Spring replacement method

I mentioned earlier, the ESA™ system allows one to change the muzzle velocity quite quickly by replacing the main spring. In fact, it can be done "from the outside".

Step 1 - slide the stock off and unscrew the buffer tube of the return mechanism.

Step 2 - remove and disconnect the battery.

Step 3 - with an Allen key loosen the screw that holds the stock mount and stabilizes the spring guide.

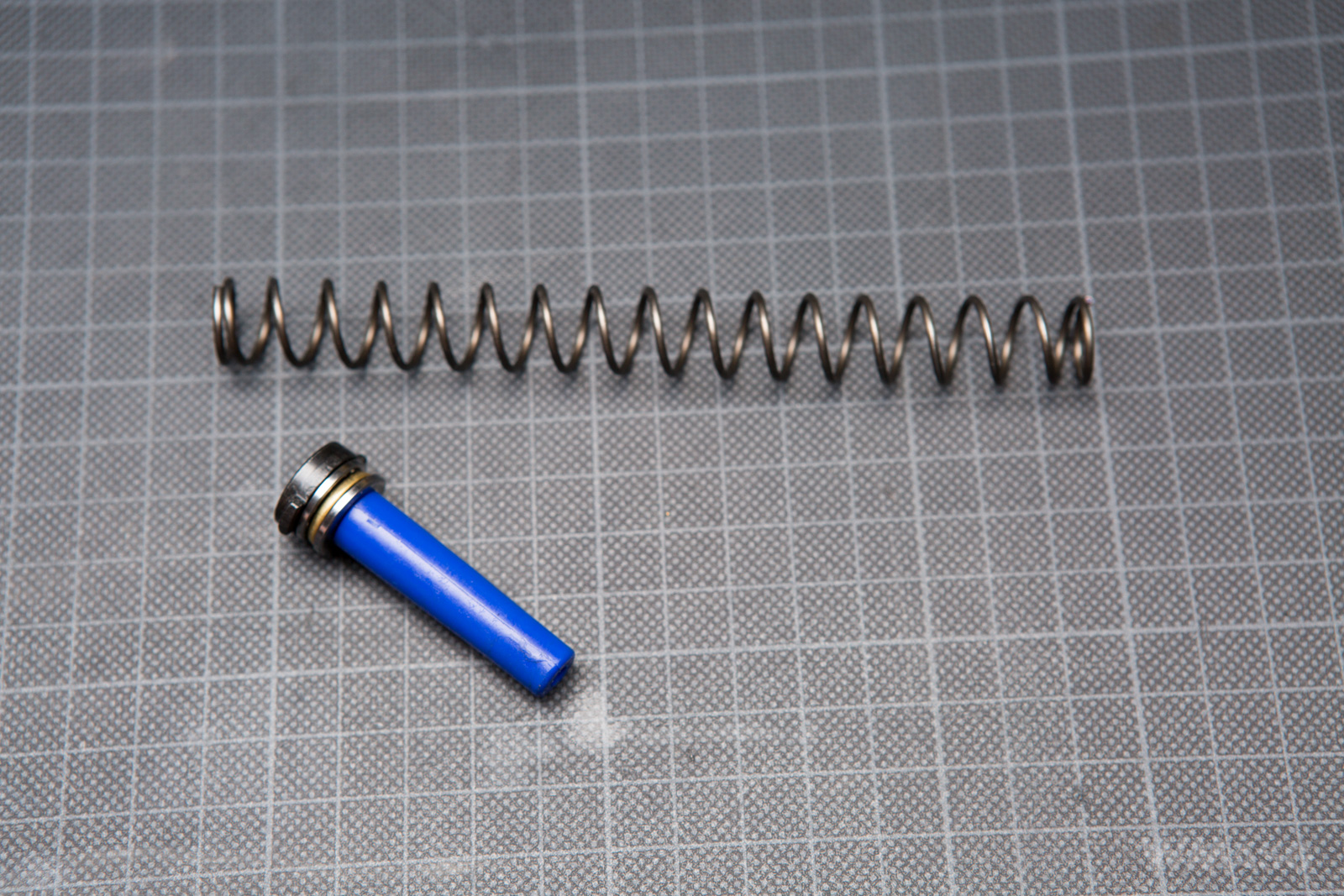

We gain access to the spring guide.

Step 4 - The spring can be replaced.

