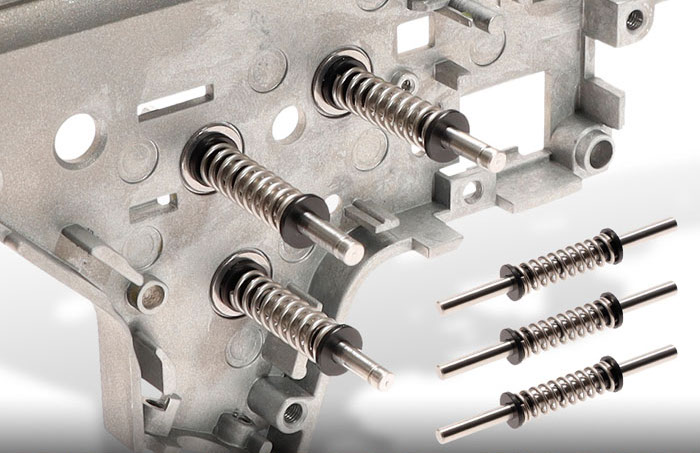

No matter how good the bearings are, how well made and shimmed the gears are, gearboxes will not work perfectly if the bearing seats are not aligned. LayLax has a patent for this:

The solution is to use 3 centering pins during the placement of the bearings. Washers and springs placed on them are to ensure the axiality of parallel bearings during bonding of the anaerobic adhesive.

In theory, the solution seems great. If the bearing seats are misaligned relative to each other they can be centered with a pin but will the adhesive withstand stress and the bearings will not peel off after a while? The patent will certainly prove itself in good quality frames in which any misalignment is slight. Unfortunately, poor quality (non-axial) frames cannot be saved this ways.

There are 2 sets of pins: dedicated for ball bearings - pin diameter 2.98 mm

and for bushings - pin diameter 3 mm:

Source: LayLax