A bit of semantics

MMR carbines belong to the exceptionally large CXP family, under which ICS currently produces (since autumn 2018) 85 models divided into 10 series. These series are:

- CXP-MMR

- CXP-Peleador

- CXP-YAK

- CXP-MARS

- CXP-08

- CXP-15

- CXP-16

- CXP-APE

- CXP-HOG

- CXP-UK1

Within one series, the differences between individual models are minimal. For example, of the six models of the MMR series that are available, three ore identical in terms of airsoft mechanics and differ only in length of the barrel, the front, the type of buttstock used and color (black or tan).

The differences between individual series are definitely bigger. Starting from such a basic thing as the material from which the receiver is made, a good example is the difference between the budget CXP-Peleador with a receiver made of plastic and the high end CXP-MARS replicas with a digitally controlled mechanism. By the way: we tested Peleador and MARS replicas simultaneously and you will find information on them in separate articles.

CXP-MMR

Highlight of the series:

- a receiver made of metal

- a classic lower receiver

- an upper receiver similar in appearance to the VLTOR MUR

- an aluminium front made in the M-LOK system

- a double sided charging handle

- an enlarged trigger guard

- an enlarged magazine release button.

Additionally, fearures found in other ICS models:

- a two part gearbox

- a quick spring change system

- an electric blowback system (EBB)

- an electrical system with a simple MOSFET;

- folding CFS sights.

Differences between individual MMR models:

| SBR | Carbine | DMR | |

| overall length | 725/800 | 835/930 | 975 |

| inner barrel length | 263 | 375 | 458 |

| weight | 2678 | 2886 | 3393 |

| buttstock | MTR | MTR-S1 | UKSR |

I have two replicas on the table: the shortest CXP-MMR SBR (ICS-402) and the longest CXP-MMR DMR (ICS-400), both in black. Since their internally identical, we will try to include all those details in one description.

Packaging and first impression

CXP carbines are packed in cardboard boxes that adequately protect them against damage. Inside, there are plastic inserts with molded sockets for holding individual parts the sets. The whole is covered with a foam sheet from the top.

CXP carbines are packed in cardboard boxes that adequately protect them against damage. Inside, there are plastic inserts with molded sockets for holding individual parts the sets. The whole is covered with a foam sheet from the top.

Each set, apart from the replica, includes:

- a Hi-Cap magazine holding 300 BBs, visually resembling PMAG magazines

- a key to the seat ring of the bed and the outer barrel

- a plastic cleaning rod

- a small packet of BBs of undetermined weight

- 2 spare mini type fuses, 20 and 25 A

- a detailed instruction manual in English and Chinese

- instructions for adjusting the buttstock and installing the battery

- a folded colored leaflet with a list of ICS replicas.

Visually, the carbines make an excellent impression. They are uniformly black with a semi-matte texture. The only parts with a distinctly different color are the pins connecting the two parts of the receiver and the two-sided mounting ring of the carrying sling located between the receiver and the buttstock guide.

The first minor drawback in both replicas is a slight clearance between the upper and lower receiver, which became apparent at first glance. It result in the upper receiver and the front turning slightly around the barrel axis when held and moved by hand. This defect was also present in the CXP-MARS series which we tested simultaneously which these replicas.

During the initial inspection of the SBR version our attention was drawn to the position of the buttstock - it is set in the second position, not the shortest one and can not be shortened any further. I will give the reasons behind in later parts of this review.

External parts

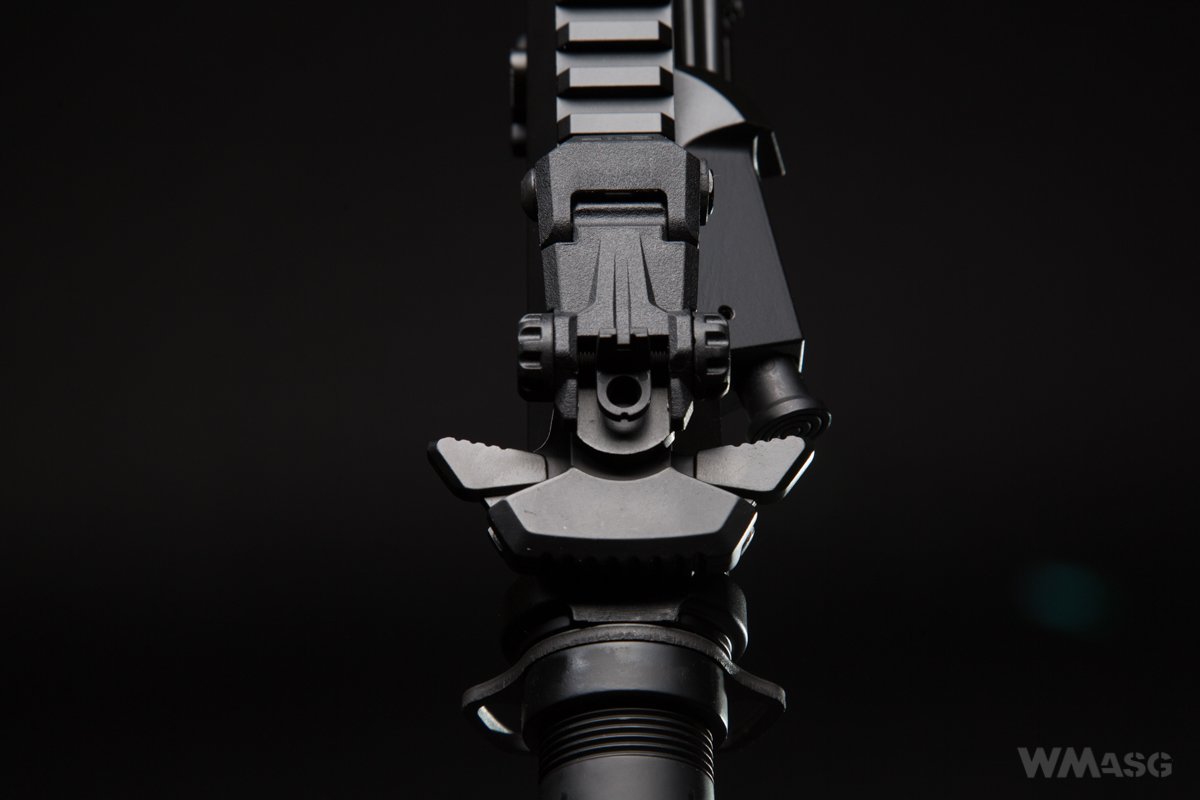

The receiver is made of metal. The lower receivers is standard and has no modern reinforcements, improvements or quirks. The upper receiver is modeled on the VLTOR MUR design. Its angular and massive. Attention is drawn to the prominent forward assist housing integrated with the deflector, visible in the photo above. Unlike many other ICS replicas, the forward assist is fake as it does not have the function of releasing the spring. Apart from the charging handle, all manipulators are one-sided. The dummy bolt catch is slightly prolonged due to the shape of the upper receiver.

Magazine release button is also enlarged. Repeated attempts have shown that, despite its uncomplicated form, it works very well. The index finger of the right hand surely and without hindrance hits the button each time.

The ejection port visible in the photo opens after pulling the charging handle and stays open after releasing it. The Double-sided charging handle has enlarged latches.

In the photo below you can see the access to Hop-Up adjustment. Unfortunately, the dummy bolt carrier does not lock in the rear position therefore, during the adjustment, it is necessary to hold the charging handle back. While shooting, the dummy bolt carrier moves together with the piston moving inside the cylinder (the EBB system).

The trigger guard is enlarged, which is to facilitate handling the replica using gloves. As per standard, it can be detached from the front hitch. It can be disconnected entirely by pressing the mounting pin on the right side with anything of a diameter no more than 2 mm. To mount it back again, just hold the part of the pin protruding from the lowered guard (e.g. with a fingernail) and slide it into the socket in the lover receiver.

The carbine is distinguished by the pistol grip used as. It does not have a characteristic profile between the middle finger and the ring finger. At first glance, it looks similar to grips used in the first version of the M16 rifles. Its whole surface has a very distinct texture. The bottom of the grip is ribbed, fully openwork to facilitate better motor cooling. There is no spacing washer. It has glues threaded brass sleeves used for tightening the screws fixing the bottom plate. The motor adjustment is done with a 4 mm Allen key.

The front

The MMRs are equipped with the M-LOK system licensed by Magpul. The fronts are made using CNC machining are very aesthetic. They do not have any sharp edges or failures. They are mounted very securely. To disassemble them you need a 3 mm Allen key. To pull the front towards the barrel exit just loosen the 2 screws at the bottom. Then, using the key attached to the carbine, unscrew the stabilizing ring and, possibly with the same key, the ring fixing the outer barrel.

The sights

The folding CFS sights are made of plastic and are mounted on a Picatinny rail. They are raised by hand and are very stable in the working position. They are adjusted using knobs (without the use of tools): the front sight vertically and the rear sight horizontally. It is also possible to use the sights without lifting them, as low profile sights. Then only the rear sight (horizontally) is adjustable.

The buttstock

The short SBR model has a collapsible MTR type stock. It is made of reinforced nylon polymer. It has several options for attaching the carrying sling, including 2 QD sockets (one on each side). Noteworthy is the inverted lever, which is used to move the stock on the guide.

Between the buttstock and the receiver, an additional double-sided mounting ring of a carrying sling is placed.

Between the buttstock and the receiver, an additional double-sided mounting ring of a carrying sling is placed.

The Carbine model has a stock marked as the MTR-S1, similar to the bustocks known from the HK416. The DMR model is equipped with the UKSR sniper stock with smooth adjustment of the cheek pad and rubber butt plate.

UKSR has another hidden way to adjust its length. For details read the text dedicated to the CXP-MARS replica.