The inner barrel and Hop-Up chamber

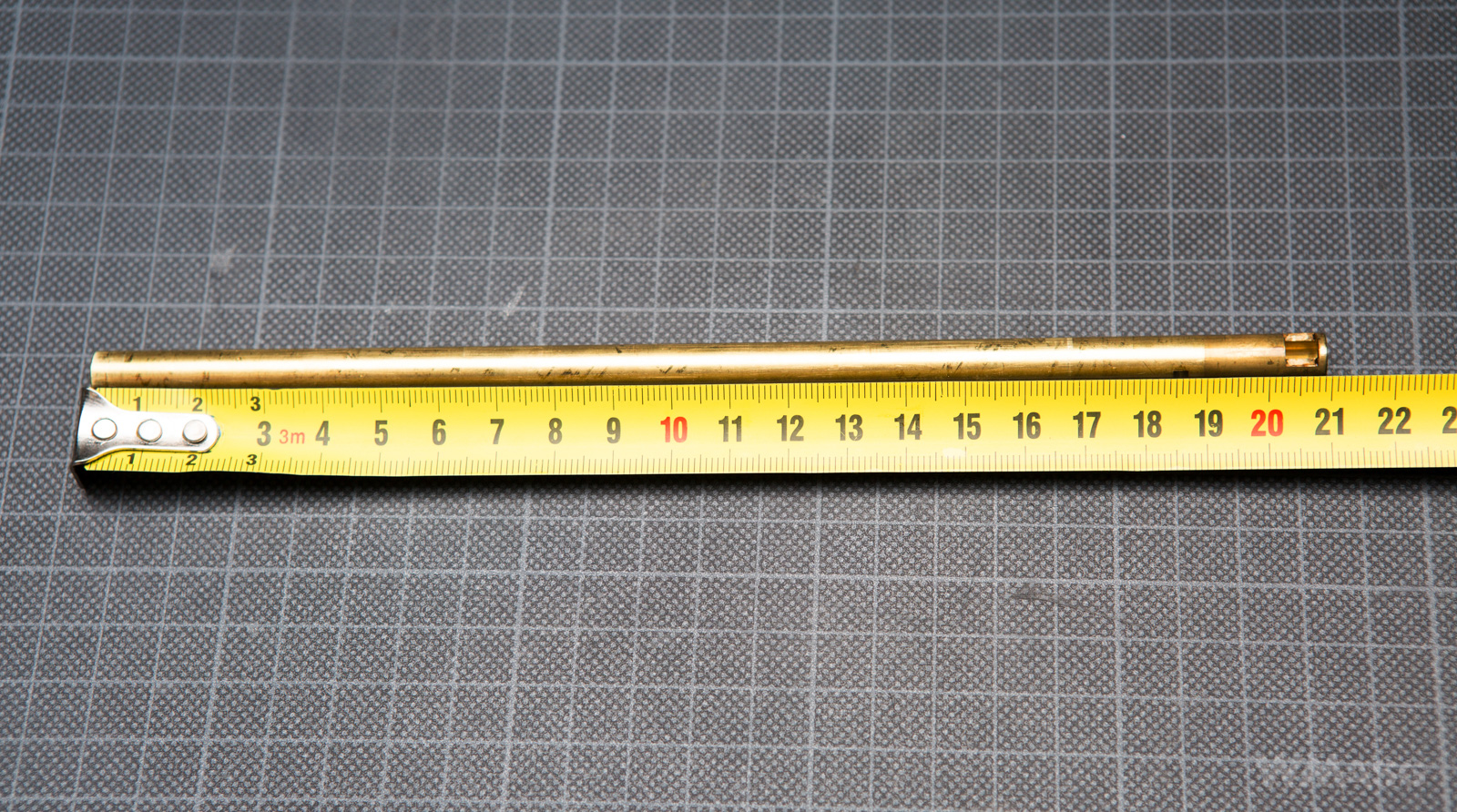

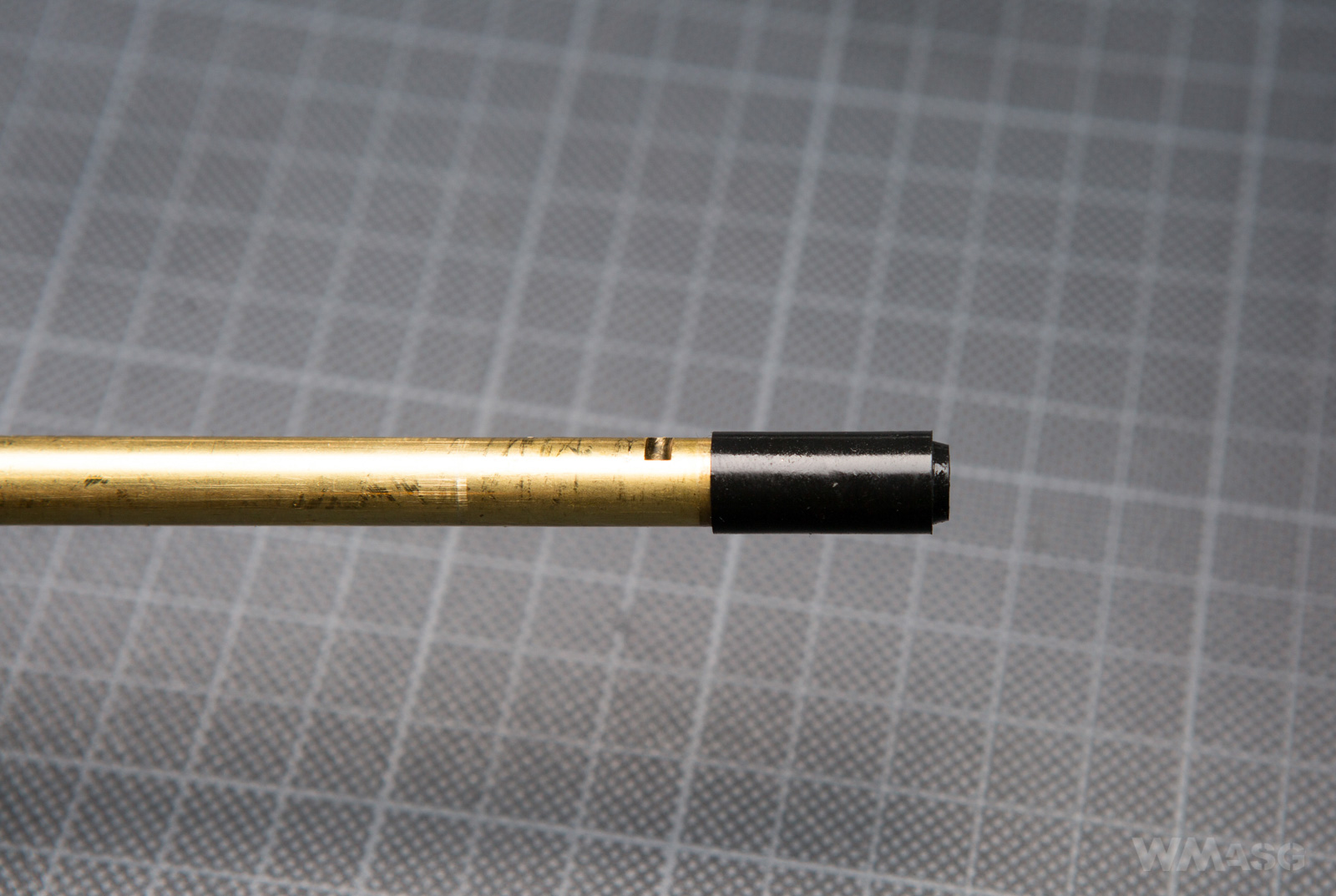

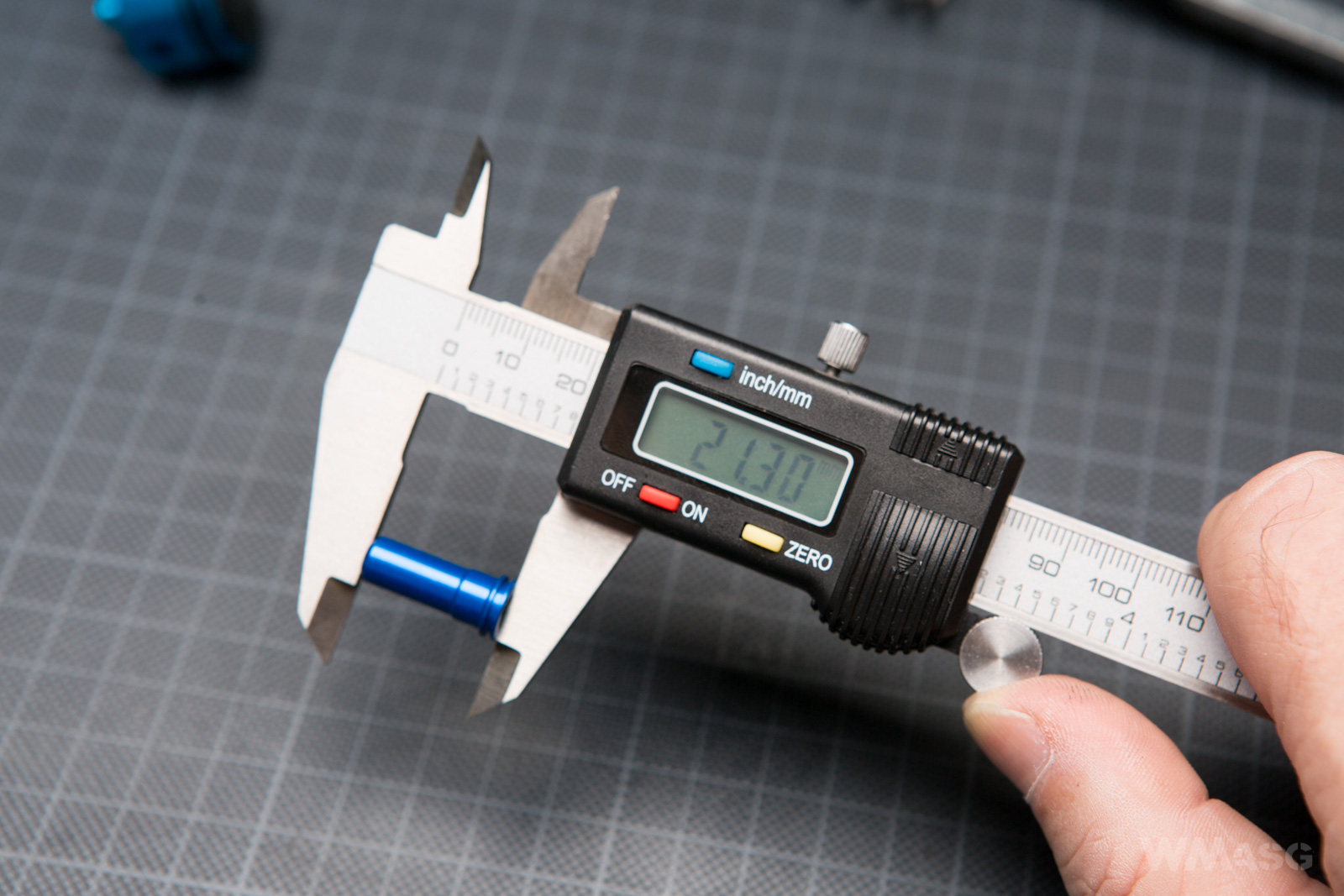

The inner barrel, like most factory-fitted barrels, is made of brass. According to information from the manufacturer, its internal diameter is 6.03 mm. This is the standard type of barrel for EDGE replicas. In the E12 PDW the barrel has an actual length of 21 cm although, according to catalog data, it should be 19 cm. We hope that the