Warhead Industries is one of the main manufacturers of brushless motors for airsoft replicas. In addition to already known products, they also introduce new ones. Thanks to the courtesy of the CEO of Warhead Industries, Chris K, we had the pleasure of talking about their plans and upcoming products in a short interview.

Grzegorz Woźnica WMASG editorial team (WMASG): Maybe first a few words about Warhead Industries itself and its history?

Chris K. CEO of Warhead Industries (Warhead Industries): So Warhead Industries itself was founded about 5 years ago, and recently there have been quite a few internal changes. The Warhead Industries brand is part of a larger group focused on electric motors, controllers, and power sources such as LiPo batteries. We're talking about electric bikes and marine engines here. Our company uses this technology, but operates independently.

Recently, we've started to see quite an increase in competitive activity in the brushless motor field, despite making one of the first airsoft brushless motors ourselves. At first, our only competition was from Option One products from Taiwan. About a year ago, we changed our business profile a bit, with some changes within the company and individual departments. The overall operation began after the changes and my taking over the management as one of the owners. I started paying a lot of attention to the company's operations personally.

WMASG: I think we've seen changes, mainly on social media.

Warhead Industries: Yes, they included the marketing, logistics, and quality control departments, as well as the Research & Development department. We ended up taking a closer look at the current situation and products, terminating all projects, and starting over. We can't discuss all the projects yet because we're waiting for patents. Currently, one of the revealed projects is a new motor connector.

WMASG: Made entirely of brass, as shown in the profile?

Warhead Industries: Yes, the part is made entirely of brass, but until now, connectors in brushless motors were most often made using a stamping technique. This reduces costs and speeds up production, but it's not exceptional in terms of reliability. This is evident in other industries (drones, RC models) where high-quality connectors are used, which increases efficiency, reduces overheating, and generally improves workflow. Our new connector was made from a single piece of brass using CNC. The whole thing is thicker and has a larger base for soldering onto the integrated circuit board. Despite being such a small component, we put quite a bit of work into it.

WMASG: A small thing, but certainly satisfying. What other surprises are in store for Warhead Industries?

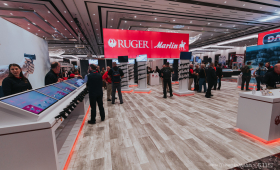

Warhead Industries: We can't reveal too much at this time, but we've managed to establish a partnership with a firearms manufacturer. Their AEG replicas will have our motors as standard from the factory. Just like Delta Armory.

WMASG: During this year's IWA trade show, we had the opportunity to take a closer look at replicas from Delta Armory, including their latest offerings. One of them was the Delta Armory Grand Power Striborg SP10 A3 AEG replica in the Alpha variant, the highest standard with a motor from Warhead Industries. (Delta Armory at IWA 2025)

Warhead Industries: Yes. As a standard, we have decided that Warhead Industries will not produce parts for other airsoft brands (OEMs). There's a possibility of collaboration, but our products will always be marked with the Warhead Industries logo alongside the partner's additional logo. Since we're familiar with Delta Armory and they asked to use our motors, we joined the project and not only provided the motors themselves but also modified them for the new Delta Armory Grand Power Striborg SP10 A3 AEG replica, which turned out quite well. This collaboration has led to another one, which we can't discuss yet. The details will be finalized within the next 2-3 weeks.

WMASG: Any tips?

Warhead Industries: If this is the case, we're dealing with a weapons manufacturer that has been on the market for over 100 years and is slowly entering the airsoft market. This collaboration will be quite unique, as their replicas will feature dedicated motors made specifically for their replicas. The whole thing promises to be amazing.

WMASG: This hasn't been published anywhere yet, and quite a lot has been happening on your profile lately. More new releases, including announcements of the motors themselves for AEG replicas. What can we expect in the near future?

Warhead Industries: So let's start with a quick review of the individual models. Currently, we have the Base, CNC Black, and Ronin (top-of-the-line) variants.

The Base series motor is the most budget-friendly option. It might not be mind-blowing, but it offers very satisfactory performance. Then we have the mid-range CNC Black series. One of the first we released. The top-of-the-line motor is the Ronin series. We think it's a great motor, but quite expensive with its titanium shaft and expensive magnets, which is why we've decided to discontinue this variant. After 4 years since its launch, it's probably time for a successor.

WMASG: What does this mean for users of this variant? Complete discontinuation of parts production, or is there any possibility of further support?

Warhead Industries: We still maintain access to spare parts, and elements such as the controller are compatible with subsequent generations.

The successor to the Ronin series will be the Vanguard, which we are slowly introducing.

In the case of CNC Black (a motor that first appeared 5 years ago), it's a fairly proven product and we plan to continue offering it as long as there's interest from players/the market.

The Base series is currently V.1 and is still available, but the V.2 variant is approaching fast. We haven't mentioned the next generation of the Base series at this time, but it will appear after the launch of the Vanguard series.

