RPD

RPD (rus. РПД, Ручной Пулемет Дегтярева a) is a Soviet light machine gun constructed by Vasily Degtyaryov. The project began in 1942. This machinegun was being designed as a successor of an obsolete DP model. As new ammunition type (an intermediate 7,62x39mm M43) was being developed as well, the RPD was one of the first firearms constructed chambered for the new cartridge. The light machine gun was adopted by the Red Army in 1949 as PПД (RPD).

Due to the high costs of production and numerous malfunctions, the 'career' of RPD in the Red Army seems to be rather brief. In 1960s it was succeeded by the RPK. Yet, the large quantity of RPDs can be found in Russin Army’s warehouses, as well as among supplies from numerous former Warsaw Pact countries. The licensed verison of the RPD, called Type 56, can be found in China. The RPD was also produced in Polish Radom Arms Factory, as one of the firearms contracted by the Polish Military. Despite being decommissioned, it was still stacked in Civil Defense warehouses until 1980s.

The RPD was used not only by Soviets and their formal allies. During the Vietnam War it was used by each side engaged in the conflict - even by SOG units with custom-shorted barrels. The machine gun is still popular among American collectors and shooters. Just take a look below at the RPD175CARBINE-A produced by DS Arms.

Source: http://survincity.com/2010/07/second-life-light-machine-gun-degtyarev/

Source: http://survincity.com/2010/07/second-life-light-machine-gun-degtyarev/

As this firearm was used during numerous wars and conflicts within last 70 years, it gained some place in pop-culture. You may spot RPD in legendary "Sniper" with Tom Berenger, "Tears of the Sun", "Hitman", "Shooter", James Bond tried to avoid it in "Golden Eye", Mel Gibson tasted it in "We Were Soldiers", "Behind Enemy Lines" and many more. Recently it was mounted at The People Eater vehicle in "Mad Max: Fury Road". Gamers can find it in "Call of Duty: Black Ops II", "Survarium" and "Max Payne 3".

LCT Airsoft RPD Limited Edition

As this firearm was used during numerous wars and conflicts within last 70 years, it gained some place in pop-culture. You may spot RPDs in the legendary movie "Sniper", with Tom Berenger and aslo others such as "Tears of the Sun", "Hitman", "Behind Enemy Lines" and "Shooter". Even James Bond tried to avoid it in "Golden Eye" and Mel Gibson tasted it in "We Were Soldiers". And recently it was mounted at The People Eater vehicle in "Mad Max: Fury Road". Gamers can find it in various instalments of "Call of Duty" series, "Survarium" and "Max Payne 3".

The external parts

While getting the replica out of the box, we had an unusual feeling, very similar to holding a real-steel firearm. If compared, it would be very hard to point the difference between real light machine gun and the LCT replica. The weight of 7 kilograms is a nice surprise and makes everyone smile. The replica is a very classic combination of steel and wood, where the only "loose" piece is the bipod. The entire construction is very well fitted, as it may have been expected knowing the price and the number of units produced (roughly 1000). There are no material excess, wood is appropriately shiny and the replica is appropriately heavy. The majority of a weight is put to the front, as the outer barrel is made of steel, the same as the bipod. To disassemble the RPD a lot of strength is required as well as a hammer. It simply a steel monolith, a dream of a Soviet technology fanatics and collectors.

The stock is made of varnished plywood, the same method used in the real firearm. The shade of wooden elements seems to be slightly lighter than in original construction. The stock, apart from the obvious role is also a housing for a battery. The space for a power source is really vast, yet rather longer than wider. This may be essential information for all of the people using wide batteries of 2000 mAh and more. To get inside one should open the hatch in the buttstock. The stock has a minor horizontal slack, but it does not influence usage it in any way.

The pistol grip is also made of varnished plywood, exactly the same as a stock. Despite tightening screws there is some vertical slack, but as above - it is acceptable.

The charging handle is foldable and made of steel. It moves with significant, even too strong resistance. While trying to reload, one may feel clear friction on the receiver. This element must be slightly greased, as the manufacturer forgot about it.

The bolt cover is a solid piece of steel equipped with locking mechanism, very similar to one known from M249. We really like the cavernous sound of closing the cover, that really reassembles the firearm. This piece is perfectly matched with the rest of the body. No slack so known all to well from other AK replicas appears here. Fun fact - check out how similar it is to the MG42’s cover.