other data including, for example, the internal diameter of the barrel were stated correctly.

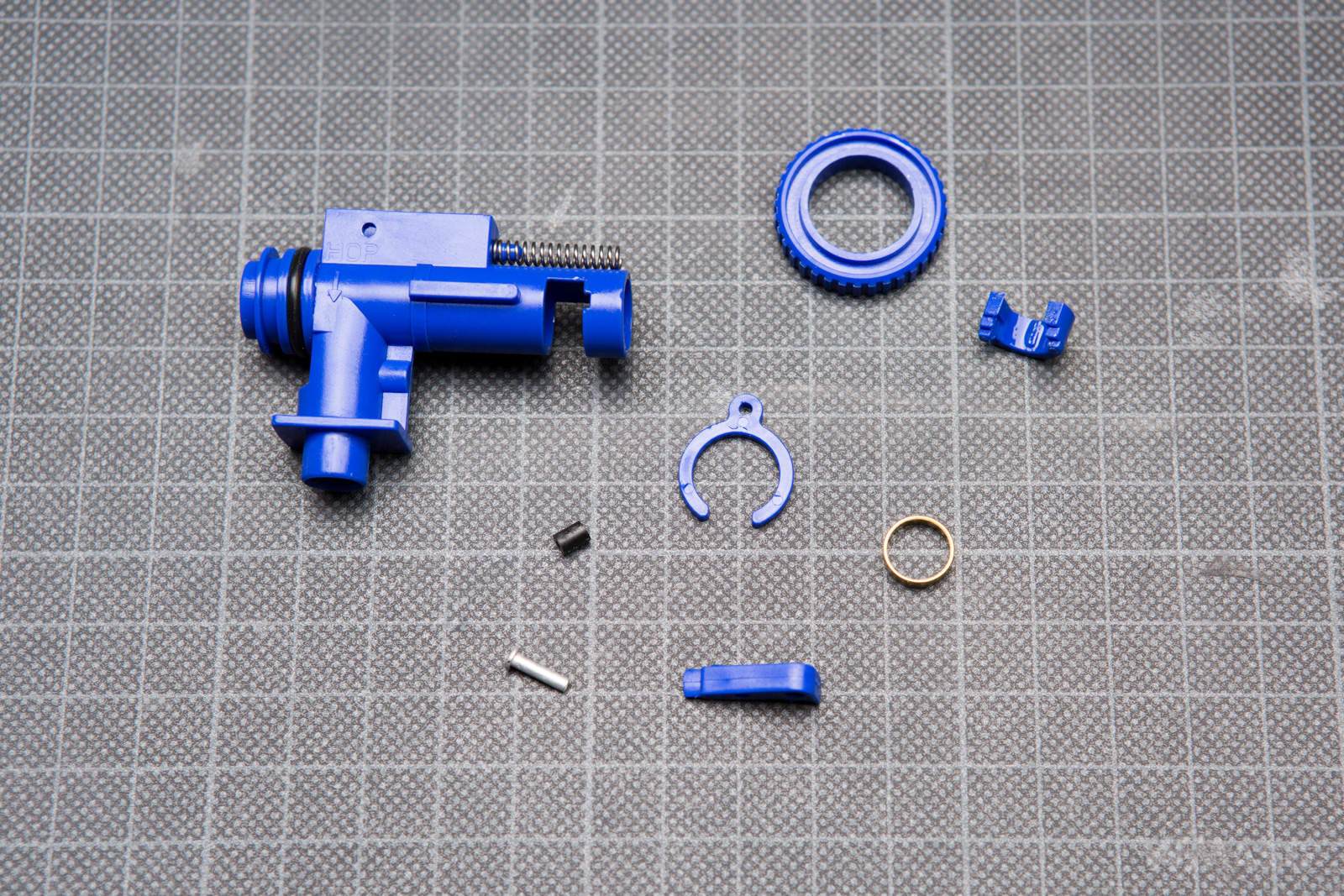

The Hop-Up chamber is the same one currently used in all AR replicas by Specna. It is a polymer chamber with an adjustment knob located perpendicular to the axis of the barrel (rotary type). This is a good solution allowing for precise adjustment and retention of settings.

The bucking and spacer used are completely typical and do not stand out with anything.