After all the changes, the three series of motor at different price points will still be available. Some variants of each series will also appear, such as the Vanguard PRO, which packs even more capabilities and features into the motor. Simply more.

All this will also translate into prices that should suit everyone's budget. All new motors are also expected to be significantly cheaper than the Ronin.

WMASG: Quick correction for the Base series: will V1 and V2 be compatible with each other, or will we be dealing with a completely new product from the ground up?

Warhead Industries: The main component that will be compatible is the controller. There's still some work ahead of us to convince players, but it looks like this: we can use the Vanguard series controller in the Base series motors, receiving additional functions. We will still be limited by the magnets and other motor components (hardware) used and will not get the same performance. Controller compatibility isn't exclusive to these two series, but works across all motors, both current and upcoming.

WMASG: This is probably one of the key features players want to hear about when choosing a motor.

Warhead Industries: This is one of the key ideas we had when creating the motors. If you have an older motor, e.g., a Base motor 4 years old, you can replace the controller with one of the newer models.

WMASG: So the controllers will also be sold as separate spare parts?

Warhead Industries: Yes, and that's one of the reasons we're trying to be so vocal about it. Because it's not just new motors, but also a new controller available as an upgrade or replacement. The price isn't significantly higher, and we have better software, performance, and reliability.

WMASG: What additional features can we still find in the new controllers?

Warhead Industries: More advanced security systems. The controller will additionally monitor the ETU and battery, allowing to prevent a failure that could take a replica out of a game. The FAILSAFE system will prioritize protecting the battery and ETU first, possibly switching to SAFEMODE and ultimately sacrificing itself. There are several layers of security solely responsible for protection. In the event of a failure, this will be the cheapest part to replace.

WMASG: As you mentioned the ETU systems, what about compatibility with systems from top manufacturers such as GATE Enterprise, Perun Airsoft or Jefftron?

Warhead Industries: We use all available ETU systems in our R&D department. They're compatible with our products as much as our software allows, which is quite broad.

WMASG: And what about any other products from Warhead Industries?

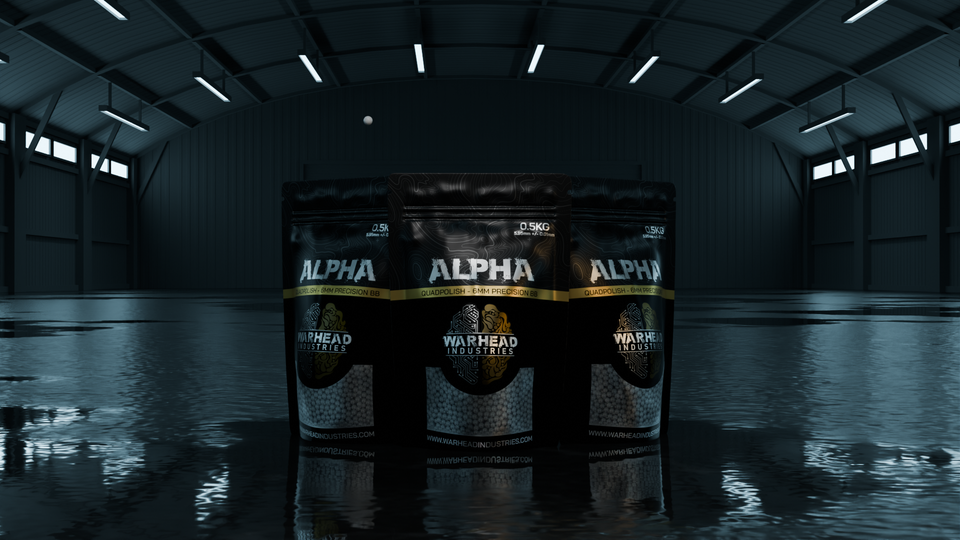

Warhead Industries: Of course, we have our own brand of BBs. Looking at the BBs slowly started to drive me crazy, just BBs and BBs for a few months (laughter). The question was simple: how can we improve what we already have? It's hard to reinvent them. Ultimately, we focused on quality control, carried out in our dedicated department alongside manufacturer quality control. We also changed our production technique slightly, introducing a longer cooling time in the mold and increasing the number of polishing and washing/rinsing cycles. The standard is to hold the part (in this case BBs) in the mold for about 5 seconds, after which the mold is cooled and the finished product is ejected. In our case, we extended this time to 10 seconds, which resulted in a more uniform and repeatable structure. After that, the BBs are sent from the manufacturer to us for testing. Each batch undergoes quality control involving a range of machines and tests. If even a single deviation occurs in a tested BB, the entire batch is rejected.

WMASG: Sounds fantastic!

Warhead Industries: Contrary to appearances, it doesn't cost that much. This is the second layer of security after factory inspection.