With just a bit of patience the user is able to put there the ammunition belt from the real firearm to cover the gearbox visible through the gap.

he barrel is made of blued steel. It gets scratches, but at an acceptable level, what certainly gives the replica some character.

The bipod is made entirely of steel. In a folded position, it blocks in two stages: both parallel to the barrel (the mount has appropriate locks) and both legs are connected in the same way as in the RPK. Both legs got special sharp ending that allow for firm placement on the ground and stabilizing the machine gun during suppressing fire. It can be seen that the manufacturer did a decent job reconstructing even such minor details.

The drum magazine has a capacity of 2800 BBs. The spring is wound up by a button located in the case. It is powered by two AA batteries. The magazine presents itself splendidly. If not for the red button for wounding the spring it would be easy to mistake it for a real one. Even the smallest details were recreated in the LCT product. The only difference is the thickness. The magazine for a replica is wider by almost a centimetre. With some adjustment, the real-steel original might fit the replica quite well.

The machine gun looks simply great. The quality of manufacturing and fitting is impressive, which is admitted even by people who do not really fancy Soviet themed products. The replica is heavy, bulky and with low ergonomics, but it's fine - that's how the real-steel version looks like. When facing such a dose of genuine greatness, the slacks on pistol grip and the stock are especially visible. It's a bit of shame that the manufacturer did not grease the entire replica, as the E&L used to do. It feels a lot better to have this illusion of touching and smelling the weapon brought straight from the factory. Yet, these are such irrelevant drawbacks that no one will pay much attention to them, as the replica has a high 'fun-factor' straight-from-the-box anyway.

Internal parts

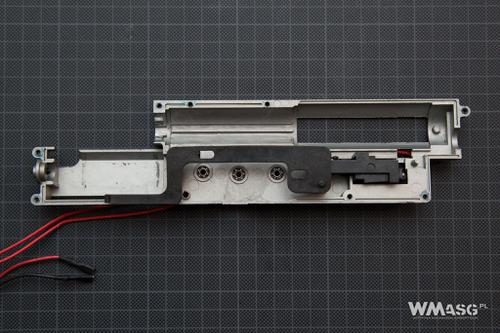

The disassembly starts with unscrewing a screw and a nut in the back part of the body and removing the pin. Later we need to raise the cover and set the selector between the firing modes. The next step is removing the stock, what is being done by pulling the pistol grip assembled together with the front part of the stock in the lower part of the receiver.

You must remember about gentle manipulation of the selector while trying to do that, as steel parts are connected really firmly.

Later, we remove the wires from the inside of the stock and start the last part of the disassembly, which is removing 4 hexagonal screws located in the bottom part of the receiver which stabilize a gearbox.

Then you gently widen the end of the receiver using your fingers and move the gearbox through the hole in the back. And its done!

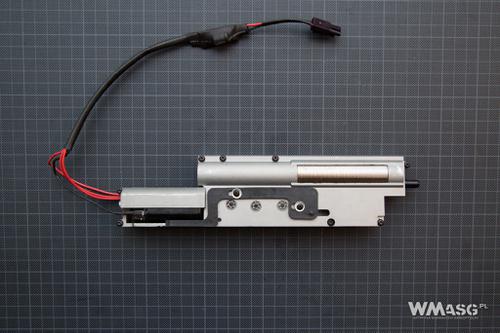

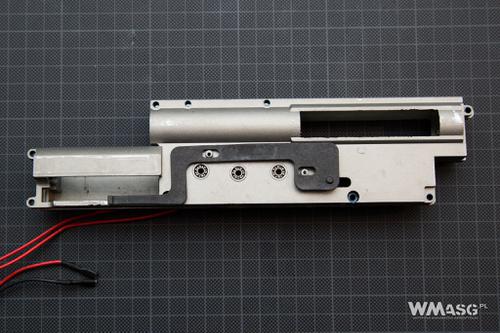

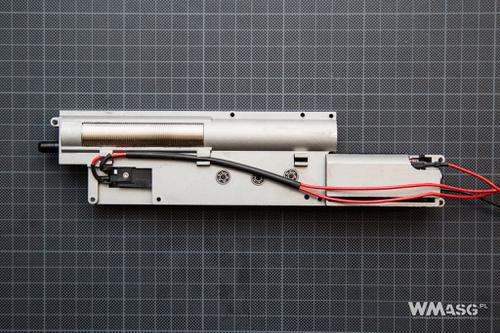

After partial disassembly of solid piece of steel, which the LCT RPD is, you get to a non-standard gearbox, which is similar to ones used in M249 or SVD replicas.