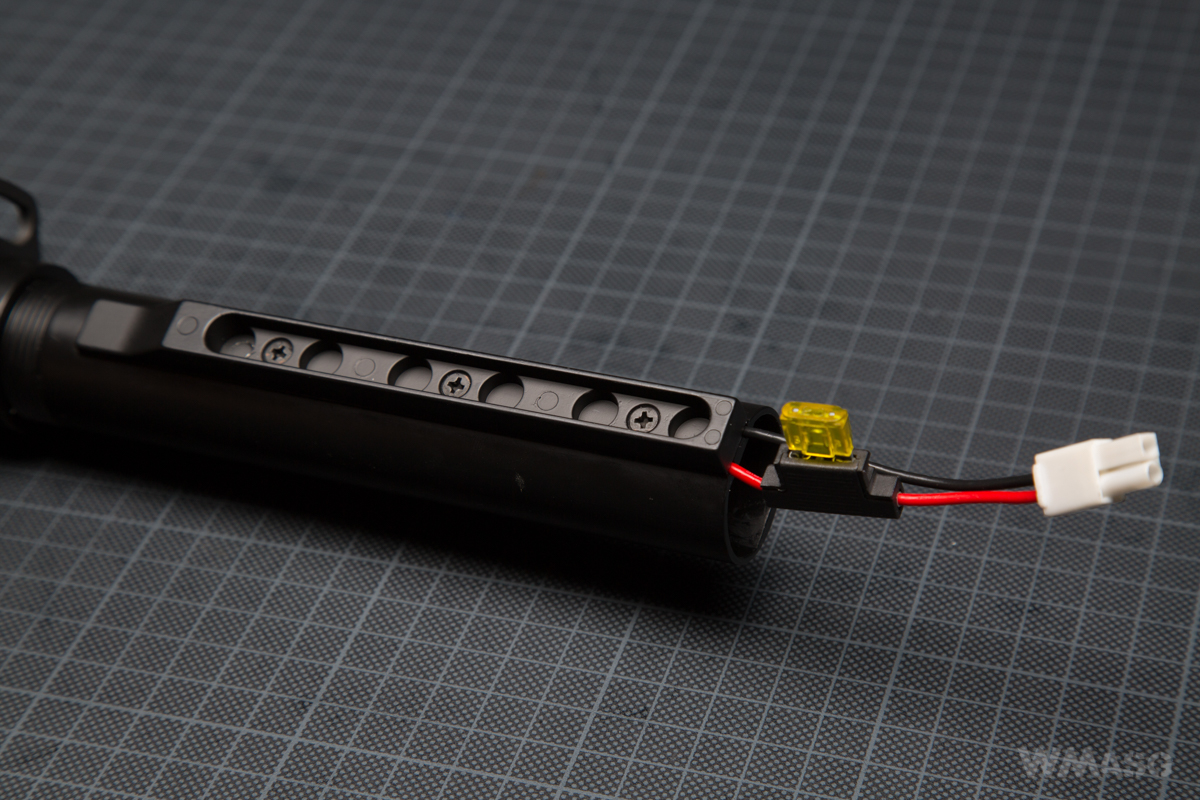

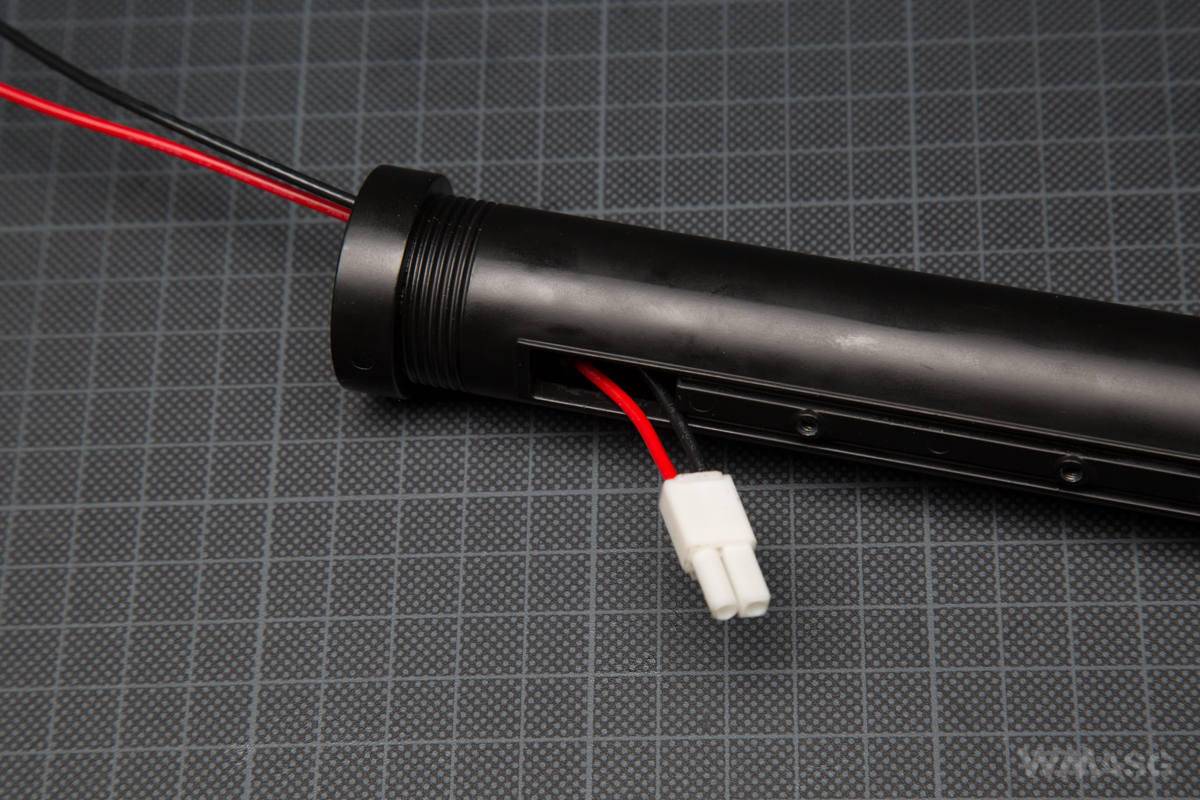

Both buttstocks are mounted on a standard guide designed in an interesting way. The wires are routed in special channels and protected against damage. An additional benefit if this design is more space for the battery inside the guide. An 11.1 V 1400 mAh LiPo battery with dimensions of 21 x 20 x 130 mm can be easily fitted there.

The external barrel and flash hider

The barrel made of 2 metal parts. The connection is stiff and there are no clearances. There is no dummy gas block nor a gas tube. The barrel ends with a 14 mm counterclockwise thread and a flash hider called Raider.

The magazine![]()

A hi-cap type magazine is made from polymer and has a capacity of 300 BBs. It resembles the version of the PMAG magazines with a window on the side. The spring is traditionally wound by a knob at the bottom. The covering flap closes with a distinct "click" and will not open by itself. When opened it moves very freely. One have to be careful when filling the magazine.

A hi-cap type magazine is made from polymer and has a capacity of 300 BBs. It resembles the version of the PMAG magazines with a window on the side. The spring is traditionally wound by a knob at the bottom. The covering flap closes with a distinct "click" and will not open by itself. When opened it moves very freely. One have to be careful when filling the magazine.

Blowback

I have already written several times that MMRs are equipped with a mechanical blowback, meaning the dummy bolt carrier moves forward and back during shooting. The stroke of the bolt carrier is small, equal to approximately half the length of the ejection port. The system is not perfect and does not work in a manner that is 100% true to the real rifle. It happens, for example, that when we release the trigger when shooting in the full-auto mode, the dummy bolt carrier will stop in the middle of the ejection port. It results directly from the EBB design and does not obstruct anything. For those who will be bothered by this solution, it will be necessary to use an electronic control system that will force the piston to stop in the front position. Then the dummy bolt carrier will always remain closed.

Disassembly

MMRs belong to replicas that one can "break" open. To do that, one must take out the rear pin and simply "break" the replica open. Then you can also take out the front pin and disconnect the upper receiver from the lower receiver. Unlike in economic Peleador, the pins have security spring and do not fall out of the sockets. After breaking open the carbine, you can easily replace the spring by pushing the string guide slightly and turning it by 45 degrees. The entire upper part of the gearbox can be pulled out with the use of the charging handle. In order to pull out the lower part, it is necessary to unscrew the pistol grip, the magazine latch and unscrew and take of the stock guide.

Correct alignment of the gears when assembling the carbine after replacing the spring or the top part of the gearbox is described in the instructions. It is essential to follow these recommendations. Improper piston position relative to the gears leads to immediate damage to the replica.

