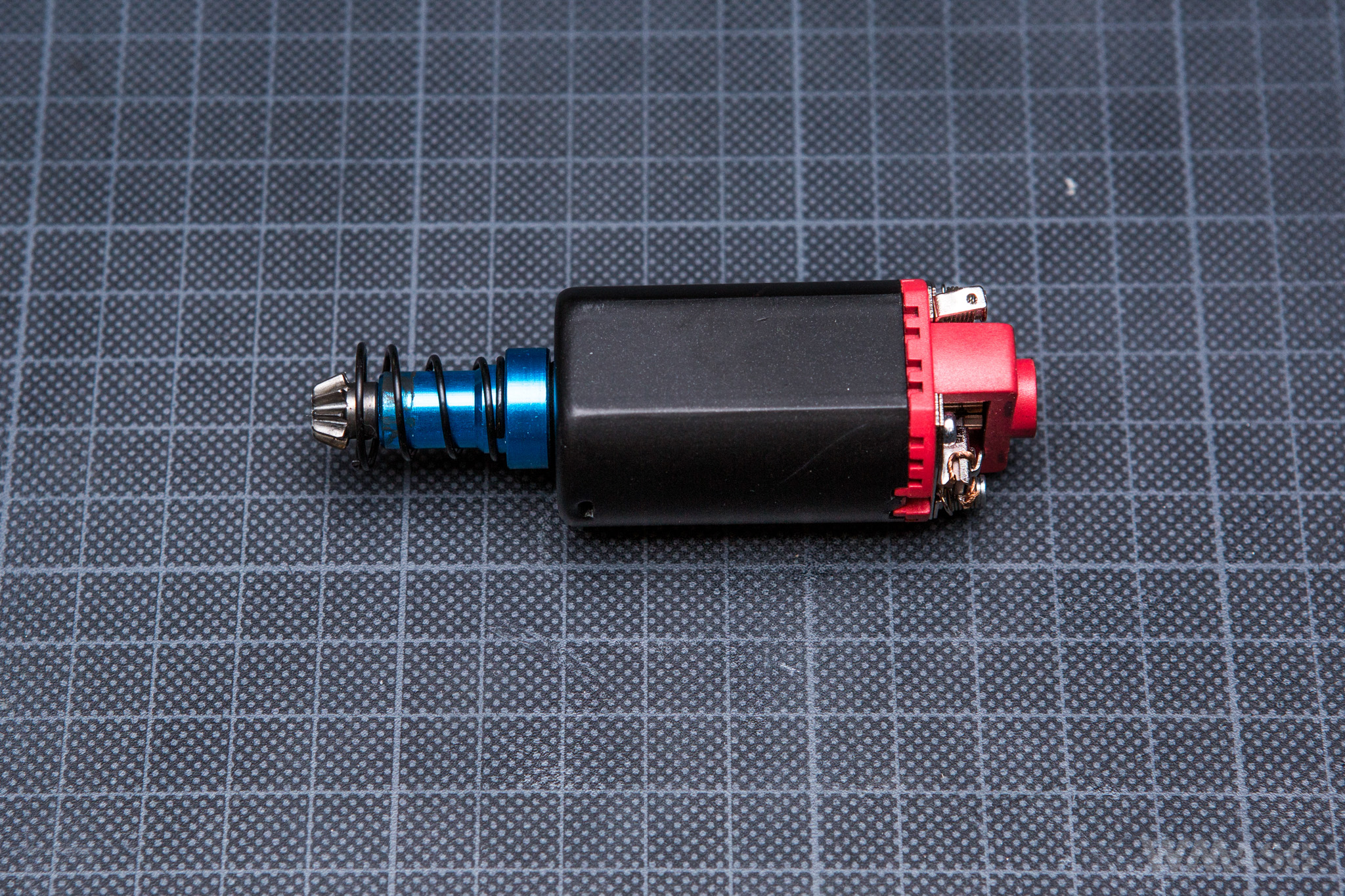

The motor is a long type without markings.

There is not much space in the pistol grip, but brass threads are placed at the bottom.

The bottom plate is secured with 2 bolts with an additional latch rotated at 90, whose protruding tabs go into cutouts inside the grip.

The whole mechanism, or more broadly, the entire carbine was assembled very carefully. We had no remarks about the shimming of the gears. The amount of grease seemed optimal. We also noticed the exemplary aliment of the reviewed replica - the axis of the barrel coincided with the axis of the nozzle.