The gearbox is dedicated especially for this replica and was manufactured from zinc and aluminium alloy in silver colour. On the surface, one may spot some blemishes resulted from insufficient amount of material here and there, but only in spots not strictly vital for gearbox’s performance, like the horizontal cylinder window or one of screw’s ports.

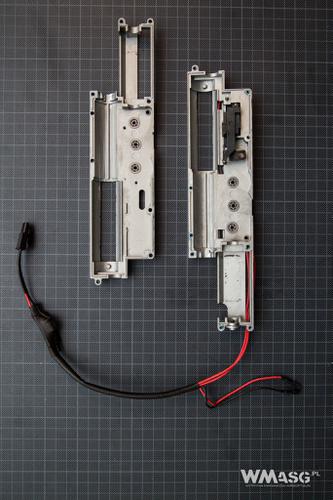

The RPD replica is equipped with a quick spring exchange system, that slowly becomes a standard feature among various manufacturers of airsoft replicas. While disassembling the replica we had a slight problem with turning the spring guide and fitting it into the appropriate grooves in the gearbox. Nonetheless, it took us less than 30 seconds to figure it out and after cautious study of the construction of this part, fitting it will not be a problem in a future. Before we get to gearbox disassembly, it is worth to remove spring with the guide first to make a gearbox opening process a lot easier. It's halves are connected with 8 steel hexagonal screws, additionally secured with thread glue. Their tops are durable and are not prone to damage while being twisted off. Pay some attention to the fact, that one of them is hidden under the trigger transfer plate, which needs to be removed with unscrewing two Phillips screws with shims. The RPD has 9 mm ball bearings glued into the gearbox to prevent unwanted slack.

The spring guide is made of steel and despite being adjusted for quick exchange it had a bearing (to the contrary - for instance - Specna Arms replicas). Each player considering upgrading this replica should duly note this fact. The spring is made of steel is nonlinear. The initial velocity of 400 FPS suggests it is the equivalent of M120.

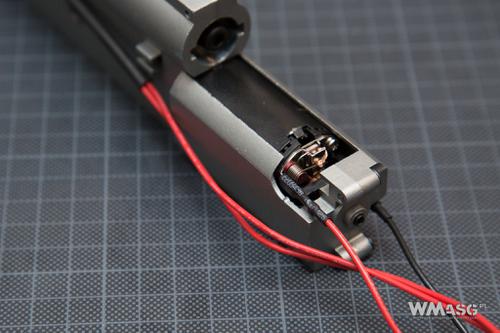

The wiring consists on stiff cables 1mm in diameter, very similar to the ones used in ASCU modules. The cables are lead through three holders on the side of the gearbox. The motor is connected with 2.5 mm standard connectors.

Despite the more frequent usage of microswitches among support weapons replicas, here we have a classic contact switch.

The flow of the electric current is regulated by factory installed MOSFET, efficiently lessening the bearing on the switch and improving trigger reaction. The wiring is equipped with partial tearing protection, that may occur while disassembling the replica. In our unit we have torn the outer insulation layer while moving the cable in the tightly assembled receiver during disassembly. It is very nice of the manufacturer to add a spare set of wiring without the transistor for installation if somehow factory MOSFET is damaged.

The gears are made of steel. They only have LCT marks without any information about their ratio. Each one of them has a single shim on both sides of the axis, so it is advised to give the replica for maintenance check-up in order to improve the shimming for smoother work of the mechanism. The grease is of good-quality and was spread correctly. So far there are not many replicas on the market with such fine greasing. The sector gear is equipped with a huge tappet plate delayer, which should positively influence the BB feeding even if rate of fire is upgraded.

We have some doubts about the tappet plate, which is made of white, very elastic polymer, but it caused no problem with our replica so far.

The motor is a standard short version with usual magnets. It is provided with a D-type gear having additional safety hexagonal screw.

The nozzle is made of polymer. It is 19.46 mm long. The inner o-ring for additional seal, is present. Sadly, the precise pneumatic CNC mechanism is finished with plastic nozzle. For us it is the very first part to be exchanged.

The piston is made of durable red polymer. It has 15 steel narrowed teeth. The flat, aluminium-made piston head with a bearing is ventilated. Attention: while assembling the gearbox the piston used to move from rails frequently. We advise to make sure it is located correctly to avoid any further problems.