Internal parts of the upper part of the gearbox

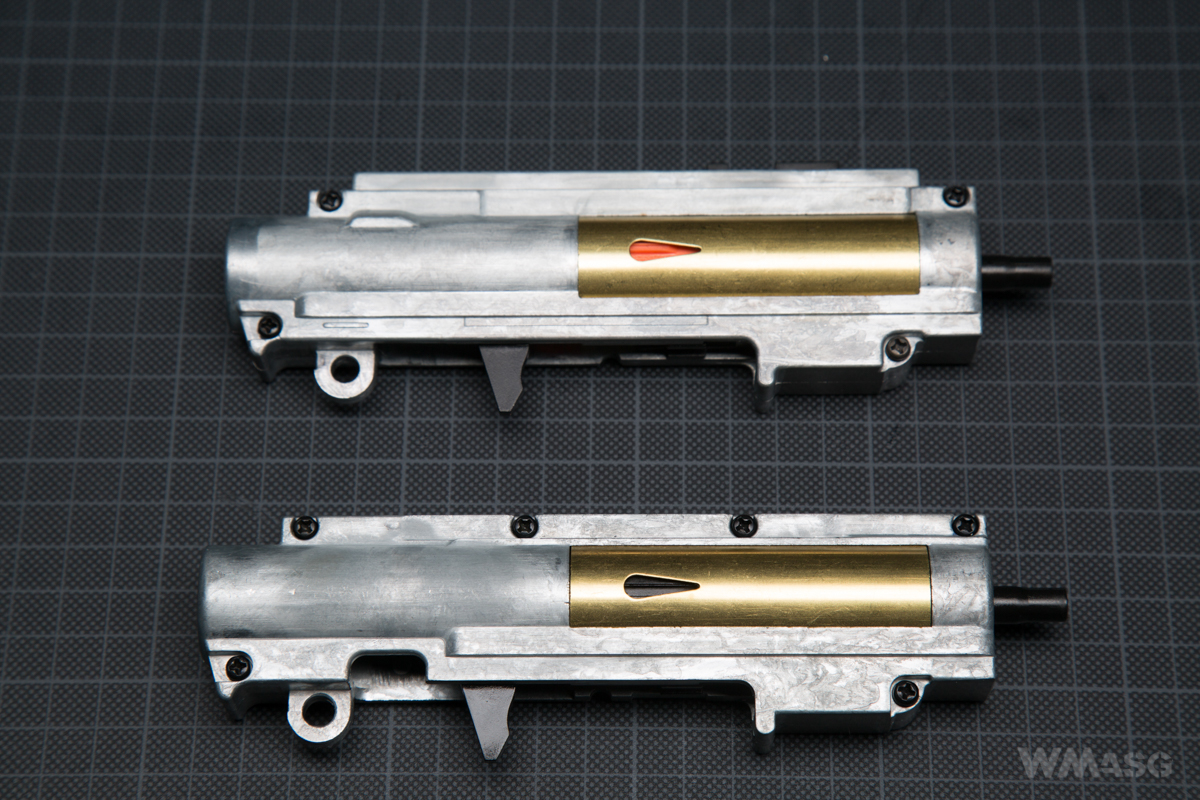

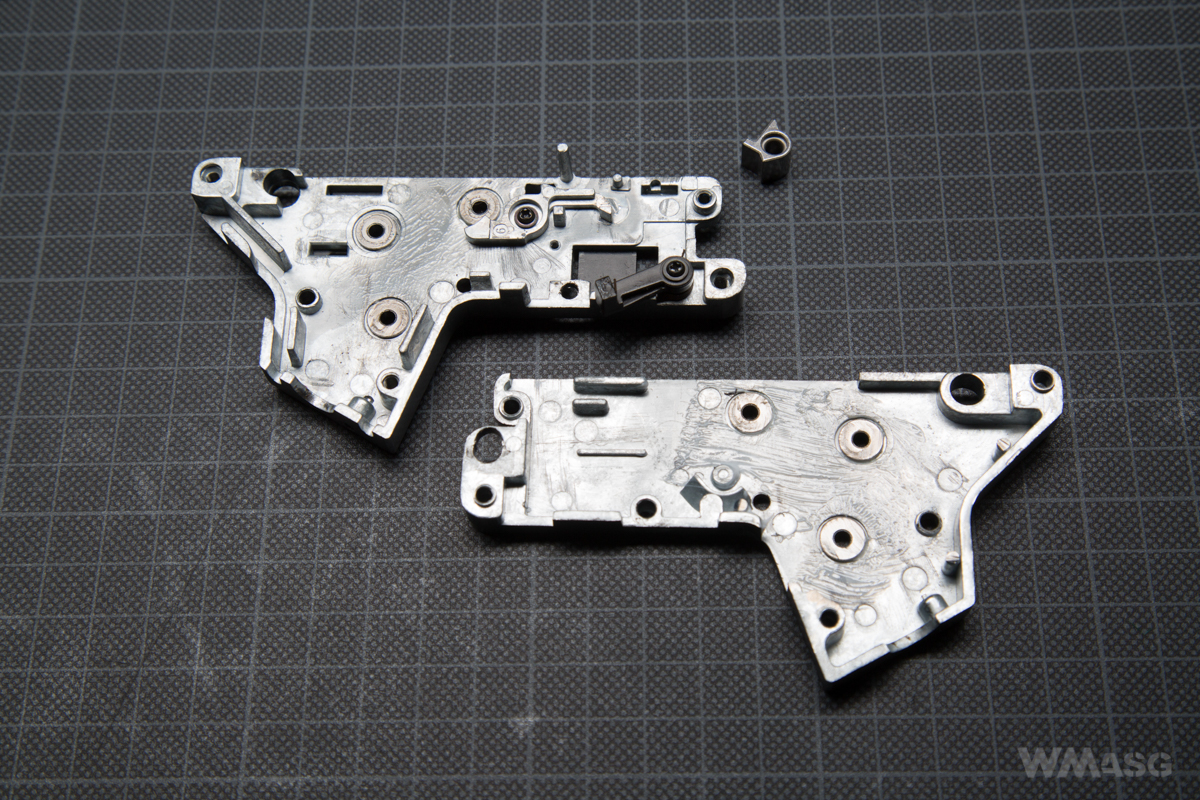

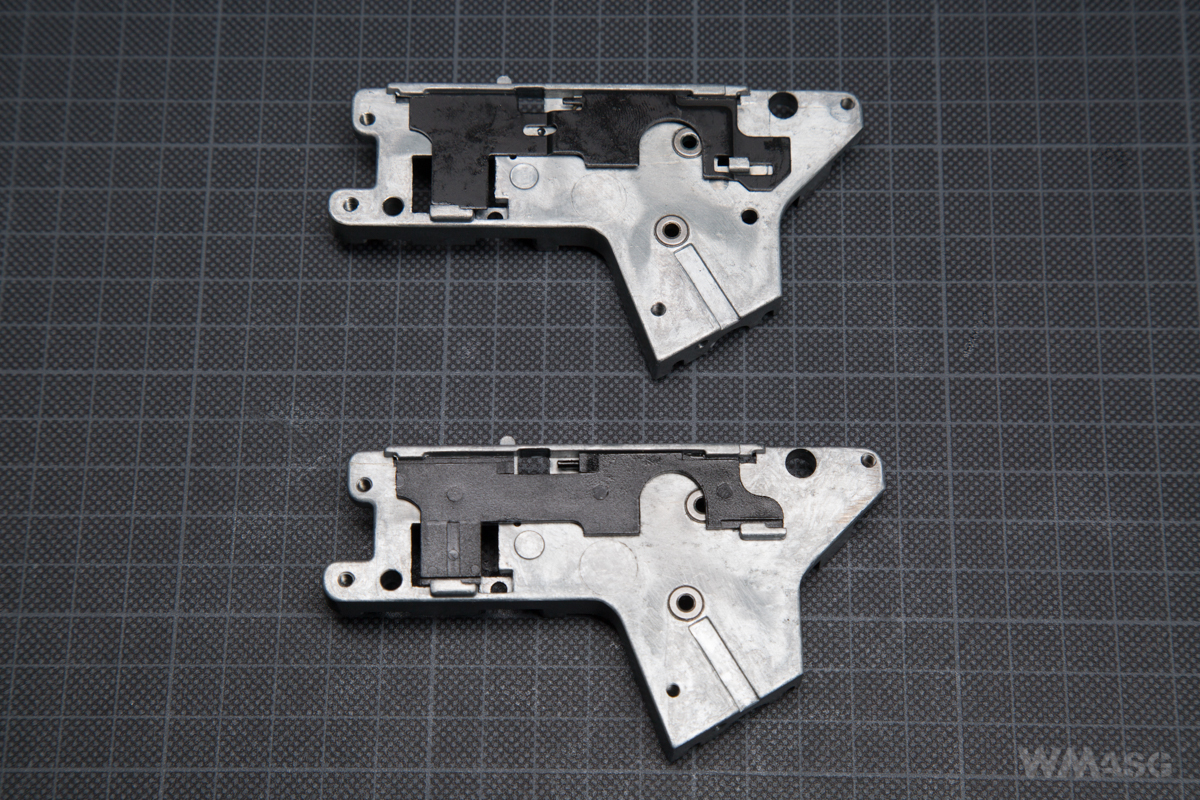

At the top of the MMR gearbox with the electric blowback system, at the bottom of a "normal" ICS gearbox.

Once again, but with a dismantled dummy bolt carrier.

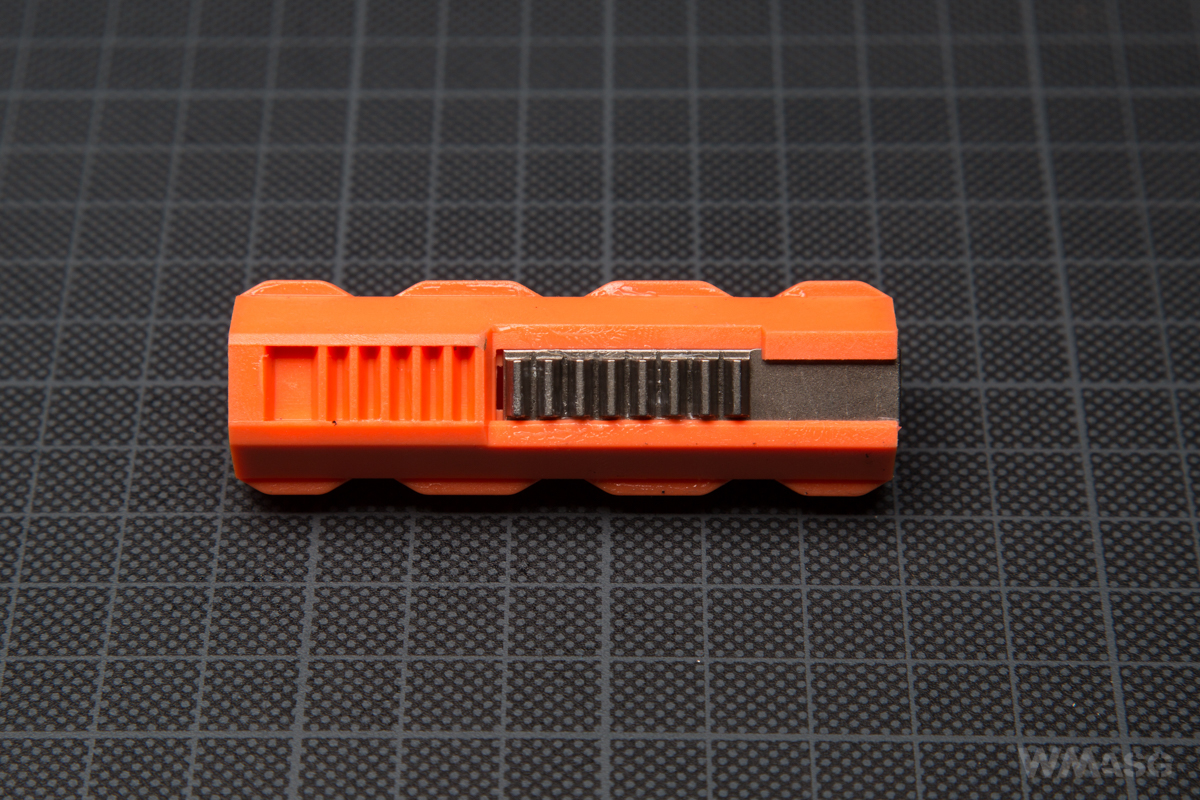

In addition to the piston and spring guide, the internal parts are made in an unwritten standard. The piston has eight steel teeth and a characteristic hook on top used to drive the electric blowback system.

In addition to the piston and spring guide, the internal parts are made in an unwritten standard. The piston has eight steel teeth and a characteristic hook on top used to drive the electric blowback system.

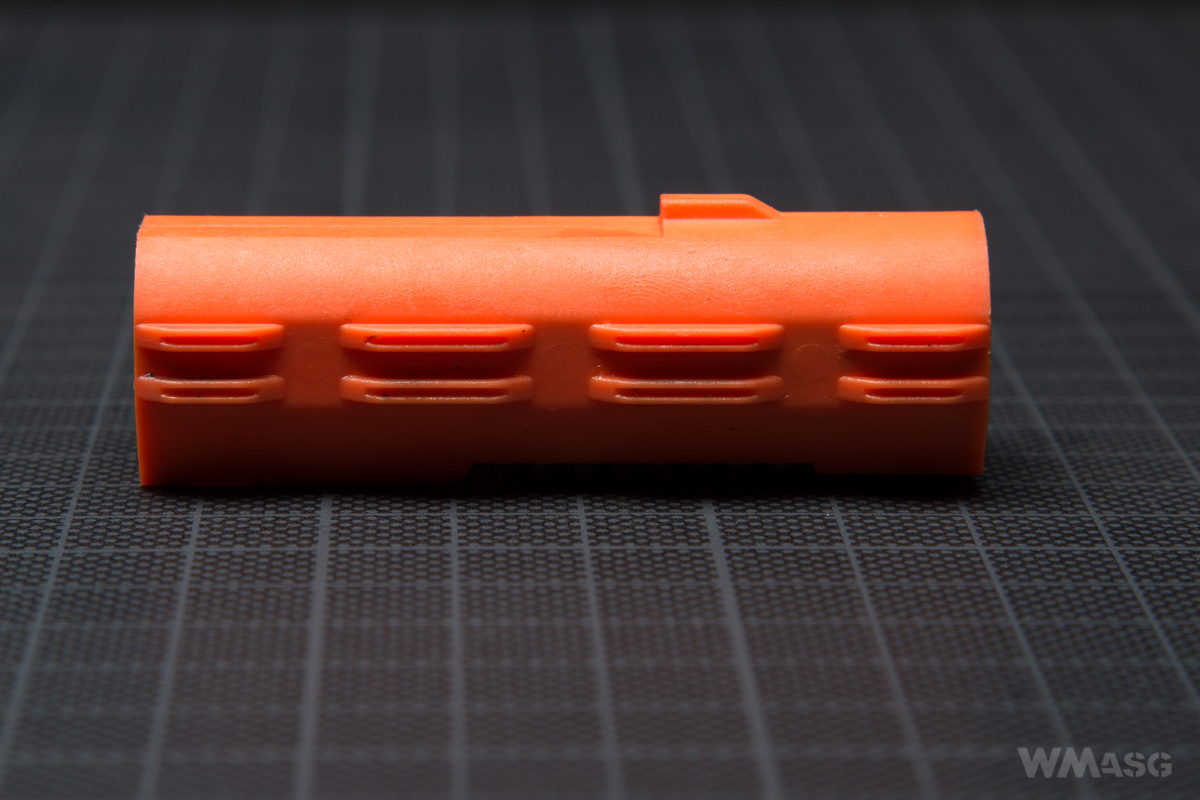

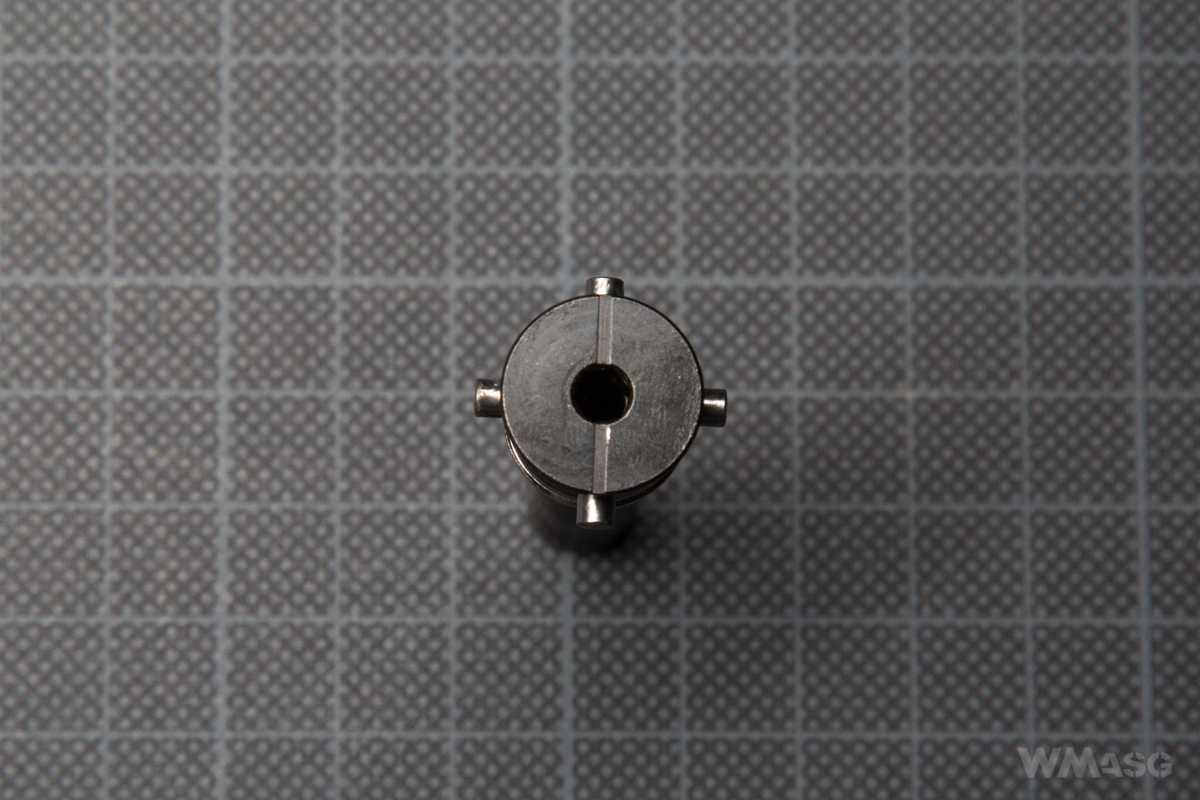

The Spring guide with four tabs (used for quick spring replacement).

The Spring guide with four tabs (used for quick spring replacement).

Below a comparison of gearboxes with the quick spring change system and without one.

Below a comparison of gearboxes with the quick spring change system and without one.