WMASG: This is probably a standard question: do you also offer BIO BBs? In Poland, we often encounter requests for BIO BBs, which translates into interest in them.

Warhead Industries: Currently, the entire shipment of regular BBs is coming to us, and the next shipment will contain BIO BBs. We are also working on a different weight of BBs, specifically 0.50 grams, and a line of Tracer BBs with an even wider range of weights.

The BIO BBs themselves are quite problematic, both in production and subsequent processing (polishing and washing), so they won't be at the same level as regular BBs.

To improve quality, the BIO BBs from Warhead Industries are also subjected to more polishing cycles (4 cycles in stead of 3), as well as two additional washing cycles. This removes more dust. We will never claim that our BBs are magical, they are simply better. By how much? We'll leave that to players to decide for themselves.

WMASG: To conclude on the subject of BBs, what's the best way to buy Warhead Industries BBs? Directly on your website?

Warhead Industries: We used to sell directly, but we're currently in talks with distributors for specific regions. We're already in talks with a distributor for Europe, where we're 80%-90% certain we'll cooperate on BB distribution. This is probably the best solution, as we'll avoid unnecessary margins. The BBs themselves are very affordable, and we make a relatively small profit on the BBs themselves, so we focus on quantity and quality rather than price. Additionally, we have price recommendations for retailers to maintain a given level.

WMASG: So can we expect another line of BBs?

Warhead Industries: If I were to create another BB, I'd probably go crazy (laughter). Compared to the Delta BBs (completed), the main change is even greater attention to quality control. (Editor's note: Warhead Industries had a Delta line of BBs, and now they're introducing the Alpha line)

WMASG: So what other products is Warhead Industries preparing for the future?

Warhead Industries: We plan to release an ETU system. About two years ago, we "threatened" to release our own ETU system, but that didn't happen and we decided to start over. We already have something up our sleeve, but we're taking a slightly different path due to our brushless motor and controller base. Thanks to the changes, we managed to make the engine more intelligent through the controller and we want to pair it with our ETU system. An example of an intelligent motor would be the Vangard Pro, which takes over some of the functions of the ETU system using a different approach than the systems we already know. We assume that the motor will manage and the ETU will only support, i.e., the other way around, as we know it.

WMASG: A fully Smart product.

Warhead Industries: Yes, instead of connecting the app to the ETU system, we will connect the app to the motor. In addition to the software changes, there will also be changes in the design. Warhead Industries motors will fit replicas like no other.

WMASG: Both long and short?

Additionally, we have a PTW motor ready, which we will present soon. The only motor we won't be making is the SLIM variant. We're also working on a motor for TokyoMarui replicas. Work is also underway on an HPA systems, which seems logical for a company dealing with motors. When? We can't reveal that yet.

WMASG: Quite a large product base. Providing service for such a large number of products worldwide is certainly a challenge.

Warhead Industries: We've managed to build a fairly large network of service technicians servicing Warhead Industries products, from Japan through the Philippines and Indonesia to Europe and America. We've done this with a simple goal - no matter where you are, physical service support is available. Whether we're talking about warranty repairs or out-of-warranty equipment, there will always be someone trained and authorized/certified to perform the repair. This includes not only knowledge but also access to spare parts. The equipment will still be covered by the warranty. Access to certified service centers is very easy. A map and information about the service centers can be found at warheadindustries.com. We're constantly expanding our service center database, accepting both applications from those willing to help and offering collaboration. The verification process itself involves several steps (which the editorial team will skip for obvious reasons). If we're satisfied with the level of service provided by a given service center, they join the Warhead Industries program.

WMASG: This brings us to the next question. Are you planning to open a service center in Poland? Currently, the closest one is in the Czech Republic, in one of their stores.

Warhead Industries: Definitely! We're constantly posting job ads and recruiting. We often don't limit ourselves to servicing our own products, but also provide general replica service for product assembly and simple inspections. We often receive inquiries about this type of information and we're happy to recommend the services we work with. We care about both the reputation of the Warhead brand and the level of service provided by our partner repair shops.

WMASG: How large a service network do you plan to create?

Warhead Industries: We're still working on it, but it's difficult to say. We'll focus more on regions to cover the largest possible customer base in each region.

WMASG: How will this work?

Warhead Industries: All reports are submitted to Warhead Industries, which forwards the detailed information to the service technician performing the repair.

Finally, I'd like to make a proposition to service technicians. If you are interested in working with Warhead Industries, please contact us through official channels.

WMASG: And with that, we conclude our interview. Thanks for your time and all the information.

Participants:

Chris K. CEO of Warhead Industries

Grzegorz Woźnica WMASG Editorial Team

![Motors, BBS and more - an interview with the CEO of the Warhead Industries brand [INTERVIEW]](/uploads/gallery/a5c67c7a4893e21fd39ba1646ee20fe7.jpg)