The cylinder is made of ridged aluminium. Because of long inner barrel it is a type 0 cylinder. The double-sealed cylinder head is made of CNC aluminium. Between the cylinder, the piston and the head the pressure created a syringe effect. Unfortunately, after adding the nozzle to this set, air compression drops gently, yet it is still satisfying.

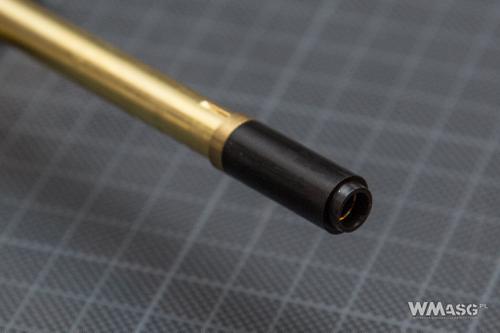

The Hop-Up chamber is made of the very light golden-colour metal alloy and is shaped as cylinder. It does not reassemble any other design used so far in airsoft replicas that we had contact with. An interesting fact - the chamber is mounted on the outer part of the body.

In the central part of the chamber there is a groove, where barrel clip fits. It is best to use small long nose pliers for removing it, as it does not stand out of the chamber surface.

The adjustment of the Hop-Up is made in the form of a ring dial with a gasket. This solution is known from other products such as Madbulla or Prowin. The adjustment works fluently and without any jams, it is not to lose and does not change its settings despite vibrations generated while shooting.

The stock hop-up bucking is made of usual high-hardness rubber. The brass 515 mm length and 6,02 mm diameter barrel is set in the chamber. It looks very solid and has a neatly finish crown of a delicate angle.

LCT vs RKM-D

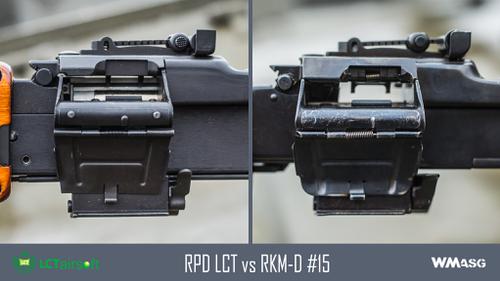

With the courtesy of SprzetMilitarny.pl we could compare the LCT replica with Polish licensed RPD version - RKM-D light machine gun produced in 1960s in Radom Arms Factory.

When compared to the actual firearm, LCT RPD looks very well. The differences in size of barrel, stock or the guide between airsoft replica and real-steel original are insignificant - up to few millimetres. LCT made a great job regarding the drum magazine as well. It was made with great precision and quite possibly with use of similar machines as ones used for producing the "cans" for the original.

However, there are places where the differences are more visible. Usually such a place is the receiver and this is also the case with the LCT RPD. The difference in height between it ant the real steel version is over 12 mm. The replica is also 2,5 mm wider. The cause for this are the limitations deriving from the gearbox used. This fact is most problematic for advocates of full replication of the real firearm’s dimensions but, what is worth mentioning, you do not see it at first glance!

The visible difference can be found in the place where the coking handle is located - originally this part is place on the inside, replica got it mounted on the outside.

For unknown reasons (maybe there are versions we are not aware of) the safety switch works in reverse in the replica – the "safe" in the replica is "fire" in the firearm. The shape of the trigger guard is also different, but in general - LCT RPD makes a great impression, as the majority of their replicas to be honest.

The summary

Despite the price, which is very high considering the current airsoft market conditions, this replica is worth the attention not only for its collectible values. When it comes to similarities with the original it may still surprise people who dealt with the actual firearm and is still cheaper. The argument of the price of a replica compared with the price of a real firearms is very frequently mentioned while discussing premium replicas. If someone reasons within such boundaries, the price of a real steel RPD is approximately 1500 USD, while the stock price of the LCT RPD in Poland is 4500 PLN (about 1125 USD). It is worth to remember, that law regarding decommissioned firearms has changed recently. Collectors and reenactors cannot buy such a weapon which has the possibility of cocking or disassembling it apart from the second hand market, where prices are expected to sky-rocket soon. Bearing this in mind, if one wants to have their favourite weapon from a movie or a game or seems to just like the RPD for some other reason, 4500 PLN for very well made replica, which can be additionally taken to the field for an airsoft game, stops being an unimaginable amount of money.

The test of the replica was conducted in courtesy of LCT Airsoft

Translation by Wacol

Corrected by SHOGUN_YAMATO