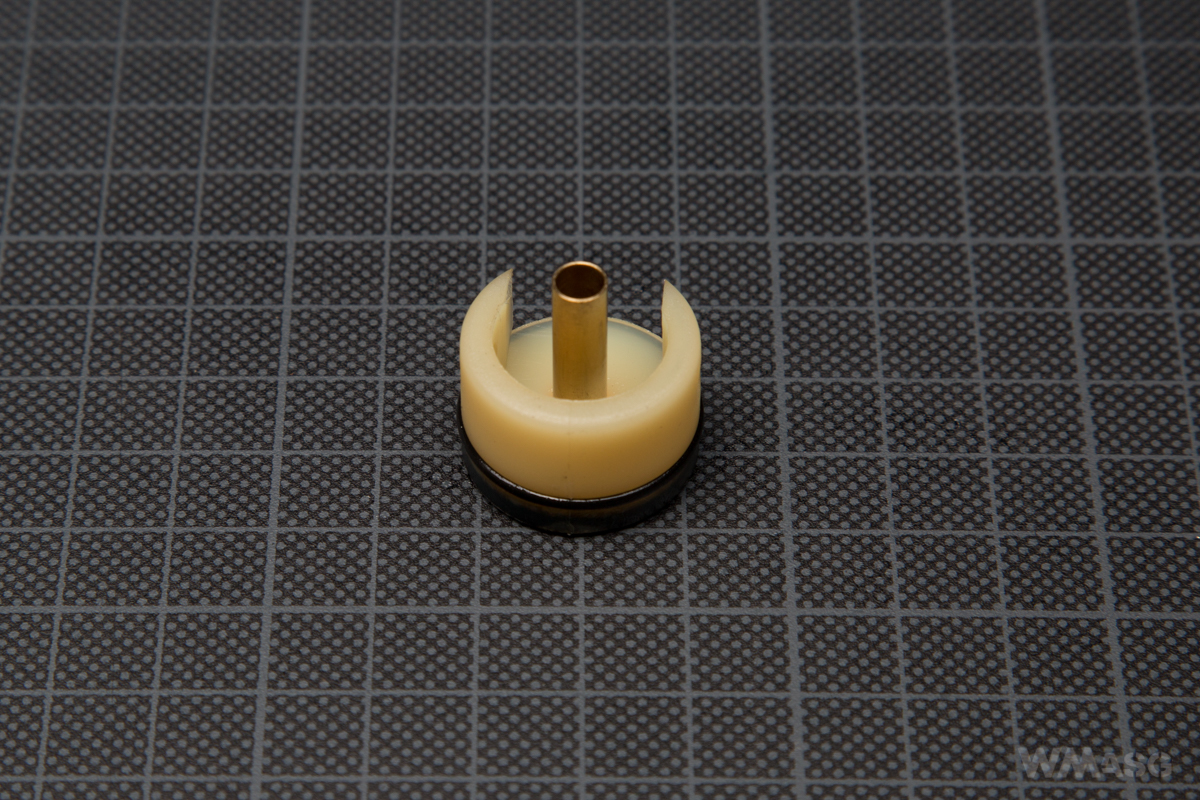

Other parts - type 2 cylinder. Type 2 polymer cylinder head with a single o-ring.

Type 2 polymer cylinder head with a single o-ring. Nozzle with a length of 20.94 mm and without an o-ring.

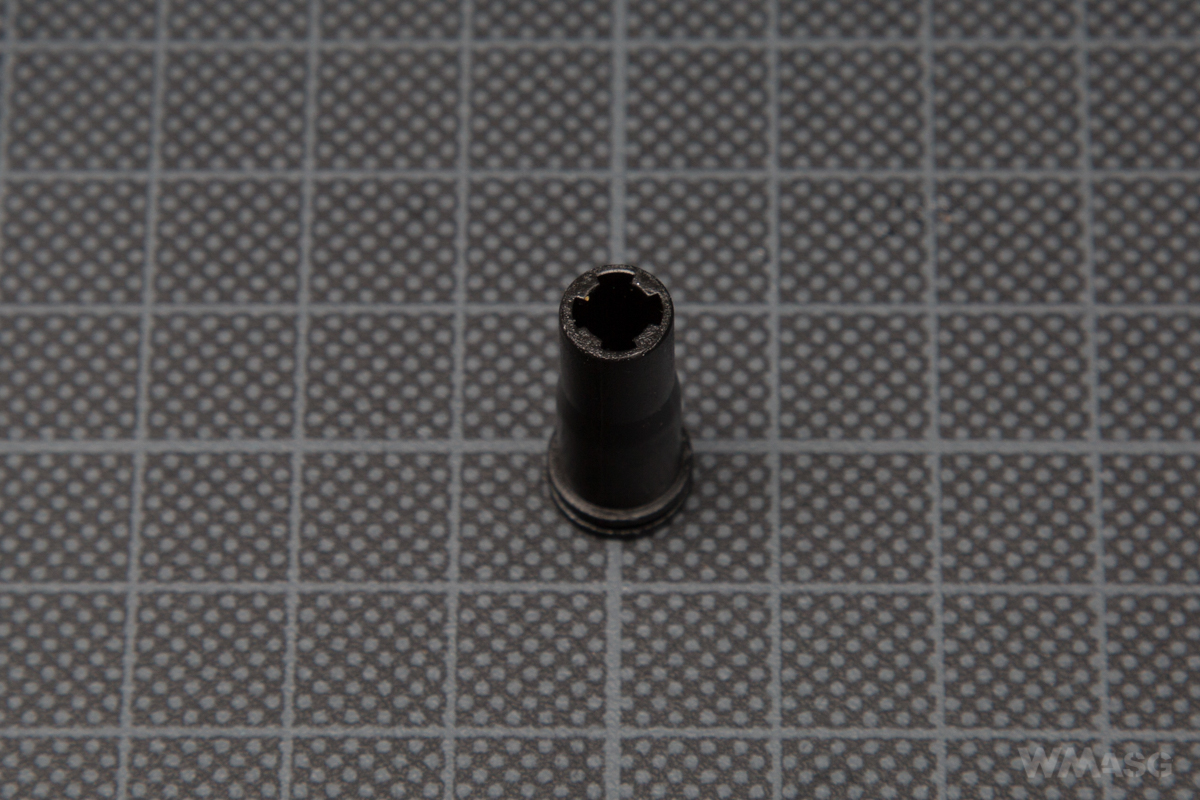

Nozzle with a length of 20.94 mm and without an o-ring.

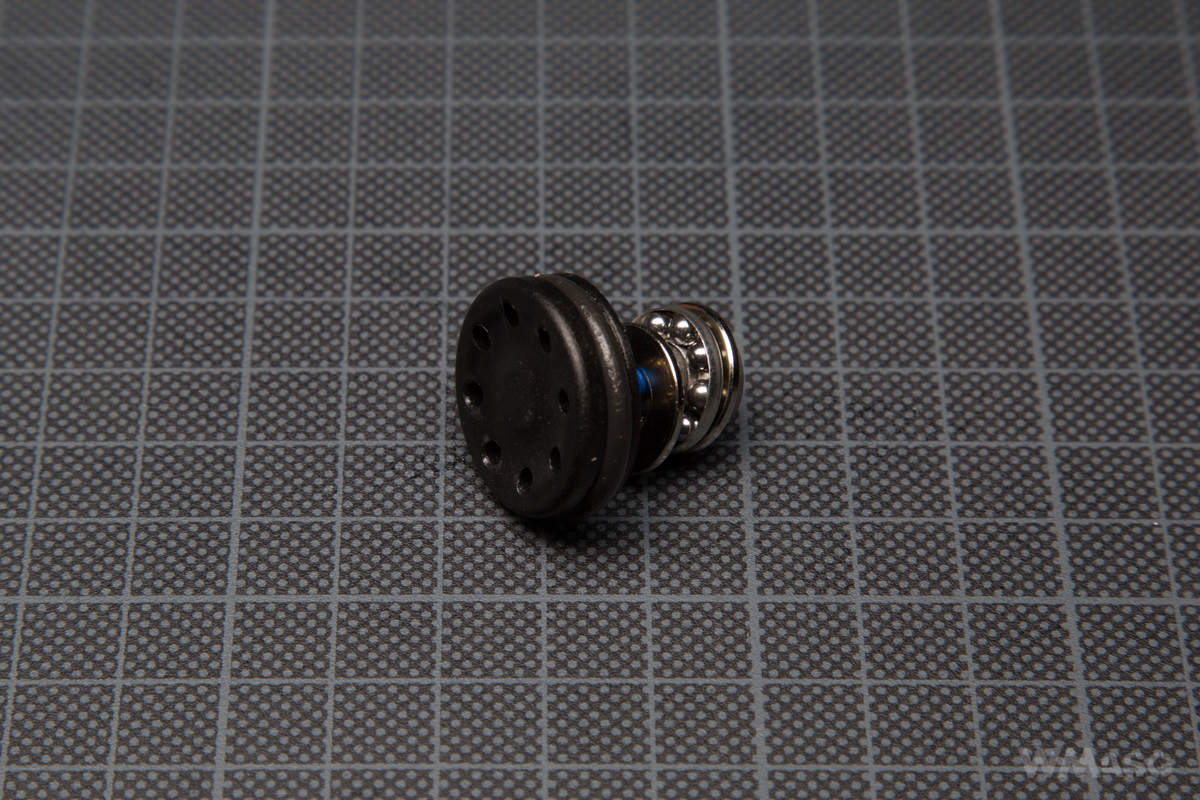

A polymer piston head with a full bearing.

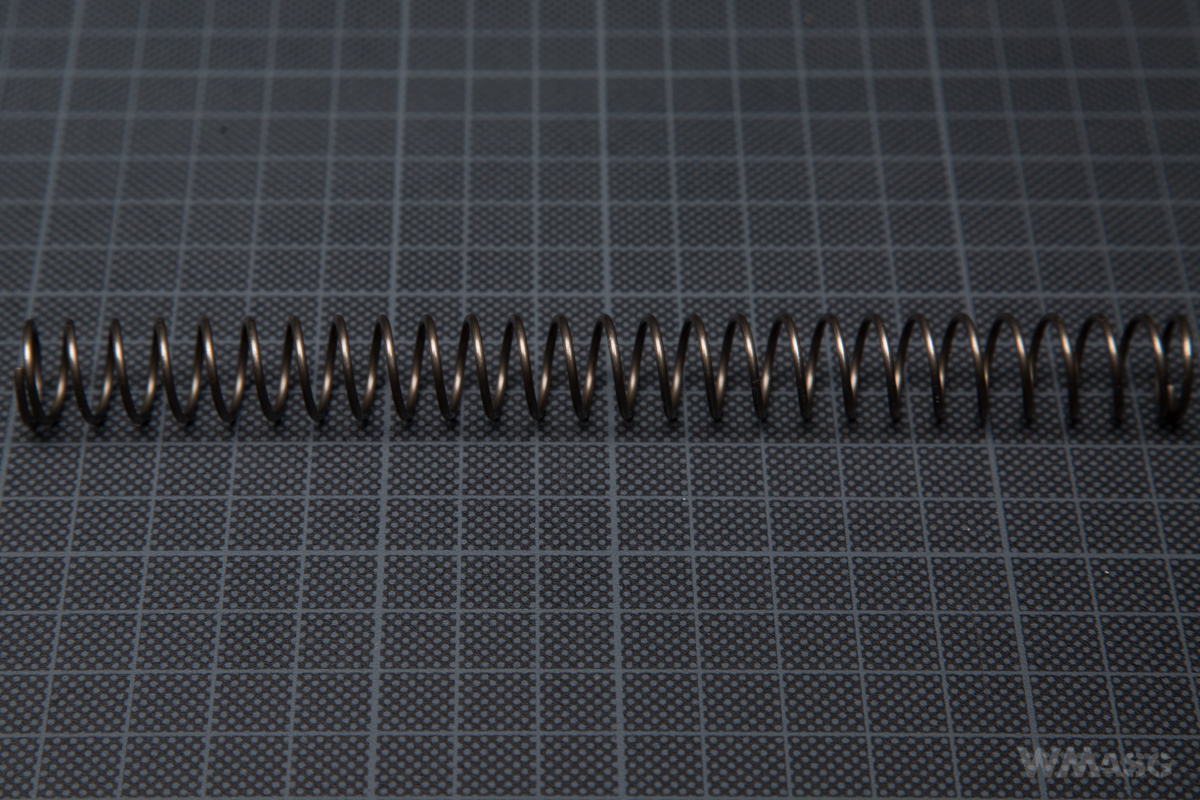

A polymer piston head with a full bearing. A spring with regular coils.

