First, we took a closer look at the prototype of the new pistol, which name we did not get to know... as this pistol has not been named yet. It is to be the first gas powered replica made in Italy. What is interesting, it is designed together with a real gun which will look exactly the same. The pistol, in its ASG and air gun version, will be available sooner than the real firearm. The design itself is based on many modern designs such as Glock, Arsenal Strike One, or pistols made by German company H&K.

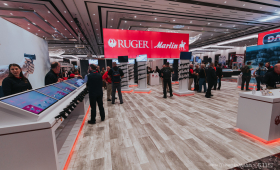

Another product showcased was the new series of PDW EVO replica. They are made completely of metal and have aluminum fronts with the M-Lok mounting system. For people that like their replicas as light as possible, a version with M-Lok sockets in stead of a RIS rail on top have also been prepared. All replicas are covered with a durable coating made by Cerakote, which will be available in different colour versions. The receivers bear the Lone Star Tactical markings. The replicas are shipped with HexMag magazines. The licensed parts also include the pistol grip by Magpul. Inside each replica is a 6,01 mm precision inner barre and a gearbox with a quick spirng exchange system. They also have a feature of quick motor disassembly. The price of presented models will be around 400 Euro.

People who do not concern themselves with licensed marking of real firearm manufacturers, will be interested in the Recon series. They have the same technical characteristics as the upper class models but have their own engravings. The have front using the KeyMod system. The full metal versions will cost about 250 Euro, and version with polymer receivers will cost slightly below 200 Euro.

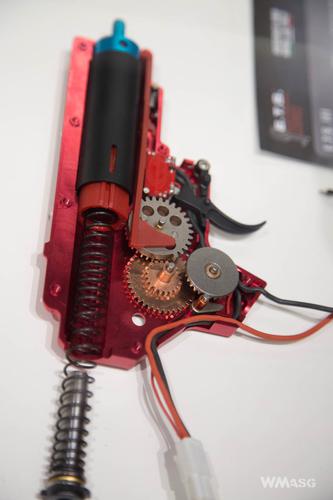

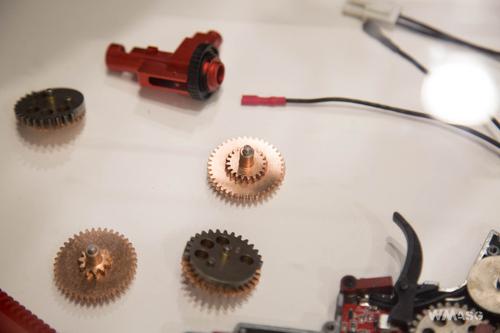

One of the cabinets at Evolution Airsoft's booth presented new, ultra-light gearboxes with 8 mm bearings. Their frames are made from CNC machined aluminum.

This is not the end of new internal parts from EA. A prototype of the new MOSFET circuit, installed in stead of the trigger switch, has also been presented.

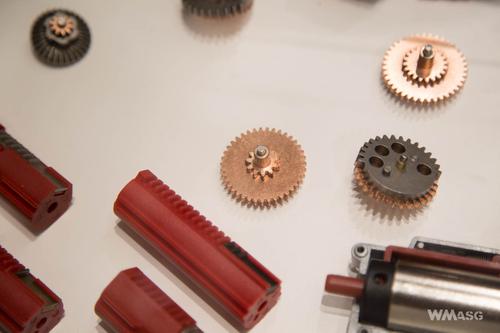

Another new item were the gears that do not need any kind of lubricant for proper working.

Next to them was a rotary hop-up chamber made using CNC machining.