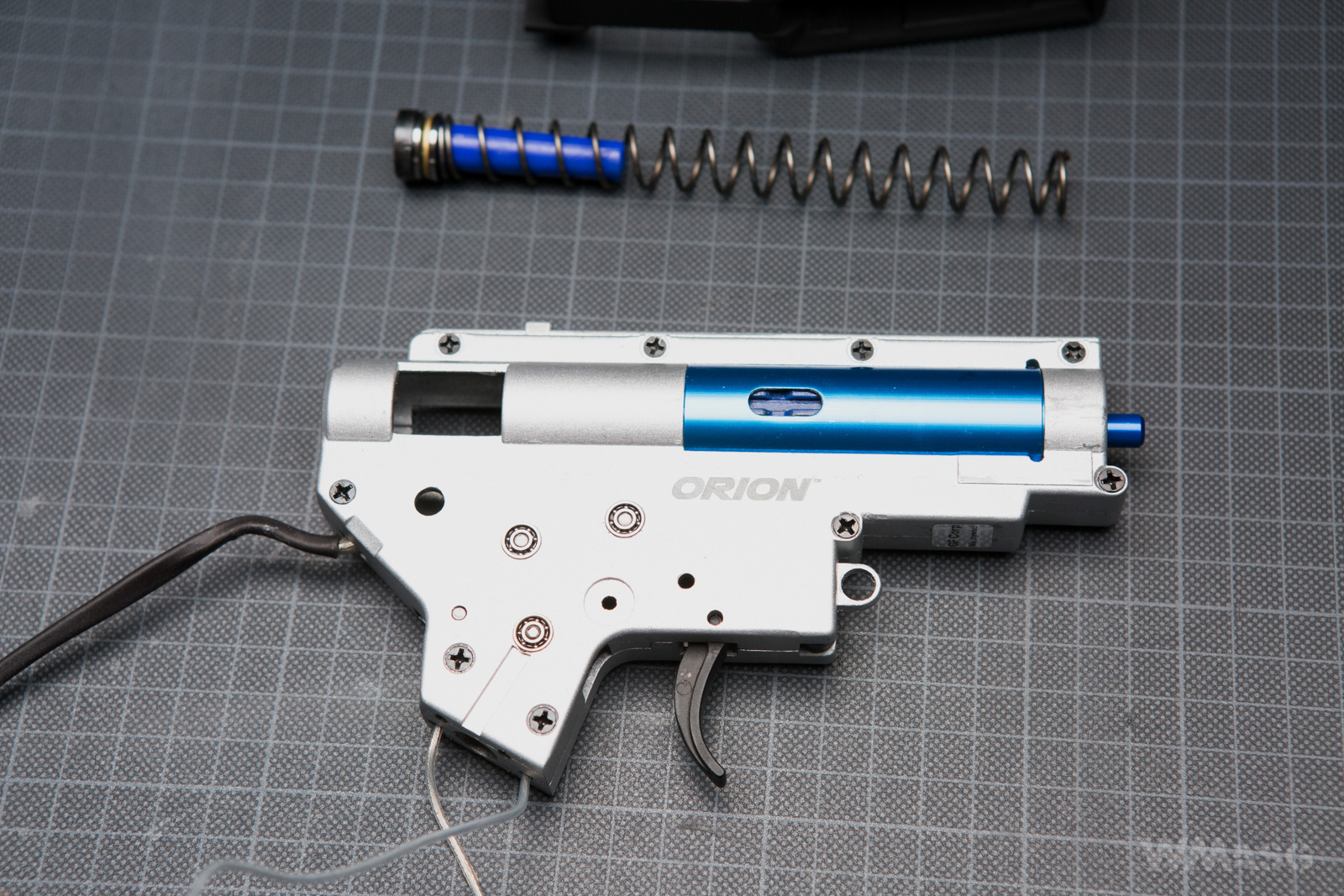

The Orion gearbox

The ball bearings with a diameter of 8 mm and the round finish of the cylinder ports corners are noteworthy. In the left half there is a port for releasing the anti-reversal latch and a port with a cable cover.

The parts of the gearbox are 100% compliant with the unwritten standard. Only the spring guide has slightly larger lugs, but this is the case in the vast majority of "quick-change" spring guides.

The pneumatic system is airtight.

A type 2 cylinder was used, which is slightly oversized relative to the short length of the barrel, but the problem could be noticeable only at the higher rates of fire. With factory (and somewhat annoying) low rate of fire, its has no negative effects when firing in full-auto mode.

Parts of the mechanism

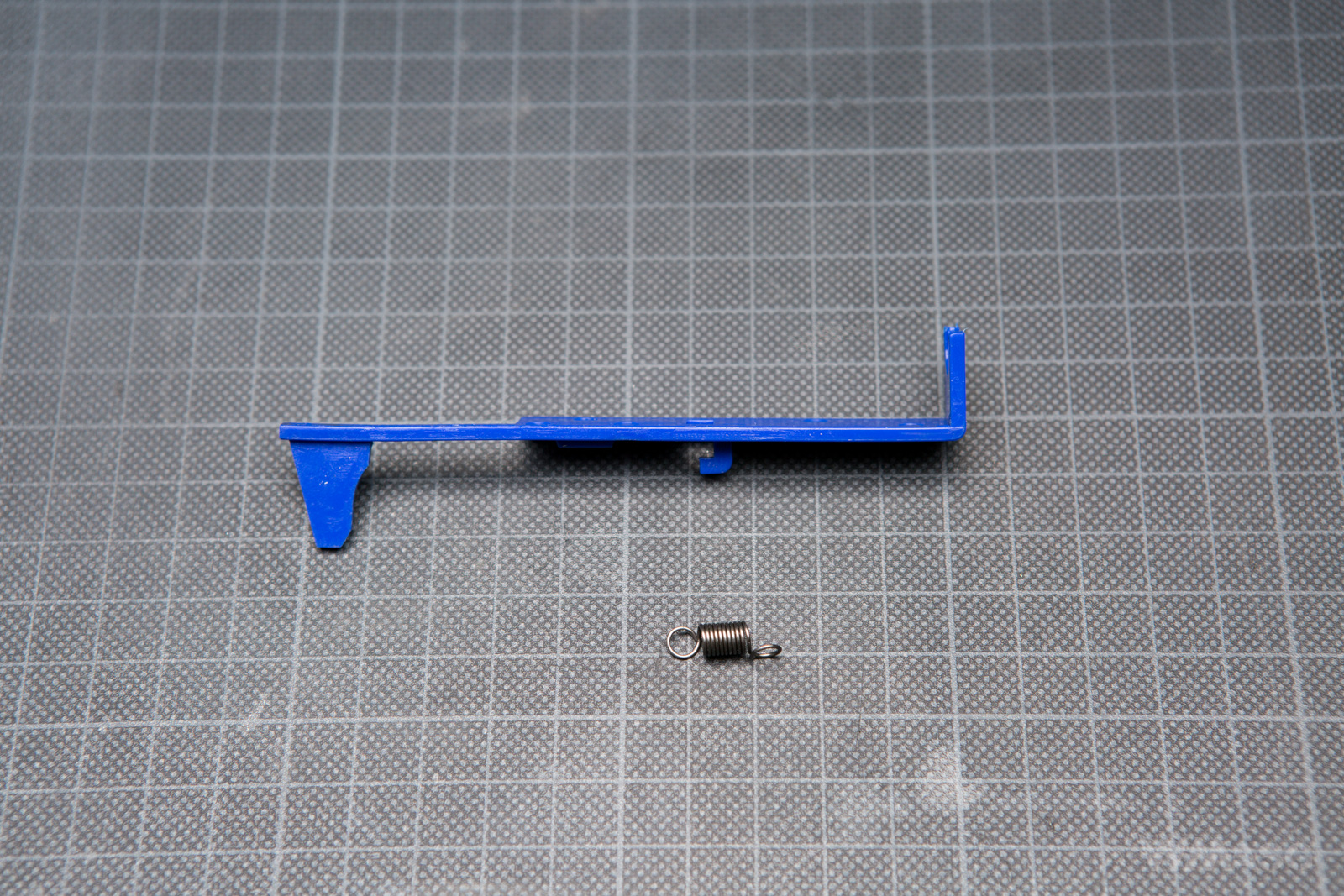

A standard tappet plate:

A piston with full steel teeth:

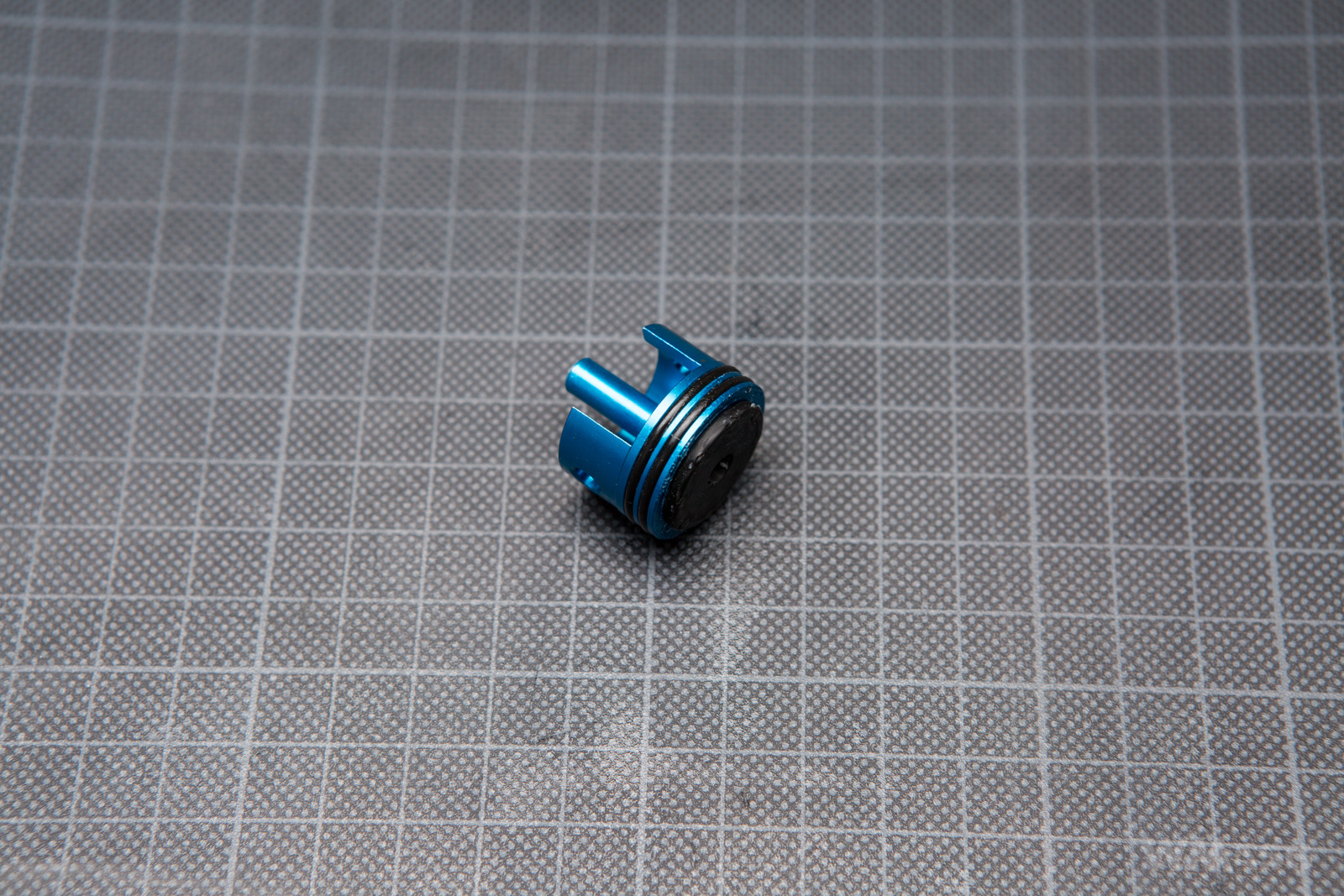

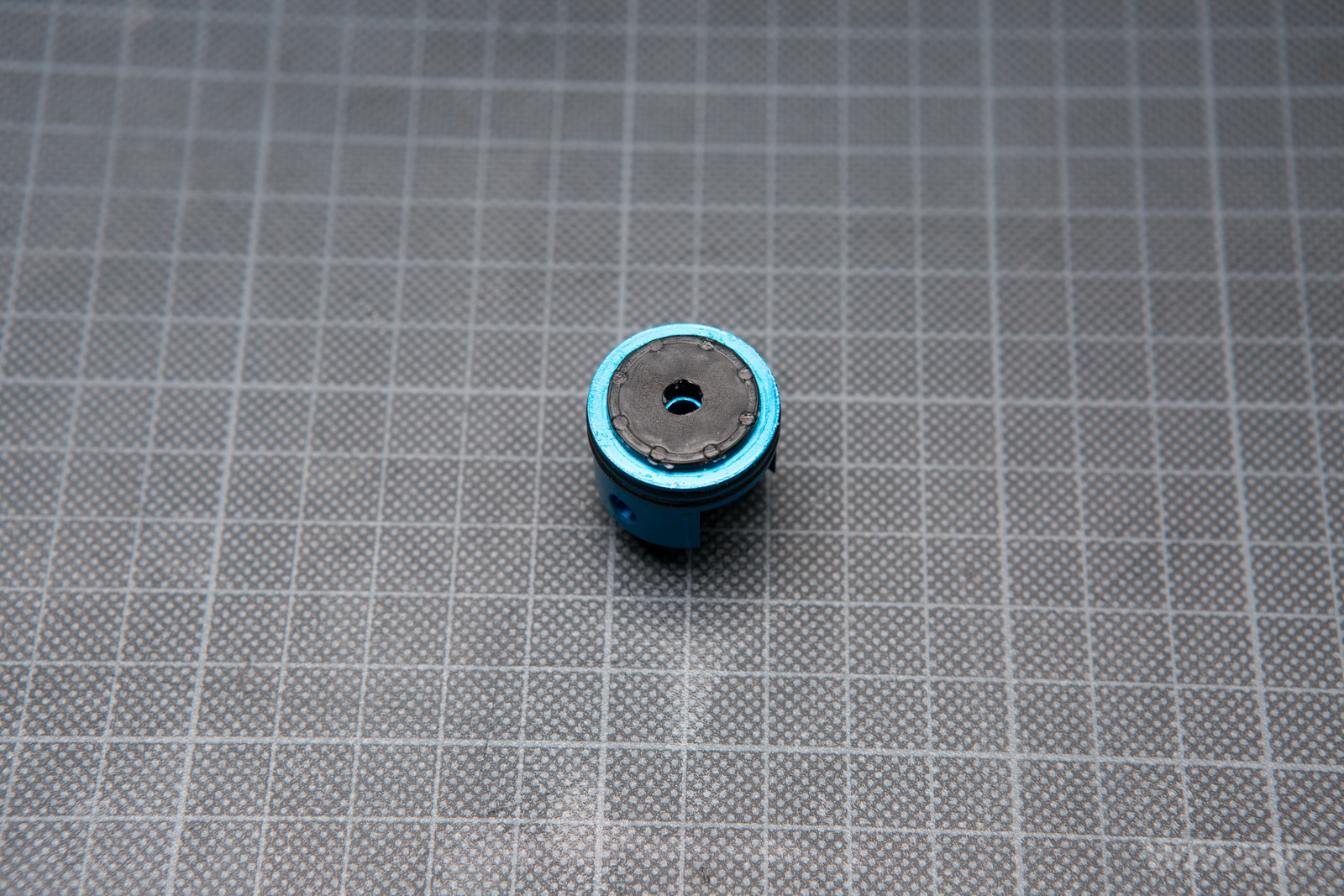

An aluminum piston head with a double O-ring:

An aluminum cylinder head with a double O-ring and a thicker bumper:

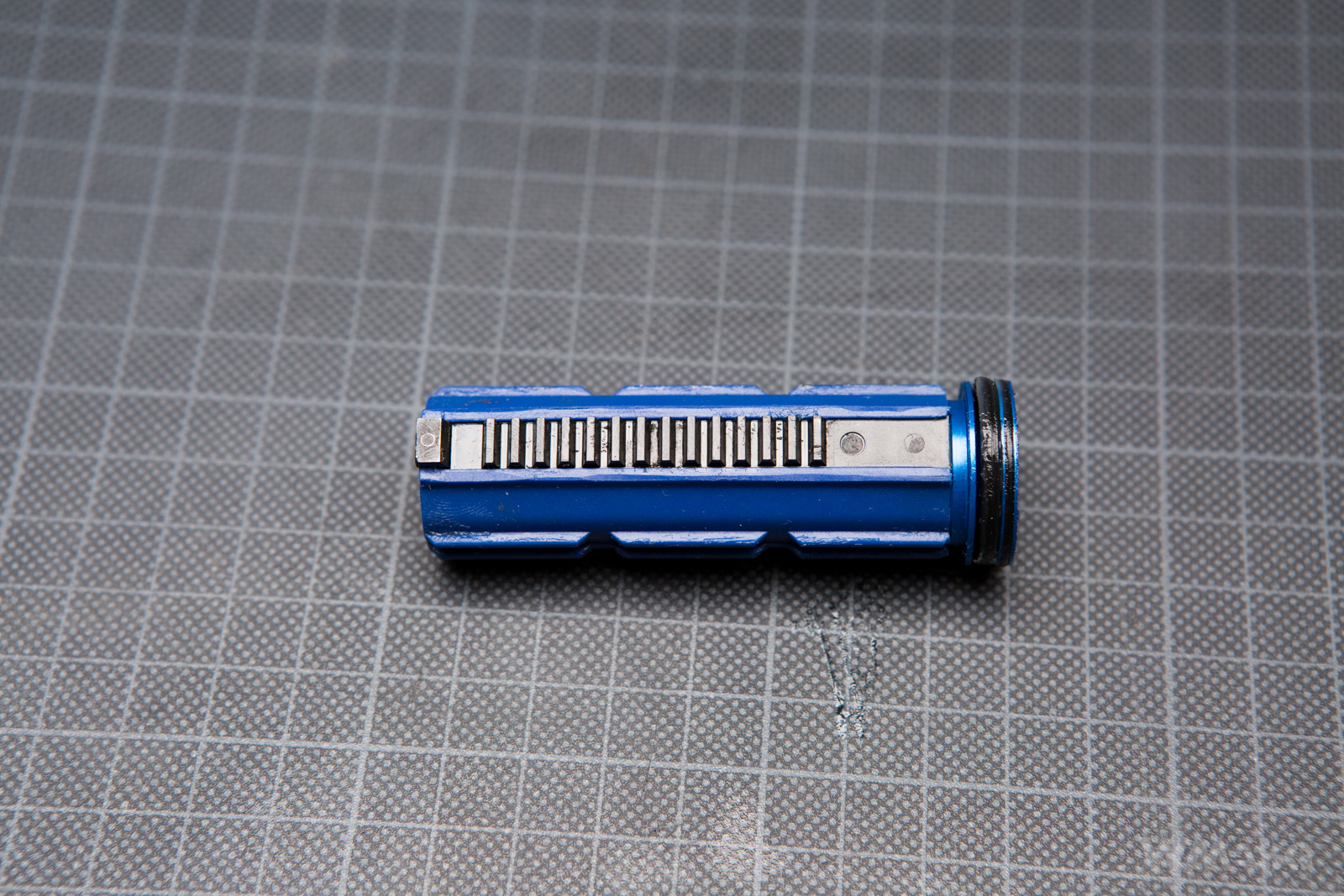

An aluminum cylinder:

An aluminum nozzle with an O-ring:

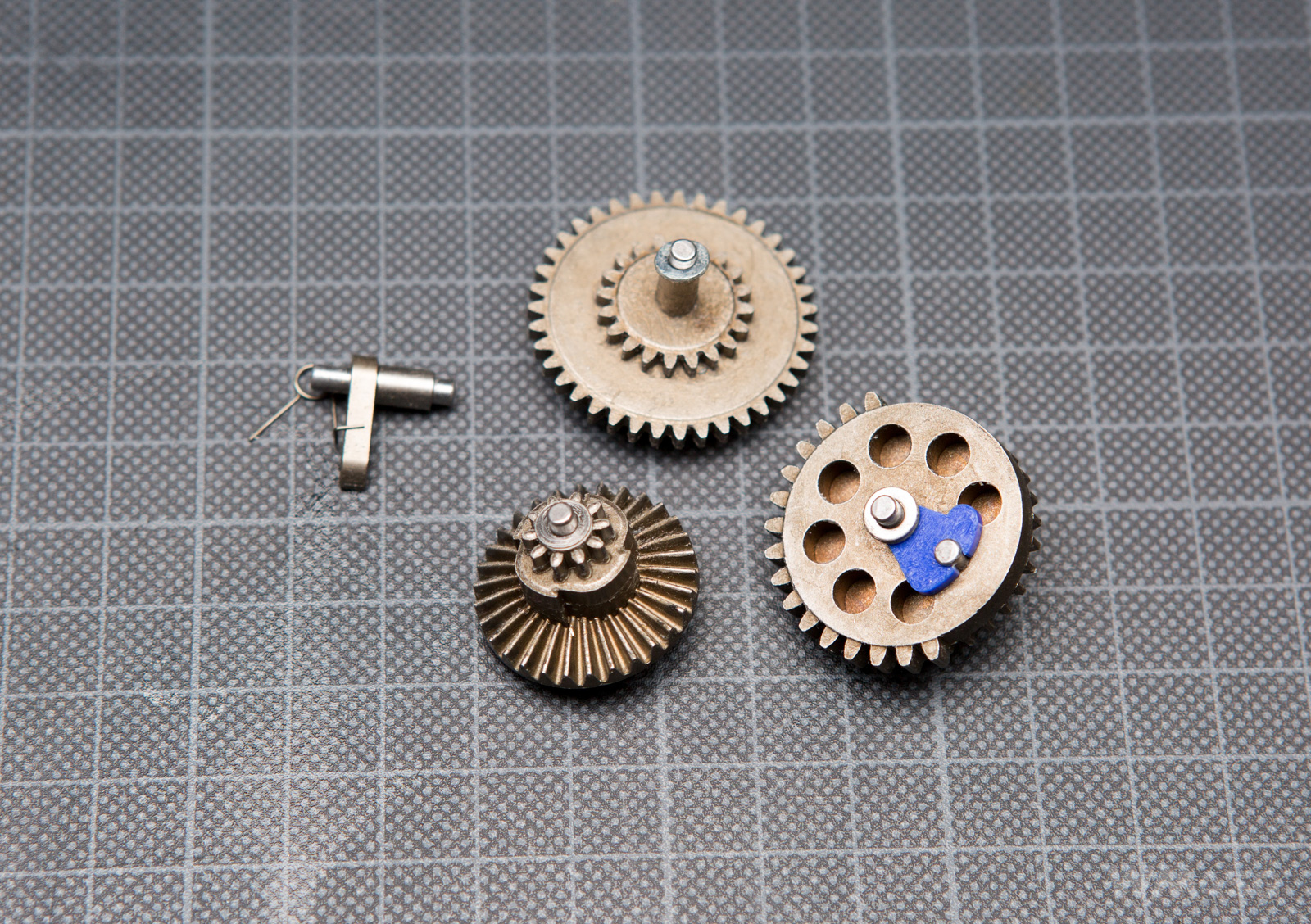

Steel (sintered) gears with a standard ration with delayer on the sector gear. According to the manufacturer, they will work well with up to an M140 spring:

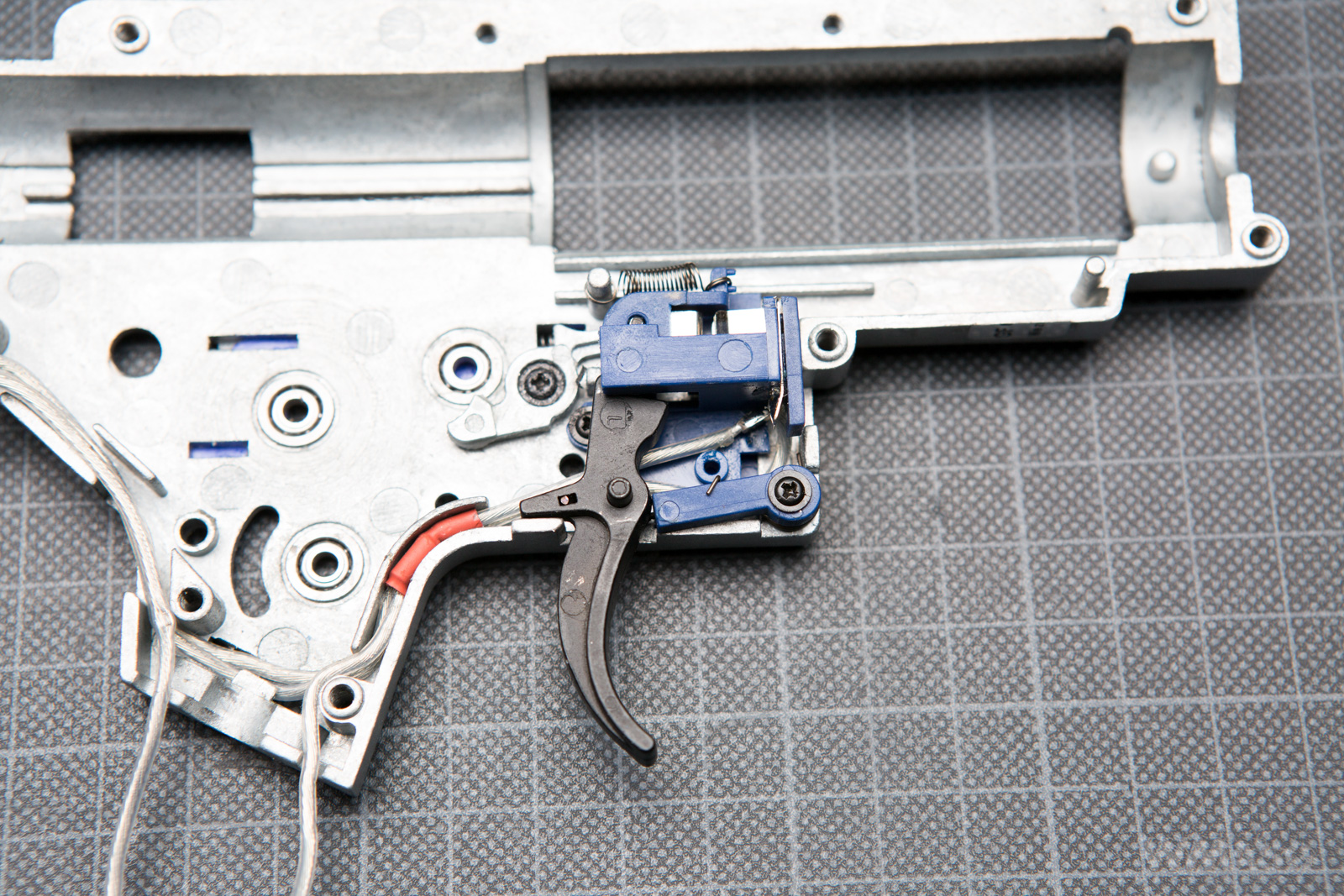

Traditional contact switch:

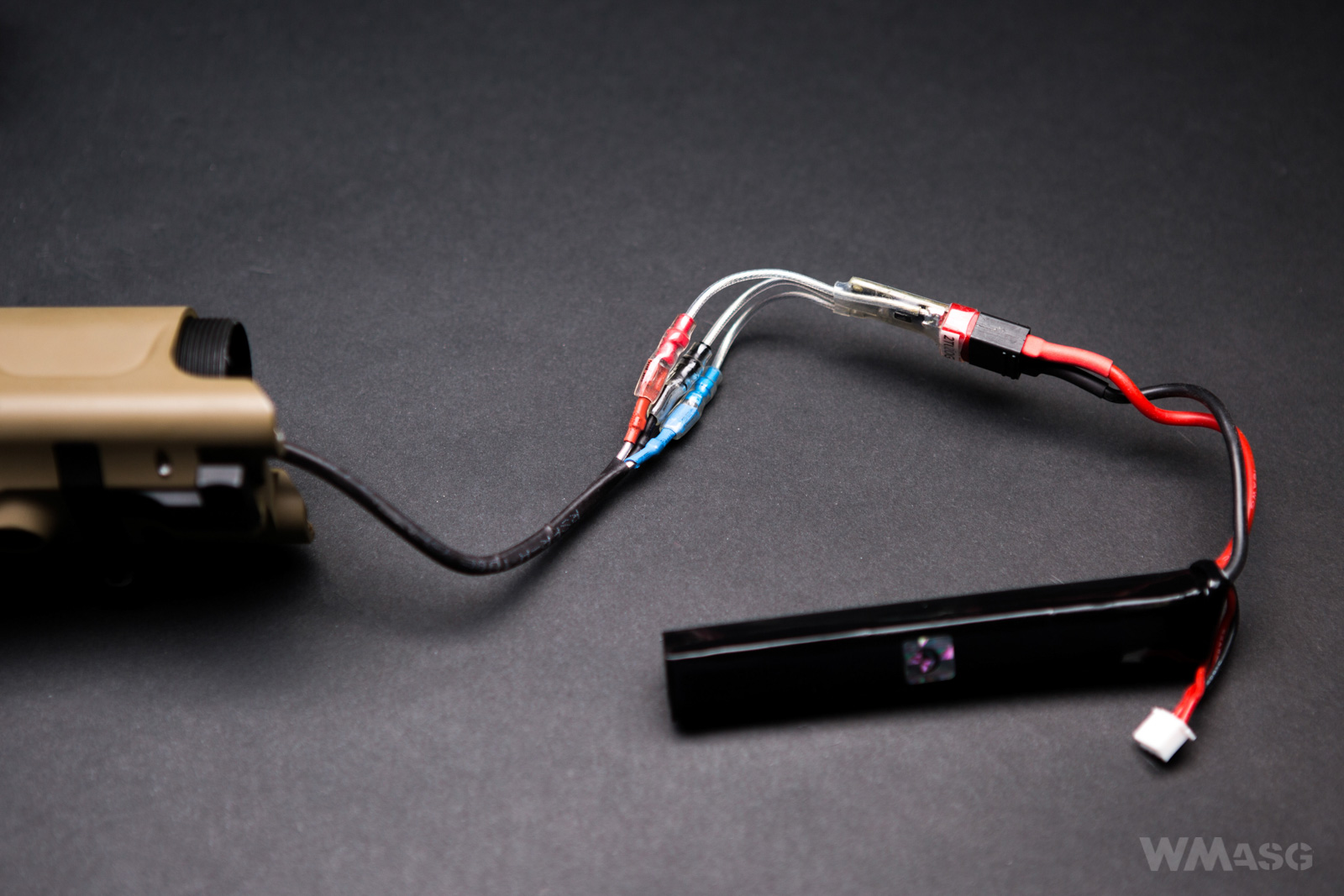

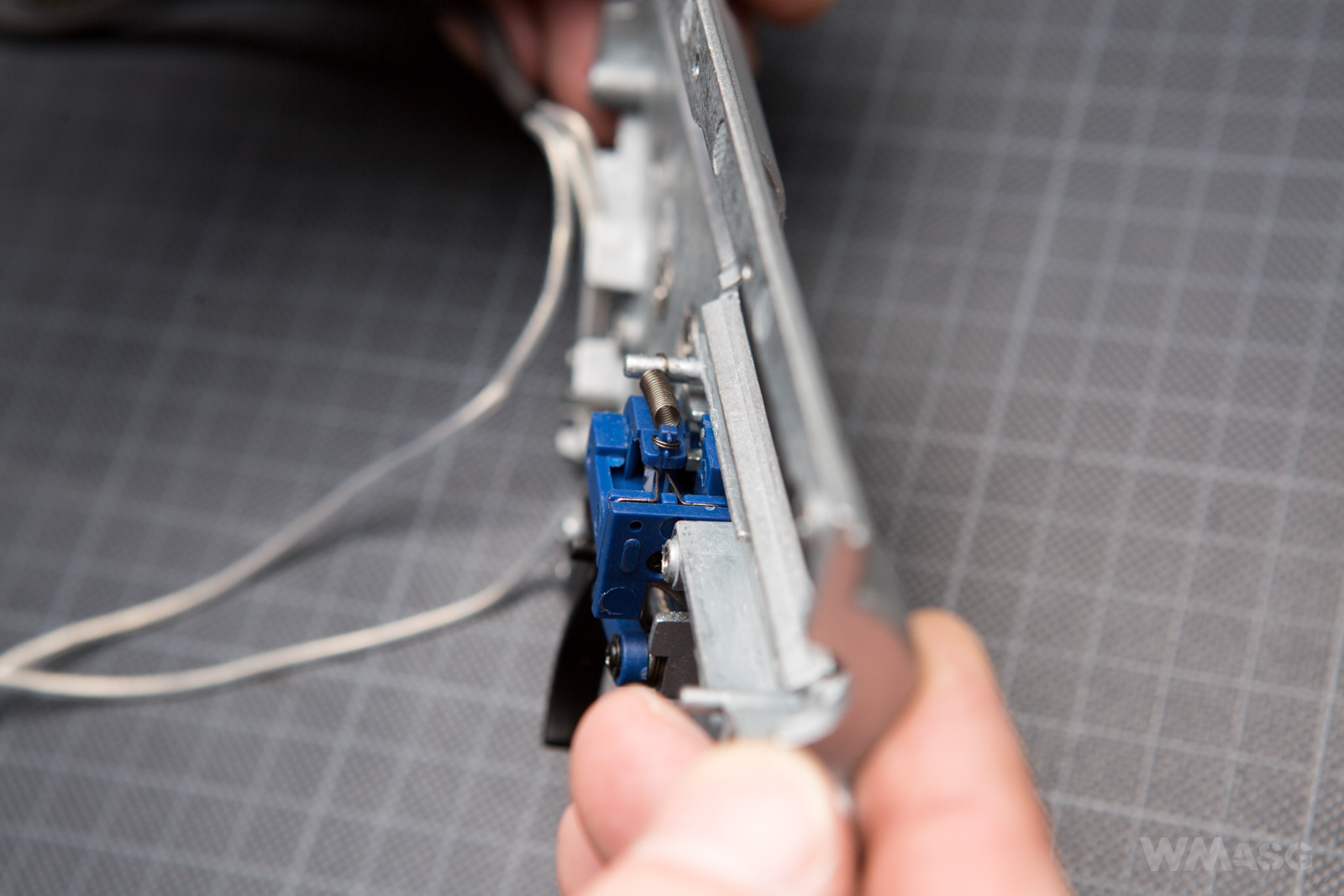

And low-resistance wires in hard insulation. The way the cables are routed and secured around the motor shaft is noteworthy:

The only thing we would do differently is gear lubrication. In our opinion, there was too little lubricant in this case. We had no issues with other things, including the way the mechanism was shimmed. This observations are very similar to the ones we made while reviewing the other EDGE series replica that we tested in February.