A spring with regular coils. Standard tappet plate for V2 gearboxes.

Standard tappet plate for V2 gearboxes.

Internal parts of the lower gearbox

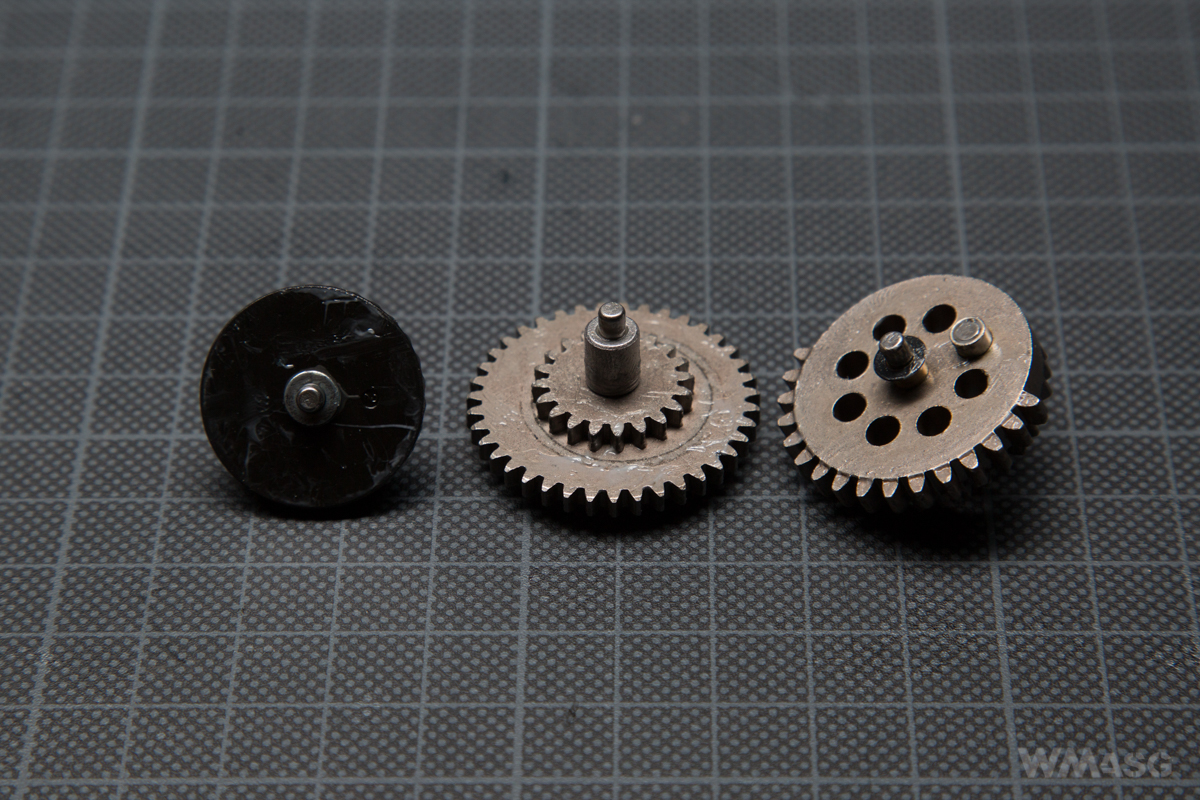

Mutual setting of gears with slight lateral play.

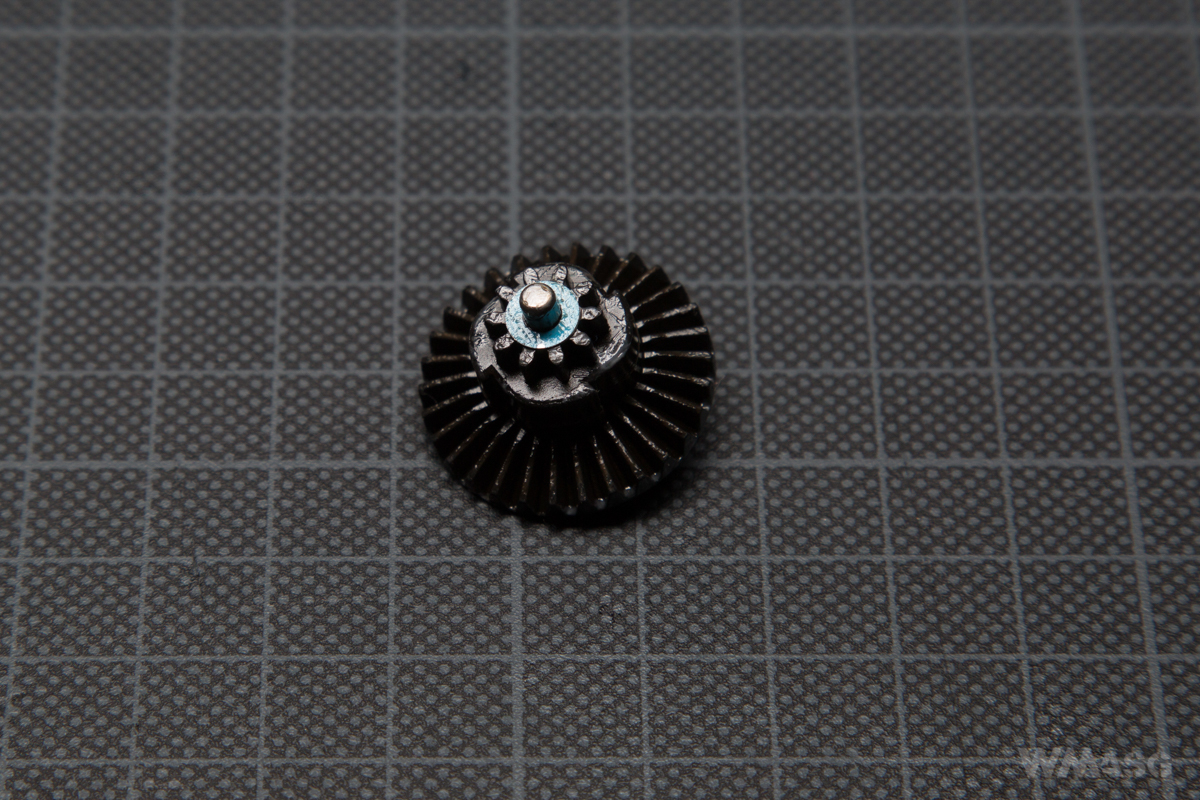

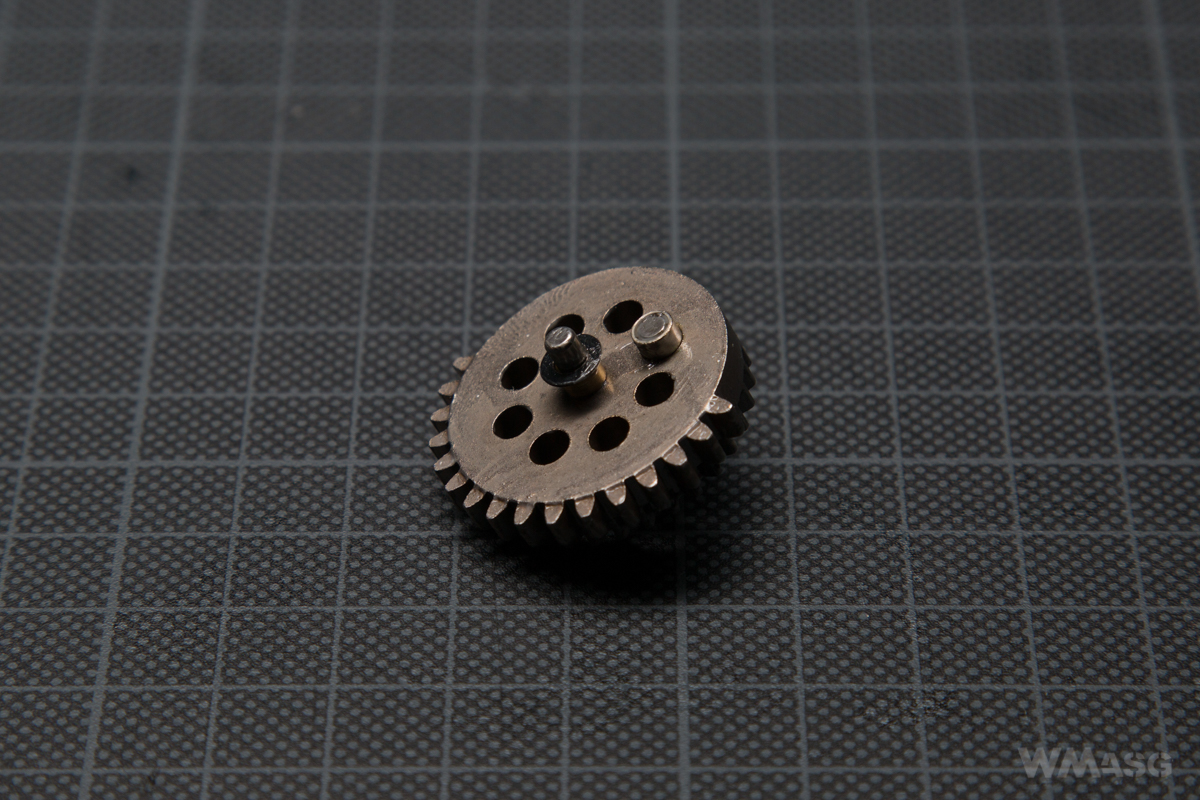

They are set in 7 mm steel bushings. The gears themselves are standard and made of sintered steel. The bevel gear and one on the motor shaft are made using the MIM technology. This is clearly visible as they look completely different than the others.

The bevel gear and one on the motor shaft are made using the MIM technology. This is clearly visible as they look completely different than the others. On the sector gear, a thin sleeve is applied to the push tappet plate, which is likely to improve the feeding of the BBs.

On the sector gear, a thin sleeve is applied to the push tappet plate, which is likely to improve the feeding of the BBs.

The cut-off lever and trigger safety latch are typical for V2 gearboxes.

The trigger - standard for AR15 replicas.

Electrical contacts - standard for V2 gearboxes without additional external contacts closed by the selector plate.

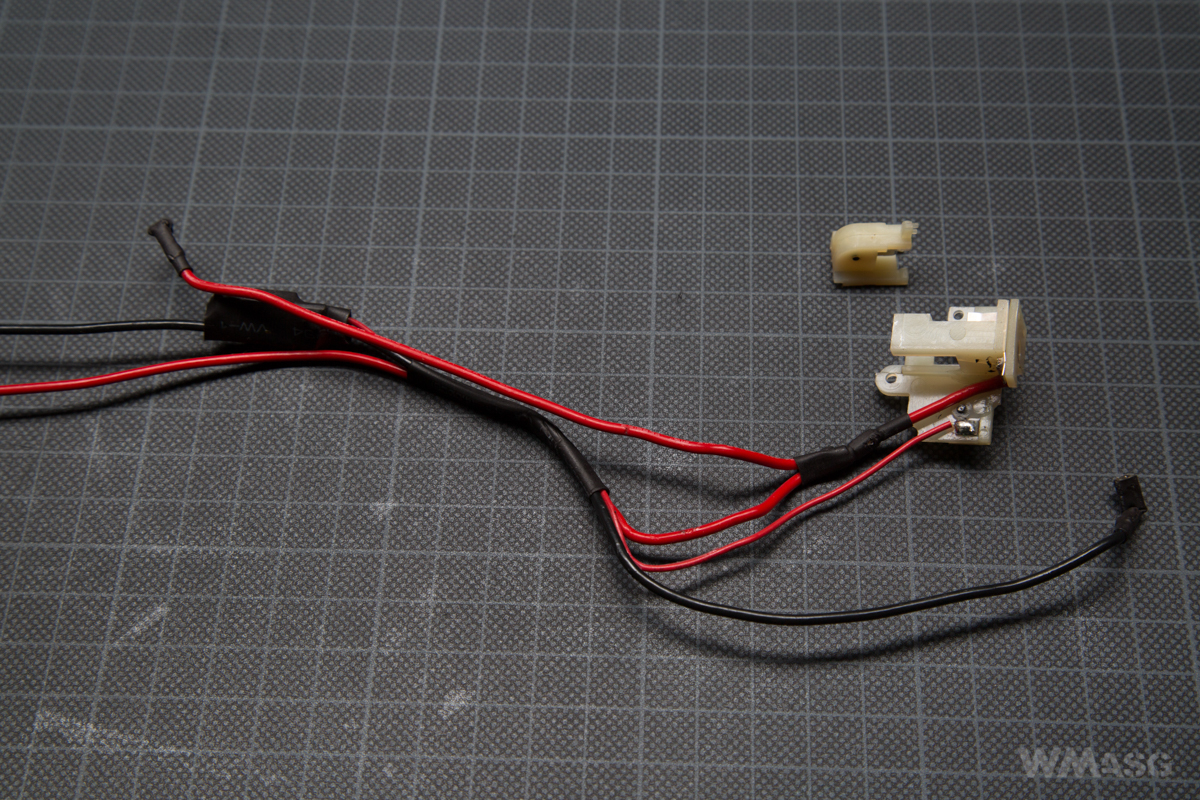

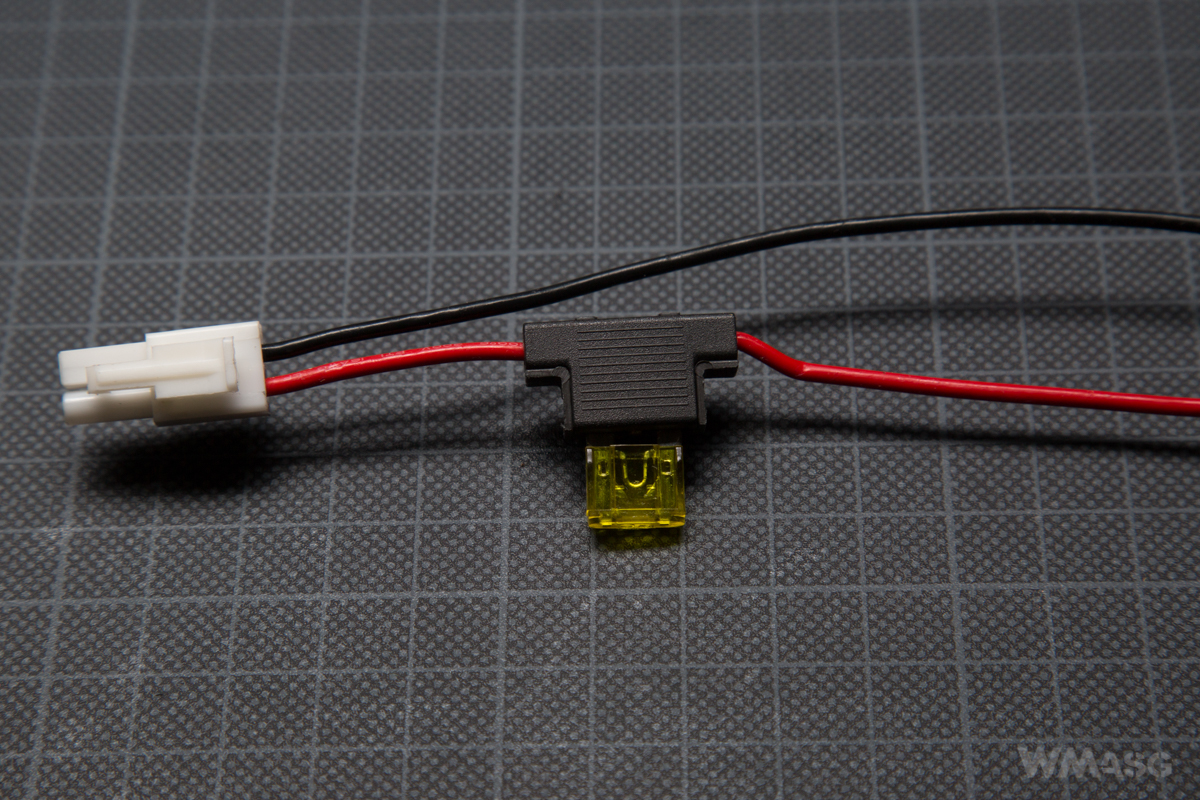

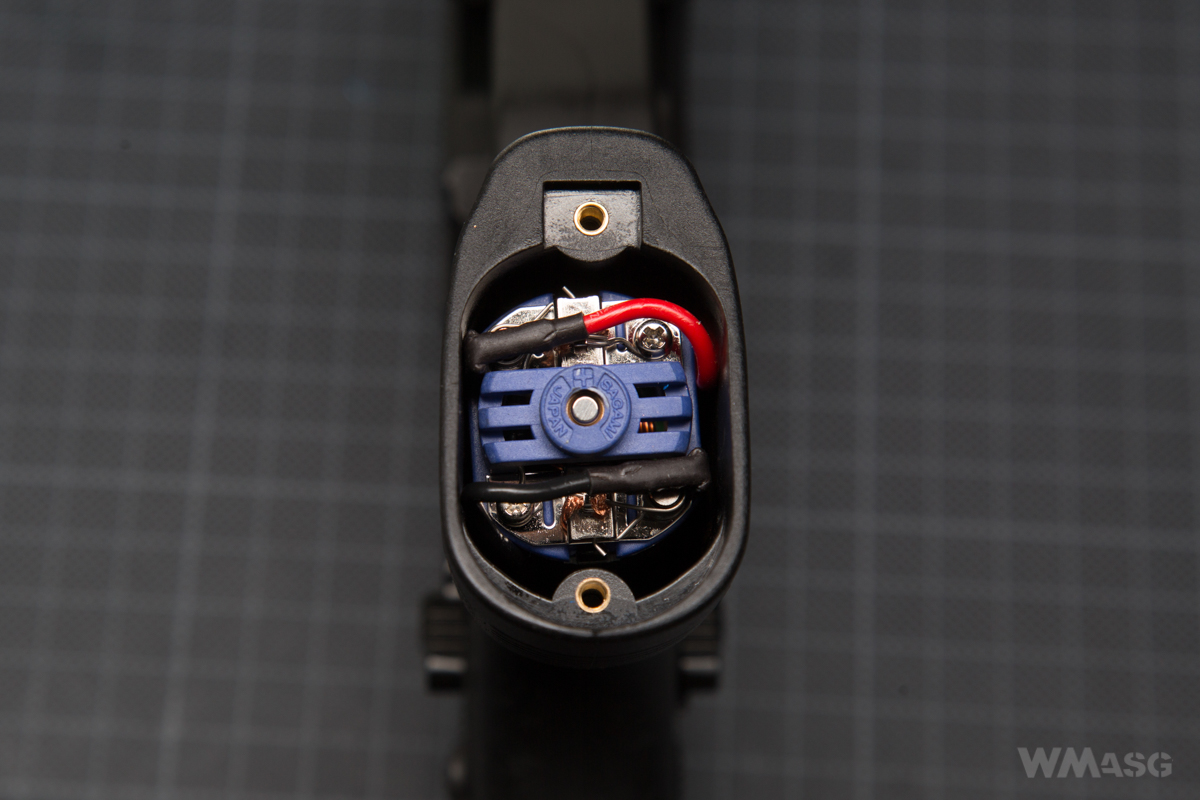

The wires are rigid, encased in hard insulation. The electrical installation equipped with a simple MOSFET. Its installation method simplified and there are no separate control wires. It also has a mini type fuse. The battery plug is a mini Tamiya type.

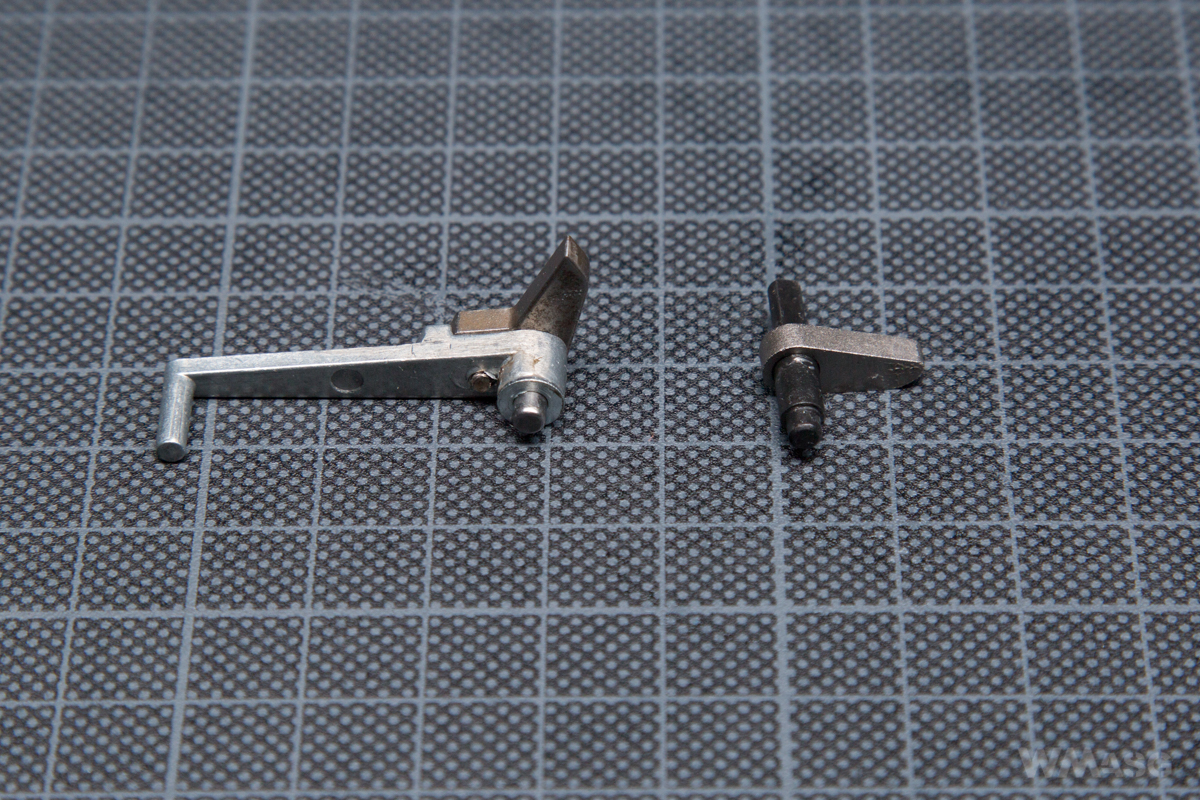

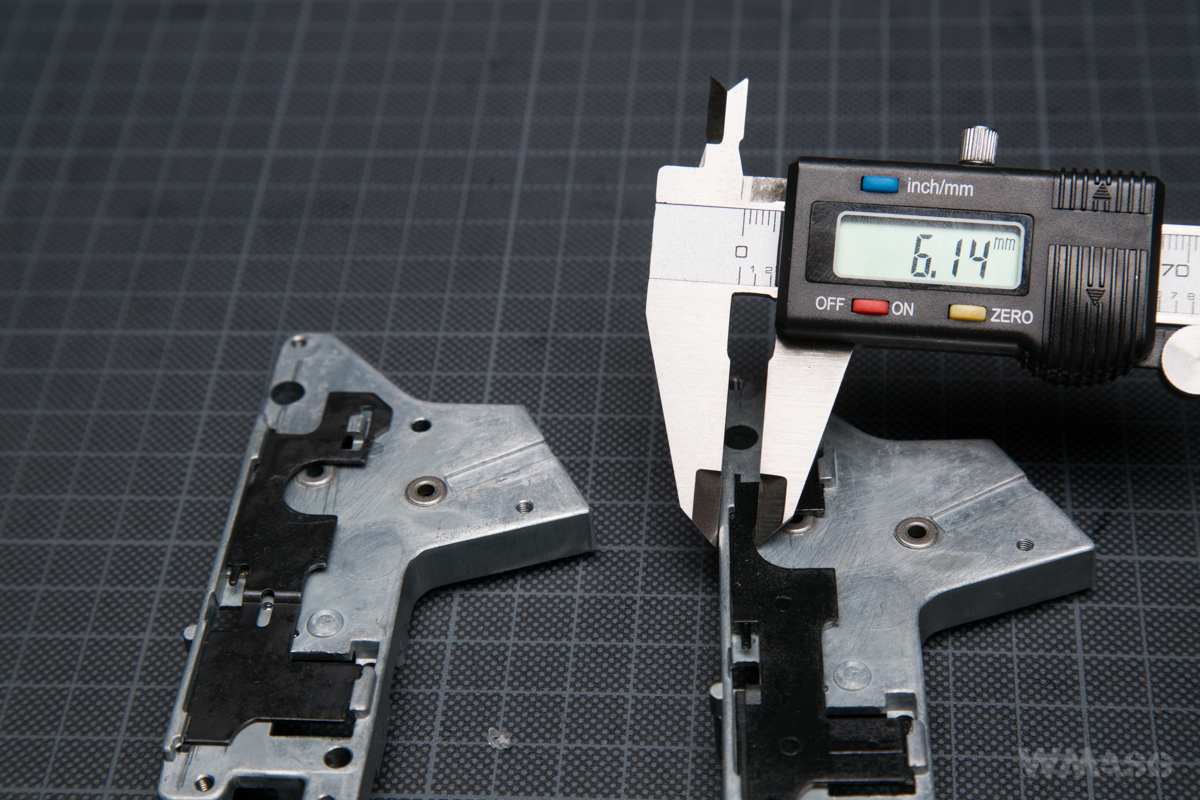

The Anti-reversal latch, is different than in other ICS replicas where you can release the main spring using the forward assist. The shape of the working part is standard, but the axis is slightly longer and ends with a characteristic spline shaft. The MMR part is on the right. The one on the left is working together with the forward assist.

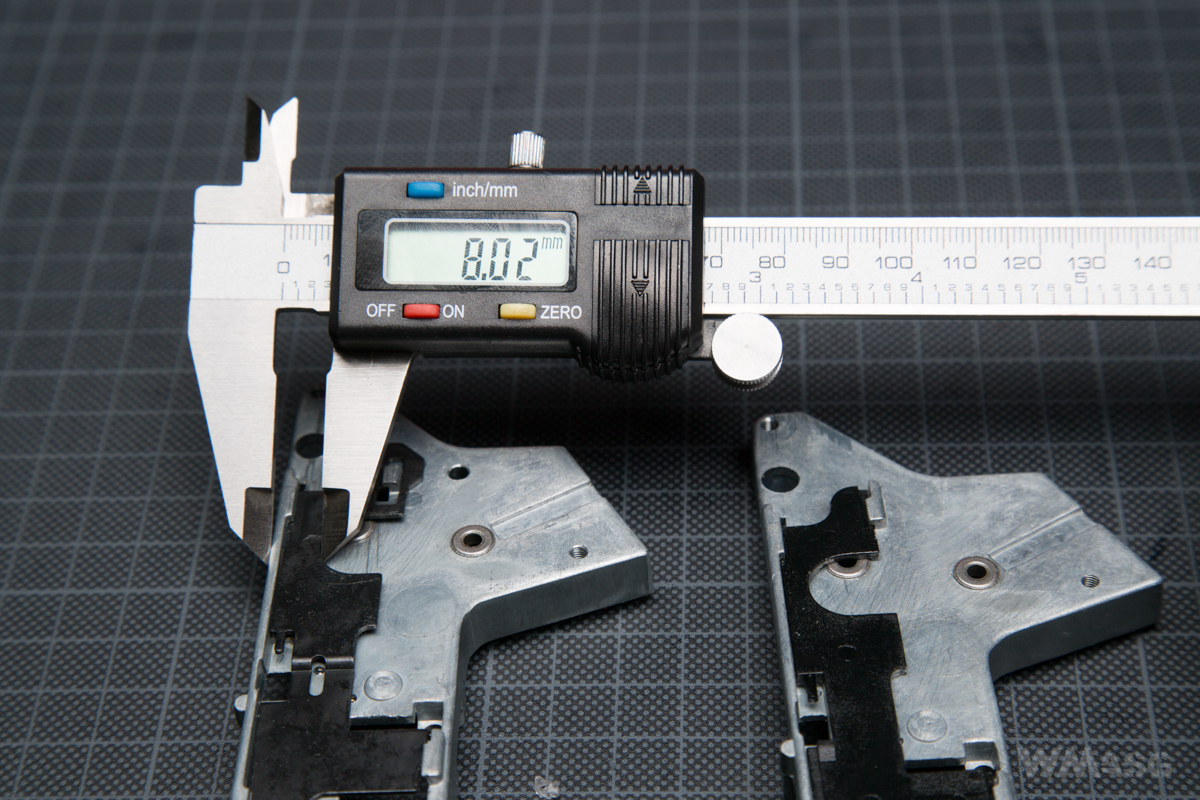

From the outside the selector plate non-standard and made of metal. In the photos we show the difference between the CXP-MMR replicas plate and the standard V2 gearbox plate. The CXP-MMR is at the top.

And on the left.

I could not find a word about it, but the selector plate and the anti-reversal latch used in the MMR series are the same as the ones that in the MARS series are responsible for releasing the main spring using the safety selector switch. The MMR does not have a cam that connects these elements and therefore does allow to use this function.

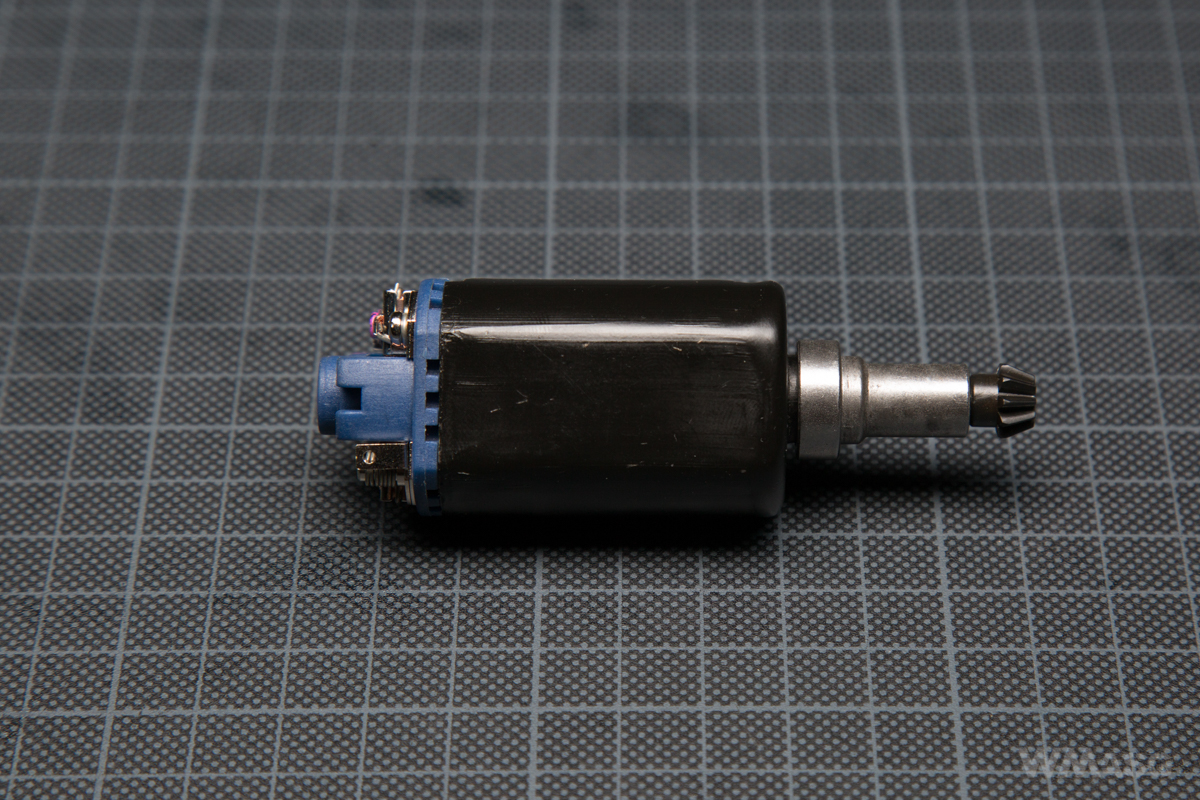

A long type motor has without markings. Its magnets are of rather average strength and are definitely not neodymium.

The wires in the pistol grip run straight, the red wire at the front and the black wire at the back of the grip.

And the final piece of information in the end of the section about the gearboxes, the frames with and without EBB are not compatible. When looking for spare parts for your replica, pay attention to this fact.

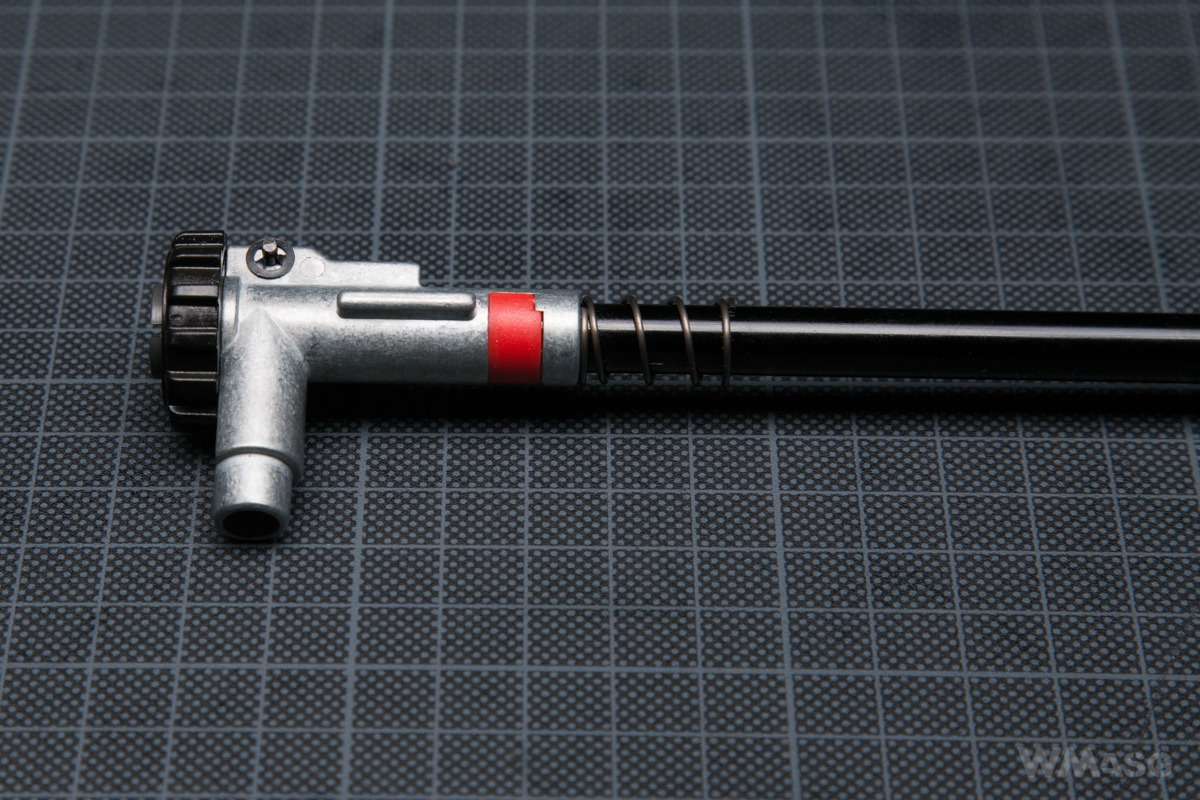

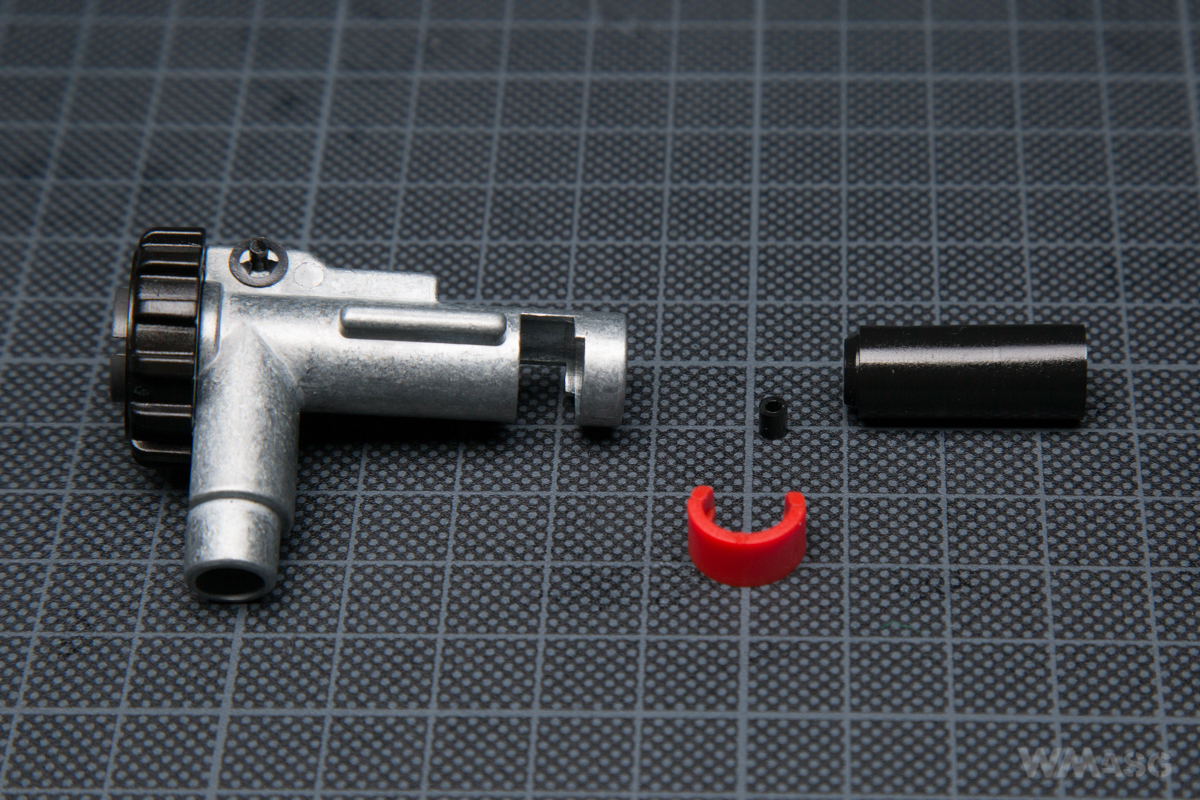

The inner barrel and the HopUp chmaber

The internal barrels have a length of 263 mm in the SBR version and 458 mm in the DMR. They are made of aluminum, are light and painted black. They are very similar to Mad Bull's Black Python barrels. The manufacturer does not specify the inner diameter of the barrels.

HopUp chamber chamber is made out of a single piece aluminum alloy, with the adjustment knob placed around the barrel axis. By turning the adjusting ring downwards, we increase the HopUp and turning it upwards we reduce it. The bucking and the spacer are standard. CAUTION! The chamber does not fit in replicas without the electric blowback system.

CAUTION! The chamber does not fit in replicas without the electric blowback system.

Target shooting test and muzzle velocity test

The test was carried out on our own enclosed shooting range, at an ambient temperature of 23°C, the Hop-Up was set to zero. The muzzle velocity measurements were made with the XCORTECH X3500 chronograph using 0.2 g BBs.

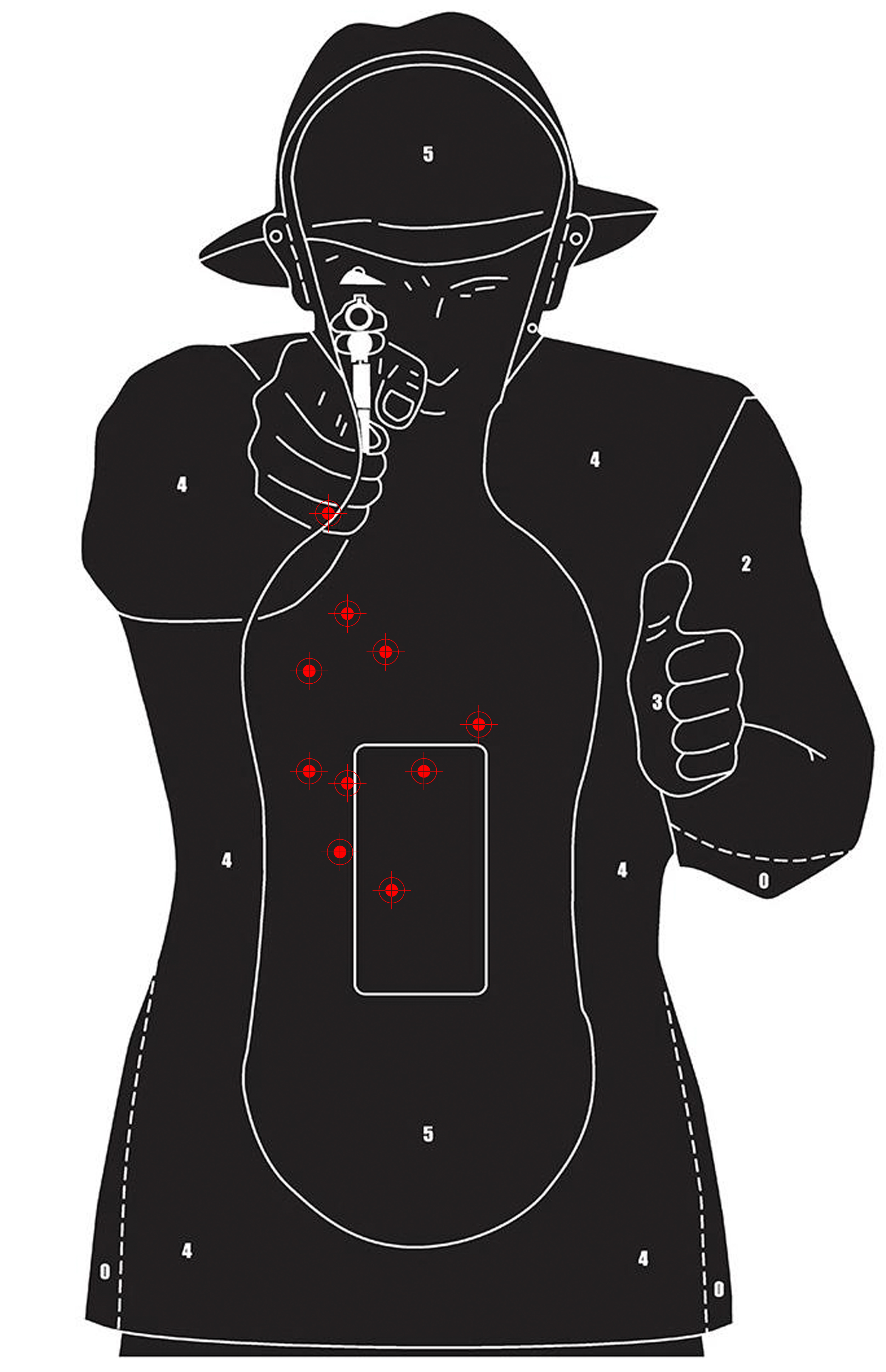

The target shooting test was done using 0.25 g BBs. Distance from the target was 25 m. The shooting was made using the K-Zone shooting rest.

CXP-MMR SBR measurement results (375 mm long barrel)

1. 323.6

2. 325.7

3. 322.4

4. 320.8

5. 322.1

6. 324.9

7. 321.7

8. 319.3

9. 321.0

10. 322.5

Average: 322.36 fps

The results indicate that, contrary to the markings on the packaging, we tested a unit was equipped with a weaker spring than an M120.

Measured rate of fire (using an 11.1 V 2400 mAh 15C LiPo battery) was 24 BBs/s.

CXP-MMR DMR measurement results (458 mm long barrel)

1. 331.6

2. 330.1

3. 333.2

4. 333.1

5. 329.4

6. 330.5

7. 320.6

8. 319.3

9. 330.8

10. 330.4

Average: 328.9 fps

As in the SBR, the results indicate a weaker spring than an M120. This is likely because the carbines are manufactured in 5 different specifications.

Measured rate of fire (using an 11.1 V 2400 mAh 15C LiPo battery) was 24 BBs/s.

Target shooting

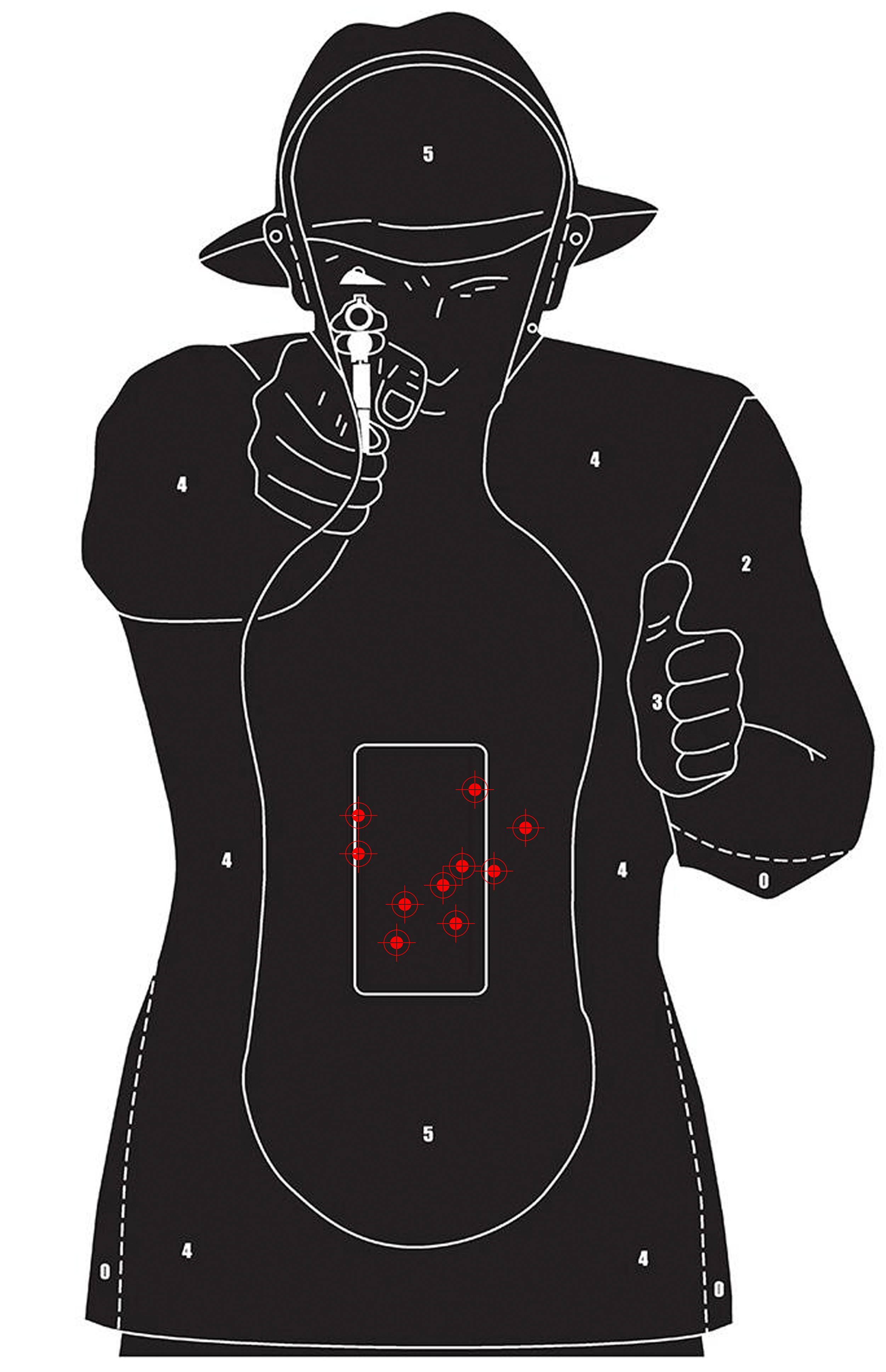

We fired 10 shots

CXP-MMR SBR (375 mm long barrel)

All shots hit the target. The greatest distance between hits - 17 cm.

CXP-MMR DMR (458 mm long barrel)

All shots hit the target. The greatest distance between hits - 6,5 cm.

Summary

Pros:

- very aesthetic design

- it is extremely easy to change the muzzle velocity

- factory-installed simple MOSFET.

Cons:

- slight clearance between lower and upper receiver

- limited availability of spare parts in Poland

- unfortunately, quite a high price.

In the CXP family, the MMR series is a typical middle ground. Classic lower receivers combined with slightly futuristic upper receivers in the Vltor MUR style. Moreover, several lengths of barrels and carefully made M-Lok fronts and different types of buttstocks are available. You are spoiled for choice. Technically, the MMRs are completely identical to the slightly higher tier MARS series, that is, the factory configuration leaves some space for tuners to tinker with, but even without any modification these replicas will work just fine. Factory installed parts are also of above-average quality and durability. A two part gearbox combined with an additional quick spring change system provides makes its extremely easy to change those replicas performance in the field. In addition, an ICS replicas user will do it in a much shorter time than users of replicas of other manufacturers. For many players, this can be a huge advantage. Small imperfections will remain a problem, which, as it turns out, are present in the more expensive MARS series. Therefore, as in the case of the latter, some will probably be bothered by the clearance between the receiver parts and also with the price of the replica.